Professional Documents

Culture Documents

Normativa de Durabilidad Del ACI y Su Impacto en La Normativa Latinoamericana (E)

Uploaded by

Carlos ArcilaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Normativa de Durabilidad Del ACI y Su Impacto en La Normativa Latinoamericana (E)

Uploaded by

Carlos ArcilaCopyright:

Available Formats

ACI Durability Standards and its impact in Latin America Summary The recommendations stated in ACI-318 have been

for many years the base for the standarization in most of the Latin American countries. In particular, many structural design codes have adopted the recommendations of this important document. By doing so, they have adopted, without a deep analysis of its convenience, the durability recommendations presented in the northamerican document, where some of the phenomena are specific for countries with marked seasons. This has two inmediate effects: ACIs recommendations have no application in the tropics, and secondly, common phenomena in the tropics do not get covered in the recommendations, which makes the document meaningless. It is a must that when adopting foreign standards, material engineers be invited to the discussion to establish any necessary actualization of the local standards with the aim of adapting them to the specific conditions of the point of use. Chapter 4 of the ACI-318-08 In several latin american countries the latest update of the referenced north american code was been expected inpatiantly, as based on it the local codes would be updated (for example the NSR10 in Colombia). Even for the material engineers, who considered that chapter 4 Durability requirements from ACI-318-05 was quite poor when applied its recommendations to tropical environments, the changes greatly announced, predicted a new way of confronting the durability specifications of structures in Latinamerica. The surprise was major as when analyzing the new material the only thing that was found was a different way of saying the same thing, and with the exception of a few valuable contributions, which will be mentioned later, instead of a progress in durability specifications actually the contrary was presented. Enough to just mention the introduction of the 17.5 MPa strength for some environments and exposure conditions, which does not make sense when the intention is to specify durability. To point out that in Europe, a vulnerable concrete presents strengths between 10 and 20 MPa, as shown in tables 1 and 2.

Carbonation damage Strength Level % of pozz. addition 10% pozzolan, Silica Fume or slag % of pozz. addition Chlorides Damage

Concrete Class

Durable

50 MPa

Resistant Normal Attackable

35-45 MPa 25-30 MPa 10-20 MPa

10% pozzolan or Silica Fume or slag 65% slag 10% pozzolan, Silica 10% pozzolan or Fume Silica Fume <15% slag 35% slag No restriction No restriction No restriction No restriction

Table 1. Classification of concrete with regard to risk of reinforcement corrosion

Damage caused by expansion Concrete Class Durable Strength Level C3A in anhydrous Cement 5% Pozzolans (%)

Damage caused by leakage Pozzolans (%)

50 MPa

Resistant Normal Attackable

35-45 MPa 25-30 MPa 10-20 MPa

5% 8% No restriction

20% pozzolan or 20% pozzolan or Silica Fume or slag Silica Fume or slag 65% slag 65% slag 10% pozzolan or 10% pozzolan or Silica Fume Silica Fume 35% slag 35% slag No restriction No restriction No restriction No restriction

Table 2. Classification of concretes with regard to the risk of deterioration due to expansion or lixiviation. On the other hand, being rigorous, it is necessary to clarify that the durability specifications by the ACI consider Northamerican conditions, with special climatic conditions and for the most common and serious structural attacks in that country, and not for other climatic conditions or other type of attacks more common in other countries. It cannot be expected that the ACI legislates for us. The problem lays with whoever adopts a foreign standard without the adequate analysis done by experts in materials and durability, where the need of a possible aclimatization or adaptation of a chapter gets defined, before putting it in use. It is also important to mention that in some countries these standards become local law, which makes its application mandatory and hence the importance that they are adequate for the local conditions, that they are applicable. It seems that in all latitudes there exists a division within the engineering between the experts in structural design and the experts in materials. Both have the same desire: to obtain resistant and durable structures. But there is nobody working to unite their efforts for a common target, and it is actualy rare that the structural experts invite the materials experts when discussing durability and when minimum requirements are being established to face the different types of exposition. Attacks suffered by reinforced concrete Let us observe in a graphical way the main internationally recognized attacks undergone by reinforced concrete structures:

Type of Attack

Chlorides Electrochemical

Carbonation

Sulfates pH (water, soil)

Chemicals Permeability (Humidity)

CO2,Ammonia, Magnesium ASR

Dry Residue

Freezing and Thawing

Physical

Abrasion

Figure 1: Main attacks undergone by reinforced concrete structures As can be seen, attacks can be group in those of electrochemical nature that lead to the well-known phenomena of corrosion, which has chemical and electrical components, those of net chemical origin and those of physical origin. Reviewing the types of exposition presented in chapter 4 of the ACI-318-08 standard and adjusting the previous outline, some coincide while others do not; let us see:

Figure 2: Types of exposure as from chapter 4 from the ACI-318-08 standard

A brief evaluation of this diagram immediately shows some differences. First, the ACI standard does not mention the effect of the attack by carbon dioxide, worldwide recognized as causing carbonation and responsible of the depassivation of the reinforcement in environments where the corrosion is not originated by salts. This includes all inland cities away from shores, industrial centers, and in any place where no deicing salts are used, like in our tropics.. When analyzing the type of exposure C from chapter 4 of the ACI-318-08 standard (Reinforced and prestressed concrete exposed to conditions that require special protection against corrosion), we realize that it only covers the attack by chlorides as shown in table 3. Excluding the attack due to carbonation, because it is less severe, would be like excluding shear stresses and consider only flexural ones. A second important difference is with regard to moisture. In many of the phenomena that cause deterioration of reinforced concrete structures, water is the vehicle that transports the ions (case of chlorides and sulfates), or it is an element without which the phenomena does not occur (corrosion, reactivity alkali-aggregate, expansion by sulfates, and even deterioration due to freeze-thaw). In figure 1, moisture appears covering all the common attacks, like a participating factor, and also as an essential element in some of them. And the goal of showing it as such is to make it clear that in order to produce structures resistant to many of these attacks, watertight or low-permeability structures are the first factor in order to obtain the required or specified service life. The same does not happen with the ACI-318-08 standard, where a separate category (P) of structures that would require to we watertight or not, which would lead a inexperienced specifier to

the conclusion that the other exposure conditions (freeze-thaw, chlorides, and sulfates for example) do not require a concrete resistant to the transport of water (in other words, impermeable). Now, reviewing the minimum requirements of the concrete for the type (P) exposure, the only specifications are the water/cement ratio and the strength, ignoring other factors not less important when producing a watertight concrete, like the use of reactive pozzolans (fly ash, slag and microsilica), and the air entrainment of the mix. Something similar happens with the type of exposure (C). Even though the use of pozzolanic additions is recommended, minimum addition levels are not specified, wasting this way the enormous power of these materials in the elaboration of concretes of low permeability to chlorides, and only water/cement and strengths are specified. Here it is important to remember that a series of mixes with the same water/cement ratio, and the same strength, but with different type of binder systems can produce very different results with respect to the passage of chloride ions, for example in the RCPT test (Rapid Chloride Permeability Test), governed by the ASTM C-1202-97 standard, and which measures the permeability towards chloride ions as a function of the charge in coulombs that passes through the specimen, as can be seen in Figure 3.

Charge passed (Coulomubs)

Water/cementious material

Figure 3. Results obtained with the RCPT for different mix designs with and without pozzolanic additions (2). Graph 3 shows not only the beneficial influence of pozzolanic additions when aiming for a concrete with lower chloride permeability, but also differences in performance between the available additions, and even that a ternary mix (cement + addition 1 + addition 2) can perform even better. This is the case of mixes, for example with a blend of cement, microsilica, and slag used as binder. It is important to clarify that a low permeability to chlorides is obtained when the passing charge is less than 2000 coulombs. This situation shows once again, the urgent need to start specifying performance when discussing durability of structures. Unfortunately, while the ACI does not take the initiative, and as in Europe, the specifiers of large projects stop including mix designs (which with the variety of cements and the usual moderate strength values of many projects, may or may not work) and start including performance values of

