Professional Documents

Culture Documents

Thermo Cem S

Uploaded by

fahshaikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermo Cem S

Uploaded by

fahshaikCopyright:

Available Formats

An Overview of the Current NOx, O2, SO2 Analyzers and Sample Acquisition Technologies and Equipment Installed by the

Electric Utility Industry

Presented by

J. Ron Jernigan, P.E., DEE

2nd U.S.-China NOx and SO2 Control Workshop August 2-5, 2005 Dalian Bangchui Island Hotel Zhongshan District, Dalian, Liaoning Province The Peoples Republic of China

Overview of CEMS Technologies & Equipment

This Presentation Will Present The Air Emissions Monitoring Techniques Selected By The U.S. Electric Utility Industry For Complying With U.S. EPAs Part 75 Acid Rain Monitoring Program Since Early 1993 Over 3000 New CEM Systems Have Installed By The Electric Utility Industry This Presentations CEMS Technologies Data Are Compiled From EPAs 4th Quarter 2003 EDR Data

Overview of CEMS Technologies & Equipment

Sample Acquisition Techniques

Dilution-Extractive Systems In-Stack Out-of-Stack Extractive Systems Cold/Dry Hot/Wet

In-Situ Systems

Across-Stack Point

3

Overview of CEMS Technologies & Equipment

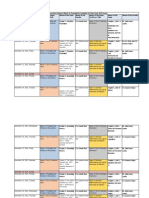

Part 75 CEMS Sample Acquisition Methods

Sample Acquisition Method

Total SO2 CEMS

(1,045 analyzers)

% SO2 CEMS 88.0

Total NOx CEMS

(3,193 analyzers)

% NOx CEMS 47.2

Dilution Extractive

920

1,508

Extractive (cool/dry & hot/wet)

104

10.0

1,357

51.5

In-Situ (Point & Across-Stack)

21

2.0

46

1.3

Overview of CEMS Technologies & Equipment

Part 75 CEMS Sample Acquisition Methods

All of the 1,045 SO2 Analyzers are Installed on Coal-Fired boilers. 920 (88%) of the SO2 and NOx analyzers chose dilution-extractive over non-dilution extractive due to dilution-extractive providing wetbasis concentrations working more economically with flue gas flow rate monitor which also provides wet-basis stack flow rate values, therefore no moisture analyzers required for data correction to wetbasis and also lower maintenance cost (50% -100% less cost than non-dilution extractive CEMS. 588 oil and gas-fired boilers also chose to install the dilution-extractive technology over non-dilution extractive technology. Approximately 2,000 of the 3,193 NOx analyzers are installed on gasfired combustion turbines which only measure NOx and O2 with CEMS, these units chose non-dilution extractive systems.

5

Overview of CEMS Technologies & Equipment

Part 75 CEMS Sample Acquisition Methods

For gas-fired combustion turbines NOx & O2 non-dilution extractives systems have a slightly lower initial cost, and annual cost of maintenance is only slightly higher than dilution extractive systems. In-Situ, both point and across-stack types, are not popular with the U.S. electric utility industry because they have proven to be less reliable and more costly to operate than dilution and non-dilution extractive systems. Only 21 of the 1,045 SO2 CEMS were listed as In-Situ systems. Only 46 of the 3,193 NOx CEMS were listed as In-Situ systems.

Overview of CEMS Technologies & Equipment

In-Stack Dilution Probe Sampling System

Overview of CEMS Technologies & Equipment

Dilution Probe Sampling System

Dilution probe particulate matter filter flow through the filter is typically 100 cubic centimeters per minute compared to a non-dilution probe system which is approximately 3,500 cubic centimeters per minute, accordingly, dilution probe systems have must less problem with filter plugging and lower annual maintenance cost. Dilution probe sampling systems do not require a heated sample line Non-dilution sampling systems require a more expensive heated sample line which periodically fail or malfunction. Heated sample line failures can cause sample line plugging and result in high maintenance cost. Dilution probe sampling systems do not require moisture removal systems therefore, no additional cost for a moisture analyzer, or high maintenance cost due to moisture removal systems malfunctions or failures that may result in analyzer failures due to contamination from moisture condensation and corrosion gases.

