Professional Documents

Culture Documents

Unit 8 Lus

Uploaded by

Malagouda PatilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit 8 Lus

Uploaded by

Malagouda PatilCopyright:

Available Formats

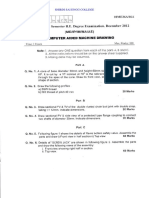

FLOW MEASUREMENT IN CLOSED CONDUIT

Closed conduit flow:

It is a flow with boundaries and runs full. As in the case of open channel flow, the surface is not

exposed to atmosphere. Since it runs full it is also called as pressure flow and the conduit in

which it flows as pressure conduit. The examples are water mains, blood flow in arteries, etc.

The measurement of fluid flow is important in applications ranging from measurements of

blood-flow rates in human artery to the measurement of liquid oxygen in a rocket.

The selection of the proper instrument for a particular application is governed by many variables,

including cost. Flow-rate-measurement devices frequently require accurate pressure and

temperature measurements in order to calculate the output of the instrument.

The most widely used flow metering principle involves placing a fixed area flow restriction of

some type in the pipe or duct carrying the fluid. This flow restriction causes a pressure drop that

varies with the flow rate.

Thus, measurement of the pressure drop by means of a suitable differential-pressure pick up

allows flow rate measurement. These types meters are termed as obstruction flow meters.

Each of the flow measurement devices inherently has its own advantages and disadvantages.

Some of those instruments are:

Venturi Meter

1797 - Venturi presented his work on the Venturi tube

1887 - first commercial Venturi tube produced by Clemens Herschel

Three important portions

Converging cone

Throat

Diverging cone

Fig. 1 Different segments of Venturi meter

In the venturi meter, the fluid is accelerated through a converging cone of angle 15-20 and the

pressure difference between the upstream side of the cone and the throat is measured and

provides the signal for the rate of flow.

Fig. 2 Alignments of Venturimeter

The fluid slows down in a cone with smaller angle (5-7) where most of the kinetic energy is

converted back to pressure energy. Because of the cone and the gradual reduction in the area

there is no "vena contracta". The flow area is at minimum at the throat.

High pressure and energy recovery makes the venturi meter suitable where only small pressure

heads are available.

Some important points:

Throat to diameter ratio 0.25 to 0.75

Discharge co-efficient 0.9 to 1.0

Made of cast iron, gun metal, stainless steel

May be circular, square or rectangular

A discharge coefficient Cv- of 0.975 may be taken as standard, but the value varies noticeably at

low values of the Reynolds' number.

The pressure recovery is much better for the venturi meter than for the orifice plate.

The venturi tube is suitable for clean, dirty and viscous liquid and some slurry services.

Pressure loss is low.

Typical accuracy percent is i of full range.

Required upstream pipe length 5 to 20 diameters.

Viscosity effect is high

Relative cost is medium

Most commonly used for liquids, especially water.

Discharge Equation

Fig. 3 Determination of Discharge

Applying Bernoullis equation between the points 1 and 2 for inclined manometer,

----------------------------------(1)

Where,

P/ represents pressure head, V

2

/2g velocity head and z is the datum head and h

L

head loss

between the sections 1 and 2.

Ignoring energy or head loss between the sections, the net peizometric head (P/ +z) is given by

-----------------------------------(2)

For horizontal alignment, z

1

= z

2

.

Consider a venturi meter as shown

in figure. A liquid having a specific

weight of is flowing through it.

The rate of flow of the liquid is

determined by measuring the

difference in pressure between the

two points 1 and 2 as shown in

figure. Point 1 is just at the

beginning of convergence section

and point 2 is at the throat section of

the venture meter.

The discharge through veturimeter

is determined by applying

conservation of energy and mass as

discussed below.

L

h z

g

V p

z

g

V p

+ + + = + +

2

2

2 2

1

2

1 1

2 2

L

h z

g

V p

z

g

V p

+ + + = + +

2

2

2 2

1

2

1 1

2 2

Applying continuity equation, the product of cross sectional area and velocity at any section is

constant, i.e,

A

1

V

1

= A

2

V

2

or V

1

(D

1

)

2

= V

2

(D

2

)

2

-----------------------------------(3)

Where A , V and D are the c/s area , mean velocity of flow and diameter at their respective

sections

Writing V

1

in terms of V

2

, i.e., V

1

= (A

2

/A

1

)V

2

And replacing V

1

in Eq. 2 solving for V

2

-------------------------------------(3)

------------------------------------------------(4)

OR

-------------------------------(5)

For horizontzl zlignment,

--------------------------(6)

After obtaining velocity at any section the discharge is determined by applying the continuity

equation, Q= AxV. In this analysis since the energy losses are neglected, the discharge

calculated using the continuity equation is known as theretical discharge (Qth). The theoretical

discharge flowing through the pipe in this case is equal to Q= A

2

x V

2

.

