Professional Documents

Culture Documents

Influence of Different Stress Conditions On Behaviour of Rockfill Materials

Uploaded by

Sella Adinda SesarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Influence of Different Stress Conditions On Behaviour of Rockfill Materials

Uploaded by

Sella Adinda SesarCopyright:

Available Formats

Geotech Geol Eng DOI 10.

1007/s10706-011-9435-8

ORIGINAL PAPER

Inuence of Different Stress Conditions on Behavior of Rockll Materials

Pankaj Sharma N. V. Mahure Murari Ratnam

Received: 20 July 2010 / Accepted: 20 July 2011 Springer Science+Business Media B.V. 2011

Abstract Rockll material is the most readily available and the most exible material for the construction of dams especially in the seismic prone regions. The material is obtained either by blasting available rock or is collected from the alluvial deposits of the river. During construction of the dam, the available rockll material is compacted to required density layer by layer using various sophisticated compactors to achieve the required density and slope. Gradually the vertical load on the lower layers goes on increasing due to placement of subsequent layers of the materials to achieve the desired height. This may result in variation of grain size distribution of the lower layers due to the breakage of particles. This will certainly inuence the shear parameters. Present studies have been carried out to nd the inuence of loading the rockll materials under two different stress conditions i.e. multistage loading and single stage loading on the grain size distribution and its subsequent effect on its shear parameters. Consolidated drained triaxial shear tests have been conducted on the materials obtained by blasting available rock as well as on the materials collected from the alluvial deposits of the river which are generally used for construction of rockll dams. Test data have been analyzed to study the breakage

P. Sharma (&) N. V. Mahure M. Ratnam Central Soil and Materials Research Station, Hauz Khas, New Delhi, India e-mail: pan2256@gmail.com

factor and corresponding shear parameters under both conditions. Keywords Rockll materials Consolidated drained triaxial shear tests Multistage loading Single stage loading Particle size Strength parameters and breakage factor

1 Introduction Construction of dams using rockll (RF) is becoming increasingly more common because of self realigning capacity of the materials. This makes RF dams more stable even in the seismic zones. The abundant availability of such materials in the vicinity of proposed dam construction sites makes dams construction more economical. The materials consist primarily of angular to sub-angular particles obtained by blasting parent rock (QRF) or rounded/subrounded particles obtained from terrace alluvial deposits of the river (RBRF). During construction of the dam the available RF material is compacted to required density layer by layer using various sophisticated compactors to achieve the required density and slope. Gradually the vertical load on the lower layers goes on increasing due to placement of subsequent layers of the materials to achieve the desired height. This may result in variation of grain distribution of the lower

123

Geotech Geol Eng

layers due to the breakage of particles. The behavior of RF material is signicantly affected by the grain size distribution of the used materials. This paper deals with the effect of different stress conditions encountered during construction stage on the Breakage of particles and its corresponding effect on the shear parameters for the QRF and RBRF materials. Consolidated drained tests (CD) have been conducted on both type of materials generally being used for construction of rockll dams i.e. QRF and RBRF materials under multistage loading condition (MS) and single stage loading condition (SS). The test data has been analyzed to study the breakage of particles as percent cumulative particle breakage factor Bg(cum) (%) in MS) and percent particle breakage factor Bg (%) in SS and shear parameters under both conditions.

breakage by dening it based on the modication of the grain size distribution curves before and after the tests and have presented it as breakage factor Bg (%).

3 Material Used for Testing 3.1 Quarried Material from Kol Dam Project, H.P., (QRF) The rockll material was collected by blasting the parent rock. The rockll material consists of angular to sub-angular particles in shape and size up to 500 mm. The parent rock at this project site is either dolomite or limestone. The QRF materials possess the following mechanical properties; Uniaxial compressive strength: 37.1 MPa to 40.4 MPa Los Angeles abrasion value: 48.1% Aggregate impact value: 42.3% Aggregate crushing value: 41.2%. 3.2 River Bed Material from Kol Dam Project, H.P., (RBRF) The material was collected from the alluvial deposit of the river near the proposed dam axis. It consists of well graded rounded/sub rounded grayish colored particles up to 500 mm size, mainly composed of quartzite and dolomite/lime stone. The RBRF materials possess the following mechanical properties; Uniaxial compressive strength: 42.7 MPa to 50.1 MPa Los Angeles abrasion value: 44.2% Aggregate impact value: 39.8% Aggregate crushing value: 37.9%.

2 Review Investigations conducted on rockll materials indicate that the magnitude of the particle breakage during loading has a direct impact on the shear parameters. The amount of particle breakage is affected by the stress level, stress magnitude and stress path. Large amount of particles breakage is generated when stress levels are higher and when large amounts of strains occur in regions of high stress magnitudes. These empirical factors either cause the variation of grain diameter (Lee and Farhoomand 1967; Lade and Yamamuro 1996) or the shift of the whole grain size distribution curve (Marsal 1967; Hardin 1985). The results of tests conducted by Marachi et al. (1972) show a variation of the angle of internal friction with the grain size distribution. High pressure causes considerable particle breakage (Becker 1972; Hardin 1985; Murphy 1987; Colliat-Dangus et al. 1988; Fukumoto 1990; Hagerty et al. 1993; Lade et al. 1996; Daouadji and Heicher 1997). There are several factors that affect the amount of particle breakage in a geological material (Lee and Farhoomand 1967; Ramamurthy 1969; Murphy 1971; Billam 1971; Lo and Roy 1973; Ramamurthy et al. 1974; Gupta 1980; Hardin 1985; Kjaernsli et al. 1992; Venkatachalam 1993; Lade et al. 1996). Marsal (1965), Vesic and Clough (1968), Marachi et al. (1969), Ramamurthy et al. (1974) and Venkatachalam (1993) have quantied the particle

