Professional Documents

Culture Documents

Uji Kekerasan

Uploaded by

Shiezkhaede ShirakawaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uji Kekerasan

Uploaded by

Shiezkhaede ShirakawaCopyright:

Available Formats

Why are metals tested ?

Ensure quality

Test properties

Prevent failure in use

Make informed choices in using materials

Factor of Safety is the ratio comparing the

actual stress on a material and the safe

useable stress.

Two forms of testing

Mechanical tests the material may be

physically tested to destruction. Will

normally specify a value for properties such

as strength, hardness, toughness,etc

Non-destructive tests (NDT) samples or

finished articles are tested before being

used.

Introduction

Hardness is determined by the resistance to plastic

deformations and fracture of interatomic and crystalline

bonds in the material, which also determines the mechanical

strength of a material.

There are three standard methods for measuring the hardness

which depends upon the manner in which the test is

conducted.

These are:

1- Scratch hardness measurement.

2- Rebound hardness measurement.

3- Indentation hardness measurement

Why Use a Hardness Test?

Easy to perform

Quick - 30 seconds

Relatively inexpensive

Non-destructive

Finished parts can be tested

any size and shape can be tested

Indentation hardness measurement

A load is applied by pressing the indenter at right angles to

the surface being tested.

The three commonly used indentation hardness tests is:

BRINELL HARDNESS TEST

sphere indenter of 10 mm in dia,, varying load, measure the size of

indentation

Dr. J. A. Brinell invented the Brinell test in Sweden in 1900

ROCKWELL HARDNESS TEST

using different scale (various sized indenter, different loads)

Stanley P. Rockwell invented the Rockwell hardness test

VICKERS PYRAMID HARDNESS TEST

diamond used as indenter

The Vickers (HV) test was developed in England is 1925

CH-07 LEC 27

Slide 7

Hardness

The resistance of a material metal to penetration by a pointed tool

is called Hardness. It is the property of a metal, which gives it the

ability to resist being permanently, deformed (bent, broken, or

have its shape changed), when a load is applied. The greater the

hardness of the metal, the greater resistance it has to deformation.

3-4 Hardness

CH-07 LEC 27

Slide 8

Hardness Measurement Methods

Rockwell hardness test

Brinell hardness

Vickers

Knoop hardness

Shore

3-4 Hardness

HARDNESS TESTING

Hardness is the ability to withstand dents or

scratches

Fundamentals of Hardness

Hardness is thought of as the resistance to penetration by an object or the

solidity or firmness of an object

Resistance to permanent indentation under static or dynamic loads

Energy absorption under impact loads (rebound hardness)

Resistance toe scratching (scratch hardness)

Resistance to abrasion (abrasion hardness)

Resistance to cutting or drilling (machinability)

Principles of hardness (resistance to indentation)

indenter: ball or plain or truncated cone or pyramid made of hard steel or diamond

Load measured that yields a given depth

Indentation measured that comes from a specified load

Rebound height measured in rebound test after a dynamic load is dropped onto a

surface

GAMBAR MACAM-MACAM MEDIA PENGUJIAN

BRINELL

ROCKWELL VICKERS

Hardness testing machine

The indenter is pressed

into the metal

Softer materials leave a

deeper indentation

ALAT UJI KEKERASAN MATERIAL LOGAM

Brinell hardness test

Uses ball indentor.

Cannot be used for thin

materials.

Ball may deform on very

hard materials

Surface area of indentation

is measured.

Brinell Hardness

Brinell Hardness

A spherical indenter (1 cm diameter) is shot

with 29 kN force at the target

Frequently the indenter is steel, but for

harder materials it is replaced with a

tungsten carbide sphere

The diameter of the indentation is recorded

The indentation diameter can be correlated

with the volume of the indentation.

CH-07 LEC 27

Slide 17

Brinell Hardness Test

Brinell hardness is determined by forcing a hard steel or carbide

sphere of a specified diameter under a specified load into the

surface of a material and measuring the diameter of the

indentation left after the test. The Brinell hardness number, or

simply the Brinell number, is obtained by dividing the load used,

in kilograms, by the actual surface area of the indentation, in

square millimeters. The result is a pressure measurement, but the

units are rarely stated.

