Professional Documents

Culture Documents

Aluminum Alloy Introduction of Nari Huaisheng

Uploaded by

madhukarreddy2811Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminum Alloy Introduction of Nari Huaisheng

Uploaded by

madhukarreddy2811Copyright:

Available Formats

Aluminum alloy conductor from Jiangsu NARI Huaisheng Cable Co.

,Ltd

Jinlong Wang email:wang.jinlong1985@gmail.com

Bride introduction Process of manufacture Products category Specification of conductors Introduction of

2

Brief introduction

As the grid density increases, and new transmission

line costs and environment problems are becoming hard to control. To improve the transmission capacity of power grids on the existing basis becomes the most effective way to deal with the problem. Without increasing the conductor section, the new overhead wires heat-resistant aluminum alloy conductor and high strength aluminum alloy conductor can increase transmission capacity in the most economical way.

Manufacture process

Aluminum alloy conductor melting and continuous casting and rolling mill Composition and classification of aluminum alloy conductor In the process of casting and rolling aluminum, add some rare earths and some other alloy elements such as Mg Si Zr Mn etc..According to its characteristics, it is divided into AlMg-Si alloy conductor and heat-resistant aluminum alloy .

4

Aluminum alloy rod

The heat-resistant alloy conductor and high tensile strength alloy conductor can increase the capacity by 1-2 times of normal ACSR capacity . Such conductors are suitable for some new high-capacity T/L or for some expansion of old lines and transformer substation and some large cross lines.

Aluminum alloy rod

Product category

Al-Mg-Si alloy conductor a. High tensile strength (Tensile strength 315MPa conductivity 55%long term working temperature 90) b. Middle tensile strength (tensile strength 255MPa conductivity 58% long term working temperature 90)

6

High tensile strength AAAC and Heat-resistant alloy conductor

Product category Heat-resistant aluminum alloy conductor a.60%IACSlong term working temperature at 150 b.60%IACSlong term working temperature at210

High tensile strength AAAC and Heat-resistant alloy conductor

High tensile strength AAAC and Heat-resistant aluminum alloy conductor

7

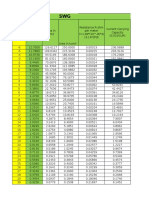

All middle aluminum alloy conductor AAAC

All middle aluminum alloy conductor AAAC

Cross section section structure diameter mm linear mass kg/km rated tensile strength kN

8.59 17.1 22.83 30.31 37.02 45.7 57.3 78.74 96 120 151.2 170.4 192 216 240

DC resistance at 20

/km 0.8764 0.4227 0.3166 0.2496 0.2043 0.1655 0.1267 0.0963 0.0758 0.0607 0.0482 0.0428 0.0379 0.0338 0.0304

No.

35 70 95 120 150 185 240 315 400 500 630 710 800 900 1000 34.36 71.25 95.14 121.21 148.07 182.8 238.76 314.55 399.98 502.9 631.3 710.14 801.43 898.25 1000.58 7 7 7 19 19 19 19 37 37 37 61 61 61 61 61

diameter mm

2.5 3.6 4.16 2.85 3.15 3.5 4.0 3.29 3.71 4.16 3.63 3.85 4.09 4.33 4.57 7.5 10.8 12.5 14.3 15.8 17.5 20.0 23 26 29.1 32.6 34.6 36.8 39 41.1 94 194.9 260.2 333.2 407 502.4 656.3 867.9 1102 1377.6 1738.3 1959.1 2207.4 2483.3 2759.2

60%IACS aluminum alloy conductor steel reinforced

60%IACS aluminum alloy conductor steel reinforced

Structure section mm2 Diam DC Rated tensile Linea Current carring cross eter Resistanc r capacity A (40) JNRLH60 section alloy steel alloy steel total mm e at 20 G1A G2A G3A mass 90 120 150 210/25 24/3.33 7/2.22 209 27.1 236 20 0.1404 0.1201 0.0977 0.0736 0.0591 0.0471 0.0361 0.0296 65.6 69.35 73.2 789 587 768 907 240/30 24/3.60 7/2.40 211 31.7 276 21.6 300/40 24/3.99 7/2.66 300 38.9 339 23.9 400/50 54/3.07 7/3.07 400 51.8 452 27.6 500/35 630/45 800/55 1000/12 5 45/3.75 7/2.50 497 34.4 45/4.20 7.2.80 624 43.1 45/4.80 7/3.20 814 56.3 19/2.9 54/4.84 994 126 0 531 30 667 33.6 871 38.4 1119 43.5 75.7 80.11 84.2 922 648 92.1 97.51 103 1136 737 850 1006 971 1152