8

Overview of CEMS Technologies & Equipment

In-Stack Dilution Probe Sampling System

Dilution probe sampling systems do not require sample pumps or numerous flow control valves as required by non-dilution sampling systems therefore, this is another area of lower maintenance cost. Industry can use very reliable ambient level analyzers, which are very robust and generally require less routine maintenance than source level analyzers. Using very clean dilution air virtually eliminates analyzer internal corrosion.

Overview of CEMS Technologies & Equipment

Dilution Probe

10

Overview of CEMS Technologies & Equipment

Dilution Probe

Dilution probe systems use dry contamination-free air (dilution air) and an eductor (also referred to as a venturi pump) to extract a diluted flue gas sample from the exhaust stack or duct. It is not necessary to remove the moisture from the flue gas sample prior to analysis by the analyzers, because the sample is diluted sufficiently (typical dilution ratios range from 100:1 to 250:1) to avoid condensation problems during analysis at normal ambient temperatures, however, the concentration is still a wet-basis concentration. Dilution probe systems provide wet-basis concentrations that works very well with flue gas flow rate monitor which also provides wet-basis stack flow rate values, therefore no moisture analyzers are required for data correction.

11

Overview of CEMS Technologies & Equipment

Dilution Air Clean-Up System

12

Overview of CEMS Technologies & Equipment

Dilution Air Clean-Up System

Dilution probe systems require a constant source of contamination free dilution air.

The air supply should be dry (-30o C to - 40o C) and delivered at 620 68 kilopascals. The dilution air should be free of oils, particulates, CO2, NOx, and SO2.

13

Overview of CEMS Technologies & Equipment

Non-Dilution Extractive System

14

Overview of CEMS Technologies & Equipment

Non-Dilution Extractive System

Typically non-dilution extractive systems are cold/dry systems The hot flue (sample) gases are transported by means of a heated sample line (120o C to 175o C) to a sample gas conditioning system Typical gas conditioning systems are condensation type systems Sample gas conditioning systems are generally either refrigeration condensers or thermoelectric chillers. Thermoelectric chillers are becoming more common now.

15

Overview of CEMS Technologies & Equipment

Gaseous Continuous Emission Monitors

SO2 Monitoring Technologies

Ultraviolet(UV) Fluorescence - 85% UV Spectrophotometric - 14% Other Technologies 1%

NOx Monitoring Technologies

Chemiluminescence 96.4% UV Spectrophotometric 2.3% Non-dispersive Infrared 1.3%

16

Overview of CEMS Technologies & Equipment

Gaseous Continuous Emission Monitors

After more than 10 years of CEMS operational experience, the most popular SO2 Monitoring & NOx Monitoring Technologies are:

SO2 Ultraviolet(UV) Fluorescence - 85% NOx- Chemiluminescence 96.4%

17

Overview of CEMS Technologies & Equipment

Gaseous CEM Technologies

After more than 10 years of CEMS operational experience in the U.S. EPAs Acid Rain Monitoring program, the electric utility industry have chosen Ultraviolet (UV) Fluorescence (85%) as the most popular SO2 monitoring technology used and Chemiluminescence (96.4%) as the most popular NOx monitoring technology used. These monitoring technologies have become the most widely used because they offer excellent monitoring accuracy, are very reliable with a very high data capture (>98%), and they have low annual maintenance costs.

18

Overview of CEMS Technologies & Equipment

SO2 Analyzers Chosen For The Part 75 Acid Rain Program Top Five SO2 Manufacturers (Source of Data, EPAs

Database Total 1,045 SO2 Analyzers) 4th Quarter 2003 EDR

Thermo Electron Corporation Teledyne/Monitor Labs/API Forney/Anarad/CSI Ametek/Western Research Siemens

747 analyzers 177 analyzers 51 analyzers 28 analyzers 16 analyzers Total

71.5% 16.9% 4.9% 2.7% 1.5% _____ 97.5%

19

Overview of CEMS Technologies & Equipment

NOx Analyzers Chosen For The Part 75 Acid Rain Program Top Five NOx Manufacturers (Source of Data, EPAs

Database Total 3,193 NOx Analyzers) 4th Quarter 2003 EDR

Thermo Electron Corporation Teledyne/Monitor Labs/API Rosemount Forney/Anarad/CSI Horiba

2,003 analyzers 411 analyzers 384 analyzers 156 analyzers 98 analyzers Total

62.7% 12.9% 12.0% 4.9% 3.1% _____ 95.6%

20

Overview of CEMS Technologies & Equipment

NOx & SO2 Analyzers Chosen For The Part 75 Acid Rain Program

After more than 10 years of CEMS operational experience in the U.S. EPAs Acid Rain Monitoring program, the electric utility industry have continued to use, or replaced, their previous CEM analyzers with analyzers supplied primarily by two manufacturers, Thermo Electron Corporation and Teledyne Instruments. These two manufacturers supply over 88% of all the SO2 analyzers and over 75% of all the NOx analyzers. These two analyzer manufacturers have become the most widely used SO2 and NOx analyzer supplies because they offer robust, very accurate, very reliable analyzers with low annual cost of operation.