CH-07 LEC 27

Slide 18

For steels

The relationship between the minimum ultimate strength and

the Brinell harness number for is

0.495

3.41

B

u

B

H kpsi

S

H MPa

200 450

B

H s s

Cast Iron

The minimum strength, as defined by the ASTM, is found to be

0.238 12.5

1.58 86

B

u

B

H kpsi

S

H MPa

Brinell Hardness

( ) ( )

2 2

2

d D D D

P

BHN

=

t

Brinell Hardness

ASTM and ISO use the HB value. It can be

HBS (Hardness, Brinell, Steel) or the HBW

(Hardness, Brinell, Tungsten)

HBW = 0.102 BHN

Sometimes written as HBW 10/3000

(Tungsten, 10 mm diameter, 3,000 kg force)

Typical HB values

Material Hardness

Softwood (e.g., pine) 1.6 HBS 10/100

Hardwood 2.67.0 HBS 1.6 10/100

Aluminum 15 HB

Copper 35 HB

Mild steel 120 HB

18-8 (304) stainless steel annealed 200 HB

Glass 1550 HB

Hardened tool steel 15001900 HB

Rhenium diboride 4600 HB

Hardness Mechanical Tests

Brinell Test Method

One of the oldest tests

Static test that involves pressing a hardened steel ball (10mm) into a test

specimen while under a load of

3000 kg load for hard metals,

1500 kg load for intermediate hardness metals

500 kg load for soft materials

Various types of Brinell

Method of load application:oil pressure, gear-driven screw, or weights with a lever

Method of operation: hand or electric power

Method of measuring load: piston with weights, bourdon gage, dynamoeter, or

weights with a lever

Size of machine: stationary (large) or portable (hand-held)

Brinell Test Conditions

Brinell Test Method (continued)

Method

Specimen is placed on the anvil and raised to contact the ball

Load is applied by forcing the main piston down and presses the ball

into the specimen

A Bourbon gage is used to indicate the applied load

When the desired load is applied, the balance weight on top of the

machine is lifted to prevent an overload on the ball

The diameter of the ball indentation is measured with a micrometer

microscope, which has a transparent engraved scale in the field of view

Brinell Test Example

Brinell Test Method (continued)

Units: pressure per unit area

Brinell Hardness Number (BHN) = applied load divided

by area of the surface indenter

( )

2 2

2

d D D D

L

BHN

=

t

Where: BHN = Brinell Hardness Number

L = applied load (kg)

D = diameter of the ball (10 mm)

d = diameter of indentation (in mm)

Example: What is the Brinell hardness for a specimen with an indentation

of 5 mm is produced with a 3000 kg applied load.

Ans:

( )

2

2 2

/ 6 . 142

) 5 ( ) 10 ( 10 ) 10 (

) 3000 ( 2

mm kg

mm mm mm mm

kg

BHN =

=

t

Brinell Test Method

(continued)

Range of Brinell Numbers

90 to 360 values with higher number indicating higher hardness

The deeper the penetration the higher the number

Brinell numbers greater than 650 should not be trusted because the

diameter of the indentation is too small to be measured accurately and the

ball penetrator may flatten out.

Rules of thumb

3000 kg load should be used for a BHN of 150 and above

1500 kg load should be used for a BHN between 75 and 300

500 kg load should be used for a BHN less than 100

The materials thickness should not be less than 10 times the depth of the

indentation

Advantages & Disadvantages

of the

Brinell Hardness Test

Advantages

Well known throughout industry with well accepted results

Tests are run quickly (within 2 minutes)

Test inexpensive to run once the machine is purchased

Insensitive to imperfections (hard spot or crater) in the material

Limitations

Not well adapted for very hard materials, wherein the ball deforms excessively

Not well adapted for thin pieces

Not well adapted for case-hardened materials

Heavy and more expensive than other tests ($5,000)