122 129.1 136 1511 881 1167 1388 120 124.5 129 1642 1004 1334 1589 148 154.3 160 2060 1156 1544 1844 191 199.5 207 2690 1360 1829 2192 301 318.6 335 3733 1549 2095 2519

Brief introduction of plant

Jiangsu Nari Huaisheng Cable Co., Ltd. ("NARI Huaisheng" for short ), as a company directly under the State Grid Corporation of China (SGCC)is specialized in production of wire and cable products and the provision of related technical service. Since its establishment on August 12, 1993, the company has successfully passed ISO certification.

10

ISO certification

11

Product certification

Main products: conductors as ACSR AAAC etc. and power cable as PVC or XPLE insulation cables under 35kV and ABC cable , control cable etc.. All products have passed certificates such as National Production License of China , CCC National Mandatory Product Certification and PCCC, and will get KEMA certification in 2012.

12

Brief products

13

R&D and production

More than 200 technical research staff. More than 50,000 tons conductors annual 5000 km power cable New manufacture base start to operate in 2012 and will increase the annual production to 160,000 tons conductor and 8000km power cable

14

Plant overview

The plant

now

New plant in 2012

15

Thank you!

You might also like

- LG Bus Duct System Guide - Leader in Electrics & AutomationDocument51 pagesLG Bus Duct System Guide - Leader in Electrics & AutomationRajneesh KatochNo ratings yet

- Accr Conductor PropertiesDocument8 pagesAccr Conductor Propertiesdeepu_erNo ratings yet

- Soporte AAC - KcmilDocument6 pagesSoporte AAC - Kcmilmzabala99No ratings yet

- Na2Xsefgby 3 X (25-300) MM 3.6/6 KVDocument5 pagesNa2Xsefgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- N2XSYDocument5 pagesN2XSYRinda_RaynaNo ratings yet

- LSIS Bus Duct System CatalogDocument52 pagesLSIS Bus Duct System CatalogedcooNo ratings yet

- Al Alloy & CCA CatalogDocument8 pagesAl Alloy & CCA CatalogGaurav GuptaNo ratings yet

- Conductor Iec StandardDocument34 pagesConductor Iec StandardWalter Cataldo100% (2)

- Electrics CablesDocument10 pagesElectrics CablesGerson FernandesNo ratings yet

- PVC Cables FinolexDocument8 pagesPVC Cables FinolexMaria DenetNo ratings yet

- HENGTONG Overhead Bare ConductorsDocument44 pagesHENGTONG Overhead Bare ConductorsBoris Darío Peréz DuránNo ratings yet

- Conductor SizeDocument1 pageConductor SizeBilal AhmadNo ratings yet

- GSWDocument1 pageGSWNur Cholis HadiNo ratings yet

- Surge Arrestors AmericaDocument8 pagesSurge Arrestors AmericagustavopaloNo ratings yet

- N2 XFGB YDocument4 pagesN2 XFGB YRinda_RaynaNo ratings yet

- Magnakabel NusantaraDocument13 pagesMagnakabel Nusantaratees220510No ratings yet

- JNC Cables PDFDocument30 pagesJNC Cables PDFVasudev AgrawalNo ratings yet

- OPGW CatalogDocument6 pagesOPGW CatalogKrishna VenkataramanNo ratings yet

- According To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesDocument10 pagesAccording To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesRaj KiranNo ratings yet

- NA2XSEKRY 3 X (25-300) MM 3.6/6 KVDocument5 pagesNA2XSEKRY 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- SR 4Document12 pagesSR 4Parker333No ratings yet