I.e.,

---------------------------------(7)

( ) [ ]

4

1 2

2 1

2

1

) ( 2

D D

p p g

V

( ) [ ]

4

1 2

2 1

2

1

) ( 2

D D

p p g

V

For horizontal alignment,

--------------------------(8)

Considering the energy losses in to consideration, the treoretical discharge equation is to be

multiplied by a coefficient known aas coefficient of discharge (C

d

) to get actual discharge

flowing through the venturimeter.

Coefficient of discharge, C

d

= Q

act

/ Q

Th

Therefore, Q

act

= C

d

Q

Th

Therefore,

OR ---------(9)

Where h is the difference in pressure between the section 1 & 2

For horizontal alignment,

OR -- (10)

DETERMINATION OF DIFFERENTIAL PRESSURE, h OR (P

1

P

2

)/ or h

The differential pressure between the sections can be determined by appluing the manometric

principle.

Applying monometric equation to equate the pressure along A-A in terms of flowing liquid (Fig.

4),

Let flowing liquid RD (specific gravity) be s and the manometric liquid with RD s

m

.

Fig. 4 Determination of Differential Pressure

P

1

/ + sz

1

= P

2

/ + s(z

2

-y)+ s

m

y

P

1

/ - P

2

/ +s(z

1

- z

2

) = s

m

y-sy

P

1

/ - P

2

/ +s(z

1

- z

2

) = y(s

m

-s)

P

1

/ - P

2

/ +(z

1

- z

2

) = h = y((s

m

/s)

-1) -------------------------(11)

For horizontal alignment, z

1

= z

2

P

1

/ - P

2

/ = h = y((s

m

/s)

-1) ---------------------- (12)

Hence, the peizometric head difference, h, depends on the gauge reading y, the

respective relative densities of flowing fluid and mamometric liquid and

regardless of orientation of venturimeter (horizontal, inclined, vertical).

i.e, h = y((s

m

/s)

-1)

The general discharge equation can be represented as,

-------------------(13)

Where, A

1

= Area of c/s at inlet and A

2

= Area of c/s at throat

Since friction cannot be eliminated in the venturi meter a permanent loss in pressure occurs

Because of the small angle of divergence in the recovery cone, the permanent pressure loss is

relatively small (about 10% of the venturi differential p

a

p

b

).

Fig. 5 Pressure loss in Venturimeter

Fluid slows down in a cone with smaller angle (5-7) where most of the kinetic energy is

converted back to pressure energy.

Because of the cone and the gradual reduction in the area there is no "vena contracta".

The flow area is at minimum at the throat

.

High pressure and energy recovery makes the venturi meter suitable where only small pressure

heads are available

A discharge coefficient of 0.975 may be taken as standard, but the value varies noticeably at low

values of the Reynolds' number.

PROBLEM:

An oil of relative density 0.9 flows through a vertical pipie of diameter 10 cm. The flow is

measured by a 20 cm x 10 cm venturimeter. The throat is 10 cm above the inlet section. A

differential U-tube manometer containing mercury is connected to the throat and the inlet. If C

d

is 0.99 what is (a) flow for a manometer reading of 9 cm and (b) the manometer reading for a

flow of 50 l/s ?

Solution:

Given;

Inlet (pipe diameter) = 20 cm

Throat diameter = 10 cm.

Oil specific gravity = 0.9

C

d

= 0.99

Discharge Equation,

For,

Oil specific gravity, s = 0.9,

s

m

= 13.6 (mercury)

h = y((s

m

/s)

-1) = y((13.6/0.9) -1) = 14.11 y

A

1

= Area of c/s at inlet; A

1

= ((/4)(0.2)

2

= 0.0314 m

2

A

2

= Area of c/s at throat A

2

= ((/4)(0.1)

2

= 0.007854 m

2

Case (a)

y=0.09 m, Q = ?

