Professional Documents

Culture Documents

Setting Standard Times

Uploaded by

Im In TroubleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Setting Standard Times

Uploaded by

Im In TroubleCopyright:

Available Formats

TIME STUDY

- A technique for developing a standard

based on actual observations of the

operator

- Sets a standard time based on timed

observations of one employee taken

over a number of cycles

- A cycle includes all the elements of the

job.

PROCEDURE FOR A TIME STUDY

1. Choose the job for the time study

2. Tell the worker whose job you will be studying

3. Break the job into easily recognizable units

4. Calculate the number of cycles you must observe.

5. Time each element, record the times, and rate the

workers performance

6. Compute normal time

7. Compute the standard time

HOW TO DO A TIME STUDY

When making a time study several

decisions are made to assure desired

results:

# of observations to make

Desired level of accuracy

Desired level of confidence for the estimated

standard time

Desired accuracy level is typically

expressed as a % of the mean observed

times

DOING A TIME STUDY

Need to determine how many observations are required

Involves determining the level of accuracy required and

confidence level desired

n: number of observations of an element that are needed

z: the number of normal standard deviations needed for desired confidence

s: the standard deviation of the sample

a: desired accuracy or precision

x-bar: the mean of the sample observations

2

(

|

.

|

\

|

|

.

|

\

|

>

x

s

a

z

n

Pats Pizza Place: Pat hires an analyst to determine a

standard time to prepare a large pepperoni and cheese

pizza. He takes 10 observations of the 7 elements and

calculates the mean time and the standard deviation

per element. He must then calculate the # of

observations to be within 5% of the true mean 95% of

the time.

1

2

3

4

5

6

7

8

9

10

A B C D E

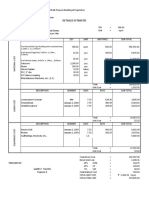

Example 11.3 Pat's Pizza Place

Standard Deviation Mean Observed Revised Observed

Work Element (minutes) Time (minutes) Time (minutes) # Observations

1. