Professional Documents

Culture Documents

Engineering Ethics: Chapter 8

Uploaded by

Ahmad ShdifatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Ethics: Chapter 8

Uploaded by

Ahmad ShdifatCopyright:

Available Formats

Hashemite university Industrial Engineering Department

By 1.Omran Al-Hajji 2. Ahmad Shdefat 3.Ahmad Abu Al Sailat 4.Yazzan Assaf

1

Most of the cases presented in engineering ethics studies are retrospective at disaster . These cases all have in common that the a bad thing happened for many reasons like: 1-A mistake was made in a design. 2-Illegal or immoral activity was being covered up. 3-A pressure were put on engineers to make bas decisions.

The purpose of these cases is to is to see what went wrong and to understand how to go about doing the right thing when faced with similar circumstance. The difference between the cases in this chapter and the previous cases that the cases involves in this chapter do not involve disasters, but rather are examples of things should be done in the first place to avoid disasters.

In the early 1970s, planning started for a new headquarter for Citicorp in Manhattan. The new building, to be called Citicorp centre, would take up an entire city block. One of the problems was a corner of the block was occupied by a church that had been built in 1905. in order to acquire the site, Citicorp agreed to demolish the old church and build a new freestanding church as a part of Citicorp centre .

Structural engineer William designed 59-story tower that was set on four large nine storyhigh columns. This arrangement allowed the church to be built beneath the tower, one corner of which was cantilevered over the church. Le Messurier designed a unique system of wind braces for the building calling 48 chevronshaped steel members welded together from the superstructure.

Four years after the Citicorp centre had been built, question from an engineering student led LeMessurier to look at his design. His new calculations showed that under some wind conditions, the forces that the braces had to withstand were about 40% larger than his original calculations had shown. This wouldnt have been a problem, since the factor of safety were presented.

also known as safety factor (SF), is a term describing the structural capacity of a system beyond the expected loads or actual loads. Essentially, how much stronger the system is than it usually needs to be for an intended load. Safety factors are often calculated using detailed analysis because comprehensive testing is impractical on many projects, such as bridges and buildings, but the structure's ability to carry load must be determined to a reasonable accuracy.

The reason for this that that the welded joints is the superstructure had been replaced with bolted joints. This replacement was done with the approval of engineers from LeMessuriers firm. Calculations and testing showed that his concerns were well founded and the bolted joints would be dangerously weak when the building was subjected to strong wind.

Meteorological records for New York indicated that a storm with sufficiently strong wind to tear the joints apart could be expected on average once every 16 years. LeMessurier quickly developed a plan to solve this problem. He felt that the joints could be secured by welding two-inch-thick steel plates over 200 of the joints. Of course, this solution would not be cheap, but it was essential.

As a first step, LeMessurier consulted with lawyers for his insurance company and for the projects architect. The chair of Citicorp Walter Wriston was very supportive of LeMessurier and decided that Citicorp had to work together with the engineer to ensure that the building would be safe. A firm was also hired to fit the building with gauges to measure the strain on the individual structural members, and meteorologists were hired to provide daily weather forecasting of expected winds.

Citicorp and the City of New York were able to keep the information gives to the press to a minimum, which meant that there would be no mass panic about the safety of the building. The welders were able to start the repairs immediately and worked at night to prevent disturbance tenants.

Work progressed seven days a week and was directed by LeMessurier. When completed, it was estimated that the building could withstand a storm that was expected only every 700 years. The total costs for the repairs were never revealed, but they exceeded $ 8 million. Citicorp didnt begin litigation until after the repairs had been made .

Suing LeMessurier and Stubbins to recover the repair costs. They settled for the $2 million that was the limit of LeMessuriers insurance.

Automobile fatalities increased in number during the early years of the car, and by the 1930s, most of the fatalities were the result of nighttime accidents. Paul Goodell, a streetlighting engineering with the General Illumination Engineering Company, put out a call for the development better automobile headlamps in 1935. This call led members of the Illumination Engineering Society to seek better designs and technology. Engineers and headlamp suppliers collaborated and, in 1939, introduced brighter, longer-lasting headlamps and head lighting standards into production. That headlamp design, called the sealed beam headlamp, lasted 40 years before newer technology superseded it.

