Professional Documents

Culture Documents

Elias Senbeto

Uploaded by

Bersumihret TerefeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elias Senbeto

Uploaded by

Bersumihret TerefeCopyright:

Available Formats

THE INCIDENCE DETERMINANTS

OF INJURIES

AND

THEIR FACTORY

IN AKAKI TEXTILE

A THESIS SUBMITTED TO THE STUDIES OF

SCHOOL OF GRADUATE ADDIS ABABA

UNIVERSITY

IN PARTIAL OF THE REQUIREMENTS MASTER

FULFILMENT FOR THE DEGREE OF

OF PUBLIC HEALTH

BY Elias Senbeto(MD)

March,

1991

ACDlOWLEDGKEN'l'S

I am indebted and Ato Gebremanuel

to my advisors Teka for

Dr. George. guidance

W . Olwit and the was

their

assistance

they provided

to me.

Or Joyce Pickering

also very helpful

in supporting

me with the analysis and

write up of the study. All staff of Addis Ababa University Department Project and the Mcill-Ethiopia community Health community support. Health I am

are also acknowledged to wIt Yemeserach

for their Ashenafi

also thankful manuscript.

for typing this

This investigation the International to the Department Addis

was funded throuogh Research

a grant from of Canada of with

Development of

Center

Community University

Health,

Faculty

Medicine,

Ababa

in collaboration Project.

the McGill-Ethiopia

Community

Health

TABLB OF CONTENTS

ACKNOWLEDGMENTS TABLE OF CONTEN'TS LIST OF TABLES

e _

i ii iii iv

LI ST OF FIGUR.ES

ABSTRAC'r INTRODUcrION HISTORY AND DEVELOPMENT OF THE AKAKI TEXTILE Working FAC'rORY Environment Services in the of the

v

1

3 Factory Factory 4 5

7

The Health

STATE OF KNOWLEDGE

OroECTIVE

13

H-ypothes is ....

ME'I'H.ODS study study

13

14 14 14

Design ...................................... Population .................................

Sample Size ...............................

ConsentandEthicalApproval Methods of Analysis

14 17

18 18 37 43

45

e

RES'ULTS DISCUSSION CONCLUSION AND RECOMMENDATIONS REFERENCES .ANNEXES

47

ABSTRACT

A descriptive and case control study was done to observe the incidence of injuries and their determinants in Akaki textile factory. There were a total of 143

accidents during the study period giving an incidence density of 200 per 1000 person years. This is very high

in comparison to developed countries. The most frequent cause of injury was machinery Most (29.4%), of the and hit

by/against objects occurred in the

(20.3%).

accidents 1000

Weaving

department

(109.2 per

exposed workers).

From our study, we found out that most (35.7%) and on Fridays

accidents occurred on Mondays

(17.5%). The most common time of accidents was from 8am to lOam. The most common parts of the body which were accidents were (13.3%). finger (42%), lower type leg of

affected by

(18.9%), hand

The most

frequent

accidents were prick bruise (16.8%). the interviewed

(32.9%), laceration (30.8%), and

From the result of our study, 87.4% of workers and were 86.1% not had wearing not personal safety

protective training.

devices

taken

1001 total man days was lost due to 143 More injuries

accidents over a period of 12 weeks.

occurred in those workers who were below the age of 30 years as compared to those above 30 year (p <.05), and more injuries occurred in those workers who were above 6~ grade (p<.05). Recommendations in how to reduce the rate of accidents are made.

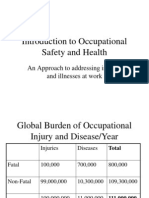

INTRODUCTIOIi In the developing countries, the function of

occupational health services in the place of employment is based on International Labour Organization No. 112 taking into account (ILO) their

recommendation

resources, as well as special problems relating to those developing countries. The ILO recommendation No.112

recommends essential functions which must be carried out by occupational health emergency services on site such as: out

1.administering medical

treatment,

2.carrying

examinations prescribed by

national

laws or

regulations,

3. exercising surveillance

over hygiene

conditions in the undertaking (1). The occupational health service must play a part in applying the general principles of preventive medicine.

They should be active in the prevention and treatment of occupational diseases and injuries and should make

efforts to adapt the work to the man and the man to the job. When a developing country is entering a period of rapid industrialization, health service and welfare

conditions must be developed at the same speed as the industrialization. problems may arise. not developed Otherwise many serious health

If occupational health service are with industry during

together

industrialization, the industrial worker will have to

face the health problems relating not only to the general morbidity of the population but also those related to the

new occupation. The developing national health benefit of occupational is seen positive may be health service as on in a

countries level. The

locally impact

as well of

occupational in reduced injuries. and and of

service

locally

observed

morbidity

and lower frequency

of occupational

In addition worker

this also means fewer losses to employer of wage The losses

as there will be a reduction compensation is of great so costs. importance

decreased absenteeism labour, shortage

reduction

concerning where

skilled is a

especially of skilled

in countries

there

labour.