- NYSYDocument5 pagesNYSYRinda_RaynaNo ratings yet

- N2XSEBYDocument5 pagesN2XSEBYRinda_RaynaNo ratings yet

- MVLV Wire and CableDocument66 pagesMVLV Wire and CableMahmoud FawzyNo ratings yet

- N2XYDocument5 pagesN2XYRinda_RaynaNo ratings yet

- Eland Cables Steel Wire Armoured PVC Cable DatasheetDocument4 pagesEland Cables Steel Wire Armoured PVC Cable DatasheetDao Ming ElijordeNo ratings yet

- Copper Weld BrochureDocument4 pagesCopper Weld Brochurefarfugliare100% (1)

- Q7. Define Specific Resistance. Q8. List The Three Factors Used To Calculate Resistance of A Particular Conductor in OhmsDocument4 pagesQ7. Define Specific Resistance. Q8. List The Three Factors Used To Calculate Resistance of A Particular Conductor in OhmsAnonymous ufMAGXcskMNo ratings yet

- N2XSEKBYDocument5 pagesN2XSEKBYRinda_RaynaNo ratings yet

- THHN TC FuerzaDocument2 pagesTHHN TC Fuerzajuan pablo castro gallegoNo ratings yet

- Catalogue Wire StrandDocument18 pagesCatalogue Wire StrandbronsenwijayaNo ratings yet

- Low and Medium Voltage Cable Fundamentals GuideDocument52 pagesLow and Medium Voltage Cable Fundamentals GuideHemendra Jani100% (1)

- Lab 2-WPDocument14 pagesLab 2-WPrizwan900No ratings yet

- Acsr Din en 50182Document1 pageAcsr Din en 50182MarioNo ratings yet

- Uncoated, Weldless, 2-And 3-Wire Steel Strand For Prestressed ConcreteDocument4 pagesUncoated, Weldless, 2-And 3-Wire Steel Strand For Prestressed ConcreteGustavo SuarezNo ratings yet

- N2XCYDocument5 pagesN2XCYRinda_RaynaNo ratings yet

- Copperhead Conductor SystemDocument24 pagesCopperhead Conductor SystembhsujanNo ratings yet

- Weight Conductor CableDocument94 pagesWeight Conductor CablemehulrabariNo ratings yet

- Single Core & Multicore Flexible CablesDocument12 pagesSingle Core & Multicore Flexible Cablesdh24992499No ratings yet

- N2XSERYDocument5 pagesN2XSERYRinda_RaynaNo ratings yet

- Specs of The Tehsino Opgw Fiber CableDocument12 pagesSpecs of The Tehsino Opgw Fiber CableCarlos Aviles CutiñoNo ratings yet

- N2XSEKRY 3 X (25-300) MM 3.6/6 KVDocument5 pagesN2XSEKRY 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- AR307 Building Services Materials Market SurveyDocument22 pagesAR307 Building Services Materials Market SurveyAhtesham KhanNo ratings yet

- PC1 54 PDFDocument122 pagesPC1 54 PDFbharatsehgal00@gmail.comNo ratings yet

- Charoong Thai Wire & Cable Public Company Limited: Ctw-AcsrDocument2 pagesCharoong Thai Wire & Cable Public Company Limited: Ctw-AcsrAchint KumarNo ratings yet

- PHELPS DODGE Superflex Pdic01214Document5 pagesPHELPS DODGE Superflex Pdic01214unividenteNo ratings yet

- SWG & MM ConversionDocument70 pagesSWG & MM Conversionshalu2980% (10)

- Find SWA cable online at ElandDocument5 pagesFind SWA cable online at ElandIppiNo ratings yet

- 09 Technical TablesDocument8 pages09 Technical TablesRuban Vijaya SinghNo ratings yet

- Na2Xsekfgby 3 X (25-300) MM 3.6/6 KVDocument5 pagesNa2Xsekfgby 3 X (25-300) MM 3.6/6 KVRinda_RaynaNo ratings yet

- Eland AAC conductor technical dataDocument7 pagesEland AAC conductor technical dataSathit BuapanommasNo ratings yet