Today, nobody worries about the quality of headlamps on automobiles. There are million of automobiles on the road equipped with headlamp that meet federal safety standers and provides excellent nighttime visibility for the driver. However, this was not always the case.

In the early days of the automobile, headlamps were often an unreliable and barely useful part of the vehicle. How unreliable they were became obvious in the early 1930s. By 1933, there were already 24 million motor vehicles operating on the highways in the United States, with over 31,000 fatalities and over 1 million injuries.

In 1920, 35% of fatalities occurred during nighttime driving, but this number had risen to 56% by 1933. In 1935, Paul Goodell, are street-lighting working for the General Illumination Engineering Company, wrote that visibility has become the weak link in traffic safety, and, as illuminating engineers, we must assume at least a portion of the responsibility in the improvement of traffic hazards

Here, we seeban engineer urging other engineers to take responsibility for improving the safety of cars, much as modern codes of ethics hold that safety is a paramount concern of the engineer. In fact, the Illumination Engineering Society (IES) in many ways led the way in developing and testing new designs and working with state and fedral regulators to set appropriate standards.

Headlamp

Light source

Reflectors

Lens

The basic components have remained the same since the invention of automotive lighting through today Early lamps erer housed in a metal box, originally designed to prevent the lamps from being extinguished.(They used oil or acetylene flames!). The box was later used to protect electric bulbs from damage.

Early reflectors were made of highly polished, silvered brass formed into a parabolic shape.

Early lenses were made of pressed glass and were used to direct the light in the appropriate direction.

( a study showed that light output was reduced by 60% in automobiles only six months old).

First: The silver on the reflector tarnished very easily, leading to diminished headlight intensity.

Second: Problem with the light bulb. The filament had to be located at the focus of the optical system with a very narrow tolerance or the light output would be diminished or misdirected.

By the mid-1930s, despite decades of effort, nearly all of the potential performance had been gotten out of the traditional lighting system with still an inadequate lighting situation on the roads.

Of course, there were many potential solutions to this problem that were being considered. Fixed lighting of highways was considered. This was a very expensive alternative, involving large uufront capital costs to install lighting along the thousands of miles of highway in the nation

This solution would involve high operating costs for electricity and maintaining the bulbs. It is much less expensive to mount a light on the automobile to driver illumination on demand, rather than to light a highway all night whether there are cars present or not.

Cities could justify such lighting where there is a relatively high traffic density, but highways outside the city were ( and still are!) another matter. Other options included severely limiting the amount of driving thet could be permitted at night, reducing nighttime speed limits to below 30 mph, or imposing large fines for improper maintenance of automotive lighting systems by the owner.

Any new, innovative design for headlamps was sure to be hard for the automobile manufacturers to introduce because during the depression the high costs of retooling would be very hard to recover.

In 1937, Val Roper, a research engineer at General Electric Companys Automotive Lighting Laboratory in Cleveland, spoke at a meeting of the IES. In his talk, he outlined the requirements for an improved lighting system: a higher wattage bulb; at least two beams, one for open road and the other for use when meeting another car to reduce glare; and the key point, a noticeable difference between the two beams to aid the driver in selecting the correct beam for the driving situation.

Roper could make these recommendations in part because he had been working on developing a brighter bulb already. The reason brighter bulbs could not be produced was that the filaments could not be sealed adequately. Bright bulbs, in which there was considerable heat generated, developed cracks due to high thermal expansion of the glass.

Cracks were especially a problem where the electrical leads entered the glass envelope. The only way to prevent cracking and the resulting bulb failure was to limit the bulbs light output, which reduced the amount of heat generated.

In 1935, Roper was working with another lamp inventor at GE, Daniel K. Wright, who had developed a means for placing seals at the point where the electrical leads passed through the glass for use in motion picture projector bulbs

His design also used borosilicate glass, which was harder than the glass previously used and had a lower coefficient of thermal expansion.

These innovations reduced bulb cracking and seemed perfect for application to automotive lamps.

Still, there was a need for improvement in the parabolic reflector. The GE re-search team could be coated with metal to make it reflective. The whole assembly would then be sealed from the outside environment, thus reducing the problems with tar- nishing of the reflector. The problem with this idea was that the technology didnt exist to make a glass surface to parabolic shape reliably.

