Professional Documents

Culture Documents

SCADA

Uploaded by

Asif Ali ShaikOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCADA

Uploaded by

Asif Ali ShaikCopyright:

Available Formats

SCADA

Shaik.Asif Ali, ANUCET, GUNTUR asif_jin2002@yahoo.com , Cell: 9290232915 A.S.S.Raghuram. ANUCET, GUNTUR raghuram_ammavajjala@yahoo.com. Cell: 9494213096

CONTENTS: -ABSTRACT -INTRODUCTION

-SCADA SUBSYSTEMS

-SYSTEM CONCEPTS -COMMUNICATION INFRASTRUCTURE AND METHODS -SCADA ARCHITECTURES -TRENDS IN SCADA -SUPERVISION VS SCADA -ADVANTAGES -DISADVANTAGES -CONCLUSION

Abstract SCADA is an acronym that stands for Supervisory Control and Data Acquisition. SCADA refers to a system that collects data from various sensors at a factory, plant or in other remote locations and then sends this data to a central computer which then manages and controls the data. SCADA is a term that is used broadly to portray control and management solutions in a wide range of industries. Some of the industries where SCADA is used are Water Management Systems, Electric Power, Traffic Signals, Mass Transit Systems, Environmental Control Systems, and Manufacturing Systems. There are many parts of a working SCADA system. A SCADA system usually includes signal hardware (input and output), controllers, networks, user interface (HMI), communications equipment and software. All together, the term SCADA refers to the entire central system. The central system usually monitors data from various sensors that are either in close proximity or off site (sometimes miles away). For the most part, the brains of a SCADA system are performed by the Remote Terminal Units (sometimes referred to as the RTU). The Remote Terminal Units consists of a programmable logic converter. The RTU are usually set to specific requirements, however, most RTU allow human intervention, for instance, in a factory setting, the RTU might control the setting of a conveyer belt, and the speed can be changed or overridden at any time by human intervention. In addition, any changes or errors are usually automatically logged for and/or displayed. Most often, a SCADA system will monitor and make slight changes to function optimally; SCADA systems are considered closed loop systems and run with relatively little human intervention. One of key processes of SCADA is the ability to monitor an entire system in real time. This is facilitated by data acquisitions including meter reading, checking statuses of sensors, etc that are communicated at regular intervals depending on the system. Besides the data being used by the RTU, it is also displayed to a human that is able to interface with the system to override settings or make changes when necessary. SCADA can be seen as a system with many data elements called points. Usually each point is a monitor or sensor. Usually points can be either hard or soft. A hard data point can be an actual monitor; a soft point can be seen as an application or software calculation. Data elements from hard and soft points are usually always recorded and logged to create a time stamp or history.

INTRODUCTION: SCADA stands for supervisory control and data acquisition. It generally refers to an industrial control system: a computer system monitoring and controlling a process. The process can be industrial, infrastructure or facility-based such as : Industrial processes include those of manufacturing, production, power generation, fabrication, and refining , Infrastructure processes may be public or private, and include water treatment and distribution, wastewater collection and treatment, oil and gas pipeline. Facility processes occur both in public facilities and private ones, including buildings, airports, ships, and space stations. They monitor and control HVAC, access, and energy consumption.

SCADA SUBSYSTEMS: A SCADA's System usually consists of the following subsystems:

and sending commands (control) to the process. Remote Terminal Unit (RTUs) connecting to sensors in the process, converting sensor signals to digital data and sending digital data to the supervisory system.

A Human-Machine Interface or HMI is the apparatus which presents process data to a human operator, and through this, the human operator monitors and controls the process. A supervisory (computer) system, gathering (acquiring) data on the process

Programmable Logic Controller (PLCs) used as field devices because they are more economical, versatile, flexible, and configurable than special-purpose RTUs.

Communication infrastructure connecting the supervisory system to

the Remote Terminal Units.