Rockwell Test

Hardness is a function of the degree of indentation

of the test piece by action of an indenter under a

given static load (similar to the Brinell test)

Rockwell test has a choice of 3 different loads and

three different indenters

The loads are smaller and the indentation is

shallower than the Brinell test

Rockwell test is applicable to testing materials

beyond the scope of the Brinell test

Rockwell test is faster because it gives readings

that do not require calculations and whose values

can be compared to tables of results (ASTM E 18)

Rockwell Test Description

Specially designed machine that applies load through a system of

weights and levers

Indenter can be 1/16 in hardened steel ball, 1/8 in steel ball, or

120 diamond cone with a somewhat rounded point (brale)

Hardness number is an arbitrary value that is inversely related to

the depth of indentation

Scale used is a function of load applied and the indenter

Rockwell B- 1/16in ball with a 100 kg load

Rockwell C- Brale is used with the 150 kg load

Operation

Minor load is applied (10 kg) to set the indenter in material

Dial is set and the major load applied (60 to 100 kg)

Hardness reading is measured

Rockwell hardness includes the value and the scale letter

CH-07 LEC 27

Slide 30

3-4 Hardness

Rockwell Hardness Test

The Rockwell Hardness test is a hardness measurement based on

the net increase in depth of impression as a load is applied.

Hardness numbers have no units and are commonly given in the

R, L, M, E and K scales. The higher the number in each of the

scales means the harder the material.

Rockwell hardness tests

Gives direct reading.

Rockwell B (ball) used

for soft materials.

Rockwell C (cone) uses

diamond cone for hard

materials.

Flexible, quick and easy

to use.

Rockwell Hardness

Rockwell Hardness Measurements

In the Rockwell hardness test either a 120 conical diamond (C scale) or a

steel ball (B scale) indentor is pushed into the surface of the test piece with

a load of .

Rockwell C Diamond Indenter Test Rockwell B Indenter test

HR = E - e

Rockwell Hardness

Rockwell Hardness Scales

Scale Code Load Indenter Use

A HRA 60 kgf 120 diamond cone

Tungsten

carbide

B HRB 100 kgf 1/16 in diameter steel sphere

Al, brass, and

soft steels

C HRC 150 kgf 120 diamond cone Harder steels

D HRD 100 kgf 120 diamond cone

E HRE 100 kgf 1/8 in diameter steel sphere

F HRF 60 kgf 1/16 in diameter steel sphere

G HRG 150 kgf 1/16 in diameter steel sphere

Conversion/Comparison

HBW

10/3000 HRA 60KG HRB 100KG HRC 150KG

Tensile

Strength

(Approx)

638 80.8 - 59.2 329,000

578 79.1 - 56 297,000

461 74.9 - 48.5 235,000

375 70.6 - 40.4 188,000

311 66.9 - 33.1 155,000

241 61.8 100 22.8 118,000

207 - 94.6 16 100,000

179 - 89 - 87,000

149 - 80.8 - 73,000

111 - 65.7 - 56,000

Rockwell Values

Scale Indenter Applied Load

(kg)

A Brale 60

B 1/16 in 100

C Brale 150

D Brale 100

E 1/8 in 100

F 1/16 in 60

G 1/16 in 150

B Scale: Materials of medium hardness (0 to 100HR

B

) Most Common

C Scale: Materials of harder materials (> 100HR

B

) Most Common

Rockwell scales divided into 100 divisions with each division (point of

hardness) equal to 0.002mm in indentation. Thus difference between a

HR

B

51 and HR

B

54 is 3 x 0.002 mm - 0.006 mm indentation

The higher the number the harder the number

Rockwell and Brinell Conversion

For a Rockwell C values between -20 and

40, the Brinell hardness is calculated by

For HR

C

values greater than 40, use

For HR

B

values between 35 and 100 use

( )

C

HR

x

BHN

=

100

10 42 . 1

6

( )

C

HR

x

BHN

=

100

10 5 . 2

4

( )

B

HR

x

BHN

=

130

10 3 . 7

3

Rockwell and Brinell Conversion

For a Rockwell C values, HR

C

, values

greater than 40,

Example,

Convert the Rockwell hardness number HRc 60

to BHN

( )

C

HR

x

BHN

=

100

10 5 . 2

4

( ) 60 100

10 5 . 2

4

=

x

BHN

625 = BHN

T a r a r a n g k y u

CH-07 LEC 27

Slide 41

Vickers hardness test

Uses square pyramid

indentor.