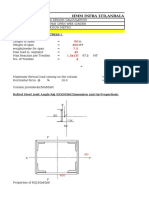

4 Gradation of Materials 4.1 Gradation of Prototype Materials Representative rockll materials are collected from different locations and are subjected to grain size analysis. The grain size distribution results are plotted and an average curve is drawn. This curve has been designated as the average prototype curve of the

123

Geotech Geol Eng

100

80 60 40 20 0 0.01

0.1

10

100

1000

Grain size (mm)

Prototype Model (50mm) Model (80mm) Model (25mm)

Fig. 1 Prototype and modeled grain size distribution curves (QRF)

100

Percent finer (%)

80 60 40 20 0 0.01

such a material having this big size particles in the laboratory is not possible so the actual prototype material are scaled down to some degree to keep maximum particle size of the particles as 80 mm. The material so obtained is designated as modeled material is used for the testing. Three modeled gradation curves are derived using John Lowes Parallel Gradation modeling technique (Lowe 1964) having a maximum particle size of 80, 50 and 25 mm, respectively. Modeled gradation curves in respect of QRF and RBRF material are presented in Figs. 1 and 2, respectively. Using these model grain size distribution curves, the required quantities of various fractions of rock ll materials have been calculated. The total quantities of materials thus required for carrying out laboratory tests are sieved from the materials collected from two potential locations of Kol dam.

Percent finer (%)

5 Laboratory Investigations

0.1 1 10 100 1000

Grain size (mm)

Prototype Model (50mm) Model (80mm) Model (25mm)

Fig. 2 Prototype and modeled grain size distribution curves (RBRF)

Laboratory tests were conducted on both type of materials collected from the project site for evaluating Relative Density, Specic Gravity, Shear parameters under MS loading and SS loading and their corresponding breakage factor. 5.1 Relative Density

representative rockll materials. Prototype gradation curves for both quarried and river bed rockll materials from Kol H.E. Project, H. P. are shown in Figs. 1 and 2, respectively. 4.2 Gradation of Modeled Materials The maximum particle sizes available in the prototype material is of the order of 500 mm. Testing of

The values of the maximum dry density, minimum dry density and relative density have been determined as per IS 2720 (Part 14):1983 Method test for soils Determination of density index (relative density) of cohesion less soils. The values of the maximum dry density, minimum dry density and required dry density corresponding to 87% of relative density (ID) are given in Table 1.

Table 1 Results of relative density test

Type of material

Max. particle size (mm) 25 50 80

cmin. (gm/cc) 1.81 1.77 1.71 1.55 1.55 1.60

cmax. (gm/cc) 2.04 2.01 1.99 2.22 2.22 2.28

Test density (ID, gm/cc), (87% relative density) 2.01 1.98 1.95 2.10 2.10 2.16

Quarried material

River bed material

25 50 80

123

Geotech Geol Eng Table 2 Details of triaxial shear tests conducted on QRF and RBRF materials Max particle size (mm) 80 Test procedure: 1 (multistage loading) Step 1 Sample 1 Sample 2 Sample 3 50 Sample 1 Sample 2 Sample 3 25 Sample 1 Sample 2 Sample 3 r3 Kg/cm2 r3 Kg/cm2 r3 Kg/cm2 3 3 3 3 3 3 3 3 3 Step 2 6 6 6 6 6 6 6 6 6 Step 3 9 9 9 9 9 9 Step 4 12 12 12 Test procedure: 2 (single step loading) 12 9 6 12 9 6 12 9 6

Deviator Stress, kg/sqcm

50 40 30 20 10 0 0 4 8 12 16 20

Deviator Stress, kg/sqcm

50 40 30 20 10 0 0 4 8 12 16 20

Deviator Stress, kg/sqcm

Fig. 3 Stressstrain behavior of QRF material for samples with 25 (ac), 50 (df) and 80 (gi) mm maximum particle size

B

60

C

60

60 50 40 30 20 10 0 0 4 8 12 16 20

Strain (%)

Strain (%)

Strain (%)

D

Deviator Stress, kg/sqcm

Deviator Stress, kg/sqcm

50 40 30 20 10 0 0 4 8 12 16 20

50 40 30 20 10 0 0 4 8 12 16 20

Deviator Stress, kg/sqcm

60

60

60 50 40 30 20 10 0 0 4 8 12 16 20

Strain (%)

Strain (%)

Strain (%)

G

Deviator Stress, kg/sqcm

Deviator Stress, kg/sqcm

60 50 40 30 20 10 0 0 4 8 12 16 20

60 50 40 30 20 10 0 0 4 8 12 16 20

I

Direct Stress, kg/sq cm

60 50 40 30 20 10 0 0 4 8 12 16 20

Strain (%)

Legends for A, D & G

Strain (%)