Substitute in discharge equation,

Q

act

= 0.99(0.0314)(.007854)((2x9.81x14.11x0.09)/(0.0314

2

-0.007854

2

))

0.5

Q = 0.040 m

3

/s

Q = 40 l/s

Case(b)

Q= 50l/s = 0.050 m

3

/s ; y= ?

Substituting in the equation,

0.05 = 0.99(0.0314)(.007854)((2x9.81x14.11xy)/(0.0314

2

-0.007854

2

))

0.5

Solving for y,

y = 0.14 m = 14 cm.

ORIFICE METER

It consists of a flat orifice plate with a circular hole drilled in it.

The construction is very simple and so cost is low compared to other obstruction meters..

Fig. 6a Salient Features of Orifice Meter

Fig. 6b Salient Features of Orifice Meter

Usually pressure tapping is at a distance D & D/2 for up stream & down stream

Fig. 7 Flow Through Orifice Meter

Reduction of pressure between taps is measured using a differential manometer and it gives a

measure of the discharge.

The pressure recovery is poor compared to the Venturi meter

Types of Orifice Meter

Depending upon the position shape of opening, generally, there are three types orifice meter.

Fig. 8 Types of Orifice Meter

A) Concentric Orifice meter : The centers of the orifice plate and circular opening coincide with

each other . Concentric bore design Used for most clean fluids May clog if fluid contains solids

(B) Eccentric Orifice meter: The centers of the orifice plate and circular opening not coincide

with each other .Eccentric bore design Hole is off-center Used for liquids that contain some

solids

(C) Segmental Orifice meter: The opening is in the form of a segment, like semi circle.

Segmental plate Used for thin slurries but less accurate

Discharge Equation

Expression for discharge through any obstruction flow meter can be theoretically obtained using

the continuity and Bernoullis equations together.

Derivation for discharge is same as that of Venturi meter.

Fig. 9 Flow Through Orifice Meter

Applying Benoullis equation between the sections, 1 and 2

Consider an orifice meter as shown in figure.

Consider two sections one to upstream and

another to downstream of orifice plate as shown.

As in the case of venture meter, the discharge

through orifice meter is determined using

Bernoulli and continuity equations applied at two

sections considered for the analysis.

L

h z

g

V p

z

g

V p

+ + + = + +

2

2

2 2

1

2

1 1

2 2

L

h z

g

V p

z

g

V p

+ + + = + +

2

2

2 2

1

2

1 1

2 2

---------------(14)

Ignoring the energy losses, h

L

, the equation takes the form as,

----(15)

Now, applying continuity equation, A

1

V

1

= A

2

V

2

Where A , V and D are the c/s area , mean velocity of flow and diameter at their respective

sections. Writing V

1

in terms of V

2

, i.e., V

1

= (A

2

/A

1

)V

2

And replacing V

1

in Eq. 15 solving for

V

2

----------------(16)

----------------(17)

Applying Continuity equation at section 2, Q= A

2

V

2

, the theoretical discharge is given by,

----------------(18)

The coefficient of discharge, C

d

= Q

act

/ Q

Th

Therefore, Q

act

= C

d

Q

Th

OR

----------------(19)

g

V

g

V p p

2 2

2

1

2

2 2 1

=

g

V

g

V p p

2 2

2

1

2

2 2 1

=

(

(

|

|

\

|

=

4

1

2

2

2 2 1

1

2 D

D

g

V p p

(

(

|

|

\

|

=

4

1

2

2

2 2 1

1

2 D

D

g

V p p

( ) [ ]

4

1 2

2 1

2

1

) ( 2

D D

p p g

V

( ) [ ]

4

1 2

2 1

2

1

) ( 2

D D

p p g

V

Applying manometric equation to equate the pressure along A-A in terms of flowing liquid,

Let the flowing liquid RD be s and manometric liquid RD be s

m

.