21

Overview of CEMS Technologies & Equipment

Gaseous Continuous Emission Monitors

CO2 Monitoring Technologies Non-Dispersive Infrared(NDIR) - 100% O2 Monitoring Technologies Paramagnetic - 73% Electrocatalytic - 27%

22

Overview of CEMS Technologies & Equipment

CO2 Analyzers Chosen For The Part 75 Acid Rain Program Top Five CO2 Manufacturers (Source of Data, EPAs

Database Total 1,586 CO2 Analyzers) 4th Quarter 2003 EDR

California Analytical Inc. Thermo Electron Corporation Siemens Teledyne/Monitor Labs/API Forney/Anarad

617 analyzers 554 analyzers 190 analyzers 116 analyzers 34 analyzers

Total

38.9% 34.9% 12.0% 7.3% 2.1%

_____ 95.2%

23

Overview of CEMS Technologies & Equipment

O2 Analyzers Chosen For The Part 75 Acid Rain Program Top Five O2 Manufacturers (Source of Data, EPAs 4th Quarter 2003 EDR

Database Total 1,588 O2 Analyzers)

Servomex Siemens Ametek/Thermox Teledyne/Monitor Labs Rosemount

599 analyzers 259 analyzers 174 analyzers 143 analyzers 122 analyzers Total

37.7% 16.3% 11.0% 9.0% 7.7% ______ 81.7%

24

Overview of CEMS Technologies & Equipment

Flue Gas Flow Rate Monitors

Ultrasonic 61.9% Differential Pressure 29.6% Thermal 5.0% Optical Scintillation 1.8 Audible Acoustic 1.6%

25

Overview of CEMS Technologies & Equipment

Ultrasonic Flow Rate Monitor

26

Overview of CEMS Technologies & Equipment

EMRC S-Type Pitot Pressure Differential

27

Overview of CEMS Technologies & Equipment

Schematic of An Air Monitor Corp. Pitot Probe

28

Overview of CEMS Technologies & Equipment

Flow Rate Monitors Chosen For The Part 75 Acid Rain Program

Top Five Flow Rate Monitor Manufacturers (Source of Data, EPAs

Quarter 2003 EDR Database Total 1,219 Flow Rate Monitors)

4th

Teledyne/Monitor Labs [Ultrasonic] EMRC [DP] Air Monitor Corp. [DP] Sick [Ultrasonic] Kurz [Thermal]

652 analyzers 245 analyzers 67 analyzers 46 analyzers 41 analyzers Total

53.5% 20.1% 5.5% 3.8% 3.4% _____ 86.3%

29

Overview of CEMS Technologies & Equipment

Summary

The Major CEMS Technologies & Equipment Currently Used by U.S. Electric Utility Part 75 Sources Have Been Proven To Be Reliable, Accurate and have the Lowest Annual Cost of Operation

EPA Reports Average CEMS Data Availability >98%

EPA Reports Indicate That The Median Relative Accuracy for NOx, and SO2 and Flow Rate Monitors Were Approximately 3% Relative Accuracy.

30

You might also like

- Environmental Measurement SolutionsDocument4 pagesEnvironmental Measurement SolutionsMouayed ZeadanNo ratings yet

- CEMS Technologies: Dilution Extractive Dilution ExtractiveDocument3 pagesCEMS Technologies: Dilution Extractive Dilution Extractivemkgupta64No ratings yet

- Emerson CEMSDocument12 pagesEmerson CEMSquinteroudinaNo ratings yet

- Art & Science of Continuous Emissions Monitoring SystemsDocument44 pagesArt & Science of Continuous Emissions Monitoring SystemshuyNo ratings yet

- Technical Paper - Selection of Particulate Monitors PDFDocument8 pagesTechnical Paper - Selection of Particulate Monitors PDFAtika RahmaNo ratings yet