HUMAN-MACHINE INTERFACE A Human-Machine Interface or HMI is the apparatus which presents process data to a human operator, and through which the human operator controls the process. An HMI is usually linked to the SCADA system's databases and software programs, to provide trending, diagnostic data, and management information such as scheduled maintenance procedures, logistic information, detailed schematics for a particular sensor or machine, and expertsystem troubleshooting guides. The HMI system usually presents the information to the operating personnel graphically, in the form of a mimic diagram. This means that the operator can see a schematic representation of the plant being

controlled. For example, a picture of a pump connected to a pipe can show the operator that the pump is running and how much fluid it is pumping through the pipe at the moment. The operator can then switch the pump off. The HMI software will show the flow rate of the fluid in the pipe decrease in real time. Mimic diagrams may consist of line graphics and schematic symbols to represent process elements, or may consist of digital photographs of the process equipment overlain with animated symbols. Remote Terminal Unit (RTU) The RTU connects to physical equipment. Typically, an RTU converts the electrical signals from the equipment to digital values such as the open/closed status from a switch or a valve, or measurements such as

pressure, flow, voltage or current. By converting and sending these electrical signals out to equipment the RTU can control equipment, such as opening or closing a switch or a valve, or setting the speed of a pump. Supervisory Station The term "Supervisory Station" refers to the servers and software responsible for communicating with the field equipment (RTUs, PLCs, etc), and then to the HMI software running on workstations in the SYSTEM CONCEPTS: The term SCADA usually refers to centralized systems which monitors and controls entire sites, or complexes of systems spread out over large areas (anything between an industrial plant and a country). Most control actions are performed automatically by Remote Terminal Units ("RTUs") or by programmable logic controllers ("PLCs"). Host control functions are usually restricted to basic overriding or supervisory level intervention. For example, a PLC may control the flow of cooling water through part of an industrial process, but the SCADA system may allow operators to change the set points for the flow, and enable alarm conditions, such as loss of flow and high temperature, to be displayed and recorded. The feedback control loop passes through the RTU or PLC, while the SCADA system monitors the

control room, or elsewhere. In smaller SCADA systems, the master station may be composed of a single PC. In larger SCADA systems, the master station may include multiple servers, distributed software applications, and disaster recovery sites. To increase the integrity of the system the multiple servers will often be configured in a dual-redundant or hot-standby formation providing continuous control and monitoring in the event of a server failure.

overall performance of the loop.

Data acquisition begins at the RTU or PLC level and includes meter readings and equipment status reports that are communicated to SCADA as required. Data is then compiled and formatted in such a way that a control room operator using the

HMI can make supervisory decisions to adjust or override normal RTU (PLC) controls. Data may also be fed to a Historian, often built on a commodity Database Management System, to allow trending and other analytical auditing. SCADA systems typically implement a distributed database, commonly referred to as a tag database, which contains data elements called tags or points. A point represents a single input or output value monitored or controlled by the system. Points can be either "hard" or "soft". A hard point represents an actual input or output

within the system, while a soft point results from logic and math operations applied to other points. (Most implementations conceptually remove the distinction by making every property a "soft" point expression, which may, in the simplest case, equal a single hard point.) Points are normally stored as value-timestamp pairs: a value, and the timestamp when it was recorded or calculated. A series of valuetimestamp pairs gives the history of that point. It's also common to store additional metadata with tags, such as the path to a field device or PLC register, design time comments, and alarm information.

COMMUNICATION INFRASTRUCTURE AND METHODS: SCADA systems have traditionally used combinations of radio and direct serial or modem connections to meet communication requirements, although Ethernet and IP over SONET / SDH is also frequently used at large sites such as railways and power stations. The remote management or monitoring function of a SCADA system is often referred to as telemetry. This has also come under threat with some customers wanting SCADA data to travel over their pre-established corporate networks or to share the network with other applications. The legacy of the early lowbandwidth protocols remains, though. SCADA protocols are designed to be very

compact and many are designed to send information to the master station only when the master station polls the RTU. Typical legacy SCADA protocols include Modbus RTU, RP-570,Profibus and Conitel. These communication protocols are all SCADA-vendor specific but are widely adopted and used. Standard protocols are IEC 60870-5-101 or 104, IEC 61850 and DNP3. These communication protocols are standardized and recognized by all major SCADA vendors. Many of these protocols now contain extensions to operate over TCP/IP. It is good security engineering practice to avoid connecting SCADA systems to the Internet so the attack surface is reduced.