Accurate results.

Measures length of

diagonal on indentation.

Hardness Test

The hardness test offers the engineer a

quick, inexpensive and nondestructive way to

estimate the tensile strength of a specimen.

Hardness tests all make a small (sometimes

microscopic) indentation into the surface of

a specimen, and then use the force applied

and the size of the indentation to calculate a

"hardness number."

The correlation between this value and the

tensile strength allows this to be used as a

quality control parameter

Brinell Hardness Test

The Brinell Hardness Test utilizes a

steel sphere which is usually 10mm in

diameter.

The sphere is forced into the surface

of a material. Then, the diameter of

the resulting impression is measured.

The corresponding Brinell Hardness

number is then calculated.

D; diameter of indenter

Di; diameter of impression in mm

F; applied load in Kg

Hardness correlates well with wear

resistance

For steel, nondestructive test

Tensile strength (psi)=500*HB

( )

2 2

2

i

D D D D

F

HB

=

t

The Rockwell Hardness Test utilizes two

kinds of indentors.

A small steel ball is used for soft materials

and a diamond-shaped cone called a Brale is

used for hard materials. To perform the

test, the indentor is pushed into the surface

of the material being tested. The test

machine measures the depth of penetration

and automatically converts this data into a

Rockwell Hardness number

Relationship between hardness & Strength

For steel, H

B

between 200 to 400

Su=0.495 H

B

Kpsi

Su=3.42 H

B

Mpa

Cast iron (ASTM data)

Su=0.23 H

B

12.5 Kpsi

Su=1.58 H

B

-86 Mpa

SAE minimum strength

Su=0.2375 H

B

-16 Kpsi

Example 3.2

It is necessary to ensure that a certain part

supplied by a foundry always meets or

exceeds ASTM No. 20 specifications for

cast iron. What hardness should be

specified?

Solution of Example 3.2

Su=0.23 H

B

12.5 Kpsi

If the foundry can control within 20 points

145< H

B

<165

141

23 . 0

5 . 12

=

+

=

u

B

S

H

Example 3.3

Brinell hardness tests were made on a random

sample of five steel parts during processing

The results were HB values of 248, 247, 244, and

246

Estimate the mean and the standard deviation of

the ultimate strength in SI units

The ASTM minimum is established at a level that

99 % of the population can meet or exceed. On

the basis of this definition, what minimum

ultimate strength corresponds to this sample

testing?

Solution of Example 3.2

( ) 760 0432 . 0 * 326 . 2 1 3 . 844 ) 1 (

5 . 36 0432 . 0 * 3 . 844

0432 . 0 0136 . 0 041 . 0 ) (

3 . 844 6 . 247 * 41 . 3

) 0136 . 0 , 1 ( 6 . 247 ) 041 . 0 , 1 ( 41 . 3

) 041 . 0 , 1 ( 41 . 3

450 200

0136 . 0

36 . 3

6 . 247

99 . 0

2 2 2

2

= + = + =

= = =

= + = + =

= =

=

=

s s

=

=

=

Su u u

Su u Su

y s su

mean

u

u

B u

B

HB

HB

B

C z S S

MPa C S

C C C

MPA S

S

MPa H S

H f or

C

MPa

MPa H

o

o

Five data, normal distribution

Eq 3.21

u(z)=0.01, then z=-2.326

Conversion of Data to DPH

Vickers hardness (HV) - DPH (Diamond Pyramid Hardness)

DPH covers entire range from HRF up to HRC

You might also like

- DT - Hardness TestDocument30 pagesDT - Hardness TestSamuel Christian GiovanniNo ratings yet