Legends for B, E & H

Strain (%)

Legends for C, F I &

123

Geotech Geol Eng

In accordance with the model gradation curves, the total dry weight required for achieving 87% of relative density is computed for each of the specimens to be tested. 5.2 Triaxial Shear Tests Consolidated drained (CD) triaxial tests have been conducted on the modeled rockll materials. A specimen size of 381 mm diameter by 813 mm long was used for testing. For testing, a dry density corresponding to 87% of relative density was

adopted. Samples were isotropically consolidated under four different conning pressures (r3), kg/ cm2 in the range between 3 and 12 kg/cm2 for each modeled rockll material. In accordance with the modeled gradation curves the total quantity of various fractions of rockll materials required to achieve the specied density was determined by weight. The computed quantity of fractions was thoroughly mixed and moistened with 34% water by weight for maintaining reasonably uniform composition as per physical observations based on pilot test. The mixed sample was compacted in a split mould in

Deviator Stress, kg/sqcm

Deviator Stress, kg/sqcm

70 60 50 40 30 20 10 0 0 4 8 12 16 20

70 60 50 40 30 20 10 0 0 4 8 12 16 20

Deviator Stress, kg/sqcm

Fig. 4 Stressstrain behavior of RBRF material for samples with 25 (ac), 50 (df) and 80 (gi) mm maximum particle size

80

80

80 70 60 50 40 30 20 10 0 0 4 8 12 16 20

Strain (%)

Strain (%)

Strain (%)

D

Deviator Stress, kg/sqcm

Deviator Stress, kg/sqcm

80 70 60 50 40 30 20 10 0 0 4 8 12 16 20

80 70 60 50 40 30 20 10 0 0 4 8 12 16 20

F

Deviator Stress, kg/sqcm

80 70 60 50 40 30 20 10 0 0 4 8 12 16 20

Strain (%)

Strain (%)

Strain (%)

G

Deviator Stress, kg/sqcm

Deviator Stress, kg/sqcm

70 60 50 40 30 20 10 0 0 4 8 12 16 20

70 60 50 40 30 20 10 0 0 4 8 12 16 20

Deviator Stress, kg/sqcm

80

80

80 70 60 50 40 30 20 10 0 0 4 8 12 16 20

Strain (%)

Legends for A, D & G

Strain (%)

Legends for B, E & H

Strain (%)

Legends for C, F & I

123

Geotech Geol Eng Table 3 Results of the triaxial shear tests for QRF material under both MS and SS conditions for sample with 25 mm maximum particle size Test type r3 (kg/cm2) Density (gm/cc) cp MS 3 6 9 12 MS 6 9 12 MS SS MS 9 12 12 3 6 9 MS SS MS SS 6 9 9 3 6 6 2.01 2.01 2.01 2.01 2.01 2.01 2.01 2.01 2.01 cc 2.059 2.091 2.107 2.119 2.063 2.104 2.107 2.073 2.087 2.070 2.063 2.108 2.123 2.063 2.110 2.073 2.063 2.110 2.063 cnf 2.080 2.100 2.114 2.103 2.106 2.086 2.101 2.115 2.103 2.102 2.125 2.111 2.091 2.109 2.124 2.126 2.091 2.113 2.101 14.0 11.0 44.8 45.45 4.0 cf 18.5 17.5 15.5 14.5 16.5 14.0 12.5 42.51 43.03 43.81 44.50 43.41 44.21 45.2 4.8 4.8 5.2 5.7 6.2 6.6 7.1 ef (%) () degrees Breakage factor (%) Bg(cum) 7.6 Bg

six equal layers by vibratory compaction. The sample was saturated by allowing water to pass through the base of the triaxial cell and using a top drainage system for removing air from the voids. CD tests were conducted adopting Multistage Loading (MS) and Single Stage Loading (SS). In the MS loading, the sample was consolidated at the lowest pre decided r3 and then sheared at 1 mm/ min rate of loading under drained conditions to near failure stage.1 The specimen was reconsolidated at next higher pre decided r3 keeping the attained load constant and then it was again sheared to near failure stage (if it was intermittent step) or to achieve the failure stage (if it was nal step). In SS loading, specimen is consolidated at the pre decided r3 and then sheared at 1 mm/min. rate of

loading under drained conditions to achieve the failure stage. The details of the various tests conducted on QRF and TRF under the two procedures is presented in Table 2. 5.2.1 StressStrain Behavior Care was taken to avoid attaining of failure stage at each intermittent step during shearing under MS loading by plotting stressstrain curve for each test simultaneously during shearing of the specimen. Stress strain curves for samples with 25 mm, 50 mm and 80 mm maximum particle size for QRF material and RBRF material are presented in Figs. 3ai and 4ai. It can be seen from the stress strain curves that during the MS loading conditions the axial strain at failure ef, (%) is comparatively more than that during the SS loading condition. The same trend is observed even for each intermittent relative loading step during MS loading condition.

Stress strain curves for each test were simultaneously plotted during the shearing of the specimen (Figs. 3ai, 4ai) to take the decision for the application of next r3 before achieving maximum deviator stress (a near failure stage).

