Professional Documents

Culture Documents

Activity Hazard Analysis

Uploaded by

Gerrard SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Activity Hazard Analysis

Uploaded by

Gerrard SinghCopyright:

Available Formats

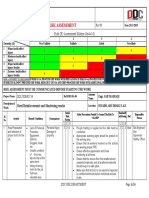

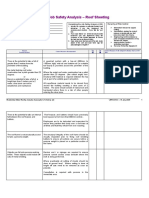

ACTIVITY HAZARD ANALYSIS

Date Prepared: JSABuilder Sample Library - 4 AHA No.: (AHA - short) Project Name: General weld Activity/Work Task: Electric Arc Welding Dept. / Div. / Section: Facility Maintenance Activity Location(s): Welding Shop Prepared By: Name Person 2 Task Start Date: Task Duration: 2 hours Task Supervisor: Name Person 1 Reviewed By: Name Person 3 Job Steps 1. Sign in and inspect (Step 1) Hazards - Welding/Cutting/Burning Equipment - Wires, cables, hoses

E=Extremely High Risk H=High Risk M=Moderate Risk L=Low Risk

Overall Risk Assessment Code (RAC): M Risk Assessment Code Matrix

Probability Frequent E E H M Likely E H M L Occasional H H M L Seldom H M L L Unlikely M L L L

S e v e r i t y

Catastrophic Critical Marginal Negligible

Actions to Eliminate or Minimize Hazards - Before setting up the welding shop, visit the Admin desk to sign in. - Inspect arc welding equipment cables and connections; look for loose connections, frayed insulation on electrode holders and cables (see photo), make sure electrical cables are dry (complete safety checklist). - Required controls: certified welder, ergonomic training for the task, hot work training, proper housekeeping, monitoring hazardous atmosphere, proper operating procedures, safety checklist.

RAC L

Step 1 Image:

JSA No: JSABuilder Sample Library - 4 (AHA - short) | Electric Arc Welding

1 of 4

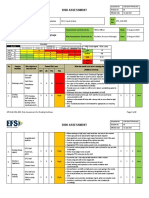

2. Steps 2 - 6

- x--- NA ---x

Steps 2 - 6 have been removed to keep this sample to a reasonable length. - Follow manufacturer recommended procedures, lessons learned and experience. - If possible, position shelf so that head is not in fumes while welding. - If possible use sub arc process to minmimize light and fumes, and/or minimize the production of welding fumes by using the lowest acceptable amperage and holding the electrode perpendicular and as close to the work surface and possible. - Keep electrode moving. Tack as appropriate for project and metal type. - Finish the weld. - Required PPE (see photo): boots (OSHA electrical), fire resistant clothing/coveralls, longs pants, long sleeved shirts/coveralls, fire resistant gauntlet glove, safety glasses (see manual for lens shade requirements for welder & spotter), side shield, welding hood, welding jacket & apron.

3. Perform the weld (Step 7)

- Arc rays - Combustible materials - Electrical equipment (transformers, switching gear, breakers, high voltage lines) - Ignitable materials and liquids - Infrared (IR) - Light (optical) radiation (i.e. welding operations, etc.). - Repetitive motion or other ergonomic concerns - Rolling or pinching objects - Sharp objects - Slag splatter - Sparks - Ultraviolet (UV) - WELDING FUMES AND GASES - Welding/Cutting/Burning Equipment

JSA No: JSABuilder Sample Library - 4 (AHA - short) | Electric Arc Welding

2 of 4

- Wires, cables, hoses Step 3 Image:

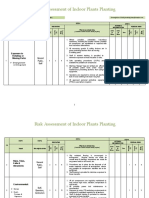

4. Steps 8 - 9

- x--- NA ---x

Steps 8 - 9 have been removed to keep this sample to a reasonable length. When welded material has cooled, use chipping hammer or grinder to remove excess slag from weld (see photo). Secure material to workbench with clamps as necessary, before chipping. FACE SHIELD IS REQUIRED FOR THIS ACTIVITY TO PROTECT FROM FLYING DEBRIS. Be alert to fingers and pinch points and struck-by potential.