The GE engineers con- sulted with Corning Glass Works about this problem. Coring was able to produce a parabolic, aluminized reflector that was more accurate than the conventional de- sign, with the design of an appropriate lens to add the front surface, the team had developed a far superior lamp[meese,19821]

Additional development of this design leading up to 1937 indicated that mass production of this type of headlight was technically feasible, but would be very difficult. It is important to recognize the economic context of this situation .

Although there was a huge potential market for such a lamp, there would be substantial extra costs involved . It was not obvious whether the production of this lamp would be financially feasible given the economic situation in the country at the time-the Depression was in full swing.

There was also a potential with GEs customers, the headlamp manuporation into their headlamps, this new technology made the headlight a single unit, which might have put these customers out of business, as well as for the chair of the Engineering Relations Committee of the society of Automotive Engineers (SAE) and representatives of Ford and General Motors.

Of course, this demonstration wasnt necessary, but seemed like the ethical choice, considering the revolutionary nature of the technology. It is interesting to note the names of the automotive light manufacturers present at this demonstration: Guide Lamp,C.M.Hall Company, and Corcoran Brown Company.

None of these companies exist today, an indication of how revolutionary the new technology was, As a result of this meeting, the Automobile Manufacturers 'Association set up a steering committee to note establish standards for headlight. In this context, it is interesting to note that GE was very generous in its customers and others in the use of its sealed beam patents. In fact, Allowed several manufacturers to consult with their engineers on the design.

While production was being geared up, work began on resolving questions of standardization and regulation of the new design. By 1939,the new standards had been adopted, and the work of the engineers was to help educate state and federal lawmakers who were charged with developing new regulatory strandards.

The new lawmakers who were charged with developing new regulatory standards. The new headlights were introduced in the fall of 1939, and improvements in automotive lighting and highway safety were realized almost immediately.

What are the ethical dimensions of this case ? GE could have kept this new technology strictly proprietary . But, realizing the potential for protecting the public safety, the engineers worked with GE management to make the technology as widely available as possible to all lighting and automobile manufacturers.

They also worked with regulators and those who developed engineering standards to ensure that this technology would be both accepted engineering practice and required by regulation as soon as possible.

The sealed beam lamp underwent some limited improvement and change during the 40 years after its introduction . However, a new type of design has since been developed in which a high- intensity , replaceable, sealed bulb is a separate component from the reflector and lens of the headlight assembly.

The technology to build these bulbs and to easily them while protecting the reflector from tarnish has been developed.

The type of ethical behavior demonstrated by GE in this case was echoed more recently when General Motors petitioned the national Highway traffic safety Administration (NHTSA) in 2001 to mandate daytime running lamps on all vehicles sold in the United States.

Daytime running lamps are low-intensity headlight that are illuminated whenever a vehicle is on. An NHTSA study has indicated that daytime running lamps reduce pedestrian fatalities by 28%,and GM studies show a reduction of 5% in accidents when daytime lamps are used.

These types of lighting systems are already mandatory in many European countries. GM estimates the cost of installing these systems at between $20 and $40 per vehicle. The federal government has still not required this for vehicles sold in the U.S.

Like the Citicorp case, this is an example of engineers doing the right and ethical thing up front and avoiding safety problems and other issues that would later occur. Some innovations that improve safety ought to be shared widely in an industry, even when it means loss of a competitive advantage.

This case illustrates what can be done when there is cooperation between industries, professional societies, and the government in trying to solve problem.

Since 1979, the National Highway Safety Administration (NHTSA) has conduced tests of automobiles and trucks sold in United States to determine how well they can withstand a collision. Most everyone is familiar with the NHTSA crash-testing methodology: Test dummies are strapped into a vehicle, and the vehicle is accelerated and crashed headlong into a barrier at 35 mph.

The NHTSA evaluates the tests for damage to the vehicle and for injury to the occupants. The data gathered in these experiments are used to help set standards and also to consumers make better choices regarding what vehicle to buy. A different automotive testing methodology has been developed by the Insurance Institute for Highway Safety (IIHS), a nonprofit research organization funded by automobile insurance companies.

Although the IIHS is funded by a consortium of insurers, it is not owned directly by any the insurers. The IIHs uses a different type of methodology to crash-test vehicles. Rather than a full frontal crash into a rigid barrier, the IIHS test use offset frontal crash test into a barrier that partially deforms during the collision, since most head-on crashes are offset rather than frontal.

