Professional Documents

Culture Documents

Technical data sheet for iron-base superalloy Type A286 (UNS S66286

Uploaded by

Jitendra SoniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical data sheet for iron-base superalloy Type A286 (UNS S66286

Uploaded by

Jitendra SoniCopyright:

Available Formats

Ferguson Metals

Specialist in Specialty Metals

Technical Data

Ferguson Metals, Inc.

u

Hamilton, Ohio

Iron-Base Superalloy Type A286 (UNS Designation S66286)

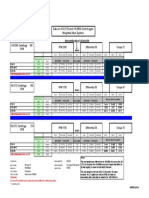

LINEAR COEFFICIENT OF THERMAL EXPANSION

Tests Conducted on Solution Treated and Aged Material

Linear Coefficients of Thermal Expansion (Units of 10-6) /C /F 16.5 9.17 16.8 9.35 17.0 9.47 17.4 9.64 17.6 9.78 17.8 9.88 18.6 10.32

GENERAL PROPERTIES Type A286 alloy (S66286) is an iron-base superalloy useful for applications requiring high strength and corrosion resistance up to 1300F (704C) and for lower stress applications at higher temperatures. Type A286 alloy is a heat and corrosion resistant austenitic ironbase material which can be age hardened to a high strength level. The alloy is also used for low temperature applications requiring a ductile, non-magnetic high strength material at temperatures ranging from above room temperature down to at least -320F (-196C). The alloy may be used for moderate corrosion applications in aqueous solutions. Type A286 alloy can be produced by AOD refining or vacuum induction melting. Vacuum arc or electroslag remelting procedures may be used to further refine the material. Type A286 alloy is available in plate, sheet and strip. CHEMICAL COMPOSITION

Temperature Range C F 21-93 70-200 21-204 70-400 21-316 70-600 21-427 70-800 21-538 70-1000 21-649 70-1200 21-760 70-1400

THERMAL CONDUCTIVITY

Temperature Range C F 150 302 300 572 500 932 600 1112 W/m-K 15.1 17.8 21.8 23.9 Btu-ft/ft2-h-F 8.7 10.3 12.6 13.8

SPECIFIC HEAT

Joules/kg-K 420 Btu/lb/F 0.10

Typical Analysis

Element Carbon Manganese Phosphorus Sulfur Silicon Chromium Nickel Molybdenum Titanium Vanadium Aluminum Boron Iron Percent 0.08 max 2.00 max 0.025 max 0.025 max 1.00 max 13.50 - 16.00 24.00 - 27.00 1.00 - 1.50 1.90 - 2.35 0.10 - 0.50 0.35 max 0.003 - 0.010 Balance

MAGNETIC PERMEABILITY

Solution Treated Solution Treated and Aged 1.010 1.007

ELECTRICAL RESISTIVITY

Temperature Range C F 25 77 540 1004 650 1202 730 1346 815 1499 microhm-cm 91.0 115.6 118.8 120.1 122.4

RESISTANCE TO CORROSION AND OXIDATION Type A286 alloy content is similar in chromium, nickel, and molybdenum to some of the austenitic stainless steels. Consequently, A286 alloy possesses a level of aqueous corrosion resistance comparable to that of the austenitic stainless steels. In elevated temperature service, the level of corrosion resistance to atmospheres such as those encountered in jet engine applications is excellent to at least 1300F (704C). Oxidation resistance is high for continuous service up to 1500F (816C) and intermittent service up to 1800F (982C). PHYSICAL PROPERTIES Typical Values

Solution Treated Solution Treated and Aged 0.287lb./in3 7.94g/cm3 7.94 1370-1430C

MECHANICAL PROPERTIES Typical Short Time Tensile Properties as a Function of Temperature Type A286 alloy is formed most easily in the solution treated condition. Typical room temperature tensile properties of material solution treated at 1800F (982C) are shown below.

Yield Strength 40,000 psi (275 MPa)

Ultimate Tensile Strength 90,000 psi (620 MPa)

Elongation 40%

Density Specific Gravity Melting Range

0.286lb./in3 7.92g/cm3 7.92 2500-2600F

Data shown are typical, and should not be construed as maximum or minimum values for specification or for final design. Data on any particular piece of material may vary from those shown herein.

