Professional Documents

Culture Documents

Hanging A Door

Uploaded by

ApollyonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hanging A Door

Uploaded by

ApollyonCopyright:

Available Formats

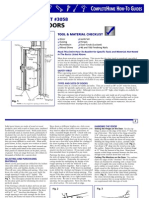

HANGING A DOOR (Internal)

( Fitting a door )

The first mistake some people make when hanging a door is to start fitting furniture (handles, hinges etc) before the door is cut to size. Standard door sizes are available to fit most existing frames but houses move. Some older houses will have moved dramatically and one of the first things that twists and bends is the door frames. Almost all doors have to be trimmed to fit the opening they are to go into and sometimes the opening has been specially made for a feature door. In this situation it is fairly easy to adapt or "build out" the frame to suit the new door. If you are ever in the position of adapting a frame do not be tempted to fit the frame to suit the door or the existing opening. If the existing frame is leaning over or twisted, insert your new timbers upright and square. You should always endeavour to start with a square frame and cut the door down to suit. Carpentry is not easy. It takes time to learn and a really good idea is to get some basic techniques under your belt before trying major projects. Standard internal door sizes are.

525mm x 2040mm 626mm x 2040mm 726mm x 2040mm 826mm x 2040mm 926mm x 2040mm 610mm x 1981mm 686mm x 1981mm 762mm x 1981mm 838mm x 1981mm Metric size door for metric frame Metric size door for metric frame Metric size door for metric frame Metric size door for metric frame Metric size door for metric frame 2ft x 6ft 6 inches 2ft 3 in. x 6ft. 6 in. 2ft. 6in. x 6ft. 6in. 2ft. 9in. x 6ft. 6in.

It is possible to get other door sizes "off the shelf" so always enquire, but generally speaking these are the most common door sizes and even so it is unlikely that you will get anything other than the 3 highlighted sizes in Diy stores. You may need to go to a builders merchants for other sizes. Doors are either "flush doors" or "panelled doors" . A type of panelled door is shown below and simply means that the door is divided into panels with two side rails, a top and bottom rail and a mid rail. A flush door is simply flat on both sides.

For extreme sizes or sizes which cannot be matched or made up, it is possible to buy "door blanks". These are oversize, solid, flush doors which can be cut down to any size. Doors come in thicknesses of 1&3 eighths of an inch, 1 & 3 quarters of an inch, and 2 inches. Check the measurement between the front of your frame and your door stop before you start work. Internal Doors are available as "hollow" lightweight doors or fire- check doors. Fire check doors should always be fitted to the kitchen and internal garage door and if you have a loft conversion they will be stipulated throughout. Their construction means that, when closed, the fire will take either or 3/4 of an hour to burn through, depending on the door used. Intumescent strips can also be fitted into doors and frames. These are strips which swell up at the first sense of heat and stop smoke from getting through any gaps. You will also, on the construction of a loft conversion, need to install automatic door closers to arrest the spread of any fire.

The first step is to make sure you have the door the right way round. At the top of a new flush, or hollow panelled lightweight door the word lock will be printed over to one side. This means that there is a section of timber fixed inside the frame of the door which is there to allow the door lock or latch to be fitted. See our project on fitting door furniture to find out how to fit the common mortice latch to doors. The images below show the top of a new door. Lock is clearly marked. Obviously the hinges are hung on the other edge. The lock block usually extends approximately 200mm up and down from the centre of the door. The right hand image shows the lock block in position on the door. If you use a screwdriver to tap down the side of the door you will hear the difference when you get to the lock block.