- Pengaruh Temperatur Pemanasan Terhadap KekerasanDocument12 pagesPengaruh Temperatur Pemanasan Terhadap KekerasanMisbach HyudinzNo ratings yet

- F 1044 - 99 - Rjewndq - PDFDocument5 pagesF 1044 - 99 - Rjewndq - PDFDavid Drolet TremblayNo ratings yet

- Hardening Process PDFDocument7 pagesHardening Process PDFVolkzNo ratings yet

- Stainless Steel Aisi 304 Terhadap Sifat MekanisDocument10 pagesStainless Steel Aisi 304 Terhadap Sifat Mekanis-AS-No ratings yet

- EU4 D2 M4 Inspection in Composites PDFDocument20 pagesEU4 D2 M4 Inspection in Composites PDFaerorenNo ratings yet

- Quality Control Form for Alignment Inspection ReportsDocument1 pageQuality Control Form for Alignment Inspection ReportsGanesh YadavNo ratings yet

- Brinell Hardness TestDocument6 pagesBrinell Hardness TestAnonymous 4APvkrc6No ratings yet

- Joining Copper-Nickel Alloys GuideDocument9 pagesJoining Copper-Nickel Alloys GuidehboodhaiNo ratings yet

- Aplikasi Mengukur Kematangan Buah Apel Betdasar Pengolahan CitraDocument0 pagesAplikasi Mengukur Kematangan Buah Apel Betdasar Pengolahan CitraJohan PeusanganNo ratings yet

- Astm E588Document9 pagesAstm E588Jesus VelizNo ratings yet

- E1158Document4 pagesE1158Irish Manglicmot LagundinoNo ratings yet

- Wettability (Kemampubasahan) (Compatibility Mode)Document38 pagesWettability (Kemampubasahan) (Compatibility Mode)Ujang Daud SeptianNo ratings yet

- 3978Document7 pages3978Shahazad ShaikNo ratings yet

- Creep IntroductionDocument56 pagesCreep IntroductionayushdbcNo ratings yet

- 3LPP Three Layer Polypropylene CoatingDocument3 pages3LPP Three Layer Polypropylene CoatingCarlos Maldonado SalazarNo ratings yet

- Astm D905.37404 PDFDocument5 pagesAstm D905.37404 PDFValentina MonsalveNo ratings yet

- WSI Corrosion Control by Weld Overlay (Boilers)Document11 pagesWSI Corrosion Control by Weld Overlay (Boilers)Claudia Mms100% (1)

- Non-Destructive Testing Methods for Welding InspectorsDocument51 pagesNon-Destructive Testing Methods for Welding InspectorsmanojballaNo ratings yet

- Evaporation Chamber: Vacuum Furnaces and Degassing EquipmentDocument7 pagesEvaporation Chamber: Vacuum Furnaces and Degassing EquipmentWilly UioNo ratings yet

- 8 Success Principles of Internet MarketersDocument28 pages8 Success Principles of Internet MarketersImanuel Sumargo IINo ratings yet

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDocument15 pagesPengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- Types of AnnealingDocument2 pagesTypes of AnnealingAshwani Kansara50% (2)

- Jurnal Las GasDocument8 pagesJurnal Las GasMuhammad Zaenal ArifinNo ratings yet

- As 2084-1987 Non-Destructive Testing - Eddy Current Testing of Metal TubesDocument7 pagesAs 2084-1987 Non-Destructive Testing - Eddy Current Testing of Metal TubesSAI Global - APACNo ratings yet

- Heat Treatment of SteelsDocument9 pagesHeat Treatment of SteelsEhsan KhanNo ratings yet

- Surface Preparation Hand and Power Tool Cleaning D ST 2 and ST 3Document29 pagesSurface Preparation Hand and Power Tool Cleaning D ST 2 and ST 3Nilesh PathareNo ratings yet

- Hardness Testing Methods ExplainedDocument3 pagesHardness Testing Methods ExplainedtuanNo ratings yet

- Aluminum 2024 PropertiesDocument3 pagesAluminum 2024 Propertiesbotan_mihaiNo ratings yet