You might also like

- RADIATION SAFETY FUNDAMENTALSDocument69 pagesRADIATION SAFETY FUNDAMENTALSJay Lawson100% (1)

- Stavanger Tourist SpotDocument96 pagesStavanger Tourist Spotregupathi6413No ratings yet

- Interlloy 440C MartensiticDocument4 pagesInterlloy 440C MartensiticGuillaume BoyerNo ratings yet

- High Alloy Steel Data SheetsDocument60 pagesHigh Alloy Steel Data SheetsIr FankovicNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Calculus I CompleteDocument578 pagesCalculus I Completexenocid3r83% (6)

- Stress Corrosion CrackingDocument2 pagesStress Corrosion CrackingrenatobellarosaNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Materials Selection For Refineries and Associated FacilitiesDocument164 pagesMaterials Selection For Refineries and Associated Facilitiesqaisarabbas9002100% (20)

- College of Medicine & Health SciencesDocument56 pagesCollege of Medicine & Health SciencesMebratu DemessNo ratings yet

- The Making Shaping and Treating of SteelDocument198 pagesThe Making Shaping and Treating of SteelJitendra SoniNo ratings yet

- Deflection of BeamsDocument41 pagesDeflection of BeamsMubaaracq Meerasahib100% (3)

- Alloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelDocument2 pagesAlloy 310 Spec Sheet: Multi-Purpose Austenitic Heat Resistant Stainless SteelManoj PaneriNo ratings yet

- ST Stainless CatalogueDocument71 pagesST Stainless CatalogueBenjamin RattharojthakunNo ratings yet

- Thermowell SpecificationDocument1 pageThermowell SpecificationNAYEEMNo ratings yet

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingFrom EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingRating: 1 out of 5 stars1/5 (1)

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Macsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LDocument4 pagesMacsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LNirav PatelNo ratings yet

- Regenerative Medicine Manual ISSCA 2020 EnglishDocument21 pagesRegenerative Medicine Manual ISSCA 2020 EnglishDana MihutNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Boiler MaterialsDocument5 pagesBoiler MaterialsRavi ShankarNo ratings yet

- Cast Steel HandBookDocument93 pagesCast Steel HandBookAlexa Harper100% (1)

- 316LNDocument3 pages316LNGanesh KcNo ratings yet

- Hindu Succession Act 1956Document8 pagesHindu Succession Act 1956viratyuguNo ratings yet

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Document2 pagesSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.No ratings yet

- Grade 316 316LDocument9 pagesGrade 316 316LvsajuNo ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- Dislocation TheoryDocument37 pagesDislocation TheoryAbbireddy Siva Ganesh100% (1)

- Nakshatra Exaltation DebilitationDocument3 pagesNakshatra Exaltation DebilitationBhanu Pinnamaneni100% (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- LSS A286Document2 pagesLSS A286anhntran4850No ratings yet

- Chemical CompositionDocument6 pagesChemical CompositionAkbar DarmawansyahNo ratings yet

- Nickel Alloy 330 Resists Carburizing OxidizingDocument2 pagesNickel Alloy 330 Resists Carburizing OxidizingAA.KarandishNo ratings yet

- Stainless Steel Grade 310 (UNS S31000)Document3 pagesStainless Steel Grade 310 (UNS S31000)V BNo ratings yet

- Hoja de Especificaciones Del Acero T-410Document2 pagesHoja de Especificaciones Del Acero T-410cristobal_tl2277No ratings yet

- SS 304Document5 pagesSS 304Nirav PatelNo ratings yet

- Specs and properties of chromium-nickel stainless steel alloys 304, 304L, and 304HDocument8 pagesSpecs and properties of chromium-nickel stainless steel alloys 304, 304L, and 304HLuis Enrique Carreon TorresNo ratings yet

- Duplex Stainless Steel 329 Round Bars ManufacturerDocument2 pagesDuplex Stainless Steel 329 Round Bars Manufacturertien100% (1)

- Stainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)Document6 pagesStainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)ganmosesNo ratings yet

- High Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®Document2 pagesHigh Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®ivanoliveira3261No ratings yet