Fig. 10 Determination of h or h

P

1

/ + sz

1

= P

2

/ + s(z

2

-y)+ s

m

y

P

1

/ - P

2

/ +s(z

1

- z

2

) = s

m

y-sy

P

1

/ - P

2

/ +s(z

1

- z

2

) = y(s

m

-s)

P

1

/ - P

2

/ +(z

1

- z

2

) = h = y((s

m

/s)

-1)

For horizontal alignment, z

1

= z

2

P

1

/ - P

2

/ = h = y((s

m

/s)

-1)

The general discharge equation can be written as,

----------------(19)

Where, A

1

= Area of c/s at inlet and A

2

= Area of c/s of orifice opening

Pressure Variation in Orifice Meter

Orifice plate- inserted to pipe to create a partial restriction to flow.

Pressure before orifice plate rises and pressure after it reduces but velocity increases. Position

where velocity is maximum & static pressure is min is known as vena contracta.

There is a large pressure drop much of which is not recoverable. This can be a severe limitation

when considering use of an orifice meter.

Discharge coefficient - C

d

- of 0.60 may be taken as standard, but the value varies noticeably at

low values of the Reynolds number.

Fig. 11 Pressure variation along Orifice Meter

Advantages and Disadvantages of Orifice meter

The orifice meter has several practical advantages when compared to venturi meters.

Lower cost

Smaller physical size

Flexibility to change throat to pipe diameter ratio to measure a larger range of flow rates

Disadvantage:

Large power consumption in the form of irrecoverable pressure loss

The orifice meter is recommended for clean and dirty liquids and some slurry services.

Comparison between Venture meter and Orifice Meter.

PROBLEM:

An orifice meter is used to measure the air flow passing through a pipe of 8 cm diameter. The

diameter of orifice meter is 2 cm. The pipe is horizontal. The head causing flow is measured by

using a manometer containing water. The measured head is 5.6 m of water. The density of air

1.193 kg/ m

3

.

.

Take C

d

= 0.65

Solution:

Given;

Pipe diameter = 8 cm = 0.08 m

Orifice diameter = 2 cm = 0.02 m

Manometric liquid = water, RD = 1.0,

Manometric difference (differential pressure ) = 5.6 m of water

Mass density of air = 1.193 kg/ m

3

.

.

C

d

= 0.65

A

1

= Area of c/s at inlet;

A

1

= ((/4)(0.08)

2

= 0.005026 m

2

A

2

= Area of c/s of orifice opening

A

2

= ((/4)(0.02)

2

= 0.0003141 m

2

Y = 5.6 m

h = y((s

m

/s)

-1) = h = y((

m

/

w

) / (

air

/

w

)

-1)

m

= density of monometric liquid

w

= density of water

air

= density of air

m

/

w

= 1 as manometric liquid is water

air

/

w

= 1.193/1000 = .001193

h = 5.6 x ((1/0.001193) -1) = 4688.4 m of air

Discharge Equation:

Q

act

= 0.65x 0.005026x 0.0003141((2x9.81x 4688.4) /((0.005026)

2

(0.0003141)

2

)

0.5

Q

act

= 0.06204 m

3

/s = 62.04 l/s

ROTAMETER

These meters fall into the category of flow measurement devices called variable area meters.

These devices have nearly constant pressure and depend on changing cross sectional area to

indicate flow rate. These are extremely simple, robust devices that can measure flow rates of

both liquids and gasses.

Fig. 12 Rotatmeter

The figure shows the pictorial representation of rotameter. Fluid

flows up through the tapered tube, typically made of glass with

suspended float in the column of fluid. The area of tube

increases in the direction of flow and hence the name variable

area meter.

A 'float', actually a shaped weight, inside that is pushed up by

the drag force of the flow and pulled down by gravity.

Drag force for a given fluid and float cross section is a function of

square of speed only

A higher volumetric flow rate through a given area results in

increase in flow speed and drag force, so the float will be pushed

upwards.

However, as the inside of the rotameter is cone shaped (widens),

the area around the float through which the medium flows

increases, the flow speed and drag force decrease until there is

mechanical equilibrium with the float's weight.

Floats are made in many different shapes, with spheres and

ellipsoids being the most common.

The float may be diagonally grooved and partially colored so that

it rotates axially as the fluid passes.

This shows if the float is stuck since it will only rotate if it is free.

Fig. 13 different Forces in the System

Fig. 14 Measurement of Discharge

Readings are usually taken at the top of the widest part of the float;

the center for an ellipsoid,

or the top for a cylinder.

Some manufacturers use a different standard.