It seems that this is a small point and that the result of two different two types of crash tests should be similar. However, in many cases the test results are very different. Some vehicles that earned the highest safety rating in the NHTSA tests failed miserably in the IIHS test and received the lowest rating.

You might also like

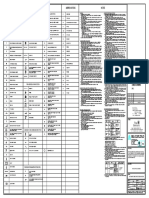

- Hvac General Notes Hvac Abbreviations Hvac Symbol LegendDocument10 pagesHvac General Notes Hvac Abbreviations Hvac Symbol LegendTeoxNo ratings yet

- L3 - Applied Engineering Code of EthicsDocument86 pagesL3 - Applied Engineering Code of EthicsShafiq MahadiNo ratings yet

- Part I General Principles of LightningDocument28 pagesPart I General Principles of LightningSuthaNo ratings yet

- Cable Schedule S/N Supply To Type Delivery Status Installation Status Remarks No - of Pair Single Length (M) Total Length (M)Document2 pagesCable Schedule S/N Supply To Type Delivery Status Installation Status Remarks No - of Pair Single Length (M) Total Length (M)Cheah ChenNo ratings yet

- Optimal Switching Times for Maximum PV Power DeliveryDocument4 pagesOptimal Switching Times for Maximum PV Power DeliveryMichael DillardNo ratings yet

- Installation Maintenance of Water Heater - ST - Updated PDFDocument17 pagesInstallation Maintenance of Water Heater - ST - Updated PDFHong Leong KuNo ratings yet

- EET301 Chapter 1Document43 pagesEET301 Chapter 1Lee Boon HongNo ratings yet

- Study Guide A - PPEDocument1 pageStudy Guide A - PPEjimNo ratings yet

- Introduction Signal & SystemDocument14 pagesIntroduction Signal & SystemmikrotonNo ratings yet

- 02 - IEM EC - Electrical Safety Seminar PDFDocument91 pages02 - IEM EC - Electrical Safety Seminar PDFredisme09No ratings yet

- Genset CalculationDocument1 pageGenset CalculationCheah ChenNo ratings yet

- Engineering Ethics: Chapter 7Document16 pagesEngineering Ethics: Chapter 7Ahmad ShdifatNo ratings yet

- CV3013 Tutoral 12 Q12,3Document4 pagesCV3013 Tutoral 12 Q12,3Steven KuaNo ratings yet

- P5 Draft Technical SpecificationDocument385 pagesP5 Draft Technical SpecificationScalperNo ratings yet

- Fixed Schedule of RatesDocument104 pagesFixed Schedule of RatesRohit KhuranaNo ratings yet

- Engineering Practice - Workplace Safety and Health 2016Document65 pagesEngineering Practice - Workplace Safety and Health 2016MiguelaTayNo ratings yet

- SPD Presentation - IPOH Dinner 300919-ShareDocument81 pagesSPD Presentation - IPOH Dinner 300919-ShareScalperNo ratings yet

- BS 5295 Part 0 1989 Enviro Cleanliness in Encl Spaces - Gen Intro Clean Rooms & Clean Air DevicesDocument10 pagesBS 5295 Part 0 1989 Enviro Cleanliness in Encl Spaces - Gen Intro Clean Rooms & Clean Air DevicesRamiAl-fuqahaNo ratings yet

- Electrical Codes PDFDocument16 pagesElectrical Codes PDFcosmin1991No ratings yet

- NUS EEE DC-DC Converter Lab ReportDocument19 pagesNUS EEE DC-DC Converter Lab ReportlionNo ratings yet

- GE LampsDocument174 pagesGE LampsAndri Mutiar100% (1)

- Module 1 - Part 01-2019Document44 pagesModule 1 - Part 01-2019Hifzhan RjNo ratings yet

- Sylvania Incandescent Willie Wiredhand 100w Lamps Brochure 1964Document2 pagesSylvania Incandescent Willie Wiredhand 100w Lamps Brochure 1964Alan MastersNo ratings yet

- Lithonia Downlighting Contractors Buyers Guide 1985Document62 pagesLithonia Downlighting Contractors Buyers Guide 1985Alan MastersNo ratings yet

- Malaysia Engineering Acts RegulationsDocument50 pagesMalaysia Engineering Acts RegulationsPrasanthRaoNo ratings yet