5. Remove excess slag from welded material (Step 10)

- Electrical equipment (transformers, switching gear, breakers, high voltage lines) - Hand tools - metal chips - Repetitive motion or other ergonomic concerns - Sharp objects - Sparks - Wires, cables, hoses

JSA No: JSABuilder Sample Library - 4 (AHA - short) | Electric Arc Welding

3 of 4

Step 5 Image:

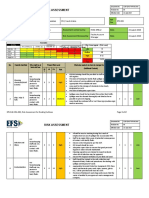

6. Steps 11 - 12

- x--- NA ---x

Steps 11 - 12 have been removed to keep this sample to a reasonable length. Inspection Training - Competent person - Emergency operations training - Normal operations training - Competent person - Emergency operations training - Normal operations training

Equipment Arc welder

- Daily - general use inspection every 1 day. - Each job - pre-inspect before each job (may be multiple times per day) every 1 day.

Grinder (if used)

- Daily - general use inspection every 1 day. - Each job - inspect prior to use each job (multiple times per day) every 1 day.

Involved Personnel: Name Person 1, Name Person 2

JSA No: JSABuilder Sample Library - 4 (AHA - short) | Electric Arc Welding

This sample created at www.JSABuilder.com.

4 of 4

You might also like

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- Electrical Conduit InstallationDocument10 pagesElectrical Conduit InstallationYahya YusufzayNo ratings yet

- JHA - Ladders TemplateDocument3 pagesJHA - Ladders TemplateShannon Williams100% (1)

- Risk Assessment - House and BuildingDocument1 pageRisk Assessment - House and Buildingnayanahari0% (1)

- HSE TRA-04 Steel Reinforcement and Shuttering WorksDocument6 pagesHSE TRA-04 Steel Reinforcement and Shuttering WorksQusai Khalil Abu Awad100% (1)

- Risk Assessment For Installation of Toilet Exhaust FanDocument10 pagesRisk Assessment For Installation of Toilet Exhaust FanMaria Carmela Rachel GazilNo ratings yet

- Activity Hazard Analysis Safety ReviewDocument7 pagesActivity Hazard Analysis Safety ReviewKCV Coretech100% (1)

- HARZAD IDENTIFICATION AND RISK ASSESSMENTDocument14 pagesHARZAD IDENTIFICATION AND RISK ASSESSMENTAmitkumar SinghNo ratings yet

- AHA - Working On Slope RoofDocument2 pagesAHA - Working On Slope RoofTopsun EnergyNo ratings yet

- Ra02 - Container OffloadingDocument3 pagesRa02 - Container OffloadingSamNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- AHA-003, ExcavationDocument5 pagesAHA-003, ExcavationBuddhika100% (2)

- King Faisal Air Academy Carpentry JSADocument1 pageKing Faisal Air Academy Carpentry JSAnabeelNo ratings yet

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh100% (1)

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- P-985-SH-AHA-008, AHA For Demolision WorksDocument4 pagesP-985-SH-AHA-008, AHA For Demolision WorksPatrick Bibila NdansiNo ratings yet

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesDocument2 pagesEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazNo ratings yet

- JSA For MobilizationDocument3 pagesJSA For MobilizationHossain amjad Hossain100% (1)

- Risk Assesment For MobilizationDocument6 pagesRisk Assesment For MobilizationAmeerHamzaWarraich100% (1)

- GEN-005 Low Pressure Turbine and Generator Coupling and Decoupling Alignment CheckDocument3 pagesGEN-005 Low Pressure Turbine and Generator Coupling and Decoupling Alignment Checkacanbasri1980No ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- PRL DEVELOPERS PVT. LTD. Hazard Identification and Risk Assessment SummaryDocument7 pagesPRL DEVELOPERS PVT. LTD. Hazard Identification and Risk Assessment Summary287100% (3)

- Risk Assessment For Back FillingDocument6 pagesRisk Assessment For Back FillingBhargav BbvsNo ratings yet

- RISK ASSESSMENT FOR EXCAVATION PROJECTDocument6 pagesRISK ASSESSMENT FOR EXCAVATION PROJECTAbdul Rasheed Mangrio100% (1)

- EHS RISK ASSESSMENT FOR MATERIAL HANDLINGDocument4 pagesEHS RISK ASSESSMENT FOR MATERIAL HANDLINGshamshu123100% (1)