To get the door to fit the frame it is first necessary to " offer it up" and mark it. As you can see in the images below we had to add timber to the existing frame to get a standard size frame. This was cut to size and screwed to the existing frame. The door was placed in position up against the new frame and the inside of the frame was marked on the door with a pencil. You will probably need a hand with this. This new door was being hung on the opposite side to the old one so the old hinge recesses will need to be filled. This can be done with either filler applied in a couple of layers, or you can try your carpentry skills at cutting a timber block down, gluing and pinning it in place (punching the heads of the pins down with a nail punch) and sanding it down to finish flush with the frame. This is called "scarfing" . Drawing lines and cutting timber in any form can cause the novice a great deal of problems. We often get emails asking simply "How do I cut a straight line" and " I have marked my work and cut on the line but I always cut my timber too small". The answer to the first is to let the hand saw do the work. Make sure you are looking at the saw from directly above it and not from the side. If your body is leaning, the chances are the saw will be leaning too, giving you a cut which is far from square. Hold the saw with your finger down the handle pointing to the work and make sure the timber is totally secure. Any movement in the timber and the saw will judder and go off line. Ok, so you have the door marked to the internal size of the frame. Another easy thing to forget is that the saw has a thickness of about 3mm including the set of the teeth. If you cut along the line therefore, the door will be 3mm smaller than you intended. This may not sound a lot, but should you cut marginally inside the line, you are talking about a difference of 5mm and this is the difference between a good job and a shoddy one. Remember ALWAYS LEAVE THE LINE. Whenever you mark a piece of timber, the line you have drawn it the exact size you want the wood. If you cut or plane the line off, your work will be smaller than you intended. Cut the work along the side of the line, just leaving the line in place. With the line still visible you cannot be wrong. You can always plane a little more off, but you can't stick it back on! People think it is so easy to grab a saw and start a piece of carpentry but even cutting a straight, square line is a problem until you have mastered it. In this instance, as we had rebuilt the frame, the cut was square, but with older frames you may find you have twists and kinks and

it will not be possible to use a saw for the cut down. Using a plane is the correct option here and we obviously prefer a power plane. Fully qualified carpenters have had to practice this, it makes sense that you should do so also. We use power tools wherever the amount of cutting allows it. Time is important to us, its our living!

Having cut the door to the correct size we have now got to hang it. This can be done on a variety of hinges but for most doors it is the standard butt hinge that is used. There is no regulation as to where these hinges should go with regard to the position on the door or frame but we like to keep the top of the top hinge at 7 inches down from the top of the door and the bottom of the bottom hinge at 7 inches from the bottom of the door. Mark the position of the hinge by opening it at right angles and laying it on the side of the door to be hung. A lot of DIY web sites will tell you to mark round the hinge with a hobby knife. Do not do this it is dangerous and almost impossible to cut along the grain neatly. Mark with a pencil and then scribe the long edges with a mortice gauge if you need to. Using a sharp chisel, cut as shown below, tapping firmly with a mallet to avoid breaking the chisel head. Remember the pencil line is outside the hinge so you need to cut inside this line. Once again, LEAVE THE LINE!

Chisel out the surplus and make sure your hinge fits neatly and is not "proud" of the timber. Neither should it be set too far in as this will cause the door to bind. The hinge should be set in just enough to be flush with the edge of the door. Practice this cut on an offcut of wood for a while this will benefit you greatly if you have a number of doors to hang.

Drill pilot holes for your hinge screws and make sure they are in the centre of the hinge holes. A screw which is against the edge of the hole will push the hinge over and out of line. When the hinges are cut in, stand the door in the opening. Check all round for the gap to be uniform. In years gone by the carpenters apprentice was made to carry an old penny, this was used to make sure the gap all round the door was the precise width. Make sure you have enough depth under the door if you are going to lay carpets etc later. Wedge the door in place. You can cut some timber wedges for this, as you can see we use chisels! With the door in the correct place you can mark the position of the hinges on the edge of the frame. Take the door away again and using the mortice gauge which is already set to the hinge width, and the carpenters square, you can mark the full position of the hinge on the frame. This can then be chiselled out also.

Wedge the door in position once again and, if you are on your own, you may find it easier to keep the top of the door in place by pinning the top hinge temporarily in place. This ensures the door does not move as you screw the hinges in.

Your door should now swing easily back and forth. Our particular door frame needed new door stop which is the last thing to go on. This is imply pinned to the frame up against the door when its in a closed position. When the stop is in position you can fit the door furniture you have chosen.