- LS XLPE & AccessoriesDocument26 pagesLS XLPE & AccessoriesNavneethNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Deployment Guide For SharePoint 2013 PDFDocument1,156 pagesDeployment Guide For SharePoint 2013 PDFRoberto Moreno DoñoroNo ratings yet

- Windows 10 Tips and Tricks PDFDocument7 pagesWindows 10 Tips and Tricks PDFmadhukarreddy2811No ratings yet

- Project Management Professional (PMP) : Examination Content OutlineDocument19 pagesProject Management Professional (PMP) : Examination Content Outlineamechmar5935No ratings yet

- A Model of CSR in PJMDocument7 pagesA Model of CSR in PJMmadhukarreddy2811No ratings yet

- Siemens Power Grp-India Org. StructureDocument28 pagesSiemens Power Grp-India Org. Structuremadhukarreddy2811No ratings yet

- Green Design As Applied To CGMP BuildingsDocument25 pagesGreen Design As Applied To CGMP Buildingsmadhukarreddy2811No ratings yet

- We Are More Than Trains and Buses.: Sourcing UnitDocument11 pagesWe Are More Than Trains and Buses.: Sourcing Unitmadhukarreddy2811No ratings yet

- Daily Routines Vocabulary Matching Exercise Worksheet PDFDocument2 pagesDaily Routines Vocabulary Matching Exercise Worksheet PDFMaria Helena Bernardelli100% (1)

- Edna CruzDocument7 pagesEdna Cruzmadhukarreddy2811No ratings yet

- Infrastructure 100 World Cities 2012Document100 pagesInfrastructure 100 World Cities 2012hebrah1111No ratings yet

- White Paper Pmo External Affairs StrategyDocument7 pagesWhite Paper Pmo External Affairs Strategymadhukarreddy2811No ratings yet

- Busway SiemensDocument72 pagesBusway SiemenssnakelostNo ratings yet

- 20 Construction of Power Electric Network For Reliable Power SupplyDocument100 pages20 Construction of Power Electric Network For Reliable Power Supplymadhukarreddy2811No ratings yet

- 13 Civil Tech Spec No 38Document41 pages13 Civil Tech Spec No 38Rajesh Parida100% (1)

- AC Tank Type Test TRFRMR by HAEFELYDocument20 pagesAC Tank Type Test TRFRMR by HAEFELYmadhukarreddy2811No ratings yet

- Demag Cranes CatalogDocument20 pagesDemag Cranes Catalogmadhukarreddy2811100% (2)

- Accounting Standard 7 Construction ContractsDocument35 pagesAccounting Standard 7 Construction Contractsvaish2u8862No ratings yet

- High Power IGBT Inverter DesignDocument29 pagesHigh Power IGBT Inverter DesignOmer Fayyaz100% (3)

- Dielectric in Electric FieldDocument34 pagesDielectric in Electric FieldBo BogdanNo ratings yet

- Practical Introduction To Power System Protection & ControlDocument94 pagesPractical Introduction To Power System Protection & Controlriogomes73% (11)

- Space Charge in Solid DielectricsDocument55 pagesSpace Charge in Solid Dielectricssnehith100% (1)

- Practical Introduction To Power System Protection & ControlDocument94 pagesPractical Introduction To Power System Protection & Controlriogomes73% (11)

- E1 11Document6 pagesE1 11madhukarreddy2811No ratings yet

- Busway SiemensDocument72 pagesBusway SiemenssnakelostNo ratings yet

- How To Define The Market Structure?: 15.835: Entrepreneurial MarketingDocument3 pagesHow To Define The Market Structure?: 15.835: Entrepreneurial Marketingmadhukarreddy2811No ratings yet

- TR - Line DesignDocument7 pagesTR - Line Designmadhukarreddy2811No ratings yet

- G R E Revised General Test: Analytical Writing Sample QuestionsDocument5 pagesG R E Revised General Test: Analytical Writing Sample Questionsmadhukarreddy2811No ratings yet

- NTPC DADRI TrainingDocument21 pagesNTPC DADRI Trainingujjawal100% (2)

- Basic Cost Management ConceptsDocument33 pagesBasic Cost Management ConceptsMarcela Nichol RaymundoNo ratings yet