- Risk assessment identifies hazards of installing cables and excavationDocument6 pagesRisk assessment identifies hazards of installing cables and excavationMohammed Shiful0% (1)

- Laying of Road Crossing Duct For Irrigation WorksDocument9 pagesLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- AHA Temp Power - 03.03.2020 - RemarksDocument3 pagesAHA Temp Power - 03.03.2020 - RemarksJerry Word100% (1)

- 003 SWMS - ExcavationDocument11 pages003 SWMS - Excavationsasi kumar50% (2)

- Job Risk Asessment. Excavation 8-6-22Document3 pagesJob Risk Asessment. Excavation 8-6-22Mohammed Ali Qazi100% (1)

- UG RA 009 - Light Materials and Equipment Loading and UnloadingDocument6 pagesUG RA 009 - Light Materials and Equipment Loading and Unloadingshamshuddin100% (1)

- Excavations: Job Safety AnalysisDocument5 pagesExcavations: Job Safety AnalysisJICKNo ratings yet

- RA For Summer Heat Stress Management A71Document4 pagesRA For Summer Heat Stress Management A71Sajid Shah100% (1)

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 pagesJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoNo ratings yet

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document9 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony Macatangay50% (2)

- 9 - Aerial Lifts and Scissor Lifts THA-AHADocument5 pages9 - Aerial Lifts and Scissor Lifts THA-AHAJojolas100% (2)

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- Risk Assessment of Fabrication, Welding, Cutting WorkDocument7 pagesRisk Assessment of Fabrication, Welding, Cutting WorkAbdul MujeebNo ratings yet

- Risk Assessment - Backfilling Around Foul Sewer and Storm Warter ManholesDocument6 pagesRisk Assessment - Backfilling Around Foul Sewer and Storm Warter Manholesloveson70950% (2)

- Risk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Document12 pagesRisk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Sachwin SachuNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- Risk Assessment of Indoor Plants PlantingDocument5 pagesRisk Assessment of Indoor Plants Plantingطارق رضوانNo ratings yet

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- Risk Assessment FOR: Over Head Crane ErectionDocument9 pagesRisk Assessment FOR: Over Head Crane ErectionZameer AhmedNo ratings yet

- Risk Assessment Concrete Cutting - 01Document5 pagesRisk Assessment Concrete Cutting - 01kapsarcNo ratings yet

- Risk Assessment for Bodily Fluid Spillage CleaningDocument2 pagesRisk Assessment for Bodily Fluid Spillage Cleaningmohammed ayazNo ratings yet

- HIRA FOR Equipment Instalation.Document8 pagesHIRA FOR Equipment Instalation.Deepak G100% (1)

- Tools / Equipment:: Job Safety Analysis (Jsa)Document5 pagesTools / Equipment:: Job Safety Analysis (Jsa)Sameer AlmahboubNo ratings yet

- Ra For Fire Protection Piping Installation WorksDocument7 pagesRa For Fire Protection Piping Installation WorksprinceNo ratings yet

- Use of Hand ToolsDocument2 pagesUse of Hand Toolsvictor100% (1)

- Fencing Installation Risk AssessmentDocument6 pagesFencing Installation Risk AssessmentVictorNo ratings yet

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21No ratings yet

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Roof Sheeting SafetyDocument6 pagesRoof Sheeting SafetyMomo XxxxNo ratings yet

- RA - 5 - For Backfilling & CompactionDocument14 pagesRA - 5 - For Backfilling & CompactionIbrahim EsmatNo ratings yet

- Jsa - Sample Hot Tapping PDFDocument4 pagesJsa - Sample Hot Tapping PDFrongohcoleman100% (1)

- Jsa Sample PDFDocument4 pagesJsa Sample PDFKaoru AmaneNo ratings yet

- Manual Version of Risk Score NomogramDocument2 pagesManual Version of Risk Score NomogramGerrard SinghNo ratings yet

- Shortcut Keys WordDocument2 pagesShortcut Keys WordGerrard SinghNo ratings yet

- How To Build A PantographDocument4 pagesHow To Build A PantographGerrard Singh100% (2)

- Adsett V K & L Steel Founders and Engineers LTDDocument1 pageAdsett V K & L Steel Founders and Engineers LTDGerrard SinghNo ratings yet