- CEMS Overview PDFDocument42 pagesCEMS Overview PDFqaedmahmoodNo ratings yet

- Measures for Air Pollution Control from Industrial ActivitiesDocument44 pagesMeasures for Air Pollution Control from Industrial ActivitiesVishal HiremathNo ratings yet

- Guidance for EIA Reports of Industries in Approved SitesDocument21 pagesGuidance for EIA Reports of Industries in Approved Sitesnashrul izzuan abdul karimNo ratings yet

- Environmental Quality (Clean Air) Regulations, 1978Document18 pagesEnvironmental Quality (Clean Air) Regulations, 1978Darren Tan100% (1)

- Eq New Air Regulation 2014Document40 pagesEq New Air Regulation 2014fuadhassanarNo ratings yet

- ESM Andersen BrochureDocument12 pagesESM Andersen BrochureGezgin BiriNo ratings yet

- Dust and Opacity Monitoring Background, Legislation and ComplianceDocument39 pagesDust and Opacity Monitoring Background, Legislation and ComplianceChristianChalcoGonzalesNo ratings yet

- CEMS EquipmentDocument18 pagesCEMS EquipmentjamesrickynNo ratings yet

- 5.1 Ambient Air Sampling Equipment & DevicesDocument68 pages5.1 Ambient Air Sampling Equipment & DevicesNurul Hidayatul Hanani Binti AripinNo ratings yet

- Stack Emission and Automobile Emission.Document29 pagesStack Emission and Automobile Emission.Kumar GauravNo ratings yet

- A Guide To The Sampling and Analysis of Air Emissions and Air QualityDocument47 pagesA Guide To The Sampling and Analysis of Air Emissions and Air QualityLaboratorium Lingkungan TulungagungNo ratings yet

- Flue Gas Analysis - (1805240028)Document15 pagesFlue Gas Analysis - (1805240028)MohdNo ratings yet

- DGR Guidance Book 2018 en Rev View PDFDocument76 pagesDGR Guidance Book 2018 en Rev View PDFAnarjin UnurjargalNo ratings yet

- Aerosol Measurement: Principles, Techniques, and ApplicationsFrom EverandAerosol Measurement: Principles, Techniques, and ApplicationsPramod KulkarniNo ratings yet

- Technical Guidance Notes M3 How To Assess Monitoring Arrangements For Emissions To Air in EPR Permit Applications Environment Agency UKDocument18 pagesTechnical Guidance Notes M3 How To Assess Monitoring Arrangements For Emissions To Air in EPR Permit Applications Environment Agency UKheljoalNo ratings yet

- CEMS RATA ProtocolDocument101 pagesCEMS RATA ProtocolALI RAZANo ratings yet

- Environmental StandardsDocument14 pagesEnvironmental StandardsJaswant VermaNo ratings yet

- TGN M20 - Quality Assurance of Continuous Emission Monitoring SystemsDocument61 pagesTGN M20 - Quality Assurance of Continuous Emission Monitoring SystemsDiego MorenoNo ratings yet

- Week 4-Emission Air Pollution (L7)Document37 pagesWeek 4-Emission Air Pollution (L7)Devendraa MuniandyNo ratings yet

- Environmental StandardsDocument119 pagesEnvironmental Standardssoubhik1987No ratings yet

- Standard Software Interfaces For CEMS Relative Accuracy Test Audit DataDocument26 pagesStandard Software Interfaces For CEMS Relative Accuracy Test Audit DataloretoNo ratings yet

- Pollution Control Handbook for Oil and Gas EngineeringFrom EverandPollution Control Handbook for Oil and Gas EngineeringNo ratings yet

- EPA Ireland Air Monitoring Guidance Note AG2 PDFDocument97 pagesEPA Ireland Air Monitoring Guidance Note AG2 PDFHelder DuraoNo ratings yet

- Technical Guidance Notes M16 Monitoring Volatile Organic Compounds in Stack Gas Emissions Environment Agency UKDocument16 pagesTechnical Guidance Notes M16 Monitoring Volatile Organic Compounds in Stack Gas Emissions Environment Agency UKheljoalNo ratings yet

- MCERTS Certified Continuous Emission Monitoring SystemsDocument22 pagesMCERTS Certified Continuous Emission Monitoring SystemsJoshiMBNo ratings yet