You might also like

- DIY Musical Instruments - Instructables AuthorsDocument485 pagesDIY Musical Instruments - Instructables AuthorsNestor Humanez Guerrero89% (9)

- Building Your Own Composting Bin: Designs For Your CommunityDocument27 pagesBuilding Your Own Composting Bin: Designs For Your CommunityuglymaskNo ratings yet

- How To Make A Stopped Dado Jig For Any Router: InstructablesDocument11 pagesHow To Make A Stopped Dado Jig For Any Router: InstructablesTroy100% (1)

- Woodworking TipsDocument13 pagesWoodworking TipsjahemscbdNo ratings yet

- Cheyenne Tipi Notes: Technical Insights Into 19th Century Plains Indian Bison Hide TanningFrom EverandCheyenne Tipi Notes: Technical Insights Into 19th Century Plains Indian Bison Hide TanningNo ratings yet

- Making A Wooden MalletDocument11 pagesMaking A Wooden MalletKoki MostafaNo ratings yet

- Pine Desk Organizer: Project 13782EZDocument6 pagesPine Desk Organizer: Project 13782EZBSulli100% (1)

- PlansDocument24 pagesPlansjoshm89100% (1)

- Popular Woodworking - 009 - 1982 PDFDocument44 pagesPopular Woodworking - 009 - 1982 PDFKawchhar Ahammed100% (2)

- Table Saw LocationDocument2 pagesTable Saw LocationShane TwogoodNo ratings yet

- WJ036 Charging CabinetDocument0 pagesWJ036 Charging Cabinetroose1100% (1)

- Installing a Pre-hung Door - Australian Woodsmith #177, 2023 - 복사본Document4 pagesInstalling a Pre-hung Door - Australian Woodsmith #177, 2023 - 복사본김동원No ratings yet

- 72 - Fold Down WorkstationDocument2 pages72 - Fold Down WorkstationGsmHelpNo ratings yet

- Stacking Desk Tray: Project 19874EZDocument4 pagesStacking Desk Tray: Project 19874EZBSulliNo ratings yet

- Drywall Installation Guide Fall 2006Document9 pagesDrywall Installation Guide Fall 2006extrcrimeaNo ratings yet

- American Boys Book of Camp Lore and WoodcraftDocument292 pagesAmerican Boys Book of Camp Lore and WoodcraftjcggriffNo ratings yet

- Curved Lid Tool ChestDocument1 pageCurved Lid Tool ChestflerziNo ratings yet

- Deisel EngineDocument11 pagesDeisel EngineSaravanaKumarNo ratings yet

- New-Fangled Workbench: With Six Pipe Clamps and Some Dressed Framing LumberDocument4 pagesNew-Fangled Workbench: With Six Pipe Clamps and Some Dressed Framing LumberBaldomero Esquivel100% (1)

- SN13128 - Modern Power Tool BenchDocument11 pagesSN13128 - Modern Power Tool Benchn1856390No ratings yet

- Plans Dovetail Jig StandDocument6 pagesPlans Dovetail Jig Standhmam_88100% (1)

- Workshop Projects-Winter 2006Document84 pagesWorkshop Projects-Winter 2006Ionut Tuta100% (2)

- Barbecue Tool Cabinet: Click Here To Download Detailed InstructionsDocument3 pagesBarbecue Tool Cabinet: Click Here To Download Detailed Instructionsmytizplicky100% (1)

- Portable Miter Saw StationDocument17 pagesPortable Miter Saw StationCarlos CostaNo ratings yet

- SN05416 - Mobile Tool CartDocument9 pagesSN05416 - Mobile Tool CartMalNo ratings yet

- 10 X 7 Guernsey ShedDocument4 pages10 X 7 Guernsey ShedDavid Brown100% (1)

- Record and Tape Cabinet: Project 11185EZDocument8 pagesRecord and Tape Cabinet: Project 11185EZBSulliNo ratings yet

- Cove CalculationsDocument1 pageCove CalculationsflerziNo ratings yet

- Bamboo Rodmaking Tips - Articles Area - Wood Planing FormsDocument7 pagesBamboo Rodmaking Tips - Articles Area - Wood Planing FormscannotdecideNo ratings yet