- Effective Thermal Design of Cooling TowersDocument6 pagesEffective Thermal Design of Cooling TowersandrshoNo ratings yet

- Act. 2Document8 pagesAct. 2olpotNo ratings yet

- Structural Design For Embankment Dam BottomdischargeDocument8 pagesStructural Design For Embankment Dam BottomdischargeAnonymous 87xpkIJ6CFNo ratings yet

- Tsp-Pogc-Nigc T.T.FDocument41 pagesTsp-Pogc-Nigc T.T.FvasudhaNo ratings yet

- 1807 VS 1 Performance SpecificationsDocument89 pages1807 VS 1 Performance SpecificationsNiko TassigiannakisNo ratings yet

- DTR MPG 1750-4p Nv14-EngDocument74 pagesDTR MPG 1750-4p Nv14-EngZvone MurkoNo ratings yet

- KESSEL System 400 Rainwater Filter For Above or Underground Installation With or Without Filter BackwashDocument2 pagesKESSEL System 400 Rainwater Filter For Above or Underground Installation With or Without Filter Backwashcris62No ratings yet

- Everything You Need to Know About the Roller IndustryDocument26 pagesEverything You Need to Know About the Roller IndustryAshwani SharmaNo ratings yet

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To Informationraisingh085No ratings yet

- Foerster Circograph 2014 enDocument6 pagesFoerster Circograph 2014 enTiến NguyễnNo ratings yet

- BVH2021 GBDocument32 pagesBVH2021 GBsamer salamehNo ratings yet

- Westds 09038 Us 1302 PDFDocument2 pagesWestds 09038 Us 1302 PDFrafaelpaiva871531No ratings yet

- Siri TriboelektrikDocument5 pagesSiri TriboelektrikRasailul AshwaqNo ratings yet

- General Properties of Elastomers Summary ChartDocument1 pageGeneral Properties of Elastomers Summary ChartvenkatramanNo ratings yet

- Cable Tray ManualDocument59 pagesCable Tray Manualamer_arauf100% (5)

- Differential CaseDocument5 pagesDifferential CaseOmar Jayson Siao VallejeraNo ratings yet

- 319 Docol Product ProgramDocument2 pages319 Docol Product Programchristos032No ratings yet

- Technical Bulletin: 3M VHB DurabilityDocument6 pagesTechnical Bulletin: 3M VHB DurabilityAlvin Dela CruzNo ratings yet

- Minolta Ep1050 ServiceDocument266 pagesMinolta Ep1050 ServiceSunny SinghNo ratings yet

- Pioneer DEH 1330R, DeH 1300R, DeH 1310 Service ManualDocument75 pagesPioneer DEH 1330R, DeH 1300R, DeH 1310 Service Manualmomi201150% (2)

- Inside BopDocument5 pagesInside BopNigin Parambath100% (1)

- Chapter 9 - Electron Beam WeldingDocument14 pagesChapter 9 - Electron Beam WeldingrafikdmeNo ratings yet

- PowerWave 044-05307 OS-1991-H0-003 Installation and Service Manual Rev ADocument70 pagesPowerWave 044-05307 OS-1991-H0-003 Installation and Service Manual Rev ARobb RobinsonNo ratings yet

- METHOD STATEMENT FOR INSTALLATION of PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete Walls PDFDocument6 pagesMETHOD STATEMENT FOR INSTALLATION of PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete Walls PDFselvamejia0% (1)

- Introduction To Drylab A: Stephan Sylvest Keller, Dtu NanolabDocument6 pagesIntroduction To Drylab A: Stephan Sylvest Keller, Dtu NanolabAlberto GallottiniNo ratings yet

- High Friction Surfacing: About Ennis-FlintDocument2 pagesHigh Friction Surfacing: About Ennis-FlintZaheer DoomahNo ratings yet

- 3.3 - Lockhart & Crescenzi - Sour Oil and Gas Management PDFDocument34 pages3.3 - Lockhart & Crescenzi - Sour Oil and Gas Management PDFsantiagoNo ratings yet

- Reactivod de FlotacionDocument4 pagesReactivod de FlotacionHector RamosNo ratings yet