When industry is further developed and the country's labour force is gradually more and more engaged on the national at work

in factories,

some activity

level will for workers

often take place; starting with legislation protection.

These laws generally define minimum standard for the place of employment, often

of safety and health beginning

with factories. accidents and disease are costly, For

Occupational the community is constantly

as a whole, they represent growing and which affects

a burden which the standard involves of for of

living of everyone.

An occupational

injury

the worker temporary or permanent adverse consequences

an objective or sUbjective nature, at both the personal and occupational levels. Most of these consequences may The psychological

have repercussions on the family. impact of injuries cannot be ignored. In developing countries

like

Ethiopia,

the

experience in the practice limited.

of occupational health is

Records of occupational diseases and injuries

are lacking and the magnitude of this problem is not known. In this study, we have tried to identify the

incidence and risk factors associated with Akaki Textile Factory. 143 injuries were found.

injuries in

In the three months follow up, This cases were compared with The total number of

systematically selected controls. workers, who work

in the production process (excluding

adminstrative staff) during the study period were 3100. After results have been analyzed and interpreted,

recommendation were given. to the factory management.

HISTORY AND DEVELOPMENT OP THE AKAKI TEXTILE PACTORY

Textile Factories in Ethiopia were mainly developed in Ethiopia between 1950 and 1970. Akaki Textile mill

was founded in 1958 as a Joint-venture between Ethiopian and Indian share holders and was called originally the Indo - Ethiopian Textile share company. After the 1974

revolution, the company was nationalised and is now under the control of the National Textiles Corporation of

Ethiopia. after the

The plant is the second biggest in the country textile mills of Diredawa. It is situated

20kms south of Addis Ababa. plant was designed of Addis to

From the very beginning this the basic needs of the areas,

satisfy

population with

Ababa,

and the neighbouring

cheap grey, fabrics. The plant had of the been managed solely quantity by the Indians of

wi th

the

target After

producing revolution

regardless

quality. increased figures figures

production

gradually Br. (These

from 40.9 mill

Br. to 88.3 mill for inflation. The final

are not corrected are not available)

The corrected products of the

factory are combed yarn for knitwear, income consumer, bleached and dyed

grey fabric for low fabrics for general canvas

consumptions

(drill, poplin,

Mohammedi),

towels,

and cotton blankets. Working Environment in the Factory corrugated iron with

The roof is made of galvanized a rather thin gauge damaged water access cleaning which has (32 gauge). led to leaks. mills.

It is widely rusted and During There rainy season free and

overflows

inside

the

is no

to the roof difficult.

which

makes

regular

inspection

The floor of the factory is composed base. However the

of concrete

slab laid on a compacted

floor slab is severely for movement

damaged in parts and causes hazard accidents.

and invites

Accoring consumption which, plant. of

to the factory is 2000 m3 per

sanitarian day

, present

water

of river water

.Out of

only 1000 m3 flows through

the effluent treatmen~

The rest runs out on to the ground, forming pools which are likely to be breeding sites for

water,

malaria

transmitting of the

mosquitos. (15). in the spinning mill are laden 2

Most with years dust ago

areas

and waste.According

to a study done in carding,

about

(1988) by a French group, the dust concentration concentration

drawing

and spinning, permissible

exceeds the maximum for cotton

at the work place

dust which is 1.5 milligrams/cubic concentration 1. is due to : which

metre. (16). This dust

The air conditioner capacity

is running only at a low of a compressor. in different and therefore sections covered

due to the collapse

2.

Outlets of the return channel are not cleaned regularly

with a thick layer of fine dust. 3. The bad floor conditions the accumulation The Health Services which have contributed to

of dust and impurities of the Factory

in the air.

The factory well equiped

has one big clinic. pharmacy

The clinic and in-

has a

laboratory,

patient The in-

department patient

as well

as out patient has 20 beds. officer,

department.

department

The staff consist of one 5 nurses, and 10 health

physician,

one health

assistants,

one lab-technician 1989 record

and one sanitarian. factory clinic, the

From the total 1354.

of the

number of workers who had accident In the same year 34,405 Br.

in 1989 was for

were paid

insurance been lost

due to accident due to accidents. in the factory

and 6,107 working days have Accident is one of the top clinic. have no training on

ten diseases The

health

personnel

occupational health. health trained service, by the

In order to promote the occupational factory about health personnel must be

experts

preventi ve,

promotive,

rehabiltative

aspect of health.