- 555 Timer ICDocument13 pages555 Timer ICRitu KashyapNo ratings yet

- PDM Series: Power Driven Medium Duty Lift Truck Serial Number 374575 and HigherDocument156 pagesPDM Series: Power Driven Medium Duty Lift Truck Serial Number 374575 and HigherDmitryNo ratings yet

- Çalışma Tezgahı PlanıDocument14 pagesÇalışma Tezgahı PlanıÖmür Eryüksel50% (2)

- 70 Triumph Repair Manual 63 70Document236 pages70 Triumph Repair Manual 63 70Swapnil PatilNo ratings yet

- Honda H3013Document77 pagesHonda H3013Kung KleeNo ratings yet

- No-Fuss Newel PostDocument5 pagesNo-Fuss Newel PostLen S100% (1)

- Garage Storage CabinetsDocument20 pagesGarage Storage CabinetsLonebeavNo ratings yet

- Ultimate Sharpening StationDocument2 pagesUltimate Sharpening Stationlsts51No ratings yet

- 2 1 4 PDFDocument7 pages2 1 4 PDFAndre STANo ratings yet

- MIG Welding Guide Under 40 CharactersDocument21 pagesMIG Welding Guide Under 40 Charactersvishnu0751No ratings yet

- Door Fitting Instructions PDFDocument5 pagesDoor Fitting Instructions PDFDo Van LuanNo ratings yet

- 8 Stairs PDFDocument6 pages8 Stairs PDFMasoudRmdnNo ratings yet

- Soot and Liquid-Phase Fuel Distributions in A Newly Designed Optically AccessibleDocument20 pagesSoot and Liquid-Phase Fuel Distributions in A Newly Designed Optically AccessibleHERMAWANNo ratings yet

- Assembly Table: Adjustable-Height Cutting DiagramDocument2 pagesAssembly Table: Adjustable-Height Cutting DiagramAymara Montilla GonzalezNo ratings yet

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Hanging A Cabinet DoorsDocument5 pagesHanging A Cabinet DoorsAnonymous QJ5j94luLmNo ratings yet

- Sea ChestDocument2 pagesSea ChestAnninha Sud AlvesNo ratings yet

- An Orchard Is An Intentional Planting of Trees or Shrubs That Is Maintained For Food ProductionDocument3 pagesAn Orchard Is An Intentional Planting of Trees or Shrubs That Is Maintained For Food ProductionDENMER MANLANGITNo ratings yet

- Router Table BasicsDocument7 pagesRouter Table BasicskelvinchanNo ratings yet

- How to Learn Home Improvement Skills: A Comprehensive GuideFrom EverandHow to Learn Home Improvement Skills: A Comprehensive GuideNo ratings yet

- Classic Two-Piece Library CabinetDocument12 pagesClassic Two-Piece Library CabinetKeith WilliamsNo ratings yet

- Carb 2Document29 pagesCarb 2Selva RamNo ratings yet

- Outdoor Storage Locker: Easy To BuildDocument13 pagesOutdoor Storage Locker: Easy To BuildjoseduardoNo ratings yet

- SSCM Series Stock Selector Counterbalanced Lift Truck Troubleshooting and Maintenance ManualDocument172 pagesSSCM Series Stock Selector Counterbalanced Lift Truck Troubleshooting and Maintenance ManualDmitryNo ratings yet

- Roll Around Kitchen Cart: MLCS Items UsedDocument15 pagesRoll Around Kitchen Cart: MLCS Items UsedTETSUO111No ratings yet

- Stowaway Bench: Woodworks: Intermediate ProjectDocument8 pagesStowaway Bench: Woodworks: Intermediate ProjectfdarelaNo ratings yet

- Mabalacat City Zoning Ordinance MinutesDocument67 pagesMabalacat City Zoning Ordinance MinutesJeysii PaduaNo ratings yet

- Home Building TipsDocument245 pagesHome Building TipsoltaiyrxNo ratings yet

- Projeto para Encaixe Rabo de AndorinhaDocument8 pagesProjeto para Encaixe Rabo de AndorinhaVInixsoad100% (2)

