Professional Documents

Culture Documents

Floating

Uploaded by

Gagan Deep GuptaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Floating

Uploaded by

Gagan Deep GuptaCopyright:

Available Formats

Floating-drum plants Design calculation

Friday, May 06, 2011 Abdul 10.1.1 Floating-drumplants 10.1.2 Fixed-domeplants 10.1.3 Earth pit with plastic-sheet gasholder 10.1.4 Estimating the earth-pressure and hydraulic forces Floating-drum plants Design calculation Sizing factors Daily substrate input, Sd Retention time, RT Daily gas production, G Storage capacity,Cs Digester volume, Vd Gasholder volume, Vg

Example = 115 l/d = 70 days = 2.5 m/d = 60% = 8 m = 1.5 m

Calculating formulae after Sasse, 1984 1. Vg = Cs G 2. ha = design-dependent 3. Vg= r p h 4. rg =

5. rd = r + 0.03 6. Vd1 = p d2 p h 7. Vd2 = R3 p 2/3 8. R =

9. Vd3 = R2 p H/3 10. H = R/5 11. Vd3 = R3 p 1/15 12. Vd2 : Vd3 = 10 : 1 13. Vd(2+3) = 1.1 Vd2 14. Vd(2+3) = Vd - Vd1 15. hd = hg 16. hdk = hd + structurally dependent free board (0.1 . . . 0.2 m)

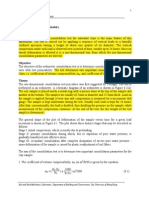

Fig. 10.1: Conceptual drawing of a floating-drum biogas plant Vd = Vdl +Vd2 +Vd3 = digester volume Vg = gasholder volume Index g = gas holder Index d = digester Sample calculation Results = 1.5 m 1. Vg = 0.6 2.5 hg = (specified) 4. r = = 0.7 m = 0.82 m

5. r = 0.85 (chosen) 6. Vdl = 0.852 3.14 0.7 = 1.58 m 14. Vd (2+3) = 8.45 - 1.58 = 6.87 m 8+ 14. R = = 1.45 m

Fig. 10.2: Constructional drawing of a floating-drum plant. Vd = 6.4 m, Vg = 1.8 m. Material requirements: Excavation 16.0 m, Foundation 1.6 m, Masonry 1.1 m, Rendered area 18.0 m, Sheet steel 5.7 m. (Source: OEKOTOP, Sasse)

Fig. 10.3: Constructional drawing of a water-jacket plant. Vd = 6.0 m, Vg = 1.8 m. Material requirements: Excavation 16.0 m, Foundation 1.6 m, Masonry 1.6 m, Rendered area 21 m, Sheet steel 5.7 m. (Source: OEKOTOP, Sasse)

Fig. 10.4: Constructional drawing of a cylindrical floating-drum plant for quarrystone masonry. Vd = 9.4 m, Vg = 2.5 m. Material requirements: Excavation 21.0 m, Foundation 1.0 m, Masonry 5.4 m, Rendered area 27.3 m, Sheet steel 6.4 m. (Source: OEKOTOP, KVIC) 10.1.2 Fixed dome plants Design calculation Sizing factors

Example Sample calculation

= 115 l/d R = (0.76 8)1/3= 1.85 m Retention time,RT = 70 days r = 0.52 R= 0.96 m Daily gas production, G = 2.5 m/d h = 0.40 R= 0.72 m Storage capacity, Cs = 60% p = 0.62 R= 1.14 m Digester volume, Vd = 8 m Gasholder volume, Vg=GCs = 1.5 m Vd : Vg = 5.3 : 1 Daily substrate input, Sd

Tab. 10.1: Calculating parameters for fixed-dome biogas plant (Source: Sasse 1984.OEKOTOP) Vg : Vd 1:5 1:6 1:8 1/3 1/3 R (0.76 Vd) (0.74 Vd) (0.72 Vd)1/3 r h p 0.52 R 0.40 R 0.62 R 0.49 R 0.37 R 0.59 R 0.45 R 0.32 R 0.50 R

Fig. 10.5: Conceptual drawing of fixed-dome biogas plant. Vg gasholder volume, Vd digester volume. (Source: OEKOTOP, Sasse)

Fig. 10.6: Constructional drawing of a fixed-dome plant. Vd = 8 m, V = 1.5 m. Material requirements: Excavation 25 m, Foundation 2.2 m, Masonry 2.0 m, Rendered area 22.0 m, Sealed area 7.0 m. (Source: OEKOTOP, Sasse, BEP Tanzania) 10.1.3 Earth pit with plastic-sheet gasholder