REFERENCES

1.

Andreoni D,1986, occupational safety and health service Bulletin no.54.,Geneva.

2.

Wagmann DH, 1983, Occupational Health pp. 177 197, Washington D.C.

3.

Puraschotama S. 1975, Accident in Textile Factories Vol. 1. Bombay. p. 6. Preparatory and Spinning Process, India.

4.

Bohtio S.P, 1975, Accident in Textile Factory Finsching Process. Vol. III p. 6. India.Bombay.

5.

Ethiopian Ministry of Industry, 1985, Manpower and Development study. Addis Ababa.

6.

Abera Fulle, 1988, Injuries in Urban Factories of Ketena One, Addis Ababa. Masters Thesis, Addis Ababa University.

7.

Kitaw Demessie, 1988, Occurrence and Determinants of Accident in Assab Port. Ababa University. Masters Thesis, Addis

8.

Womans Bureau Bulletin, 1975, Accident prevention and Safety Training. Washington DC.

9.

Dira Dawa Textile Factory, Survey by Accident Prevention Section, 1988/89. Ministry of Industry.

10.

Henrich, H.W., 1980 Industrial Accident Prevention. New York.

11.

Muraschetty. Factories.

M. 1975, Accidents Bombay, India.

in Indian Textile

12.

International Prevention,

Labour Organization, A Worker Education

1983, Accident Manual. Geneva. (3M

13.

Gremaldi,

J.V. 1975.

Safety

Management

edition) .Sweden. 14. Larson TJ, 1990, Accident Priorities 15. Annual Information and IPSO.

or Injury Prevention, of Akaki textile

Stockholm, factory,

report

1989,

Addis Ababa, Ministry 16.

of Industry

(Unpublished). of Akaki Textile

Petr L., Study on Rehabilitation Factory, 1988. Addis Ababa,

unpublished

manuscript. 17. Ministry of Labour and Social Affairs, Health lLO, MOH, Department of

Addis Ababa University (Joint Conference), Occupational 18. Human Health of Health, 19. NIOSH, Surface 20. Health

Community

1983, Fundamentals and Hygiene,

Addis Ababa. 1976, Department California. of Work

and the Environment, and Welfare,

Education

1976, Collection accident.

and Analysis Washington

D.C.

Barbara A, 1988, Fundamental hygiene, Chicago. IC 1977, Worker D.C.

of industrial

21.

Greenberg Washington

and their Tools,

You might also like

- Occupational hazards study of Assiut spinning factoryDocument14 pagesOccupational hazards study of Assiut spinning factoryGaoudam NatarajanNo ratings yet

- Prevalence and Associated Factors With Work Related Injuries Among Workers in Etab Soap and DeteregentDocument8 pagesPrevalence and Associated Factors With Work Related Injuries Among Workers in Etab Soap and DeteregentAnonymous 3G8yot4No ratings yet

- Chapter 1-Occupetional Health and SafetyDocument19 pagesChapter 1-Occupetional Health and SafetyOmit Mehfuz100% (2)

- Chapter 1 Textile IndustryDocument9 pagesChapter 1 Textile IndustryAlice ChepkuruiNo ratings yet

- Hazard in RMG SectorDocument6 pagesHazard in RMG SectorNafees Imtiaz AhmedNo ratings yet

- LN Occ Health Safety Final PDFDocument249 pagesLN Occ Health Safety Final PDFDeng Manyuon Sr.No ratings yet

- LN Occ Health Safety Final PDFDocument249 pagesLN Occ Health Safety Final PDFPablo RodriguezNo ratings yet

- LN Occ Health Safety Final PDFDocument249 pagesLN Occ Health Safety Final PDFDeng Manyuon Sr.No ratings yet

- LN Occ Health FinalDocument249 pagesLN Occ Health FinalDebasish MahapatraNo ratings yet

- Grupo 1Document5 pagesGrupo 1Luis Alberto Amaya TafurNo ratings yet

- Safety & Health Issue in Textile IndustryDocument4 pagesSafety & Health Issue in Textile Industrythongtn2007No ratings yet

- Slip, Trip, and Fall PreventionDocument56 pagesSlip, Trip, and Fall PreventionSagar TannaNo ratings yet