the concrete mixes that pretend to classify for a given project, not much will change. A decision of this type would be beneficial for both sides, as it would not only force the concrete producer to evaluate the performance of their products against common aggressors, but it would allow to extend the service life of infrastructure projects, which in many of our countries are already being subjected to rehabilitation processes even before 20 years of service, situation which is further negatively impacted due to the non-existence of project service-life requirements in the majority of important infrastructure projects in developing countries, like ours. Current situation of latin american countries with regard to durability standardization Those countries that follow literally the recommendations of chapter 4 of the ACI-318-08 standard will have an curious situation when trying to specify the durability requirements of structures away from marine environments, in particular when trying to extend the durability by stopping corrosion processes. A quick look to the types of exposure for an important structure located inland, in the tropics (for example a building with exposed concrete) would give the results shown in table 3.

Cate

S

Exposure Categorie Description Corrosion Sulfates Freezing + Thawing Permeability Exposure Class C0, C1 S0 F0 P0 Severity N/A, Moderate N/A N/A N/A

C S F P

Table 3: Types of exposure applicable as by ACI-318-08 for a structure with exposed concrete in inland regions. It is at least disturbing that the majority of the inland cities in many of our tropical countries, and even some beyond where winter is moderate and where there is no freezing, would have, based on the classification given in chapter 4 of the ACI-318-08 standard with a exposure class cero or maximum one, when analyzed based on exposure class (C) that judges the risk of corrosion. The result can be anticipated: the minimum requirements applicable to the concrete are really minimal. Minimal strength of 17.5 Mpa, any water/cement ratio (NA), additional requirements: none! It is important to remember that a concrete with a compressive strength of 17.5 Mpa has a water/cement ratio of the order of 0.8, which is a real sieve. Its porosity can easily reach 25%. And we ask ourselves, how can then, a structure with such requirements be durable, if we are practicly giving the contractor the freedom to do whatever he wants? What we expected to see in chapter 4 of the ACI-318-08 standard Some thoughts have been entertaining researchers in structural durability, which they would like to see reflected in a next, not update but rework of the chapter 4 of the ACI-318-08 standard. To redefine the calculation of the water/binder ratio. It is not possible to keep adding cement plus additions in the denominator (see 4.1.1 of the ACI Code), unless we are convinced that 1 kg of fly ash or slag is equivalent to 1 kg of Portland cement. The europeans calculate the water/binder ratio as: w/cm = water/ (cement+ kslag* slag weight + k fly Ash* Fly Ash weight)

Where K is the equivalency factor. While the k of the Fly ash and the slag vary between 0.4 and 0.7, the k of microsilica is of the order of 2. Prohibit once and for all the use of chloride containing admixtures. All admixture manufacturers already have accelerators innocuous to the reinforcing steel of the structures. Europe prohibited the use of chlorides over 20 years ago. To include carbonation as an depassivating element of the reinforcing steel and to generate minimum requirements to face it, which could start by limiting the use of reactive pozzolanic additions to 10% in concretes where the expected critical aggressor is carbon dioxide from the atmosphere. Bridges, silos, large structures with exposed concrete, etc., located in large cities or in industrial sites can be typical examples of this clase of exposure. To promote the use of larger cement quantities requiring larger strengths. The large majority of the concretes placed in structures in our latin american countries correspond to the 21 Mpa class. Currently they are manufactured with binder contents of 240 kg (cement + additions), based on the desire of the manufacturers to obtain one MPa of strength for each 10 kg of binder. A mix without cement is an anemic mix, with reference to durability, even when it complies with the required strengths level. Let us give the cement back to the concrete as it really benefits it.