Fig. 10.7: Constructional drawing of an earth-pit biogas plant with plastic-sheet gasholder. Vd = 11 m, Vg = 2.2 m. Material requirements: Excavation 16 m, Rendered area 28 m, Sheeted area 10 m (Source: OEKOTOP)

10.1.4 Estimating the earth-pressure and hydraulic forces

Fig. 10.8: Schematic diagram of earth-pressure and water-pressure forces In-depth forces, h (e, w) pW = wW hw pW = hydrostatic pressure at depth hw (m) wW = specific weight of water = 1000 kp/m pW = 1000 h (kp/m) pE = wE ce he pE = active earth pressure, i.e. force of pressure of dry, previously loose but now compact column of earth on a solid vertical wall wE = specific weight of dry backfill earth = 1800 . . . 2 100 kp/m he = height of earth column (m) ce = coefficient of earth pressure for the earth column in question = 0.3 . . . 0.4 (-) pE = (600 . . . 700) h (kp/m ) Force acting on a surface P(E, W) = p A (kp = (kp/m) m) Note: The above formulae are simplified and intended only for purposes of rough estimation.

You might also like

- EstimatesDocument39 pagesEstimatesGage Floyd Bitayo75% (4)

- Civil Cost EstimateDocument105 pagesCivil Cost EstimatednbinhNo ratings yet

- Sewerage Treatment Plant Design TemplateDocument63 pagesSewerage Treatment Plant Design TemplateArvinthran Raja Kumaran92% (12)

- Model EstimatesDocument115 pagesModel EstimatesSitaramgv Venkata75% (8)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisFrom EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisRating: 5 out of 5 stars5/5 (1)

- Sand Replacement MethodDocument19 pagesSand Replacement MethodMazliah Zainal Abidin100% (1)

- Experiment 7: Field Density (Sand Cone Method)Document8 pagesExperiment 7: Field Density (Sand Cone Method)Thanaa' Marabeh100% (1)

- Revised fire drill performance standardsDocument47 pagesRevised fire drill performance standardsKartikeya GuptaNo ratings yet

- Consolidation Test AnalysisDocument26 pagesConsolidation Test AnalysisRajeev Kusugal100% (1)

- Experiment 7-Atterberg LimitsDocument14 pagesExperiment 7-Atterberg LimitsJack RasalNo ratings yet

- Drilling PresentationDocument354 pagesDrilling Presentationمصطفى عصام شيت حمديNo ratings yet

- Hydraulics Stability (Anyer Geotube Project)Document4 pagesHydraulics Stability (Anyer Geotube Project)Anonymous IWHeUvNo ratings yet

- LOD Spec 2016 Part I 2016-10-19 PDFDocument207 pagesLOD Spec 2016 Part I 2016-10-19 PDFzakariazulkifli92No ratings yet

- Fluidized Bed Boilers: Design and ApplicationFrom EverandFluidized Bed Boilers: Design and ApplicationRating: 4.5 out of 5 stars4.5/5 (4)

- Finals-Insurance Week 5Document19 pagesFinals-Insurance Week 5Ryan ChristianNo ratings yet

- PepsicoDocument18 pagesPepsicorahil virani0% (1)

- Drilling Methods For Shallow Geothermal InstallationsDocument14 pagesDrilling Methods For Shallow Geothermal InstallationsShamit RathiNo ratings yet

- Pre-Excavation Grouting in Rock TunellingDocument140 pagesPre-Excavation Grouting in Rock Tunellingmandeepgeology100% (1)

- 4608 Eed 01Document29 pages4608 Eed 01NickNo ratings yet

- Sandtrap DesignDocument25 pagesSandtrap DesignmuazeemK100% (1)

- Perhitungan Anaerobik Digester, Floating Dome, Fixed DomeDocument51 pagesPerhitungan Anaerobik Digester, Floating Dome, Fixed DomesehonoNo ratings yet

- Definicion de Lodos de ConcretoDocument6 pagesDefinicion de Lodos de ConcretoHugo Dario Machaca CondoriNo ratings yet

- Well Performance Analysis using WellFloDocument3 pagesWell Performance Analysis using WellFloLoh Chun LiangNo ratings yet

- Soil Lab - Manual MANOJDocument33 pagesSoil Lab - Manual MANOJAbhishek MeenaNo ratings yet

- Issue10-13 P1233-1241Document9 pagesIssue10-13 P1233-1241Chima C. UgwuegbuNo ratings yet