123

Geotech Geol Eng Table 4 Results of the triaxial shear tests for QRF material under both MS and SS conditions for sample with 50 mm maximum particle size Test type r3 (kg/cm2) Density (gm/cc) cp MS 3 6 9 12 MS 6 9 12 MS SS MS 9 12 12 3 6 9 MS SS MS SS 6 9 9 3 6 6 1.98 1.98 1.98 1.98 1.98 1.98 1.98 1.98 1.98 cc 2.010 2.027 2.036 2.045 2.032 2.072 2.075 2.041 2.055 2.016 2.009 2.028 2.039 2.032 2.077 2.041 2.012 2.035 2.032 cnf 2.022 2.032 2.041 2.071 2.074 2.054 2.028 2.027 2.069 2.028 cf 2.051 2.080 2.056 2.062 2.048 2.086 2.058 2.046 2.070 19 16.5 15 12.5 16 15.5 13.5 11.5 10.5 42.21 43.01 43.62 44.11 43.56 44.07 44.81 44.74 45.43 5.0 5.9 7.5 7.9 8.4 8.4 8.7 9.1 ef (%) () degrees Breakage factor (%) Bg(cum) 9.8 Bg

ef %3; 6; 9;12 [ ef %6;9; 12 [ ef %9; 12 [ ef %12 ef %3; 6; 9 [ ef %6; 9 [ ef %9 ef %3; 6 [ ef %6 Contrary to this, the maximum deviator stress (rd, kg/cm2) achieved at failure is more for SS loading condition than MS loading condition. The same trend is observed even for each intermittent relative loading step during MS loading condition. rd12 [ rd9; 12 [ rd6;9;12 [ rd3;6;9;12 rd9 [ rd6; 9 [ rd3;6;9 rd6 [ rd3; 6 The maximum deviator stress (rd, kg/cm2) achieved at the near failure stage of each step of loading, their corresponding percent axial strain ef (%), initial placement density of each sample (cp), density at the end of consolidation at each step (cc), density at the transition stage i.e. near failure stage (cnf), the density at the nal failure stage (cf), angle of internal friction () in degrees for each step and cumulative breakage factor Bg(cum) (%) in percent

occurred during MS and breakage factor Bg (%) in percent occurred during SS represented against maximum r3 of that particular test are presented for both materials QRF and RBRF in Tables 3, 4, 5, 6, 7, 8, respectively. 5.2.2 Angle of Internal Friction () The values of the angle of internal friction (), in degrees are presented in Tables 3, 4, 5, 6, 7, 8 for QRF and RBRF materials, respectively. The pq plots for QRF and RBRF materials with 25 mm, 50 mm and 80 mm maximum particle size under MS as well as SS conditions are presented in Figs. 5 and 6. For nding average angle of internal friction for MS loading condition the p and q values corresponding to maximum deviator stress achieved on the ultimate r3 during MS loading [rd(3, 6, 9, 12), rd(3, 6, 9), rd(3, 6)] are taken. The value of the angle of internal friction () for various samples with different maximum particle size for both the materials are presented in Table 9. Angle of internal friction (), is found to be slightly lesser

123

Geotech Geol Eng Table 5 Results of the triaxial shear tests for QRF material under both MS and SS conditions for sample with 80 mm maximum particle size Test type r3 (kg/cm2) Density (gm/cc) cp MS 3 6 9 12 MS 6 9 12 MS SS MS 9 12 12 3 6 9 MS SS MS SS 6 9 9 3 6 6 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 1.95 cc 1.998 2.025 2.038 2.054 2.016 2.025 2.034 2.051 2.065 2.060 1.998 2.027 2.048 2.014 2.032 2.051 2.011 2.038 2.011 cnf 2.019 2.030 2.044 2.021 2.030 2.061 2.022 2.041 2.027 2.037 cf 2.057 2.043 2.069 2.075 2.050 2.038 2.061 2.047 2.039 16.0 15.0 13.5 12.0 13.5 14.5 11.5 12.5 9.5 41.62 42.06 42.82 43.16 42.99 43.42 44.02 43.93 44.42 6.7 7.6 9.3 9.9 10.5 11.7 12.0 12.6 ef (%) () degrees Breakage factor (%) Bg(cum) 13.2 Bg

for MS loading irrespective of type of material or maximum particle size. The relationship between the angle of internal friction and the maximum particle size for both the materials is presented in Figs. 7 and 8. It is observed that the QRF material shows decrease in the angle of internal friction with the increase in size of particles. Marachi et al. (1969) has reported a similar trend for blasted angular materials. The RBRF materials show an increase in the value of the angle of internal friction with the size of the particle. Venkatachalam (1993) has reported similar trend for river bed materials. 5.2.3 Breakage Factor The breakage is quantitatively expressed as breakage factor, Bg (%) or Bg(cum) (%) as proposed by Marsal (1965). It is taken as percent variation in the pre and post shear grain size distribution of the rockll material used. Bg (%) and Bg(cum) (%) has been determined using following equation for each test conducted under MS as well as SS for both QRF and RBRF materials.