- Stack Monitoring - Material andDocument65 pagesStack Monitoring - Material andRohitNo ratings yet

- EPA HandbookDocument201 pagesEPA Handbookdecio ventura rodrigues miraNo ratings yet

- Certification of AMS Acc. en 15267, Part 3 - Overview and First ExperienceDocument11 pagesCertification of AMS Acc. en 15267, Part 3 - Overview and First Experiencesalekojic5332No ratings yet

- Method Implementation Document For EN 14181 Stationary Source Emissions Quality Assurance of Automated Measuring Systems v3 April 2014Document44 pagesMethod Implementation Document For EN 14181 Stationary Source Emissions Quality Assurance of Automated Measuring Systems v3 April 2014Helder DuraoNo ratings yet

- Unit 5Document127 pagesUnit 5as bhagavanreddyNo ratings yet

- Aqms - EnveaDocument40 pagesAqms - EnveaAtika RahmaNo ratings yet

- CEMS GuidlinesDocument94 pagesCEMS GuidlinesBiohm ConsultareNo ratings yet

- EPA Control Technologies Hazardous Pollutants 1991Document260 pagesEPA Control Technologies Hazardous Pollutants 1991Bruno ThiemeNo ratings yet

- OverviewDocument20 pagesOverviewHashemAliHashem100% (1)

- Chapter Three Concentrations and EmissionsDocument39 pagesChapter Three Concentrations and EmissionsBassam RiachiNo ratings yet

- CEms Uras 26Document18 pagesCEms Uras 26Hammad Ashraf100% (1)

- Cem HandbookDocument34 pagesCem HandbookJavier LemusNo ratings yet

- AirPollution PDFDocument33 pagesAirPollution PDFvishwajitNo ratings yet

- Continuous Emission Monitoring System (CEMS) : Larsen & Toubro Limited Epc Power Training ManualDocument28 pagesContinuous Emission Monitoring System (CEMS) : Larsen & Toubro Limited Epc Power Training ManualABVSAINo ratings yet

- Air SamplingDocument10 pagesAir SamplingBudiawan PramonoNo ratings yet

- Stack MonitoringDocument35 pagesStack Monitoringnagendra_rd100% (1)

- CEMS Guidelines Volume I Full VersionDocument28 pagesCEMS Guidelines Volume I Full Versionbabis1980100% (1)

- ECOTECH Continuous Emissions Monitoring Systems CEMS Brochure 20171113Document12 pagesECOTECH Continuous Emissions Monitoring Systems CEMS Brochure 20171113Er Dipak PatelNo ratings yet

- Environmental MonitoringDocument9 pagesEnvironmental MonitoringWAGUDELONo ratings yet

- CEMS Primer: Automated Control Systems Inc. 122 Woodburn Drive - Dothan, AL 36301 334-792-0113 Fax 334-671-4298Document8 pagesCEMS Primer: Automated Control Systems Inc. 122 Woodburn Drive - Dothan, AL 36301 334-792-0113 Fax 334-671-4298ryan_keller_23No ratings yet

- Unit One This or That 1Document9 pagesUnit One This or That 1sushantNo ratings yet

- Application of Measuring Gas Flow in The DowncomerDocument4 pagesApplication of Measuring Gas Flow in The DowncomerAhmad NilNo ratings yet

- Kiln Inlet Analyser Presentation 2014 (PPTminimizer) - PrintingDocument27 pagesKiln Inlet Analyser Presentation 2014 (PPTminimizer) - PrintingMuhammad100% (1)

- CEMS Newsletter: CEMS From A-Z: A Multi-Part SeriesDocument4 pagesCEMS Newsletter: CEMS From A-Z: A Multi-Part Seriesbabis1980No ratings yet

- Differences Between In-Situ and Extractive Emissions MonitoringDocument7 pagesDifferences Between In-Situ and Extractive Emissions MonitoringAniketNo ratings yet

- Ps-8a.pdf2 PDFDocument9 pagesPs-8a.pdf2 PDFdevsadNo ratings yet

- New Developments in Continuous Emissions Monitoring CEMS)Document8 pagesNew Developments in Continuous Emissions Monitoring CEMS)Bill WorthingtonNo ratings yet

- Flow Meter BrochureDocument8 pagesFlow Meter BrochureJavier IglesiasNo ratings yet

