Professional Documents

Culture Documents

Hull Framing Systems3

Uploaded by

Sona DhillonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hull Framing Systems3

Uploaded by

Sona DhillonCopyright:

Available Formats

HULL FRAMING SYSTEMS

Modern ships vary considerably in the details of their construction, according to their size and type, but almost all conform to one of three basic systems of construction

The

sketches, here, merely illustrate the main features of each system and are kept as simple as possible, for purposes of comparison.

Transverse System

Wooden

ships were always built on this system, because closely spaced transverse frames were needed to hold the planks together so that the seams could be caulked.

It was also necessary to use it because sailing ships needed considerable transverse strength to enable them to resist the racking stresses set up by the masts and rigging.

Longitudinal

strength was less important in these ships because they were comparatively small and hogging and sagging stresses were not large.

This

system is not the most efficient for steel steam ships, but it has continued in general use until recently. This was partly because it was cheap to build and served its purpose; and partly because a suitable alternative was not available for many years.

Longitudinal Systems

With

the coming of steam ships, racking stresses became less important, but hogging and sagging stresses became more serious as ships grew longer.

It

soon became obvious that more longitudinal strength could be achieved by running the frames longitudinally (fore and aft), provided that reasonable transverse strength was maintained.

Various

attempts were made to do this during the 19th century, but all had serious disadvantages and none were generally adopted

Early

in this century, a satisfactory system of longitudinal framing was invented, which came to be called the 'Isherwood System', after its inventor.

This has longitudinal frames at the bottom, sides and decks, supported by widely spaced transverse web frames, called 'transverses'. It gives great longitudinal strength and is much used for oil-tankers and other types of bulk carrier.

few dry cargo ships were built on this system in the past, but it is not now used for them because the transverses interfere too much with the stowage of cargo. A dry cargo ship of this type is shown in the sketch, however, because it serves as a good illustration of the system.

Combination

System

Combination System-This was introduced to overcome the disadvantages of the longitudinal system for dry cargo ships.

The longitudinal frames are retained in the bottom and under the strength deck, where they give great longitudinal strength; but transverse frames are fitted on the ship's side, where the longitudinal stresses are smaller.

Plate floors and heavy transverse beams are fitted at intervals to give transverse strength and to support the longitudinals.

This

system was not widely used for riveted ships, although a number were built in this way, but it came more into use with the coming of all-welded ships.

This

was partly because it was found that, if these ships were built on the transverse system, their- decks and bottom tended to corrugate under hogging and sagging stresses: whereas the longitudinal frames prevent this from happening.

Lloyds'

Rules now require longitudinals to be fitted, in general, in the bottoms and under strength decks of all ships of over 120 metres long: so it seems that this system will eventually replace the transverse one for all larger dry cargo ships.

The

combination system is also often used for small to mediumsized oil tankers and for some other types of bulk carrier, for which it has certain slight advantages.

Cantilever framing

This

is really only a modification of the combination system, but is included here because of its special features. It has been developed for some modern types of ship, which have very long and wide hatchways

In

these ships, there is too little left of the decks and beams to give the necessary strength to resist longitudinal and transverse stresses; so the strength has to be made up in other ways.

Transverse

strength is maintained by using very strong hatch end beams wherever possible and by fitting special web frames, called 'cantilevers', at frequent intervals abreast of the hatchways.

To

give longitudinal strength, the sheer strake and deck stringer plate are much heavier than normal; whilst the hatch side coamings are extra deep and are often made continuous throughout the ship.

Sometimes,

the hull is also extended upwards at the sheer strake, to form a strong box girder in place of the ordinary bulwark or rails.

If

the ship is of the 'twin hatch type' (with two hatches abreast), a deck girder or longitudinal bulkhead is also fitted at the centre line

You might also like

- THE fORMULA BLOGGER Aimee Blaut's Beauty SecretsDocument2 pagesTHE fORMULA BLOGGER Aimee Blaut's Beauty SecretsSona Dhillon100% (1)

- Business Studies RegulationsDocument4 pagesBusiness Studies RegulationsSona DhillonNo ratings yet

- Academic English ParaphrasingDocument1 pageAcademic English ParaphrasingacademicenglishukNo ratings yet

- Atmosphere Heating 1Document24 pagesAtmosphere Heating 1Sona DhillonNo ratings yet

- Cargo WatchDocument2 pagesCargo WatchSona DhillonNo ratings yet

- Principles of ship stabilityDocument102 pagesPrinciples of ship stabilityDeepak Kumar75% (4)

- Tatler 2013 01 JanDocument331 pagesTatler 2013 01 JanSona Dhillon100% (1)

- Framing SystemsDocument12 pagesFraming SystemsSona DhillonNo ratings yet

- Cloud FormationDocument17 pagesCloud FormationSona DhillonNo ratings yet

- Wet CargoDocument17 pagesWet CargoSona DhillonNo ratings yet

- Cargo WatchDocument7 pagesCargo WatchSona DhillonNo ratings yet

- Unit 15: Ship Construction: Capt. M.D. HossainDocument8 pagesUnit 15: Ship Construction: Capt. M.D. HossainSona Dhillon100% (1)

- Herb Companion Winter 11Document100 pagesHerb Companion Winter 11Sona DhillonNo ratings yet

- Cargo WatchDocument2 pagesCargo WatchSona DhillonNo ratings yet

- Stability Formula SheetDocument2 pagesStability Formula SheetSona Dhillon100% (1)

- Spa Magazine 2011 SpringDocument93 pagesSpa Magazine 2011 SpringSona DhillonNo ratings yet

- Buoyage RecognitionDocument36 pagesBuoyage RecognitionSona Dhillon100% (1)