Bg % RPD RPI where PD, percent decrease in particle distribution in certain sizes; PI, percent increase in particle distribution in certain sizes. The Bg(cum) (%) for MS tests could be determined only after completion of the shearing of that sample at maximum r3. The values of Bg(cum) (%) for different load steps in MS and Bg (%) in SS are presented against highest r3 for that test. The values of Bg (%) and Bg(cum) (%) are presented in Tables 3, 4, 5, 6, 7, 8 for QRF and RBRF materials, respectively. For the samples with same particle size the breakage factor shows variation in the following order Bgfcum 3;6;9;12g % [ Bgfcum6;9;12g % [ Bgfcum 9;12g % [ Bg12 % Bgfcum 3;6;9g % [ Bgfcum 6;9g % [ Bg9 % Bgfcum 3;6g % [ Bg6 % Breakage factors also increases in magnitude with the increase in the maximum particle size for both the materials. Similar trends have been reported by

123

Geotech Geol Eng Table 6 Results of the triaxial shear tests for RBRF material under both MS and SS conditions for sample with 25 mm maximum particle size Test type r3 (kg/cm2) Density (gm/cc) cp MS 3 6 9 12 MS 6 9 12 MS SS MS 9 12 12 3 6 9 MS SS MS SS 6 9 9 3 6 6 2.10 2.10 2.10 2.10 2.10 2.10 2.10 2.10 2.10 cc 2.154 2.183 2.197 2.215 2.180 2.210 2.235 2.201 2.225 2.207 2.156 2.185 2.207 2.187 2.220 2.203 2.165 2.194 2.170 cnf 2.173 2.191 2.210 2.203 2.226 2.215 2.176 2.205 2.219 2.181 cf 2.224 2.238 2.240 2.233 2.229 2.220 2.229 2.209 2.200 18.5 17.5 15.5 14.5 17 13 13.5 13 13 44.53 45.67 46.44 47.28 45.80 46.40 47.61 46.83 48.44 3.1 3.9 3.9 4.5 5.3 4.4 5.0 5.4 ef (%) () degrees Breakage factor (%) Bg(cum) 6.3 Bg

Marsal (1965), Vesic and Clough (1968), Marachi et al. (1969), Ramamurthy et al. (1974) and Venkatachalam (1993). Usually, the alluvial materials suffer less breakage and have high angle of shearing resistance. But the project being located in the upper reaches of the river, the uvial transport distance for the RBRF is less which might not have allowed sufcient wearing of the particles, therefore particles in the size range of 40 mm to 80 mm show higher breakage which contribute to high value of Bg (%) and Bg(cum) (%). 5.2.4 Effect of Breakage Factor on Angle of Internal Friction The value of angle of internal friction () as observed for max. conning pressure r3 during each MS loading condition {r3(3, 6, 9, 12), r3(6, 9, 12), r3(9, 12)}, {r3(3, 6, 9), r3(6, 9)}, {r3 3, 6)} and for SS loading condition r3(6), r3(9) & r3(12) for samples with 25 mm, 50 mm and 80 mm max particle size are

plotted against the Breakage Factor, Bg(cum) (%) for MS and Bg (%) for SS loading condition for QRF (Fig. 9) and RBRF materials (Fig. 10). It is observed that the angle of internal friction () decreases as the particle breakage increases. As discussed in 5.2.3, the cumulative breakage factor Bg(cum) (%) increased as the number of intermittent steps increased during MS, accordingly the angle of internal resistance () decreased.

6 Conclusions During construction, lateral connement and increase of vertical load on the lower layers due to placement of additional layers of the material cause change in the grain size distribution of the lower layers due to breakage of the particles. This change of the grain size distribution certainly has an effect on the shear parameters of the materials.

123

Geotech Geol Eng Table 7 Results of the triaxial shear tests for RBRF material under both MS and SS conditions for sample with 50 mm maximum particle size Test type r3 (kg/cm2) Density (gm/cc) cp MS 3 6 9 12 MS 6 9 12 MS SS MS 9 12 12 3 6 9 MS SS MS SS 6 9 9 3 6 6 2.10 2.10 2.10 2.10 2.10 2.10 2.10 2.10 2.10 cc 2.180 2.228 2.252 2.285 2.205 2.247 2.289 2.215 2.285 2.200 2.175 2.230 2.245 2.195 2.233 2.215 2.187 2.214 2.203 cnf 2.225 2.237 2.275 2.238 2.281 2.272 2.222 2.240 2.223 2.206 cf 2.305 2.307 2.296 2.298 2.252 2.258 2.273 2.220 2.232 18.5 18 16 11.5 15.5 12 11.5 14 11 45.04 45.87 46.92 47.84 45.6 47.4 48.2 48.08 49.13 4.0 4.9 5.9 6.5 7.2 6.6 7.1 7.6 ef (%) () degrees Breakage factor (%) Bg(cum) 8.4 Bg

Stress strain curves indicate that during the multistage loading conditions the axial strain at failure ef, (%) is comparatively more than that during the single stage loading condition. The same trend is observed even for each intermittent relative loading step during multistage loading condition. The deviator stress (rd, kg/cm2) achieved at failure is higher for single stage loading condition than for multistage loading condition. The same trend is observed even for each intermittent relative loading step during multistage loading condition. It is observed that the quarried rockll material shows decrease in the angle of internal friction with the increase in particle size. The river bed rockll materials show an increase in the value of the angle of internal friction with particle size. The breakage factor Bg(cum) (%) increases as the number of intermittent steps increases during multistage loading. Accordingly the angle of internal resistance () decreases. The angle of internal

friction () is found to be slightly lower for multistage loading than that observed in the single stage loading, irrespective of type of material or maximum particle size. For arriving at the design parameters, laboratory testing of the materials should simulate the eld conditions as much as possible. During construction stage, the stress level on the lower layer increases with placement of each layer. Also, during lling of the dam the stress levels continuously increases more on the lower layers. The design parameters should be arrived at by simulating these eld conditions. Overall, in order to properly design a rockll structure, it is of critical importance to think over the type of the laboratory tests which can closely simulate the stress conditions developing at different stages and to study their effects on the mechanical behavior of rockll materials. CD-MS simulates the effect of step wise loading which may change the grain size distribution of RF material during construction stage.