- Medicinal and Aromatic Plants, in SE EuropeDocument201 pagesMedicinal and Aromatic Plants, in SE EuropeOana Sidor100% (1)

- Small Colonial Bench: Project 10297EZDocument5 pagesSmall Colonial Bench: Project 10297EZmhein68No ratings yet

- Selling Magical Items and Acquisition ChallengesDocument10 pagesSelling Magical Items and Acquisition ChallengesRobert TuckerNo ratings yet

- Hands DovetailsDocument5 pagesHands Dovetailsquique1967.ecNo ratings yet

- Part 2 - Furnished House or Flat Rental AgreementDocument3 pagesPart 2 - Furnished House or Flat Rental AgreementApollyonNo ratings yet

- 80 - Cutting Diagrams - Heirloom Tool CabinetDocument3 pages80 - Cutting Diagrams - Heirloom Tool CabinetGsmHelpNo ratings yet

- Moxon Vise Instructions-BC0317Document12 pagesMoxon Vise Instructions-BC0317Cameron RiosNo ratings yet

- Uf 11Document40 pagesUf 11urbanfolkNo ratings yet

- BN 901467 Pte30 PDFDocument96 pagesBN 901467 Pte30 PDFDmitryNo ratings yet

- PDS 20/25 Operation and Maintenance ManualDocument152 pagesPDS 20/25 Operation and Maintenance ManualBladimir GuerraNo ratings yet

- Modular Science (Intermediate) Exam Revision BookletDocument84 pagesModular Science (Intermediate) Exam Revision BookletApollyonNo ratings yet

- GCSE Physics P2 Exam - Jan 2008Document16 pagesGCSE Physics P2 Exam - Jan 2008ApollyonNo ratings yet

- Part 1 - Notice of A Short Assured TenancyDocument3 pagesPart 1 - Notice of A Short Assured TenancyApollyonNo ratings yet

- GCSE Physics P2 Exam - June 2009Document16 pagesGCSE Physics P2 Exam - June 2009ApollyonNo ratings yet

- Part 1 - Notice of A Short Assured TenancyDocument3 pagesPart 1 - Notice of A Short Assured TenancyApollyonNo ratings yet

- How To Construct A Suimple Garden PondDocument5 pagesHow To Construct A Suimple Garden PondAAANo ratings yet

- How To MiterDocument4 pagesHow To MiterdvskiwiNo ratings yet

- Swish Autoglide K400 Motor and Control Unit Interface and Control OptionsDocument2 pagesSwish Autoglide K400 Motor and Control Unit Interface and Control OptionsApollyonNo ratings yet

- How To Build A Retaining WallDocument4 pagesHow To Build A Retaining Wallalien2020No ratings yet

- How To Hang WallpaperDocument3 pagesHow To Hang WallpaperApollyonNo ratings yet

- How To Install PVC DownpipesDocument2 pagesHow To Install PVC DownpipesApollyonNo ratings yet

- How To Build A Raised Formal PoolDocument3 pagesHow To Build A Raised Formal Pooldamian00005No ratings yet

- Home CompostingDocument4 pagesHome CompostingratosaNo ratings yet

- Household HazardsDocument4 pagesHousehold HazardsdvskiwiNo ratings yet

- Heat GunsDocument3 pagesHeat GunsApollyonNo ratings yet

- Greener GrassDocument4 pagesGreener GrassdvskiwiNo ratings yet

- How A Lighting Circuit WorksDocument2 pagesHow A Lighting Circuit WorksApollyonNo ratings yet

- Hanging DoorsDocument4 pagesHanging Doorsapi-3830039No ratings yet

- Hanging WallpaperDocument4 pagesHanging WallpaperdvskiwiNo ratings yet

- Hanging WallpaperDocument6 pagesHanging WallpaperApollyonNo ratings yet

- Ground Covers PDFDocument4 pagesGround Covers PDFCarolea SabinaNo ratings yet

- Grass CarpetingDocument4 pagesGrass CarpetingApollyonNo ratings yet

- Hanging ShelvingDocument4 pagesHanging Shelvingapi-3830039No ratings yet

- Hanging CeilingDocument4 pagesHanging Ceilingapi-3830039No ratings yet

- Gun Applied Sealants and AdhesivesDocument2 pagesGun Applied Sealants and AdhesivesApollyonNo ratings yet