Discharge Equation

The discharge through the rotametr can also be determined from the relation

Q = C

d

A (2gh)

0.5

Where C

d

= Coefficient of discharge, lies between 0.7 and 0.75

A = Annular area between the tapering pipe and top of the float

h = Effective across the float given by,

h = (volume of float/Area of float) x (s-1)

s = specific gravity of the float material

(s-1) represents the effective specific gravity of the float.

Three types of forces must be accounted for when

analyzing rotameter performance namely:

Flow

Gravity

Buoyancy

Weight and shape of the float are designed to match the

fluid properties

As the flow increases the area between the float and

tube increase

The float finds a height where the pressure of the fluid

and weight of the float are equal.

The position of the float indicates the flow rate on a

marked scale.

Advantages

Requires no external power or fuel

Uses only the inherent properties of the fluid, along with gravity, to measure flow rate.

Relatively simple device that can be mass manufactured out of cheap materials, allowing for its

widespread use.

Disadvantages

Due to its use of gravity, a rotameter must always be vertically oriented and right way up, with

the fluid flowing upward

Graduations on a given rotameter will only be accurate for a given substance at a given

temperature.

Rotameters normally require the use of glass (or other transparent material), otherwise the user

cannot see the float.

This limits their use in many industris

Rotameters are not easily adapted for reading by machine; although magnetic floats that drive a

follower outside the tube are available.

PROBLEM

A rotameter has a 300 mm long tube which has an internal diameter of 25 mm at top and 18 mm

at bottom. The diameter of the float is 18 mm. its effective relative density is 4.8 and its volume

60 cc. If the coefficient of discharge is 0.72, at what height will the float be when metering

water at 0.1 l/s

Effective head across the float = h = (Vol of float/area of float) x (s-1)

h= (60/2.5447)x 4.8 = 113.18 cm

Discharge, Q = C

d

A (2gh)

0.5

0.1x1000 = 0.72 A (2x9.81x113.18)

0.5

Given

Length of rotameter = 300 mm

Float diameter = 18mm,

A= area = ((/4)(1.8)

2

)= 2.5447 cm

2

= 2.545 cm

2

Volume of float = 60 cc

Effective relative density = (s-1) = 4.8

C

d

= 0.72

Q = 0.1 l/s = 0.1 x 1000 cc

Solving for, A

A = 0.295 cm

2

A is the annular area between the tube and float.

Sectional area of tube = Area of float + 0.295

Arae of float = 2.5447 cm

2

Sectional area of tube = 2.545+ 0.295 = 2.84 cm

2

Let D be the diameter of the tube at the level of the float.

i.e., ((/4)(D)

2

)= 2.84

D = 1.90 cm

Diameter of tube at bottom = 1.8 cm

Diameter of tube at top = 2.5 cm

Height of the float , using the concept of similar triangle is given by

Height of float = ((1.9-1.8) /(2.5-1.8)) x 30

= 4.28 cm

Flow Through Orifices

It an opening of any cross section, at the bottom or on the side walls of a container or vessel,

through which the fluid is discharged.

If the geometric characteristics of the orifice plus the properties of the fluid are known, then the

orifice can be used to measure the flow rates.

FLOW THROUGH SMALL ORIFICE

Figure shows a sharp edged small orifice in one side of a reservoir containing liquid.

Liquid will emerge from the orifice as a free jet, that is, a jet discharged in the atmosphere

Will therefore be under the influence of gravity only.

Equation 1 is known as Torricelli's theorem and represents theoretical velocity of the jet.

Actual velocity

actual velocity of jet at vena contracta

where Cv =coefficient of velocity =

theoretical velocity of the jet

By Bernoulli's equation between the points 1 and 2,

P1=P2 = atmospheric pressure

Neglecting losses, velocity through orifice

1

The jet area is much less than the area of the orifice due to contraction and the

corresponding coefficient of contraction, is defined as C

c

area of jet at vena contracta

C

c

=

area of orifice

At the section very close to the orifice, known as vena contracta, the velocity is normal to the

cross section of the jet and hence the discharge is

Actual Q = Area of jet x velocity of jet at vena contracta

PROBLEM

A reservoir discharges through a sluice 0.915m wide by 1.22 m deep. The top of the opening is

0.61m below the water level in the reservoir and the downstream water level

is below the bottom of the opening. Calculate the discharge through the opening if Cd = 0.6. The

opening is treated as a small orifice.