- SX 316 / 316L Technical DataDocument3 pagesSX 316 / 316L Technical DatavkmsNo ratings yet

- North American Stainless: Long Products Stainless Steel Grade SheetDocument8 pagesNorth American Stainless: Long Products Stainless Steel Grade Sheettejap314No ratings yet

- Stainless Steel - High Temperature ResistanceDocument6 pagesStainless Steel - High Temperature Resistancevenurao1No ratings yet

- Guide To Selection: Stainless SteelDocument3 pagesGuide To Selection: Stainless SteelElla ChanNo ratings yet

- Carpenter Stainless Custom 630 PDFDocument9 pagesCarpenter Stainless Custom 630 PDFGrafton MontgomeryNo ratings yet

- 1.4006 en PDFDocument2 pages1.4006 en PDFdiego.peinado8856No ratings yet

- Steel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesDocument93 pagesSteel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesjosemiguelzuNo ratings yet

- 25% Cr Heat Resistant Stainless Steel SIRIUS 314Document4 pages25% Cr Heat Resistant Stainless Steel SIRIUS 314Víctor SandovskyNo ratings yet

- UR35NDocument4 pagesUR35NricardodelatorreNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationswapneel_kulkarniNo ratings yet

- Thermowell Material SelectionDocument3 pagesThermowell Material SelectionJp NairNo ratings yet

- Datasheet-Sandvik-253-Ma-En-V2021-04-22 18 - 36 Version 1Document12 pagesDatasheet-Sandvik-253-Ma-En-V2021-04-22 18 - 36 Version 1FilipNo ratings yet

- Material BoilerDocument4 pagesMaterial BoilerAdi SeptiawanNo ratings yet

- 316 SS Data SheetDocument3 pages316 SS Data SheetellisforheroesNo ratings yet

- Vanguard Steel Product ManualDocument158 pagesVanguard Steel Product ManualRajaSekarsajjaNo ratings yet

- Metal-Sheathed Cable XACTPAKDocument9 pagesMetal-Sheathed Cable XACTPAKEliasNo ratings yet

- Sandvik 2re10Document7 pagesSandvik 2re10himan_chongiNo ratings yet

- Valve Materials Service.1 PDFDocument2 pagesValve Materials Service.1 PDFshaonaaNo ratings yet

- Materials Selection Considerations Thermal Process Equipment BestpracticesDocument8 pagesMaterials Selection Considerations Thermal Process Equipment BestpracticesMandeep SinghNo ratings yet

- API Self NotesDocument13 pagesAPI Self NotesOwais AlamNo ratings yet

- ST 321 SpecificationDocument2 pagesST 321 SpecificationEl BaranNo ratings yet

- 904L (Valbruna)Document2 pages904L (Valbruna)Claudia MmsNo ratings yet

- Damasteel Martensitic Damascus SteelDocument6 pagesDamasteel Martensitic Damascus SteelsurintanNo ratings yet

- Stavax ESRDocument13 pagesStavax ESRBalram JiNo ratings yet

- Duplex Stainless Steel EN 1.4460 PDFDocument2 pagesDuplex Stainless Steel EN 1.4460 PDFtienNo ratings yet

- Maths IDocument16 pagesMaths IPrateek SharmaNo ratings yet

- Bainite in SteelsDocument479 pagesBainite in SteelsCharlie Chong100% (7)

- Feyman Lectures On Physics Vol2Document536 pagesFeyman Lectures On Physics Vol2Jitendra SoniNo ratings yet

- HSA Amendment 2005Document5 pagesHSA Amendment 2005Subhojit SamontaNo ratings yet

- R & D Lit Survey ReportDocument8 pagesR & D Lit Survey ReportJitendra SoniNo ratings yet

- Dos and Donts of Poster PresentationDocument6 pagesDos and Donts of Poster Presentationapi-236564996No ratings yet

- Brochure Smart Income Protect v1Document12 pagesBrochure Smart Income Protect v1Jitendra SoniNo ratings yet

- Traditional ProposalDocument8 pagesTraditional ProposalJitendra SoniNo ratings yet

- Dubai - Wikipedia, The Free EncyclopediaDocument34 pagesDubai - Wikipedia, The Free EncyclopediaJitendra SoniNo ratings yet