- 6507 With Cover Page v2Document9 pages6507 With Cover Page v220P438 - BALAJI V GNo ratings yet

- DR Rekha VyasDocument9 pagesDR Rekha Vyasapi-200677911100% (1)

- PSSJN Volume 9 Issue 1 Pages 330-352Document23 pagesPSSJN Volume 9 Issue 1 Pages 330-352Armela Quidilig LadoNo ratings yet

- Factors Affecting Safety in Construction SitesDocument5 pagesFactors Affecting Safety in Construction SitesShepherd Angel EhinomenNo ratings yet

- Occupational Safety and Health Risk Assessment of Workers in The Manufacturing IndustryDocument15 pagesOccupational Safety and Health Risk Assessment of Workers in The Manufacturing IndustryCj SesnorioNo ratings yet

- Ovisa Intan Auliya-205100107111038-OHS Summary PaperDocument2 pagesOvisa Intan Auliya-205100107111038-OHS Summary PaperOvisa Intan AuliyaNo ratings yet

- 4 Vijay Kumar ManwaniDocument5 pages4 Vijay Kumar Manwaniomkar bhagavat kavitakeNo ratings yet

- Health and Safety Hazard Caused by Textile Industry Ijariie6720Document5 pagesHealth and Safety Hazard Caused by Textile Industry Ijariie6720nikhil pawarNo ratings yet

- Occupational Health Hazards Among Garment Industry Workers in Unorganised Sector in TiruppurDocument5 pagesOccupational Health Hazards Among Garment Industry Workers in Unorganised Sector in TiruppurIJRASETPublicationsNo ratings yet

- Handbook of Ergonomic For The Clothing IndustryDocument69 pagesHandbook of Ergonomic For The Clothing IndustryGarmentLearner100% (1)

- Occupational Health Hazards Among Workers of Garment Factories in Dhaka City, BangladeshDocument8 pagesOccupational Health Hazards Among Workers of Garment Factories in Dhaka City, BangladeshReaz UddinNo ratings yet

- 2020 Article 8888Document10 pages2020 Article 8888Gebisa GuyasaNo ratings yet

- Case Study On Landfill SiteDocument15 pagesCase Study On Landfill SiteShankar PyakurelNo ratings yet

- Journal of AgromedicineDocument11 pagesJournal of Agromedicinesln_rjNo ratings yet

- SHE Issues in Power PlantsDocument5 pagesSHE Issues in Power PlantsUmar PatelNo ratings yet

- Impact of Pollution Generated by The Textile Industry On Health and EnvironmentDocument17 pagesImpact of Pollution Generated by The Textile Industry On Health and EnvironmentJakir Hossain TonyNo ratings yet

- Work Related Injuries and Associated Factors Among Small Scale Industry Workers of Mizan-Aman Town, Bench Maji Zone, Southwest EthiopiaDocument9 pagesWork Related Injuries and Associated Factors Among Small Scale Industry Workers of Mizan-Aman Town, Bench Maji Zone, Southwest EthiopiaaamichoNo ratings yet

- Automotive Preventive Measures Among TVL StudentsDocument22 pagesAutomotive Preventive Measures Among TVL StudentsKevan jaymes KatipunanNo ratings yet

- Construction Occupational Safety and HealthDocument22 pagesConstruction Occupational Safety and HealthMichaella Corine GonzalesNo ratings yet

- OSHADocument17 pagesOSHAMohamad IzzuanNo ratings yet

- Cong DATDocument4 pagesCong DATAhmad AshNo ratings yet

- Assessment of Needle Stick and Sharp Injuries Among Health Care Workers in Central Zone of Tigray, Northern EthiopiaDocument6 pagesAssessment of Needle Stick and Sharp Injuries Among Health Care Workers in Central Zone of Tigray, Northern Ethiopiashofia andriNo ratings yet

- Theses EthicsDocument5 pagesTheses EthicsBikash HalderNo ratings yet

- ThiNguyen TextileandApparelSustainabilityPaperDocument8 pagesThiNguyen TextileandApparelSustainabilityPaperKARMA NEGINo ratings yet

- Literature ReviewDocument8 pagesLiterature ReviewDada GbadeboNo ratings yet

- Awareness of Construction Workers On Occupational Hazards, Illness and Injuries Associated With Construction Industry in Mombasa CountyDocument8 pagesAwareness of Construction Workers On Occupational Hazards, Illness and Injuries Associated With Construction Industry in Mombasa CountyIOSRjournalNo ratings yet

- QuestionnaireDocument43 pagesQuestionnaireGracie O. Ching50% (2)