Contribution of chapter C.4 of the ACI-318-08 standard Next, some progress of the new chapter 4 of theACI-318-08 standard that have to be recognized: Due to the unavailability of type V cement in some markets, the use of pozzolanic additions is stipulated to make a concrete resistant to sulfates, which uses them in certain dosages, besides a low water/cement ratio and high strengths. Typically levels of microsilica between 7 and 10%, or fly ash or slag around 30% are specified. It is important to note that the nature of the slag can result determining of a good or bad result in the control of expansion by sulfates. On the other hand, the recommendation of controlling the attack of sulfates by using reactive pozzolans results positive as it also controls the expansion caused by the Thaumasite, which can not be controlled by managing the C3A content of the cement. The inclusion of the table that relates the maximum expansions and the ages at which the expansions are evaluated when pozzolanic additions are used instead of using low C3A cements to control the expansion by sulfates, is quite useful.

Table 4. Expansion limits when puzzolanicadditions are used to control the attack by sulfates

BIBLIOGRAPHY 1. Helene, Paulo Roberto Do Lago, Proyectar para la durabilidad, publicacin del ACI, Captulo Colombia, 2001. 2. Howland, Juan Jos, Tecnologa de Hormigonado y Durabilidad, La Habana, 2005. 3. ACI 318-08 Cap 4 Durability Requirements

Author Carlos Arcila Lpez Civil Engineer from the National University of Colombia. Specialization courses in Rehabilitation and Structural Pathology in Instituto Eduardo Torroja (Spain). 25 years of experience in the field of concrete, particularly in the area of concrete structures durability. Member of the Colombian Concrete and Mortar Standardization Committee. Cathedra Professor at the Civil Engineering Department of Universidad Javeriana. He has work as consultant in the survey of more than 300 structures in Colombia and Caribbean countries. His principal research activities involve high performance concrete, durability specifications and the concrete corrosion and its control.

arcilacarlos@yahoo.es

You might also like

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Water Journal Desalination PlantsDocument8 pagesWater Journal Desalination PlantsfastreturnNo ratings yet

- Paper 11D01 Durability Design Li Zhou Chen TsinghuaDocument9 pagesPaper 11D01 Durability Design Li Zhou Chen TsinghuaHung NguyentheNo ratings yet

- Sea Bed Near - Google SearchDocument1 pageSea Bed Near - Google SearchBAWA ALEXNo ratings yet

- Unit 2Document51 pagesUnit 2153-B RAKSHITHANo ratings yet

- Aspects of The Durability of Conventional ConcreteDocument6 pagesAspects of The Durability of Conventional Concretemehdi_hoseineeNo ratings yet

- RILEM Proposals For Prevention of AARDocument12 pagesRILEM Proposals For Prevention of AARvnilNo ratings yet

- Sulphate Attack and Chloride PenetrationDocument8 pagesSulphate Attack and Chloride PenetrationMahmood MuftiNo ratings yet

- Is.456.2000 - Plain & Reinforced Concrete - Part7Document5 pagesIs.456.2000 - Plain & Reinforced Concrete - Part7pandey71087No ratings yet

- Paper 032 Durability Guidelines For Materials in SWRO Brine - FinalDocument13 pagesPaper 032 Durability Guidelines For Materials in SWRO Brine - FinalMaqsood Ibn Shaikhul ArfeenNo ratings yet

- Case Studies in Construction Materials: Sallal R. Abid, Ali N. Hilo, Nadheer S. Ayoob, Yasir H. DaekDocument17 pagesCase Studies in Construction Materials: Sallal R. Abid, Ali N. Hilo, Nadheer S. Ayoob, Yasir H. DaekKIM ElsaNo ratings yet

- Why Chemistry Matters in ConcreteDocument6 pagesWhy Chemistry Matters in Concreteyinglv100% (1)

- Durability of ConcreteDetail Discrition of Durability of ConcreteDocument34 pagesDurability of ConcreteDetail Discrition of Durability of ConcreteVinodh GbNo ratings yet

- How To Specify Concrete For Civil Engineering Structures Using BS 8500Document8 pagesHow To Specify Concrete For Civil Engineering Structures Using BS 8500simonralphNo ratings yet