123

Geotech Geol Eng Table 8 Results of the triaxial shear tests for RBRF material under both MS and SS conditions for sample with 80 mm maximum particle size Test type r3 (kg/cm2) Density (gm/cc) cp MS 3 6 9 12 MS 6 9 12 MS SS MS 9 12 12 3 6 9 MS SS MS SS 6 9 9 3 6 6 2.16 2.16 2.16 2.16 2.16 2.16 2.16 2.16 2.16 cc 2.258 2.316 2.329 2.375 2.267 2.313 2.355 2.281 2.357 2.271 2.237 2.293 2.313 2.252 2.291 2.262 2.260 2.287 2.265 cnf 2.299 2.329 2.368 2.302 2.341 2.341 2.285 2.304 2.281 2.279 cf 2.386 2.372 2.366 2.376 2.315 2.323 2.320 2.293 2.294 19.5 18 16 13 17.5 15 13 13 9.5 45.52 46.72 47.33 48.35 46.55 48.45 49.04 49.26 50.3 5.6 6.8 7.2 8.1 8.9 8.3 9.0 9.7 ef (%) () degrees Breakage factor (%) Bg(cum) 10.8 Bg

A

For MS For S S y = 0.678x + 0.176 y = 0.702x + 0.086 = 42.680 = 44.580

B

For S S For MS y = 0.675x + 0.202 y = 0.697x + 0.113 = 44.180 = 42.450

C

For MS For S S y = 0.670x - 0.105 y = 0.686x + 0.108 = 43.310 = 42.060

Average Shear Stress, kg/sqcm

Average Shear Stress, kg/sqcm

0 10 20 30 40 50 Average Normal Stress, kg/sqcm

Average Shear Stress, kg/sqcm

30 25 20 15 10 5 0 0 10 20 30 40 50 Average Normal Stress, kg/sqcm

30 25 20 15 10 5 0

30 25 20 15 10 5 0 0 10 20 30 40 50 Average Normal Stress, kg/sqcm

Fig. 5 pq plots for samples with 25 (a), 50 (b) and 80 (c) mm maximum particle size QRF material

123

Geotech Geol Eng

A

For MS y = 0.705x + 0.195 = 44.830 For S S y = 0.735x + 0.102 = 47.300

B

For MS y = 0.708x + 0.238 = 45.070 For S S y = 0.742x + 0.116 = 47.900

C

For MS For S S y = 0.716x + 0.296 y = 0.748x + 0.189 = 48.420 = 45.720

Average Shear Stress, kg/sqcm

Average Shear Stress, kg/sqcm

Average Shear Stress, kg/sqcm

40 35 30 25 20 15 10 5 0 0 10 20 30 40 50 Average Normal Stress, kg/sqcm

40 35 30 25 20 15 10 5 0 0 10 20 30 40 50 Average Normal Stress, kg/sqcm

40 35 30 25 20 15 10 5 0 0 10 20 30 40 50

Average Normal Stress, kg/sqcm

Fig. 6 pq plots for samples with 25 (a), 50 (b) and 80 (c) mm maximum particle size RBRF material

Table 9 Results of angle of internal friction () for QRF and RBRF material under both MS and SS conditions for sample with 25, 50 and 80 mm maximum particle size Material Loading condition Angle of internal friction (), degree Max. particle size: 25 mm 42.68 44.58 44.83 47.3 Max. particle size: 50 mm 42.45 44.18 45.07 47.90 Max. particle size: 80 mm 42.06 43.31 45.72 48.48

QRF RBRF

MS SS MS SS

49.00

45.00

SS

MS

Angle of Internal Friction, degree

44.50 44.00 43.50 43.00 42.50 42.00 41.50 0 10 20 30 40 50 60 70 80 90 100

Angle of Internal Friction, degree

SS

MS

48.50 48.00 47.50 47.00 46.50 46.00 45.50 45.00 44.50 0 10 20 30 40 50 60 70 80 90 100

Particle Size (mm)

Fig. 7 Variation in angle of internal friction () with maximum particle size for QRF

Particle Size (mm)

Fig. 8 Variation in angle of internal friction () with maximum particle size for RBRF