- Reclamation of Used Sands in Foundry ProductionDocument5 pagesReclamation of Used Sands in Foundry Productionathu2294No ratings yet

- Septic Tank Detail 2Document8 pagesSeptic Tank Detail 2Xyz AvmcNo ratings yet

- Gpcoewg Gecol: Document Cover SheetDocument31 pagesGpcoewg Gecol: Document Cover Sheettanmaymajhi09_796764No ratings yet

- Geo Lab ReviewerDocument29 pagesGeo Lab ReviewerMay'two Echalas MagawayNo ratings yet

- Experiment 10 PermeabilityDocument13 pagesExperiment 10 PermeabilityjoehassNo ratings yet

- Sample IPCDocument10 pagesSample IPCArshad MahmoodNo ratings yet

- PROPOSED ONE UNIT COMMUNAL FAUCET (STAND POSTDocument16 pagesPROPOSED ONE UNIT COMMUNAL FAUCET (STAND POSTBert EngNo ratings yet

- Bill of Quantity Sheet Project BreakdownDocument94 pagesBill of Quantity Sheet Project BreakdownIvanSuryawanWinartoNo ratings yet

- Lab Manual of SoilDocument43 pagesLab Manual of Soilaishwarya mundraNo ratings yet

- Report 7Document10 pagesReport 7Azeezan AlessaNo ratings yet

- Lab No. 4 Hydrometer AnalysisDocument12 pagesLab No. 4 Hydrometer AnalysisZERO100% (2)

- Gating_System_Measuring_of_SandcastingDocument10 pagesGating_System_Measuring_of_Sandcastingمصطفى الذاريNo ratings yet

- EXPeriment 6Document12 pagesEXPeriment 6Chakshu GautamNo ratings yet

- 1 Caorbontacion Acelerada de Yeso de CalDocument6 pages1 Caorbontacion Acelerada de Yeso de CalJHONIER ANDRES TORRES URREANo ratings yet

- CE3410 EXP8 PartA 2023 Manual VFDocument10 pagesCE3410 EXP8 PartA 2023 Manual VFSUBHAM SAGARNo ratings yet

- Constant-Head Permeability Test SandDocument5 pagesConstant-Head Permeability Test Sandbacha01No ratings yet

- Lab Report 3Document5 pagesLab Report 3Bilal AhmadNo ratings yet

- Detailed Estimates of Alternative 2 (Glass Materials) :::: Subject Project LocationDocument1 pageDetailed Estimates of Alternative 2 (Glass Materials) :::: Subject Project LocationKaemeeCaiñaNo ratings yet

- "Península de Santa Elena": Universidad EstatalDocument5 pages"Península de Santa Elena": Universidad EstatalAlejoNo ratings yet

- Table 2. Intake Pipe DesignDocument2 pagesTable 2. Intake Pipe Designerjayenv7346No ratings yet

- Practical Aspects in The Design of A Compacted Concrete Mixture (RCC) For Construction PurposesDocument21 pagesPractical Aspects in The Design of A Compacted Concrete Mixture (RCC) For Construction PurposesLuis Eloy FeoNo ratings yet

- Cost Estimates for Metallic Roll-up Materials AlternativeDocument1 pageCost Estimates for Metallic Roll-up Materials AlternativeKaemeeCaiña100% (1)

- Mechanical and hydrometer particle size analysisDocument7 pagesMechanical and hydrometer particle size analysismagdyamdbNo ratings yet

- 97-2003 The Standard and The Modi̇fi̇ed Proctor TestsDocument12 pages97-2003 The Standard and The Modi̇fi̇ed Proctor TestsHaydar TaşNo ratings yet

- Integradora InglesDocument7 pagesIntegradora Inglesluis enriqueNo ratings yet

- Geo Textile Tube DewateringDocument10 pagesGeo Textile Tube Dewateringadiapr15No ratings yet

- Energy: Panpan Zhang, Yiqun Zhang, Wenhong Zhang, Shouceng TianDocument13 pagesEnergy: Panpan Zhang, Yiqun Zhang, Wenhong Zhang, Shouceng TianzaarNo ratings yet

- EAC PR-22&23 Printout-1Document12 pagesEAC PR-22&23 Printout-1NIKHIL PARDESHINo ratings yet

- Evaluation of Technical Drilling OperationDocument56 pagesEvaluation of Technical Drilling OperationAkuffo TheophilusNo ratings yet

- Experiment HidroDocument11 pagesExperiment HidroSiti NurfatinNo ratings yet

- Chemical Process Equipment DesignDocument9 pagesChemical Process Equipment Designraghu_iictNo ratings yet