Solution:

For a small orifice

a = 1.22x0.915 = 1.116 m

2

h is the distance of center of opening from the water surface.

= 0.61+(1.22/2) = 1.22 m

Therefore, Q,

Q= 0.6x1.116x(2x9.81x1.22)

0.5

= 3.276 m

3

/s

C

d

= C

v

C

c

You might also like

- ProblemsDocument7 pagesProblemsMalagouda PatilNo ratings yet

- ProblemsDocument7 pagesProblemsMalagouda PatilNo ratings yet

- Naac SSRDocument124 pagesNaac SSRAruaru AruNo ratings yet

- Screw Jack Front and Top ViewDocument38 pagesScrew Jack Front and Top ViewMalagouda PatilNo ratings yet

- Gender equity promotion programsDocument12 pagesGender equity promotion programsMalagouda PatilNo ratings yet

- FM LabDocument59 pagesFM LabMalagouda PatilNo ratings yet

- Criterion 7-Institution Values and Best Practices (100) Key IndicatorDocument2 pagesCriterion 7-Institution Values and Best Practices (100) Key IndicatorMalagouda PatilNo ratings yet

- PaperDocument7 pagesPaperMalagouda PatilNo ratings yet

- Reduction of Temperature in Silicon Photovoltaic MDocument4 pagesReduction of Temperature in Silicon Photovoltaic MMalagouda PatilNo ratings yet

- NAAC ManualDocument97 pagesNAAC ManualMalagouda PatilNo ratings yet

- Curso SolidEdge Simulation EnglishDocument25 pagesCurso SolidEdge Simulation EnglishMalagouda PatilNo ratings yet

- Course Plan: Department of Mechanical EngineeringDocument12 pagesCourse Plan: Department of Mechanical EngineeringMalagouda PatilNo ratings yet

- Mech 32 HT Lab ManualDocument74 pagesMech 32 HT Lab Manualalp_alp100% (1)

- Screw Jack Front and Top View PDFDocument1 pageScrew Jack Front and Top View PDFMalagouda PatilNo ratings yet

- Computational Analysis of Heat Transfer Through FinsDocument9 pagesComputational Analysis of Heat Transfer Through FinsIJAERS JOURNALNo ratings yet

- Study & Analysis of Knuckle Joint With The Replacement of Material by Using TeflonDocument6 pagesStudy & Analysis of Knuckle Joint With The Replacement of Material by Using TeflonShiva Krishna BhagavatulaNo ratings yet

- Chapter 1-Energy Management: January 2015Document26 pagesChapter 1-Energy Management: January 2015Malagouda PatilNo ratings yet

- Paper20109 114Document6 pagesPaper20109 114Malagouda PatilNo ratings yet

- Lecture 1Document9 pagesLecture 1SanaAfridiNo ratings yet

- Chapter 1-Energy Management: January 2015Document26 pagesChapter 1-Energy Management: January 2015Malagouda PatilNo ratings yet

- 140198Document73 pages140198KhanzadaRajputNo ratings yet

- Lecture 1Document9 pagesLecture 1SanaAfridiNo ratings yet

- Module-1: General Introduction M1: General Introduction M1.1 Introduction of CompositesDocument35 pagesModule-1: General Introduction M1: General Introduction M1.1 Introduction of CompositesANo ratings yet

- Energy Audit ChapterDocument25 pagesEnergy Audit ChapterGourav JainNo ratings yet

- Mechanical-Engineering Gate2016.InfoDocument3 pagesMechanical-Engineering Gate2016.InfoHenryNo ratings yet

- Mec 3 SCHDocument22 pagesMec 3 SCHRing MasterNo ratings yet

- VMRDocument117 pagesVMRM Sandesh ShenoyNo ratings yet

- Module-1: General Introduction M1: General Introduction M1.1 Introduction of CompositesDocument35 pagesModule-1: General Introduction M1: General Introduction M1.1 Introduction of CompositesANo ratings yet

- Module-1: General Introduction M1: General Introduction M1.1 Introduction of CompositesDocument35 pagesModule-1: General Introduction M1: General Introduction M1.1 Introduction of CompositesANo ratings yet