- Everything You Need To Know About Taking Grain Aboard in BulkDocument10 pagesEverything You Need To Know About Taking Grain Aboard in BulkSona DhillonNo ratings yet

- I Can't Accept Not Trying Michael JordanDocument3 pagesI Can't Accept Not Trying Michael JordanSona DhillonNo ratings yet

- Grooming TeaDocument1 pageGrooming TeaSona DhillonNo ratings yet

- Shape December 2012Document168 pagesShape December 2012Sona DhillonNo ratings yet

- Kris Carr Ultimate Wellness Resource Guide v3Document8 pagesKris Carr Ultimate Wellness Resource Guide v3Tatiana Beltran KleimanNo ratings yet

- StyleDocument3 pagesStyleSona DhillonNo ratings yet

- Spa Magazine Spring 12Document92 pagesSpa Magazine Spring 12Sona DhillonNo ratings yet

- Breakast Nutrition Guide WebDocument11 pagesBreakast Nutrition Guide WebSona DhillonNo ratings yet

- 10 Tips GuideDocument7 pages10 Tips GuideSona DhillonNo ratings yet

- Natural Health 2013-05-06 May JunDocument112 pagesNatural Health 2013-05-06 May JunSona DhillonNo ratings yet

- Resident June 2008Document3 pagesResident June 2008Sona DhillonNo ratings yet

- Life and Style Feb 2010Document2 pagesLife and Style Feb 2010Sona DhillonNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Dungeon World Ship & CrewDocument5 pagesDungeon World Ship & CrewRoldNo ratings yet

- Gotland Carolina Collision Report 20080419-02Document9 pagesGotland Carolina Collision Report 20080419-02PedroNo ratings yet

- Interpretations of The Colreg: International Association of Classification SocietiesDocument6 pagesInterpretations of The Colreg: International Association of Classification SocietiesAlfonso BericuaNo ratings yet

- En GlezaDocument113 pagesEn Glezaasdqwe123dsaNo ratings yet

- Equipment Sheet: Deep Water Anchor-Handling Tug, Supply VesselDocument3 pagesEquipment Sheet: Deep Water Anchor-Handling Tug, Supply VesselJeff TrinidadNo ratings yet

- Incoterms 2013 PDFDocument1 pageIncoterms 2013 PDFDon BraithwaiteNo ratings yet

- Deck Cadet Monitoring and Onboard Performance ReportDocument1 pageDeck Cadet Monitoring and Onboard Performance ReportGrachen Delos SantosNo ratings yet

- FOC BlacklistDocument2 pagesFOC BlacklistJavier LNo ratings yet

- EIF The IMO Number Explained PDFDocument8 pagesEIF The IMO Number Explained PDFhelga perangin anginNo ratings yet

- Shipbuilding Drawing-1: Short DescriptionDocument3 pagesShipbuilding Drawing-1: Short Descriptionreaz uddinNo ratings yet

- Ingilizce 68 Tum SorularDocument68 pagesIngilizce 68 Tum SorularAli KoçNo ratings yet

- Quay Wall Design in The FutureDocument22 pagesQuay Wall Design in The FutureMichael Dixon100% (1)

- Feasibility Study Dry PortsDocument74 pagesFeasibility Study Dry Portssubrat_sahoo1969No ratings yet

- Liner ShippingDocument8 pagesLiner ShippingMayank BhattNo ratings yet

- Naval Architecture Open Day PresentationDocument33 pagesNaval Architecture Open Day PresentationAkash KNo ratings yet

- Various Stresses in Ships StructureDocument5 pagesVarious Stresses in Ships Structuremeghbrishty50% (2)

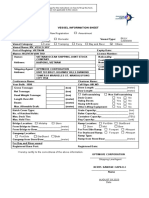

- Vessel Information Sheet PPADocument4 pagesVessel Information Sheet PPAIvy Amistad Dela Cruz-CabalzaNo ratings yet

- Flags and Morse CodeDocument3 pagesFlags and Morse Codeapi-347625027No ratings yet

- Sea Captain - Wikipedia PDFDocument41 pagesSea Captain - Wikipedia PDFJaylord ResurrecionNo ratings yet

- Oil Tanker Qubaa for SaleDocument7 pagesOil Tanker Qubaa for SaleMujahid Gill0% (1)

- The Earth: Latitude, Longitude and HemispheresDocument16 pagesThe Earth: Latitude, Longitude and HemispheresMd Shariful IslamNo ratings yet

- Basic Floating Dock CheckDocument30 pagesBasic Floating Dock CheckKelly RutkowskiNo ratings yet

- FM 104Document22 pagesFM 104Sandeep GoswamiNo ratings yet

- MUR - 9288875_compressedDocument7 pagesMUR - 9288875_compressedMaxNo ratings yet

- CV Form StellmarDocument6 pagesCV Form StellmarАндрей ДзюбаNo ratings yet

- 1993 37' Lagoon TPI Damage Claim Sample SurveyDocument19 pages1993 37' Lagoon TPI Damage Claim Sample SurveySuenos Azules100% (2)

- Ukuran Kapal 2Document10 pagesUkuran Kapal 2Bhayu DewantoNo ratings yet

- Commision On Higher EducationDocument2 pagesCommision On Higher EducationJeremias De la Cruz100% (2)

- Ship's Reporting System - Malacca & Singapore Straits: Reporting Points Call Channel Reporting CriteriaDocument2 pagesShip's Reporting System - Malacca & Singapore Straits: Reporting Points Call Channel Reporting CriteriaJagjit SinghNo ratings yet

- Chart Correction LogDocument6 pagesChart Correction LogDiana Morales67% (3)