- Handrail AnatomyDocument2 pagesHandrail AnatomyJojo LuceroNo ratings yet

- General Do It Yourself Safety CommentsDocument2 pagesGeneral Do It Yourself Safety CommentsApollyonNo ratings yet

- Gas Hot WaterDocument4 pagesGas Hot WaterApollyonNo ratings yet

- Navadhanya Crop SystemDocument8 pagesNavadhanya Crop SystemShanti Swaroop100% (1)

- The Orchid Review v.7Document483 pagesThe Orchid Review v.7tobiasaxo5653No ratings yet

- Succession and StabilityDocument6 pagesSuccession and StabilityMichael Smith100% (1)

- Hydraulics Lab-Workshop Manual, MG University, KeralaDocument54 pagesHydraulics Lab-Workshop Manual, MG University, Keralapramodkb_cusatNo ratings yet

- FloorsDocument19 pagesFloorsSaravanan KumarNo ratings yet

- Ellwanger & Barry's General Catalogue of Fruit & Ornamental Trees, Roses EtcDocument176 pagesEllwanger & Barry's General Catalogue of Fruit & Ornamental Trees, Roses Etc1BlackBeautyNo ratings yet

- Arb NewsDocument16 pagesArb NewsdraoichtNo ratings yet

- 2016-03-03 - Moneysaver - Lewis-Clark EditionDocument16 pages2016-03-03 - Moneysaver - Lewis-Clark EditionDavid ArndtNo ratings yet

- NGP Assessment-Pidsdps1627Document99 pagesNGP Assessment-Pidsdps1627Melitus NaciusNo ratings yet

- Free PDF of Exploded View of 011 Sthill Chain SawDocument2 pagesFree PDF of Exploded View of 011 Sthill Chain SawCiaraNo ratings yet

- Shaker Workbench: Woodworks: Advanced Project ProjectDocument13 pagesShaker Workbench: Woodworks: Advanced Project ProjectEucap MdzNo ratings yet

- Yadav Molai PayengDocument15 pagesYadav Molai PayengPrashanta Kumar Bordoloi100% (1)

- Plant Physio Experiment 2: Seed Germination and Seedling GrowthDocument17 pagesPlant Physio Experiment 2: Seed Germination and Seedling Growthakifuji913No ratings yet

- Identifying Conifers: Arborvitae, Douglas Fir, Fir, Juniper, Pine, Spruce, and YewDocument4 pagesIdentifying Conifers: Arborvitae, Douglas Fir, Fir, Juniper, Pine, Spruce, and YewЂорђе ЈуговићNo ratings yet

- WoodworkDocument10 pagesWoodworkMr DamphaNo ratings yet

- Horse Stall DesignDocument6 pagesHorse Stall Designshyam neogiNo ratings yet

- Update List CheckDocument20 pagesUpdate List CheckFredy SiswantoNo ratings yet

- Forest FiresDocument8 pagesForest FiresWilson Wong IIINo ratings yet

- 2009 Ruhyat PanarubanDocument217 pages2009 Ruhyat PanarubanAdhy Widya SetiawanNo ratings yet

- Rio Forest Certification DeclarationDocument2 pagesRio Forest Certification DeclarationPEFC InternationalNo ratings yet

- Herman Hidayat (Auth.) - Forest Resources Management in Indonesia (1968-2004) - A Political Ecology Approach-Springer Singapore (2016)Document359 pagesHerman Hidayat (Auth.) - Forest Resources Management in Indonesia (1968-2004) - A Political Ecology Approach-Springer Singapore (2016)Mochamad Edo ModburyNo ratings yet

- Rota Das Arvores Monumentais ViaAlgarviana EN WebDocument19 pagesRota Das Arvores Monumentais ViaAlgarviana EN Webthomy nurnbergNo ratings yet