123

Geotech Geol Eng

46 45 44 43 42 41 2 4 6 8 10 12 14

Angle of Internal Friction Degrees

References

Becker E (1972) Strength and deformation characteristics of rockll materials under plane strain conditions. Ph.D. Thesis, University of California, Berkley Billam J (1971) Some aspects of the behaviour of granular materials at high pressure. In: Proceedings of Roscoe memorial symposium on stress-strain behaviour of soils. Cambridge University, Foulis, Henley, pp 6980 Colliat-Dangus JL, Desrues J, Foray P (1988) Triaxial testing of granular soil under elevated cell pressure. Advanced triaxial testing of soil and rock. ASTM-STP977, ASTM, Philadelphia, pp 290310 Daouadji A, Hicher PY (1997) Modelling of grain breakage inuence on mechanical behaviour of sands. In: Pietruszczak and Pande (eds) Proceedings of numerical models in geomechanics. Balkema, Rotterdam, pp 6974 Fukumoto T (1990) A grading equation for decomposed granite soil. Soils and foundation, Tokyo, Japan, vol 30(1), pp 2734 Gupta KK (1980) Behaviour of modelled Rockll materials under high conning pressures. Ph.D. Thesis, IIT, Delhi Hagerty MM, Hite DR, Ullrich CR, Hagerty DJ (1993) One dimensional high pressure compression of granular media. J Geotech Eng ASCE 119(1) Hardin BO (1985) Crushing of soil particles. J Geotech Eng ASCE 111(10):11771192 Kjaernsli B, Valstad T, Hoeg K (1992) Rockll Dams-design and construction. Norwegian Institute of Technology, Division of Hydraulics Engineering, Trondheim, Norway Lade PV, Yamamuro JA (1996) Undrained sand behaviour in axisymmetric tests at high pressures. J Geotech Eng ASCE 122(2):120129 Lade PV, Yamamuro JA, Bopp PA (1996) Signicance of particle crushing in granular materials. J Geotech Eng ASCE 122(4):309316 Lee KL, Farhoomand I (1967) Compressibility and crushing of granular soil in anisotropic triaxial compression. Can Geotech J 4(1):6899 Lo KY, Roy M (1973) Response of particulate materials at high pressure. Soils Foundations Tokyo Japan 13(1):114 Lowe J (1964) Shear strength of coarse embankment dam materials. In: Proceedings of 8th international congress on Large Dams, vol 3, pp 745761 Marachi ND, Chan CK, Seed HB, Duncan JM (1969) Strength and deformation characteristics of Rockll materials. Report No. TE 69-5, University of California, Berkeley, USA, vol 14, Bund. H12 Marachi ND, Chan CK, Seed HB (1972) Evaluation of properties of Rockll materials. J SMFE ASCE 98(SM1):95114 Marsal RJ (1965) Discussion. In: Proceedings of 6th international Cant. on Soil Mechanics and Foundation Engineering, vol 3, pp 310316 Marsal RJ (1967) Large scale testing of Rockll materials. J Soil Mech Foundations Div ASCE 93(2):2743 Murphy DJ (1971) High pressure experiments on soil and rock. In: Proceedings of 13th symposium on Rock Mechanics, pp 691714 Murphy DJ (1987) Stress, degradation and shear strength of granular material. In: Sayed SM (ed) Geotechnical

Breakage Factor (Bg), (%)

80mm: MS - max. 12 kg/sqcm 80mm: MS - max. 9 kg/sqcm 80mm: MS - max. 6 kg/sqcm 50mm: MS - max. 12 kg/sqcm 50mm: MS - max. 9 kg/sqcm 50mm: MS - max. 6 kg/sqcm 25mm: MS - max. 12 kg/sqcm 25mm: MS - max. 9 kg/sqcm 25mm: MS - max. 6 kg/sqcm 80mm: SS - 12 kg/sqcm 80mm: SS - 9 kg/sqcm 80mm: SS - 6 kg/sqcm 50mm: SS - 12 kg/sqcm 50mm: SS - 9 kg/sqcm 50mm: SS - 6 kg/sqcm 25mm: SS - 12 kg/sqcm 25mm: SS - 9 kg/sqcm 25mm: SS - 6 kg/sqcm

Fig. 9 Effect of breakage factor (Bg) on angle of internal friction () for QRF material

Angle of Internal Friction Degrees

51 50 49 48 47 46 45 44 2 4 6 8 10 12 14

Breakage Factor (Bg), (%)

80mm: MS - max. 12 kg/sqcm 80mm: MS - max. 9 kg/sqcm 80mm: MS - max. 6 kg/sqcm 50mm: MS - max. 12 kg/sqcm 50mm: MS - max. 9 kg/sqcm 50mm: MS - max. 6 kg/sqcm 25mm: MS - max. 12 kg/sqcm 25mm: MS - max. 9 kg/sqcm 25mm: MS - max. 6 kg/sqcm 80mm: SS - 12 kg/sqcm 80mm: SS - 9 kg/sqcm 80mm: SS - 6 kg/sqcm 50mm: SS - 12 kg/sqcm 50mm: SS - 9 kg/sqcm 50mm: SS - 6 kg/sqcm 25mm: SS - 12 kg/sqcm 25mm: SS - 9 kg/sqcm 25mm: SS - 6 kg/sqcm

Fig. 10 Effect of breakage factor (Bg) on angle of internal friction () for RBRF material Acknowledgments The authors gratefully acknowledge and thank the Rockll Division of Central Soil and Materials Research Station, New Delhi and the authorities of Kol Dam Project, Himachal Pradesh, India for the support extended by them. We also extend our sincere gratitude to all the authors whose publications provided us directional information from time to time.