- Magnetic Particle Testing: Standard Guide ForDocument41 pagesMagnetic Particle Testing: Standard Guide ForAdrian PetrascuNo ratings yet

- Er MonitoringDocument8 pagesEr MonitoringAsma SedNo ratings yet

- Normalizing Process For SteelsDocument3 pagesNormalizing Process For Steelsduazo2009No ratings yet

- Velocity ChartDocument2 pagesVelocity Chartshanmusx100% (1)

- Alloy 6moDocument2 pagesAlloy 6moqshaath100% (1)

- Section IX welding qualification requirementsDocument1 pageSection IX welding qualification requirementsRonel John Rodriguez CustodioNo ratings yet

- Tube InspDocument8 pagesTube InspsrihariNo ratings yet

- Electroslag WeldingDocument10 pagesElectroslag WeldingNazmul Ahsan100% (1)

- ITP For Drum Screen InspectionDocument1 pageITP For Drum Screen InspectionkapsarcNo ratings yet

- Plate Rolling Machine WikiDocument1 pagePlate Rolling Machine WikiShawn SimNo ratings yet

- Heat Treatment: Dr. Mohamed Abd Elmonem DahaDocument23 pagesHeat Treatment: Dr. Mohamed Abd Elmonem DahashoroukNo ratings yet

- Iqi TableDocument3 pagesIqi TableverdiblueNo ratings yet

- Weld Wire CatalogDocument50 pagesWeld Wire CatalogMurdock Howling MadNo ratings yet

- Non-Destructive Testing Inspector S HandbookDocument132 pagesNon-Destructive Testing Inspector S HandbookAdi SutardiNo ratings yet

- Aluminizing by (08MT3012 & 08MT1030) Atanu & ManojDocument24 pagesAluminizing by (08MT3012 & 08MT1030) Atanu & ManojAtanu KumarNo ratings yet

- X Ray TestingDocument24 pagesX Ray Testingapi-27176519100% (6)

- Corrosive Damage in Metals and Its PreventionDocument36 pagesCorrosive Damage in Metals and Its Preventionsamurai7_7783% (6)

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Retroclamp Data SheetDocument2 pagesRetroclamp Data SheetDesirée PallottaNo ratings yet

- Iso 17359-2011Document34 pagesIso 17359-2011Diego Pérez AlarcónNo ratings yet

- Effect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base MetalDocument8 pagesEffect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base Metalshrikant tambeNo ratings yet

- Asm Products & Education Catalog: Celebrating Our First 100 Years of Materials InnovationDocument52 pagesAsm Products & Education Catalog: Celebrating Our First 100 Years of Materials InnovationVinit AhluwaliaNo ratings yet

- Metallurgy: SmeltingDocument42 pagesMetallurgy: SmeltingNaniNo ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- 10-DP-D704.12 6 2Document40 pages10-DP-D704.12 6 2Chechae ChaerikaNo ratings yet

- Inspection of CastingDocument23 pagesInspection of CastingRaghu SanthNo ratings yet

- High Temperature CorrosionDocument3 pagesHigh Temperature CorrosiontechzonesNo ratings yet

- Inspection technique selection guide for materialsDocument1 pageInspection technique selection guide for materialsDiki yunikaNo ratings yet

- Brinell TestDocument32 pagesBrinell TestAshish Agarwal100% (1)

- Unit IIDocument23 pagesUnit IIvizhideepaNo ratings yet

- (Useful) Unit 2 Mechanical Test of MaterialDocument57 pages(Useful) Unit 2 Mechanical Test of Materialbalajimeie100% (1)

- PSL05CMDocument5 pagesPSL05CMمراد احمدNo ratings yet

- Final Report UT Inspection BearingDocument5 pagesFinal Report UT Inspection BearingEko PurwantoNo ratings yet

- Ies-Industrial Engineering ServicesDocument4 pagesIes-Industrial Engineering ServicesSadia HasanNo ratings yet