- Why Matters in Concrete: ChemistryDocument6 pagesWhy Matters in Concrete: Chemistryjulianc08No ratings yet

- La Quimica Del ConcretoDocument7 pagesLa Quimica Del ConcretoDAVID EDUARDO GUZMAN ROJASNo ratings yet

- A Review of Concrete Corrosion InhibitorsDocument9 pagesA Review of Concrete Corrosion InhibitorsJohnNo ratings yet

- Future Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresDocument17 pagesFuture Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresSophia LiuNo ratings yet

- Technical Committees: Chloride Ions Can Penetrate Into The Concrete and CauseDocument4 pagesTechnical Committees: Chloride Ions Can Penetrate Into The Concrete and CauseTarek ChikerNo ratings yet

- Bertolini Performance Based Service Life Design of RC Structure in Chloride Environment Keynote Session A PDFDocument14 pagesBertolini Performance Based Service Life Design of RC Structure in Chloride Environment Keynote Session A PDFfdelfinNo ratings yet

- Visco-Elastic CoatingsDocument7 pagesVisco-Elastic CoatingsXiaohua ChenNo ratings yet

- Leemann y Loser - 2019 - Carbonation Resistance of Recycled Aggregate ConcrDocument21 pagesLeemann y Loser - 2019 - Carbonation Resistance of Recycled Aggregate Concrobra machupichuNo ratings yet

- Corcon Full Paper Dhanya in FormatDocument9 pagesCorcon Full Paper Dhanya in FormathuntNo ratings yet

- Cementitious Materials: High-Strength and High-Performance ConcreteDocument46 pagesCementitious Materials: High-Strength and High-Performance ConcreteLucian VoNo ratings yet

- Wastewater Treatment Plant Coating Systems-Selecting and SourcingDocument37 pagesWastewater Treatment Plant Coating Systems-Selecting and SourcingDonald Hamilton100% (1)

- Unit 8Document16 pagesUnit 8sandeep nandaNo ratings yet

- A Study of Carbonation in Concrete Structues in Marine EnvironmentDocument57 pagesA Study of Carbonation in Concrete Structues in Marine EnvironmentHaniAminNo ratings yet

- Reinforcement Corrosion - An OverviewDocument9 pagesReinforcement Corrosion - An OverviewraeggaemanNo ratings yet

- PCA Circular Tanks DesignDocument59 pagesPCA Circular Tanks Designjf59100% (1)

- A Comparison Between Chinese and British Standards For Concrete Exposed Environment in Durability Design of Concrete StructuresDocument10 pagesA Comparison Between Chinese and British Standards For Concrete Exposed Environment in Durability Design of Concrete StructuresDereje bedoreNo ratings yet

- Durability of High Performance Concrete in Relation To 'External' Chemical AttackDocument5 pagesDurability of High Performance Concrete in Relation To 'External' Chemical AttackGeraldNo ratings yet

- Corrosion Report PDFDocument22 pagesCorrosion Report PDFFong Wei Jun0% (1)

- Applied SciencesDocument29 pagesApplied Sciencesziko23No ratings yet

- Frost Resistance of Concrete Surfaces Coated With Waterproofing MaterialsDocument9 pagesFrost Resistance of Concrete Surfaces Coated With Waterproofing MaterialsAshfaq AhmedNo ratings yet

- Repair and Rehabilitation of Reinforced ConcreteDocument15 pagesRepair and Rehabilitation of Reinforced ConcreteebinVettuchirayil100% (2)

- Concrete Durability in A Marine EnvironmentDocument17 pagesConcrete Durability in A Marine EnvironmentAnonymous mcHqIfbnV1No ratings yet

- How To Use BS8500 With BS8110Document8 pagesHow To Use BS8500 With BS8110Marty AndersonNo ratings yet

- Index: Sr. No. Title Page NoDocument48 pagesIndex: Sr. No. Title Page NoajayNo ratings yet