- Lithonia Fluorescent Contractor Price List 1984Document32 pagesLithonia Fluorescent Contractor Price List 1984Alan Masters100% (1)

- HOLOPHANE Lighting Fundamentals HL 862Document24 pagesHOLOPHANE Lighting Fundamentals HL 862georgel1980No ratings yet

- GE Lighting Systems Preferred Lighting Buyers Guide 1960Document28 pagesGE Lighting Systems Preferred Lighting Buyers Guide 1960Alan MastersNo ratings yet

- EE4532 Part A Lecture - pdf0Document83 pagesEE4532 Part A Lecture - pdf0Denise Isebella LeeNo ratings yet

- Legends Abbreviations Notes: Tender DrawingDocument14 pagesLegends Abbreviations Notes: Tender DrawingSuper HNo ratings yet

- BMSM Amendments BriefingDocument41 pagesBMSM Amendments BriefingPeter NgNo ratings yet

- EG2401 Tutorial 3Document1 pageEG2401 Tutorial 3anon_435296847No ratings yet

- Engineering Ethics Course 2016 Chapter 3Document38 pagesEngineering Ethics Course 2016 Chapter 3hassanmNo ratings yet

- File Product Information Bulletin - LUMALUX PLUS XL ECO HID073 67800Document3 pagesFile Product Information Bulletin - LUMALUX PLUS XL ECO HID073 67800sealion loverNo ratings yet

- McGraw-Edison Lawnaire Series Brochure 1985Document2 pagesMcGraw-Edison Lawnaire Series Brochure 1985Alan MastersNo ratings yet

- IES PrepDocument2 pagesIES PrepOoi Wei ShengNo ratings yet

- GE Lighting Systems For Industry Brochure 6-84Document28 pagesGE Lighting Systems For Industry Brochure 6-84Alan MastersNo ratings yet

- Chapter SS-1 Signals and SystemsDocument49 pagesChapter SS-1 Signals and SystemsalokNo ratings yet

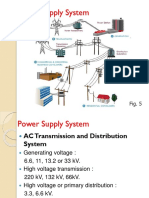

- Power Supply SystemDocument49 pagesPower Supply SystemstephenNo ratings yet

- Regulation, Harmonization and Trends in International Automotive Lamp StandardizationDocument41 pagesRegulation, Harmonization and Trends in International Automotive Lamp StandardizationGermán David Rincón MorenoNo ratings yet

- ME2114 Question 2 SolutionDocument16 pagesME2114 Question 2 SolutionLin YushengNo ratings yet

- Lec9 PDFDocument52 pagesLec9 PDFHiongyiiNo ratings yet

- Dimming Ballast LutronDocument28 pagesDimming Ballast LutronLuis E SánchezNo ratings yet

- Eg2401 THL Tutorial 1Document4 pagesEg2401 THL Tutorial 1Wai-Yen ChanNo ratings yet

- IES Progress Report 2010Document23 pagesIES Progress Report 2010Ian MadridNo ratings yet

- Working Together: To Prevent Cable DamageDocument16 pagesWorking Together: To Prevent Cable DamageinnNo ratings yet

- Ee2001 Ntu AnswerDocument47 pagesEe2001 Ntu AnswerAaron Bourne LeeNo ratings yet

- 4503 Assignment 1Document7 pages4503 Assignment 1ss100% (1)

- (BS EN 62086-1-2005) - Electrical Apparatus For Explosive Gas Atmospheres. Electrical Resistance Trace Heating - General and Testing Requirements PDFDocument32 pages(BS EN 62086-1-2005) - Electrical Apparatus For Explosive Gas Atmospheres. Electrical Resistance Trace Heating - General and Testing Requirements PDFMarijan UtrošaNo ratings yet

- Fire Resistant Coaxial CablesDocument38 pagesFire Resistant Coaxial Cablesrose chenNo ratings yet

- BS HvacDocument20 pagesBS HvacRamiAl-fuqahaNo ratings yet

- Beachfront Lighting GuideDocument490 pagesBeachfront Lighting Guidemarkigldmm918No ratings yet

- ME2151Document6 pagesME2151Delroy JqNo ratings yet

- ASHRAE climatic design conditions guideDocument2 pagesASHRAE climatic design conditions guideaya maap100% (1)

- EE 741-Power Quality & System ReliabilityDocument21 pagesEE 741-Power Quality & System ReliabilityAndrey LopesNo ratings yet