- Occupational Hazards and Risk Management in Nursing PracticeDocument27 pagesOccupational Hazards and Risk Management in Nursing PracticeMelly SumardiNo ratings yet

- DR Meenu Shrivastava-Protective Clothing For Farm Women To Eliminate Health HazardsDocument18 pagesDR Meenu Shrivastava-Protective Clothing For Farm Women To Eliminate Health Hazardsapi-200677911No ratings yet

- Status of Occupational Safety and Health in Rice Milling FINALDocument27 pagesStatus of Occupational Safety and Health in Rice Milling FINALAyon80% (5)

- Thesis On Occupational Health and Safety PDFDocument5 pagesThesis On Occupational Health and Safety PDFicatryhig100% (2)

- Project Submitted in Partial Fulfillment of The Award of The Degree ofDocument94 pagesProject Submitted in Partial Fulfillment of The Award of The Degree ofAGDSAHGDSNo ratings yet

- 226-Article Text-495-1-10-20170314Document9 pages226-Article Text-495-1-10-20170314Lillyandra PobelaNo ratings yet

- Cotton Dust Exposure and Self-Reported Respiratory Symptoms Among Textile Factory Workers in Northwest Ethiopia: A Comparative Cross-Sectional StudyDocument7 pagesCotton Dust Exposure and Self-Reported Respiratory Symptoms Among Textile Factory Workers in Northwest Ethiopia: A Comparative Cross-Sectional StudyAlvaro AlmendrasNo ratings yet

- Nursing Management of Patients With Occupational DisordersDocument100 pagesNursing Management of Patients With Occupational DisordersNandini VermaNo ratings yet

- Research Protocol 05.03.11Document19 pagesResearch Protocol 05.03.11Zahidul Alam RonnieNo ratings yet

- A General Overview On Occupational Health and Safety and Occupational Disease SubjectsDocument6 pagesA General Overview On Occupational Health and Safety and Occupational Disease SubjectsArdhia PramestiNo ratings yet

- Protecting Workers' Health and SafetyDocument3 pagesProtecting Workers' Health and SafetyLucy NaavaNo ratings yet

- Introduction To OH-SDocument20 pagesIntroduction To OH-SamalfarhanaadenanNo ratings yet

- Occupational Health Hazards Among Textile WorkersDocument9 pagesOccupational Health Hazards Among Textile WorkersINSTITUTE OF LEGAL EDUCATIONNo ratings yet

- LN Solid Haz Waste FinalDocument120 pagesLN Solid Haz Waste FinalMukesh GuptaNo ratings yet

- Major ProjectDocument10 pagesMajor ProjectKareemulla ShaikNo ratings yet

- Environment Is Everything That Is Around Us. It Can Be Living or Nonliving Things. It Includes PhysicalDocument3 pagesEnvironment Is Everything That Is Around Us. It Can Be Living or Nonliving Things. It Includes PhysicalNakanakanaknakNo ratings yet

- Treatment of Infectious BMW - Ishita - 1Document33 pagesTreatment of Infectious BMW - Ishita - 1Ishita KhazanchiNo ratings yet

- Addis Ababa Science and Technology University (AASTU)Document24 pagesAddis Ababa Science and Technology University (AASTU)Wasihun DanielNo ratings yet

- Noise Induced Hearing Loss in Manufacturing Industries: How Much Does It Cost to the Workers, Families and Society?From EverandNoise Induced Hearing Loss in Manufacturing Industries: How Much Does It Cost to the Workers, Families and Society?No ratings yet

- The Checklist Manifesto (Review and Analysis of Gawande's Book)From EverandThe Checklist Manifesto (Review and Analysis of Gawande's Book)No ratings yet

- Solomon DemamuDocument7 pagesSolomon DemamuBersumihret TerefeNo ratings yet

- Elias SenbetoDocument12 pagesElias SenbetoBersumihret TerefeNo ratings yet

- Mussie Gebremichael NegeriDocument88 pagesMussie Gebremichael NegeriBersumihret TerefeNo ratings yet

- Zufan HadisDocument13 pagesZufan HadisBersumihret TerefeNo ratings yet

- Aberra FulleDocument13 pagesAberra FulleBersumihret TerefeNo ratings yet

- Yitagesu Habtu Aweke PDFDocument77 pagesYitagesu Habtu Aweke PDFBersumihret TerefeNo ratings yet

- Taddele DessieDocument10 pagesTaddele DessieBersumihret TerefeNo ratings yet

- Kitaw DemissieDocument24 pagesKitaw DemissieBersumihret TerefeNo ratings yet