RTUs and other automatic controller devices were being developed before the advent of industry wide standards for interoperability. The result is that developers and their management created a multitude of control protocols. Among the larger vendors, there was also the incentive to create their own protocol to "lock in" their customer base. A list of automation protocols is being compiled here. Recently, OLE for Process Control (OPC) has become a widely accepted solution for intercommunicating different hardware and software, allowing communication even between devices originally not intended to

be part of an industrial network.

SCADA ARCHITECTURES: SCADA systems have evolved through 3 generations as follows: First generation: "Monolithic" In the first generation, computing was done by mainframe systems. Networks didnt exist at the time SCADA was developed. Thus SCADA systems were independent systems with no connectivity to other systems. Wide Area Networks were later designed by RTU vendors to communicate with the RTU. The communication protocols used were often proprietary at that time. The first-generation SCADA system was redundant since a back-up mainframe system was connected at the bus level and was used in the event of failure of the

primary mainframe system.

Second generation: "Distributed" The processing was distributed across multiple stations which were connected through a LAN and they shared information in real time. Each station was responsible for

a particular task thus making the size and cost of each station less than the one used in First Generation. The network protocols used were still mostly proprietary, which led to significant security problems for any SCADA system that received attention from a hacker. Since the protocols were proprietary, very few people beyond the developers and hackers knew enough to determine how secure a SCADA installation was. Since both parties had vested interests in keeping security issues quiet, the security of a SCADA installation was often badly overestimated, if it was considered at all.

environment. The SCADA system utilizes open standards and protocols, thus distributing functionality across a WAN rather than a LAN. It is easier to connect third party peripheral devices like printers, disk drives, and tape drives due to the use of open architecture. WAN protocols such as Internet Protocol (IP) are used for communication between the master station and communications equipment. Due to the usage of standard protocols and the fact that many networked SCADA systems are accessible from the Internet, the systems are potentially vulnerable to remote cyberattacks. On the other hand, the usage of standard protocols and security techniques means that standard security improvements are applicable to the SCADA systems, assuming they receive timely maintenance and updates.

Third generation: "Networked" These are the current generation SCADA systems which use open system architecture rather than a vendor-controlled proprietary

TRENDS IN SCADA: There is a trend for PLC and HMI/SCADA software to be more "mix-and-match". In the mid 1990s, the typical DAQ I/O manufacturer supplied equipment that communicated using proprietary protocols over a suitable-distance carrier like RS-485. End users who invested in a particular vendor's hardware solution often found themselves restricted to a limited choice of equipment when requirements changed (e.g. system expansions or performance improvement). To mitigate such problems, open communication protocols such as IEC IEC 60870-5-101 or 104, IEC 61850, DNP3 serial, and DNP3 LAN/WAN became increasingly popular among SCADA equipment manufacturers and solution providers alike. Open architecture SCADA systems enabled users to mix-and-match products from different vendors to develop solutions that were better than those that could be achieved when restricted to a single vendor's product offering. Towards the late 1990s, the shift towards open communications continued with individual I/O manufacturers as well, who adopted open message structures such as Modbus RTU and Modbus ASCII (originally both developed by Modicon) over RS-485. By 2000, most I/O makers offered completely open interfacing such as Modbus TCP over Ethernet and IP.