- Overview of EurocodesDocument27 pagesOverview of EurocodesbsitlerNo ratings yet

- EVE Chapter 8Document42 pagesEVE Chapter 8Erickah PerladoNo ratings yet

- Case Study 2Document5 pagesCase Study 2Anonymous YqQ1Z9y8nNo ratings yet

- Pylon BriefDocument13 pagesPylon BriefChandana KumaraNo ratings yet

- Engineering Disasters and Ethics: A Look at Six Famous FailuresDocument10 pagesEngineering Disasters and Ethics: A Look at Six Famous FailuresJoelNo ratings yet

- Information Technology Policies and Procedures: General Use and OwnershipDocument5 pagesInformation Technology Policies and Procedures: General Use and OwnershipAhmad ShdifatNo ratings yet

- PRESENT CipherDocument3 pagesPRESENT CipherAhmad ShdifatNo ratings yet

- Dragon FlyDocument10 pagesDragon FlyAhmad ShdifatNo ratings yet

- Advance SQLDocument103 pagesAdvance SQLAhmad ShdifatNo ratings yet

- Data Modeling Using The Entity-Relationship (ER) ModelDocument56 pagesData Modeling Using The Entity-Relationship (ER) ModelAhmad ShdifatNo ratings yet

- High Radix, and RoutingDocument19 pagesHigh Radix, and RoutingAhmad ShdifatNo ratings yet

- Flattened ButterflyDocument5 pagesFlattened ButterflyAhmad ShdifatNo ratings yet

- Database System Concepts and ArchitectureDocument42 pagesDatabase System Concepts and ArchitectureAhmad Shdifat100% (1)

- Relational Database Design by ER - and EER-to-Relational MappingDocument39 pagesRelational Database Design by ER - and EER-to-Relational MappingAhmad Shdifat100% (2)

- ENCh 01Document34 pagesENCh 01jonty777No ratings yet

- DML and QLDocument9 pagesDML and QLAhmad ShdifatNo ratings yet

- SQL Difinition LanguageDocument4 pagesSQL Difinition LanguageAhmad ShdifatNo ratings yet

- Engineering Ethics: Chapter 3Document33 pagesEngineering Ethics: Chapter 3Ahmad Shdifat100% (2)

- Engineering Ethics: Chapter 7Document16 pagesEngineering Ethics: Chapter 7Ahmad ShdifatNo ratings yet

- The Relational Data Model and Relational Database ConstraintsDocument43 pagesThe Relational Data Model and Relational Database ConstraintsAhmad ShdifatNo ratings yet

- 09 - Accessing Engineering Information (Ch8)Document18 pages09 - Accessing Engineering Information (Ch8)Ahmad ShdifatNo ratings yet

- ENCh 01Document34 pagesENCh 01jonty777No ratings yet

- Engineering Ethics: Chapter 6Document27 pagesEngineering Ethics: Chapter 6Ahmad ShdifatNo ratings yet

- 11 - Writing To Get An Engineering Job (Ch10)Document31 pages11 - Writing To Get An Engineering Job (Ch10)Ahmad ShdifatNo ratings yet

- Engineering Ethics: Chapter 4Document60 pagesEngineering Ethics: Chapter 4Ahmad Shdifat80% (5)

- Engineering Ethics: Chapter 2Document39 pagesEngineering Ethics: Chapter 2Ahmad Shdifat100% (1)

- Engineering Ethics: Chapter 5Document43 pagesEngineering Ethics: Chapter 5Ahmad Shdifat71% (17)

- Engineering Ethics: Chapter 1Document34 pagesEngineering Ethics: Chapter 1Ahmad Shdifat100% (2)

- 10 - Engineering Your Presentation (Ch9)Document24 pages10 - Engineering Your Presentation (Ch9)Ahmad ShdifatNo ratings yet

- Light-Weight Encryption Processor Verilog CodeDocument22 pagesLight-Weight Encryption Processor Verilog CodeAhmad Shdifat100% (1)

- 08 - Tables and Graphics (Ch7)Document17 pages08 - Tables and Graphics (Ch7)Ahmad Shdifat100% (1)

- 12 - Documentation and Ethics in Engineering Writing (Ch11)Document14 pages12 - Documentation and Ethics in Engineering Writing (Ch11)Ahmad ShdifatNo ratings yet