- From The Science of Materials To The Engineering of Materials: Cements and ConcretesDocument3 pagesFrom The Science of Materials To The Engineering of Materials: Cements and ConcretesTarek ChikerNo ratings yet

- Mont CarloDocument15 pagesMont CarloalpegambarliNo ratings yet

- Cec 225 PDFDocument14 pagesCec 225 PDF8790922772No ratings yet

- NRMCA GuideToSelectingExposureClasses DURABILITYDocument10 pagesNRMCA GuideToSelectingExposureClasses DURABILITYosama anterNo ratings yet

- Selection of Materials For High Pressure CO2 Transport: Technical Knowledge Published PapersDocument15 pagesSelection of Materials For High Pressure CO2 Transport: Technical Knowledge Published PapersJohn DNo ratings yet

- Erosion Forms - Cavitation ErosionDocument5 pagesErosion Forms - Cavitation ErosionPPMNo ratings yet

- Question: 1 Discuss The Essential Differences and Similarities Between TheDocument13 pagesQuestion: 1 Discuss The Essential Differences and Similarities Between Thesimon maaaklaNo ratings yet

- Effect of Co2 Saturated Brine On The Conductivity of Wellbore-Cement FracturesDocument12 pagesEffect of Co2 Saturated Brine On The Conductivity of Wellbore-Cement FracturesHenry A. NorzaNo ratings yet

- 100032012Document8 pages100032012Nadim527No ratings yet

- Reinforced Concrete Problems and SolutionsDocument10 pagesReinforced Concrete Problems and SolutionsMuhammad Ahmad0% (1)

- Chemical Causes of Concrete Degradation: February 2018Document8 pagesChemical Causes of Concrete Degradation: February 2018Quinta EsenciaNo ratings yet

- Corrosion ReportDocument12 pagesCorrosion ReportismailNo ratings yet

- Industrial Floors 1Document3 pagesIndustrial Floors 1barouniamineNo ratings yet

- Durability of Concrete ArticleDocument2 pagesDurability of Concrete ArticleShahab SadeghpourNo ratings yet

- Design of Structures.hDocument95 pagesDesign of Structures.hAsiimwe Moses KasirikaNo ratings yet

- CG5042 - CHISOM NWOGBO - 19180691 - Corrosion Assignment 3Document3 pagesCG5042 - CHISOM NWOGBO - 19180691 - Corrosion Assignment 3Chisom ChubaNo ratings yet

- Concrete General GuidanceDocument23 pagesConcrete General GuidanceJasmine SmithNo ratings yet

- Durability of Concrete StructuresDocument28 pagesDurability of Concrete Structuresmanu_696No ratings yet

- PriyankaDocument10 pagesPriyankaDevashish JoshiNo ratings yet

- Corrosion Performance of Medium-Strength and Silica Fume High-Strength Reinforced Concrete in A Chloride SolutionDocument8 pagesCorrosion Performance of Medium-Strength and Silica Fume High-Strength Reinforced Concrete in A Chloride SolutionanupamrawalNo ratings yet

- Specifying For Use in Concrete: Fly AshDocument7 pagesSpecifying For Use in Concrete: Fly AshSanjay MurthyNo ratings yet

- Structural Standard Details: Construction NotesDocument4 pagesStructural Standard Details: Construction Notesjohn rey toledo100% (1)

- GRVE Catalogue-PipingDocument102 pagesGRVE Catalogue-PipinganishsrNo ratings yet

- Standard and Specifications Based On NSCP 2010 DeadloadsDocument7 pagesStandard and Specifications Based On NSCP 2010 DeadloadsIan Dave AdvinculaNo ratings yet

- CF 2Document2 pagesCF 2fk0205No ratings yet

- Your Dream Home Awaits!: Rera Web Site - WWW - Rera.wb - Gov.in Rera Registration No. - WBRERA/P/SOU/2023/000281Document30 pagesYour Dream Home Awaits!: Rera Web Site - WWW - Rera.wb - Gov.in Rera Registration No. - WBRERA/P/SOU/2023/000281discovernealNo ratings yet