The North American Electric Reliability Corporation (NERC) has specified that electrical system data should be time-tagged to the nearest millisecond. Electrical system SCADA systems provide this Sequence of events recorder function, using Radio clocks to synchronize the RTU or distributed RTU clocks. SCADA systems are coming in line with standard networking technologies. Ethernet and TCP/IP based protocols are replacing the older proprietary standards. Although certain characteristics of frame-based network communication technology (determinism, synchronization, protocol selection, environment suitability) have restricted the adoption of Ethernet in a few specialized applications, the vast majority of markets have accepted Ethernet networks for HMI/SCADA. With the emergence of software as a service in the broader software industry, a few vendors have begun offering application specific SCADA systems hosted on remote platforms over the Internet. This removes the need to install and commission systems at the end-user's facility and takes advantage of security features already available in Internet technology, VPNs and SSL. Some concerns include security,[2] Internet connection reliability, and latency. SCADA systems are becoming increasingly ubiquitous. Thin clients, web portals, and web based products are gaining popularity with most major vendors. The

increased convenience of end users viewing their processes remotely introduces security considerations. While these considerations are already considered solved in other sectors of Internet services, not all entities responsible for deploying SCADA systems have understood the changes in accessibility and threat scope implicit in connecting a

system to the Internet.

SUPERVISION VS SCADA: There is, in several industries, considerable confusion over the differences between SCADA systems and distributed control systems (DCS). Generally speaking, a SCADA system usually refers to a system that coordinates, but does not control processes in real time. The discussion on real-time control is muddied somewhat by newer telecommunications technology, enabling reliable, low latency, high speed communications over wide areas. Most differences between SCADA and DCS are culturally determined and can usually be ignored. As communication infrastructures with higher capacity become available, the difference between SCADA and DCS will fade .

SUPERVISION

SCADA

ADVANTAGES: The computer can record and store a very large amount of data The data can be displayed in any way the user requires Thousands of sensors over a wide area can be connected to the system The operator can incorporate real data simulations into the system Many types of data can be collected from the RTUs The data can be viewed from anywhere, not just on site Increase Efficiency - Minimize Fault Response Time - Reduce Planned Downtimes - Isolate and Precisely Locate Faults Maximize Profitability - Reduce Failures / Unplanned Downtimes Life Time Maximize Safety - Public Safety - Site Safety - Reduce Operations Overhead - Reduce Manpower Requirement - Maximize (Achieve Expected) Equipment

DISADVANTAGES: The system is more complicated than the sensor to panel type Different operating skills are required, such as system analysts and programmer With thousands of sensors there is still a lot of wire to deal with The operator can see only as far as the PLC Communication between different computers is not easy, resulting in configuration problems Data processing and databases have to be duplicated across all computers in the system, resulting in low efficiencies There is no systematic approach to acquiring data from the plant devices if two

operators require the same data, the RTU is interrogated twice.

CONCLUSION: Todays SCADA systems are able to take advantage of the evolution from mainframe based to client/server architectures. These systems use common communications Protocols like Ethernet and TCP/IP to transmit data from the field to the central master control unit. SCADA protocols have also evolved from closed proprietary systems to an open System, allowing designers to choose equipment that can help them monitor their SCADA systems are widely used to monitor and control U.S. critical infrastructure utilities such as Electrical Power Plants and Water Distribution Centers SCADA systems, like other computer systems, are subject to many common securities Attacks such as viruses, denial of service, and hijacking of the system Because SCADA systems use leased telephone lines, twisted pair cable, microwave Radio, and spread spectrum techniques, they have many of the same security Vulnerabilities Unique system using equipment from variety of vendors While SCADA protocols are more open today, there is no clear consensus of which Protocol is best. IEC 60870-5 series and DNP3 have many similarities but are not 100% compatible. UCA 2.0, developed by EPRI, has been published by the IEEE as a Technical Report

and submitted to IEC for review. UCA is a new SCADA protocol that may replace

both DNP3 and IEC 60870-5.