- 07 - Writing An Engineering Report (Ch6)Document25 pages07 - Writing An Engineering Report (Ch6)Ahmad ShdifatNo ratings yet

- 06 - Writing Common Engineering Documents-B (Ch5)Document24 pages06 - Writing Common Engineering Documents-B (Ch5)Ahmad ShdifatNo ratings yet

- Use of High Efficient Energy Absorption Foam in Side Impact PaddingDocument6 pagesUse of High Efficient Energy Absorption Foam in Side Impact PaddingNunzio Emanuele Di LorenzoNo ratings yet

- Car Crash TestingDocument22 pagesCar Crash TestingKapil AppyNo ratings yet

- SafetyCompanion 2022Document200 pagesSafetyCompanion 2022Sreekanth DevarasettyNo ratings yet

- Crash RegulationDocument2 pagesCrash RegulationNarayananNo ratings yet

- SafetyCompanion 2013 E PDFDocument132 pagesSafetyCompanion 2013 E PDFsamisdr3946No ratings yet

- Dot 14698 DS1Document92 pagesDot 14698 DS1Joel Johnson KimatareNo ratings yet

- A Tailor Welded Blanks Design of Automotive Front Rails by ESL Optimization For Crash Safety and LightweightingDocument12 pagesA Tailor Welded Blanks Design of Automotive Front Rails by ESL Optimization For Crash Safety and LightweightingmanuelNo ratings yet

- 2012 Annual Report TRWDocument144 pages2012 Annual Report TRWDenisa FlorinaNo ratings yet

- The Volvo Preformance HandbookDocument405 pagesThe Volvo Preformance HandbookJoshua Herman93% (15)

- Group no.8.RUPD AnalysisDocument82 pagesGroup no.8.RUPD AnalysisSantosh BansodeNo ratings yet

- 420r16021 PDFDocument719 pages420r16021 PDFАКПП СервисNo ratings yet

- MB Safety Passive 18Document30 pagesMB Safety Passive 18rene_angel1No ratings yet

- PadmanabanDocument11 pagesPadmanabanarstjunkNo ratings yet

- ch08 Rev03 240-269Document30 pagesch08 Rev03 240-269m poojaNo ratings yet

- 2017 Jan NewsletterDocument56 pages2017 Jan NewsletterAlexander BalkowskiNo ratings yet

- Ford's Blueprint For Sustainability - SummaryDocument8 pagesFord's Blueprint For Sustainability - SummaryFord Motor CompanyNo ratings yet

- Motor Trend - March 2016Document122 pagesMotor Trend - March 2016neep100% (1)

- Understanding Rearend CollisionsDocument21 pagesUnderstanding Rearend CollisionsMark Hefter100% (1)

- Motor Trend New Car Buyer 27s Guide 2014Document100 pagesMotor Trend New Car Buyer 27s Guide 2014Thomas SwiftNo ratings yet

- Restriant SystemsDocument109 pagesRestriant SystemsjibharatNo ratings yet

- Crash Test1Document76 pagesCrash Test1Robin Roy100% (1)

- CARFAX Vehicle History Report On 1HGFA16508L118285Document13 pagesCARFAX Vehicle History Report On 1HGFA16508L118285cemayhanNo ratings yet

- Carhs 2019 Safety Companion PDFDocument180 pagesCarhs 2019 Safety Companion PDFvish_537756528100% (1)

- Automobile Safety System Seminar Report SummaryDocument28 pagesAutomobile Safety System Seminar Report SummaryNEERAJNo ratings yet

- Motor Trend - December 2014 USADocument136 pagesMotor Trend - December 2014 USAenricoio100% (2)

- Consumer Reports 2019Document204 pagesConsumer Reports 2019Avery Kalpin0% (1)

- Hyundai DpsDocument8 pagesHyundai DpsDeepak GNo ratings yet

- 2009 Ford Taurus Brochure From Miller FordDocument12 pages2009 Ford Taurus Brochure From Miller FordMiller FordNo ratings yet

- Headlight Test Rating ProtocolDocument12 pagesHeadlight Test Rating Protocolbox_manNo ratings yet

- Invisible Knee Airbag Module DevelopmentDocument10 pagesInvisible Knee Airbag Module Developmentjainshani2No ratings yet