- Phoenix Z10167Document2 pagesPhoenix Z10167Mohamed Sherif S MNo ratings yet

- BAR CHART - Pert - CPM SampleDocument2 pagesBAR CHART - Pert - CPM SampleLester Neil LomodNo ratings yet

- FoundationDocument48 pagesFoundationrenukaNo ratings yet

- Itp For STR Steel WorksDocument9 pagesItp For STR Steel WorksGauravSinghNo ratings yet

- BWG - Birmingham Wire GaugeDocument8 pagesBWG - Birmingham Wire GaugepurnawanNo ratings yet

- Internship Report MysoreDocument29 pagesInternship Report MysoreDhanush SNo ratings yet

- Soil: CDOT Class 1 Backfill-Drained: Material PropertiesDocument8 pagesSoil: CDOT Class 1 Backfill-Drained: Material PropertiesBraggyyy BarreraNo ratings yet

- Technical Topics: Allowable Depth-to-Width Ratios For Glulam BeamsDocument2 pagesTechnical Topics: Allowable Depth-to-Width Ratios For Glulam BeamsciviliiiNo ratings yet

- Series 44 45 4M DelVal HPButterfly ValvesDocument8 pagesSeries 44 45 4M DelVal HPButterfly ValvesProcess Controls & ServicesNo ratings yet

- Structural Design of A Reinforced Box Culvert PDFDocument33 pagesStructural Design of A Reinforced Box Culvert PDFRaja RajanNo ratings yet

- 14.gi Conduit BecDocument4 pages14.gi Conduit BeckailasamvvNo ratings yet

- Metode Kerja Umum PDA Test - 2021Document23 pagesMetode Kerja Umum PDA Test - 2021WannNo ratings yet

- Generador de Vapor PDFDocument14 pagesGenerador de Vapor PDFHector Dongo ArrayanNo ratings yet

- IDOT bd01 - 22x34Document1 pageIDOT bd01 - 22x34azsxdcfvgbNo ratings yet

- Pekerjaan Arsitek Gedung Farmasi: NO Unit Quantity Unit Cost (RP) Amount (RP) DescriptionDocument8 pagesPekerjaan Arsitek Gedung Farmasi: NO Unit Quantity Unit Cost (RP) Amount (RP) DescriptionAnan NurdinNo ratings yet

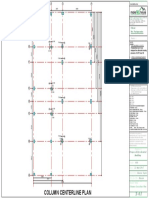

- 1 Column Centerline PlanDocument1 page1 Column Centerline PlanRhishikesh IngoleNo ratings yet

- Universiti Kuala Lumpur Malaysian Spanish Institute: Name: Mohamad Adib Fahmi Bin MahadzirDocument9 pagesUniversiti Kuala Lumpur Malaysian Spanish Institute: Name: Mohamad Adib Fahmi Bin MahadzirAizzat ZackNo ratings yet

- EN - DA 1700 Wall Fan MPR 20190722Document12 pagesEN - DA 1700 Wall Fan MPR 20190722Yutt WattNo ratings yet

- Piling BQDocument4 pagesPiling BQLeeZhengxian100% (1)

- Attachment B PDFDocument2 pagesAttachment B PDFThinh NguyenNo ratings yet

- Fuel Tank Ring Beam Design CalculationDocument11 pagesFuel Tank Ring Beam Design CalculationDawson Preethi EA94% (16)

- Zerowatt sx403Document16 pagesZerowatt sx403MaxNo ratings yet

- Embassy BoulevardDocument58 pagesEmbassy Boulevardbigdealsin14No ratings yet

- 20MCT0011 Da-1 CTSCCSDocument22 pages20MCT0011 Da-1 CTSCCSVishal SinghNo ratings yet

- Blurred Transparencies in Contemporary Glass Archi... - (PG 76 - 127)Document52 pagesBlurred Transparencies in Contemporary Glass Archi... - (PG 76 - 127)sherinshaji2002No ratings yet