- MC3 SMR CasestudyDocument1 pageMC3 SMR CasestudyEdulNo ratings yet

- 4 - Report On Gas Analysis in Cement Plant PDFDocument77 pages4 - Report On Gas Analysis in Cement Plant PDFTin Nguyen0% (1)

- Participatory Assessment of Ragay Gulf Resources and SocioeconomicsDocument167 pagesParticipatory Assessment of Ragay Gulf Resources and SocioeconomicsCres Dan Jr. BangoyNo ratings yet

- Transactionreceipt Ethereum: Transaction IdentifierDocument1 pageTransactionreceipt Ethereum: Transaction IdentifierVALR INVESTMENTNo ratings yet

- Split Plot Design GuideDocument25 pagesSplit Plot Design GuidefrawatNo ratings yet

- 05 Askeland ChapDocument10 pages05 Askeland ChapWeihanZhang100% (1)

- Purnanandalahari p3D4Document60 pagesPurnanandalahari p3D4anilkumar100% (1)

- Equivalent Record Form: Department of Education MIMAROPA RegionDocument1 pageEquivalent Record Form: Department of Education MIMAROPA RegionEnerita AllegoNo ratings yet

- ARTS 9 Q4 Week 1Document3 pagesARTS 9 Q4 Week 1Elaissa MaglanqueNo ratings yet

- Demo TeachingDocument22 pagesDemo TeachingCrissy Alison NonNo ratings yet

- Causes of The Renaissance: Silk RoadDocument6 pagesCauses of The Renaissance: Silk RoadCyryhl GutlayNo ratings yet

- Unit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsDocument6 pagesUnit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsCristina Garcia50% (2)

- 68rfe IntroductionDocument71 pages68rfe IntroductionThePokeOne83% (6)

- Course Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataDocument61 pagesCourse Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataShekinah Vingno LingcongNo ratings yet

- 74VHCU04Document6 pages74VHCU04Alexandre S. CorrêaNo ratings yet

- ALT Company Introduction 20170524.1Document51 pagesALT Company Introduction 20170524.1Terence WoonNo ratings yet

- Fixed Prosthodontics Provisional Materials: Making The Right Selection.Document7 pagesFixed Prosthodontics Provisional Materials: Making The Right Selection.veloso.rossana0% (1)

- Rigor Mortis and Lividity in Estimating Time of DeathDocument2 pagesRigor Mortis and Lividity in Estimating Time of DeathfunnyrokstarNo ratings yet

- PublicReviewDraft2742 (1) (002)Document75 pagesPublicReviewDraft2742 (1) (002)dhruv.encontrolsNo ratings yet

- A Comparison of Fuel Cell Testing Protocols PDFDocument7 pagesA Comparison of Fuel Cell Testing Protocols PDFDimitrios TsiplakidesNo ratings yet

- Sankalp Sanjeevani NEET: PhysicsDocument11 pagesSankalp Sanjeevani NEET: PhysicsKey RavenNo ratings yet

- Volume 4-6Document757 pagesVolume 4-6AKNo ratings yet

- Theravada BuddhismDocument21 pagesTheravada BuddhismClarence John G. BelzaNo ratings yet

- Range of Muscle Work.Document54 pagesRange of Muscle Work.Salman KhanNo ratings yet

- Packetfence Network Devices Configuration Guide: For Version 3.5.0Document76 pagesPacketfence Network Devices Configuration Guide: For Version 3.5.0René FabricioNo ratings yet

- Analog Communication Interview Questions and AnswersDocument34 pagesAnalog Communication Interview Questions and AnswerssarveshNo ratings yet

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDocument10 pagesChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHINo ratings yet

- Synetek Controls Inc.: Ds1-S: Installation InstructionsDocument2 pagesSynetek Controls Inc.: Ds1-S: Installation Instructionsdgd_electromecNo ratings yet

- Macbeth Introduction0Document40 pagesMacbeth Introduction0MohammedelamineNo ratings yet

- (PDF) Teach Your Baby Math - Glenn DomanDocument200 pages(PDF) Teach Your Baby Math - Glenn Domansugapovex0% (1)

- MIL (Second Quarter)Document13 pagesMIL (Second Quarter)Menma ChanNo ratings yet

- Test 1 Grammar, Revised Ecpe HonorsDocument3 pagesTest 1 Grammar, Revised Ecpe HonorsAnna Chronopoulou100% (1)