REFERENCES: WWW.WIKIPEDIA.COM WWW.GOOGLE.COM WWW.BING.COM WWW.ASK.COM

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sangfor NGAF Introduction 8.0.5 FinalDocument24 pagesSangfor NGAF Introduction 8.0.5 FinalAlbarn Paul AlicanteNo ratings yet

- Database Testing: Prepared by Sujaritha MDocument21 pagesDatabase Testing: Prepared by Sujaritha Mavumaa22No ratings yet

- Turnitin Originality ReportDocument47 pagesTurnitin Originality ReportStillward Laud Mark-MillsNo ratings yet

- TranslationsDocument19 pagesTranslationsAnonymous eSi1iZTNGNo ratings yet

- New DatabaseDocument18 pagesNew DatabaseShafiq RosmanNo ratings yet

- Dbms Lab Manual-2013Document27 pagesDbms Lab Manual-2013Arham JainNo ratings yet

- Edtpa 2nd Lesson PlanDocument5 pagesEdtpa 2nd Lesson Planapi-297045693No ratings yet

- OC Thin Shell Panels SCREENDocument19 pagesOC Thin Shell Panels SCREENKushaal VirdiNo ratings yet

- RX-78GP03S Gundam - Dendrobium Stamen - Gundam WikiDocument5 pagesRX-78GP03S Gundam - Dendrobium Stamen - Gundam WikiMark AbNo ratings yet

- Requisites of MISDocument2 pagesRequisites of MISPrasanna Sharma67% (3)

- Eaturing: To Smaller Recording Performance Speakers: - The GuideDocument76 pagesEaturing: To Smaller Recording Performance Speakers: - The GuideMatthew WalkerNo ratings yet

- Project Goals/ ObjectivesDocument51 pagesProject Goals/ ObjectivesJoyce Abegail De PedroNo ratings yet

- CMP Tutorial PDFDocument83 pagesCMP Tutorial PDFMax HaroutunianNo ratings yet

- Domus Ventilation Guide 2019Document96 pagesDomus Ventilation Guide 2019Regie CayasNo ratings yet

- 103096-CG9-20AD IIDocument30 pages103096-CG9-20AD IICristian Eduardo Chavez GallardoNo ratings yet

- SFP Module PDFDocument2 pagesSFP Module PDFMario PatarroyoNo ratings yet

- LSZH Apch11 Rwy28 IlsDocument1 pageLSZH Apch11 Rwy28 Ilssamykarim2009No ratings yet

- VCEguide 300-360Document25 pagesVCEguide 300-360olam batorNo ratings yet

- Journal Approval WorkflowDocument46 pagesJournal Approval Workflowvarachartered283No ratings yet

- Hyperloop 170201003657Document29 pagesHyperloop 170201003657RafaelLazoPomaNo ratings yet

- Hi 8586pdiDocument9 pagesHi 8586pdiDunkMeNo ratings yet

- CE ThesisDocument210 pagesCE ThesisKristin ArgosinoNo ratings yet

- Coal JourneyDocument2 pagesCoal JourneyasnandyNo ratings yet

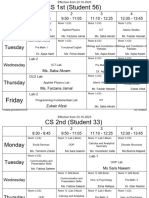

- 3b - Classwise Time Table - 2Document15 pages3b - Classwise Time Table - 2Hamza khalidNo ratings yet

- CS300.1 CS60.4 CS60.2: The Official Brand of Live MusicDocument8 pagesCS300.1 CS60.4 CS60.2: The Official Brand of Live MusicLuis RodriguezNo ratings yet

- Oracle9i Database Installation Guide Release 2 (9.2.0.1.0) For WindowsDocument274 pagesOracle9i Database Installation Guide Release 2 (9.2.0.1.0) For WindowsrameshkadamNo ratings yet

- A Research Submitted To: Student ResearchersDocument4 pagesA Research Submitted To: Student ResearchersDorothy Ann AllurinNo ratings yet

- Indian Standard: Stationary Valve Regulated Lead Acid Batteries - SpecificationDocument12 pagesIndian Standard: Stationary Valve Regulated Lead Acid Batteries - Specificationmukesh_kht1No ratings yet

- Electrical Design Checklist v1.2Document39 pagesElectrical Design Checklist v1.2huangjlNo ratings yet

- GCCDocument265 pagesGCCzhenguoliNo ratings yet