- SG1 Final PPT Rev1Document51 pagesSG1 Final PPT Rev1Swarnim RajNo ratings yet

- UNU-GTP-SC-14-22 Thorhallsson 2012 Geothermal Drilling Cost and Drilling EffectivenessDocument10 pagesUNU-GTP-SC-14-22 Thorhallsson 2012 Geothermal Drilling Cost and Drilling EffectivenessPrince MubaiwaNo ratings yet

- Influence of Cebex 112 on Technical Properties of Cement Mortar with Brick Powder Fine AggregateDocument8 pagesInfluence of Cebex 112 on Technical Properties of Cement Mortar with Brick Powder Fine AggregateFahrurizalNo ratings yet

- WasteWater 2022 2023Document94 pagesWasteWater 2022 2023Hellin DelNo ratings yet

- Gas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsFrom EverandGas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsLivio RuffineNo ratings yet

- Computational Kinematics Assignment 2021Document2 pagesComputational Kinematics Assignment 2021Simple FutureNo ratings yet

- Enviroclean 25 LTRDocument1 pageEnviroclean 25 LTRMaziyarNo ratings yet

- 1 John 2:15-27 - Bible Commentary For PreachingDocument6 pages1 John 2:15-27 - Bible Commentary For PreachingJacob D. GerberNo ratings yet

- Very Low Altitude Drag-Free Satellites: R D UpdatesDocument5 pagesVery Low Altitude Drag-Free Satellites: R D Updatesraa2010No ratings yet

- Director's Report Highlights Record Wheat Production in IndiaDocument80 pagesDirector's Report Highlights Record Wheat Production in Indiakamlesh tiwariNo ratings yet

- GE - Oil Sheen Detection, An Alternative To On-Line PPM AnalyzersDocument2 pagesGE - Oil Sheen Detection, An Alternative To On-Line PPM AnalyzersjorgegppNo ratings yet

- 841 Specific GravityDocument1 page841 Specific GravityJam SkyNo ratings yet

- Introduction 3-12-86Document13 pagesIntroduction 3-12-86Roshdy AbdelRassoulNo ratings yet

- Ebrosur Silk Town PDFDocument28 pagesEbrosur Silk Town PDFDausNo ratings yet

- The Grey Nomads Guide To AustraliaDocument3 pagesThe Grey Nomads Guide To AustraliaFreerangecamping60% (5)

- Gerovital anti-aging skin care product guideDocument10 pagesGerovital anti-aging skin care product guideכרמן גאורגיהNo ratings yet

- DCI-2 Brief Spec-Rev01Document1 pageDCI-2 Brief Spec-Rev01jack allenNo ratings yet

- Advanced Radiographic Techniques PDFDocument21 pagesAdvanced Radiographic Techniques PDFelokfaiqNo ratings yet

- IMRAD - G1 PepperDocument13 pagesIMRAD - G1 PepperRomero, Ken Angelo B.No ratings yet

- GMsetDocument8 pagesGMsetdilo001No ratings yet

- BiologyDocument21 pagesBiologyHrituraj banikNo ratings yet

- Knowing Annelida: Earthworms, Leeches and Marine WormsDocument4 pagesKnowing Annelida: Earthworms, Leeches and Marine WormsCherry Mae AdlawonNo ratings yet

- H. Bateman, A. Erdélyi Et Al. - Higher Transcendental Functions 3 (1955, McGraw-Hill)Document310 pagesH. Bateman, A. Erdélyi Et Al. - Higher Transcendental Functions 3 (1955, McGraw-Hill)ITALO HERRERA MOYANo ratings yet

- 2021 - Tet Purchase Behavior Report - INFOCUSDocument15 pages2021 - Tet Purchase Behavior Report - INFOCUSGame AccountNo ratings yet

- GT ĐỀ 04Document39 pagesGT ĐỀ 04Cao Đức HuyNo ratings yet

- Textile Pretreatment and Finishing 2023Document205 pagesTextile Pretreatment and Finishing 2023Aweru gebremariamNo ratings yet

- Spin - 2021Document60 pagesSpin - 2021Tanel LaanemägiNo ratings yet

- ME 2141 - Complete ModuleDocument114 pagesME 2141 - Complete ModuleNICOLE ANN MARCELINONo ratings yet

- Medium Strength High Conductivity MaterialsDocument37 pagesMedium Strength High Conductivity MaterialsNut AssanaiNo ratings yet

- Retired Car Jacker Screen PlayDocument4 pagesRetired Car Jacker Screen Playapi-633948182No ratings yet