- Brinell Hardness of Metallic Materials: Standard Test Method ForDocument9 pagesBrinell Hardness of Metallic Materials: Standard Test Method ForMughal DarbarNo ratings yet

- OrmatioDocument1 pageOrmatioMechanicalNo ratings yet

- Cross Reference of StandardsDocument30 pagesCross Reference of StandardsParag VirojaNo ratings yet

- Brinell en Iso 6506 Vickers en Iso 6507 Rockwell en Iso 6508 Knoop en Iso 4545Document1 pageBrinell en Iso 6506 Vickers en Iso 6507 Rockwell en Iso 6508 Knoop en Iso 4545Son NguyenNo ratings yet

- Snt-Tc-1a 2006-1Document36 pagesSnt-Tc-1a 2006-1leoand_alonNo ratings yet

- Training Schedule 2019 + Program SeasepDocument3 pagesTraining Schedule 2019 + Program SeasepDaud SitorusNo ratings yet

- Norma - Dureza E140Document21 pagesNorma - Dureza E140JeffersonCruzNo ratings yet

- A Hardness Conversion ChartDocument5 pagesA Hardness Conversion ChartimupathanNo ratings yet

- Destructive and NDT PresentationDocument9 pagesDestructive and NDT PresentationHarshvardhan SinghNo ratings yet

- Hardness Conversion Chart values for Brinell, Rockwell scalesDocument3 pagesHardness Conversion Chart values for Brinell, Rockwell scalesUlung SadewoNo ratings yet

- Hardness ComparisonDocument7 pagesHardness ComparisonankurNo ratings yet

- Tabel Konversi Nilai Kekerasan HardnessDocument14 pagesTabel Konversi Nilai Kekerasan HardnessRestuNo ratings yet

- Hardness Conversion Table - EN PDFDocument1 pageHardness Conversion Table - EN PDFHesti WijayantiNo ratings yet

- Hardness Conversion ChartDocument19 pagesHardness Conversion ChartArdian KharisnaNo ratings yet

- List of NDT & Inspection Approved Training Organisations: Rev A 4 January 2016Document24 pagesList of NDT & Inspection Approved Training Organisations: Rev A 4 January 2016edwinlcsNo ratings yet

- Hydrostatic Test ReportsDocument3 pagesHydrostatic Test ReportsHanuman RaoNo ratings yet

- Hardness TheoryDocument4 pagesHardness Theorykostas.sierros937491% (11)

- Hardness Conversion Chart: Brinell, Vickers, Rockwell & Tensile StrengthDocument22 pagesHardness Conversion Chart: Brinell, Vickers, Rockwell & Tensile StrengthputrudeNo ratings yet

- List of NDT & Inspection Approved Training OrganisationsDocument24 pagesList of NDT & Inspection Approved Training Organisationsnathaniel ekaikoNo ratings yet

- Hardness Test: Department of Mechanical & Manufacturing Engineering Faculty of Engineering, University of Putra MalaysiaDocument5 pagesHardness Test: Department of Mechanical & Manufacturing Engineering Faculty of Engineering, University of Putra MalaysiaNurul Siddiqah Whakiddin100% (1)

- 1 Macro VickersDocument10 pages1 Macro VickersAbhinav ChandrakerNo ratings yet

- Astm E10 18Document33 pagesAstm E10 18Alessio MercataliNo ratings yet

- Assignment 1 (Hardness Test)Document14 pagesAssignment 1 (Hardness Test)Azri LunduNo ratings yet

- HRB To HV Details PDFDocument1 pageHRB To HV Details PDFRavichandran DNo ratings yet

- Course Schedule 2013 SarawakDocument2 pagesCourse Schedule 2013 SarawakLuqman OsmanNo ratings yet

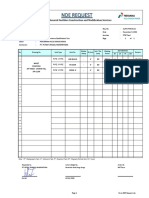

- Request NDT Welder TestDocument1 pageRequest NDT Welder TestFerdie OSNo ratings yet

- BRINELL HARDNESS TEST FinalizedDocument1 pageBRINELL HARDNESS TEST FinalizedMohsin QaziNo ratings yet