- Hydraulics LectureDocument20 pagesHydraulics Lecturee_manpreetNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- EE207 Problem Set 1Document2 pagesEE207 Problem Set 1Rishabh AgarwalNo ratings yet

- Experiment 3 MOMDocument6 pagesExperiment 3 MOMHafiz HamzaNo ratings yet

- Deber Coeficientes Globales de La Transferencia de CalorDocument13 pagesDeber Coeficientes Globales de La Transferencia de CalorJuan Francisco JácomeNo ratings yet

- DC CircuitDocument142 pagesDC CircuitBela FirmantoyoNo ratings yet

- MQC LabDocument70 pagesMQC LabAjit BandgarNo ratings yet

- 218Document261 pages218Ikhlas KittaNo ratings yet

- ASTM D287 - 12bDocument5 pagesASTM D287 - 12bmancjaNo ratings yet

- Test Planner-Repeater Course - 2023-2024 - (Phase-03)Document2 pagesTest Planner-Repeater Course - 2023-2024 - (Phase-03)SbjNo ratings yet

- Applied MathematicsDocument119 pagesApplied MathematicsIAMMARKSNo ratings yet

- Basic Inertial NavigationDocument38 pagesBasic Inertial Navigationleneneck9057100% (1)

- Experiment #3 / Unit 6 Calorimetry - Measuring Heat Changes During A Physical or Chemical ChangeDocument2 pagesExperiment #3 / Unit 6 Calorimetry - Measuring Heat Changes During A Physical or Chemical Changeapi-368121935No ratings yet

- Vesic 1975 Bearing Capacity of Shallow FoundationsDocument27 pagesVesic 1975 Bearing Capacity of Shallow Foundationst.w.c.100% (2)

- Experiment No 8: Aim: To Determine The Frequency & Wavelength in A Rectangular Waveguide Working inDocument5 pagesExperiment No 8: Aim: To Determine The Frequency & Wavelength in A Rectangular Waveguide Working inSanab KumarNo ratings yet

- Str-A6051 52 53 59 61 62 69 79Document13 pagesStr-A6051 52 53 59 61 62 69 79Александр АндриановNo ratings yet

- Lectu 14Document4 pagesLectu 14YeviraArinDiyanaNo ratings yet

- Reiki Is A Great Tool For Stress Reduction and Relaxation (!)Document16 pagesReiki Is A Great Tool For Stress Reduction and Relaxation (!)vaniaNo ratings yet

- Chapter 1Document55 pagesChapter 1nur izzah fatiniNo ratings yet

- Finding Binary Azeotropes Using Thermodynamic RelationshipsDocument7 pagesFinding Binary Azeotropes Using Thermodynamic Relationshipsshinta sariNo ratings yet

- Chapter 1 Units and VectorsDocument33 pagesChapter 1 Units and VectorslozzzzzNo ratings yet

- Applications Using The Partial Differential Equation ToolboxDocument11 pagesApplications Using The Partial Differential Equation ToolboxIgor WosniakNo ratings yet

- Carrfoster 2Document5 pagesCarrfoster 2SauravNo ratings yet

- Math 2280 - Lecture 4: Separable Equations and Applications: Dylan Zwick Fall 2013Document8 pagesMath 2280 - Lecture 4: Separable Equations and Applications: Dylan Zwick Fall 2013Kawsar MobinNo ratings yet

- Bunker DesignDocument25 pagesBunker DesignswatkoolNo ratings yet

- Assignment 1 (ELE8306 - 21)Document5 pagesAssignment 1 (ELE8306 - 21)umarsaboNo ratings yet

- CV Physics Internship 2012Document3 pagesCV Physics Internship 2012Pavan IyengarNo ratings yet

- Robot DynamicsDocument52 pagesRobot Dynamicssilviocus88No ratings yet

- Curtain Wall Calculation PDFDocument134 pagesCurtain Wall Calculation PDFAlaaBadwy100% (1)

- Compiled FluMach Problems - GROUP6 - BSME31Document58 pagesCompiled FluMach Problems - GROUP6 - BSME31Jhun Briones100% (1)

- Helium Pycnometry Density TestDocument2 pagesHelium Pycnometry Density TestDapoer OmaOpa100% (1)

- Higher efficiency synchronous motors for industrial applicationsDocument6 pagesHigher efficiency synchronous motors for industrial applicationsAmirNo ratings yet