- A Precise Table Saw From An Electric Hand SawDocument17 pagesA Precise Table Saw From An Electric Hand SawGerrard SinghNo ratings yet

- Nstoklosa Resume 2Document2 pagesNstoklosa Resume 2api-412343369No ratings yet

- Word Wall Frys ListDocument10 pagesWord Wall Frys Listapi-348815804No ratings yet

- Qimen Grup2Document64 pagesQimen Grup2lazuli29100% (3)

- Στιχοι απο εμεναDocument30 pagesΣτιχοι απο εμεναVassos Serghiou SrNo ratings yet

- Article 9 of Japan ConstitutionDocument32 pagesArticle 9 of Japan ConstitutionRedNo ratings yet

- Chapter 14 ECON NOTESDocument12 pagesChapter 14 ECON NOTESMarkNo ratings yet

- Virl 1655 Sandbox July v1Document16 pagesVirl 1655 Sandbox July v1PrasannaNo ratings yet

- NSCC Great Expectations 09Document6 pagesNSCC Great Expectations 09HDTT_09101199No ratings yet

- Urology: Hydronephrosis and Kidney StonesDocument13 pagesUrology: Hydronephrosis and Kidney StonesendiNo ratings yet

- Integ Equ Phys571 T131Document19 pagesInteg Equ Phys571 T131raoni_jampaNo ratings yet

- Human Resource Management and The Banking SectorDocument5 pagesHuman Resource Management and The Banking SectorAkshay DagurNo ratings yet

- CIR Vs CA Fortune Tobacco CaseDocument1 pageCIR Vs CA Fortune Tobacco CaseAlexylle Garsula de ConcepcionNo ratings yet

- Pastors Sunday MessageDocument4 pagesPastors Sunday MessageDiana Janica Magalong100% (1)

- THE PHILIPPINE JUDICIAL SYSTEM: PRE-SPANISH AND SPANISH PERIODDocument17 pagesTHE PHILIPPINE JUDICIAL SYSTEM: PRE-SPANISH AND SPANISH PERIODFranchesca Revello100% (1)

- Destined To ReignDocument7 pagesDestined To ReignMichael B. BolotaoloNo ratings yet

- Communication Process Quiz AnswersDocument3 pagesCommunication Process Quiz AnswersAbigail CullaNo ratings yet

- HTTPDocument40 pagesHTTPDherick RaleighNo ratings yet

- TPADocument9 pagesTPAAli ShahNo ratings yet

- 320 Lecture 26Document8 pages320 Lecture 26marcelofilgueirasNo ratings yet

- Positive Efefcts of Extra Curricular ActivitiesDocument6 pagesPositive Efefcts of Extra Curricular Activitiesamira ashariNo ratings yet

- Advertising and Promotion An Integrated Marketing Communications Perspective 11Th Edition Belch Solutions Manual Full Chapter PDFDocument36 pagesAdvertising and Promotion An Integrated Marketing Communications Perspective 11Th Edition Belch Solutions Manual Full Chapter PDFjames.graven613100% (13)

- Workshop 3-6: RCS of A Cube: Introduction To ANSYS HFSSDocument11 pagesWorkshop 3-6: RCS of A Cube: Introduction To ANSYS HFSSRicardo MichelinNo ratings yet

- Beginners Guide To Sketching Chapter 06Document30 pagesBeginners Guide To Sketching Chapter 06renzo alfaroNo ratings yet

- Graduation SpeechesDocument9 pagesGraduation SpeechesSeun IsraelNo ratings yet

- Bai Tap LonDocument10 pagesBai Tap LonMyNguyenNo ratings yet

- Y3 Module 1 QuizDocument6 pagesY3 Module 1 QuizMohd HattaNo ratings yet

- Dilkeswar PDFDocument21 pagesDilkeswar PDFDilkeshwar PandeyNo ratings yet

- Albelda - MechanicsDocument19 pagesAlbelda - MechanicsPrince SanjiNo ratings yet

- Back Order ProcessDocument11 pagesBack Order ProcessManiJyotiNo ratings yet

- 2015 International Qualifications UCA RecognitionDocument103 pages2015 International Qualifications UCA RecognitionRodica Ioana BandilaNo ratings yet