123

Geotech Geol Eng modeling and applications. Gulf Publishing Company, Houston, pp 181211 Ramamurthy T (1969) Crushing phenomena in granular soils. J Indian Natl Soc SMFE 8(1):6786 Ramamurthy T, Kanitkar VK, Prakash K (1974) Behaviour of coarse grained soils under high stresses. Indian Geotech J 4(1):3963 Venkatachalam K (1993) Prediction of mechanical behaviour of Rockll materials. Ph.D. Thesis, IIT Delhi Vesic AB, Clough GW (1968) Behaviour of granular materials under high stresses. J SMFE ASCE 94(8M 3):661688

123

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Design calculations for 60m span open web girder trestleDocument10 pagesDesign calculations for 60m span open web girder trestleAnonymous sfkedkymNo ratings yet

- Young's Modulus of Strut Materials (39Document6 pagesYoung's Modulus of Strut Materials (39Newton ShikderNo ratings yet

- Plastic Analysis of Unbraced Portal Frames of Steel Structures in PDFDocument99 pagesPlastic Analysis of Unbraced Portal Frames of Steel Structures in PDFbiniamNo ratings yet

- ASMEThermal Shock Design Guidleines 2007Document9 pagesASMEThermal Shock Design Guidleines 2007Harold Edmundo Calvache VallejoNo ratings yet

- Formula Sheet For Exam 1Document1 pageFormula Sheet For Exam 1chris ricaNo ratings yet

- Peng2019 PDFDocument7 pagesPeng2019 PDFRoja AllampallyNo ratings yet

- CH 04Document135 pagesCH 04RODRIGO JAVIER BRIZUELA PADILLANo ratings yet

- Reinforced Concrete DesignDocument17 pagesReinforced Concrete Designricosanojuan100% (1)

- Analysis of Piled Raft Foundation-A Geo-Structural ApproachDocument68 pagesAnalysis of Piled Raft Foundation-A Geo-Structural Approachنعمان سولکرNo ratings yet

- 6 - Soil Data in Orcaflex-Y.T.kimDocument9 pages6 - Soil Data in Orcaflex-Y.T.kimYoungtae KimNo ratings yet

- The Analysis of Earth Pressure On Retaining Wall Based On ABAQUSDocument4 pagesThe Analysis of Earth Pressure On Retaining Wall Based On ABAQUSroloheNo ratings yet

- Material Testing TechniquesDocument66 pagesMaterial Testing Techniquesrakamew442.epevaNo ratings yet

- Biaxial Bending (Beams in Both Axis) : Ce 514 - Steel DesignDocument6 pagesBiaxial Bending (Beams in Both Axis) : Ce 514 - Steel DesignFrederick Perez IINo ratings yet

- Tutorial 01Document20 pagesTutorial 01Ka Man ChangNo ratings yet

- Introduction Deep Foundation TypesDocument38 pagesIntroduction Deep Foundation TypesKhalid AljanabiNo ratings yet

- Prc-I Lec 7 - 18th March 014 - Flexural Analysis of BeamsDocument51 pagesPrc-I Lec 7 - 18th March 014 - Flexural Analysis of BeamsDavidm AndosNo ratings yet

- Fatigue Fracture MechanicsDocument12 pagesFatigue Fracture MechanicsInspection Engineer0% (1)

- STEEL STAIR DESIGNDocument4 pagesSTEEL STAIR DESIGNNikki RobertsNo ratings yet

- Fatigue analysis and endurance limit determinationDocument12 pagesFatigue analysis and endurance limit determinationSon TranNo ratings yet

- 5 - Simple Seismic Design For Reinforced Concrete BuildingDocument87 pages5 - Simple Seismic Design For Reinforced Concrete BuildingKatherine Shayne Yee100% (3)

- Valsamis - Design Charts For Single Pile Under Lateral SpreadingDocument4 pagesValsamis - Design Charts For Single Pile Under Lateral SpreadingFederico MontesverdesNo ratings yet

- Structural Modeling of Cold-Formed Steel Portal Frames by Zhang and Rasmussen 2015Document11 pagesStructural Modeling of Cold-Formed Steel Portal Frames by Zhang and Rasmussen 2015fahmi aballiNo ratings yet

- RCC Retaining Wall Design ReportDocument76 pagesRCC Retaining Wall Design Reportshashibhushan singhNo ratings yet

- Underground Circular Tank R2 Sump WellDocument14 pagesUnderground Circular Tank R2 Sump Wellsurendra_panga100% (1)

- Maximum Rivet Pitch Study 20111115Document18 pagesMaximum Rivet Pitch Study 20111115Jatin KhuranaNo ratings yet

- CIVL311/911: Introduction to Reinforced Concrete DesignDocument18 pagesCIVL311/911: Introduction to Reinforced Concrete DesignBurhan AhmadNo ratings yet

- Underground Pipe THK CalDocument12 pagesUnderground Pipe THK Calmkchy12100% (3)

- Stresses in Rock: Understanding Underground Stress PatternsDocument4 pagesStresses in Rock: Understanding Underground Stress PatternsAna Julia Becerra HernandezNo ratings yet

- Axial Load Deformation AnalysisDocument27 pagesAxial Load Deformation Analysispoom2007No ratings yet

- An Analytical Solution For Axisymmetric Tunnel Problems in Elasto Plastic MediaDocument18 pagesAn Analytical Solution For Axisymmetric Tunnel Problems in Elasto Plastic MediaYashwanth KumarNo ratings yet