- Metallographic Specimen Preparation Basics: by Donald C. Zipperian, Ph.D. Pace TechnologiesDocument14 pagesMetallographic Specimen Preparation Basics: by Donald C. Zipperian, Ph.D. Pace Technologiesrazor75apNo ratings yet

- Fatigue Consideration in DesignDocument9 pagesFatigue Consideration in DesignJitendra SoniNo ratings yet

- Heat Treatment EnglishDocument13 pagesHeat Treatment EnglishdhasdjNo ratings yet

- Dos and Donts of Poster PresentationDocument6 pagesDos and Donts of Poster Presentationapi-236564996No ratings yet

- IMRAD - G1 PepperDocument13 pagesIMRAD - G1 PepperRomero, Ken Angelo B.No ratings yet

- Thank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3Document3 pagesThank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3DhivyaNo ratings yet

- Shaw-Box Hoist - 700 Series Electric Wire Rope 10 To 25 Ton Manual PDFDocument68 pagesShaw-Box Hoist - 700 Series Electric Wire Rope 10 To 25 Ton Manual PDFMbalekelwa MpembeNo ratings yet

- Products and Services For Consumers: True / False QuestionsDocument65 pagesProducts and Services For Consumers: True / False QuestionsThúy HiềnNo ratings yet

- Manual Del GVMapper v3 3 PDFDocument102 pagesManual Del GVMapper v3 3 PDFguanatosNo ratings yet

- PDLAMMPS - made easy: An introductionDocument8 pagesPDLAMMPS - made easy: An introductionSaeed AbdNo ratings yet

- Nitocote WP DDocument4 pagesNitocote WP DdaragNo ratings yet

- CE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingDocument36 pagesCE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingCelil OrakNo ratings yet

- Absence Makes The Heart Grow FonderDocument27 pagesAbsence Makes The Heart Grow FondereljhunNo ratings yet

- Patient Positioning: Complete Guide For Nurses: Marjo S. Malabanan, R.N.,M.NDocument43 pagesPatient Positioning: Complete Guide For Nurses: Marjo S. Malabanan, R.N.,M.NMercy Anne EcatNo ratings yet

- Mfz-Odv065r15j DS 1-0-0 PDFDocument1 pageMfz-Odv065r15j DS 1-0-0 PDFelxsoonNo ratings yet

- Sony HCD-GTX999 PDFDocument86 pagesSony HCD-GTX999 PDFMarcosAlves100% (1)

- HS-2172 Vs HS-5500 Test ComparisonDocument1 pageHS-2172 Vs HS-5500 Test ComparisonRicardo VillarNo ratings yet

- National Gypsum Purple Book Fire Rated Assemblies in Commercial Construction 1189979Document106 pagesNational Gypsum Purple Book Fire Rated Assemblies in Commercial Construction 1189979alvychuNo ratings yet

- GERD – Definition, pathophysiology, epidemiology and diagnostic investigationsDocument132 pagesGERD – Definition, pathophysiology, epidemiology and diagnostic investigationsSorana VasilescuNo ratings yet

- Belden CatalogDocument24 pagesBelden CatalogMani MaranNo ratings yet

- History: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHDocument3 pagesHistory: Ludwig Hunger: About Us: Home - Ludwig Hunger GMBHPatrizio MassaroNo ratings yet

- BELL B40C - 872071-01 Section 2 EngineDocument38 pagesBELL B40C - 872071-01 Section 2 EngineALI AKBAR100% (1)

- Design of PID controllersDocument4 pagesDesign of PID controllersFseha GetahunNo ratings yet

- The Quill Vol. LVIII Issue 1 1-12Document12 pagesThe Quill Vol. LVIII Issue 1 1-12Yves Lawrence Ivan OardeNo ratings yet

- QUESTION A2 and A3 Examples PDFDocument24 pagesQUESTION A2 and A3 Examples PDFDemian VeNo ratings yet

- Surface Hardening enDocument20 pagesSurface Hardening engtm1207No ratings yet

- EiaDocument14 pagesEiaRamir FamorcanNo ratings yet

- Advanced Radiographic Techniques PDFDocument21 pagesAdvanced Radiographic Techniques PDFelokfaiqNo ratings yet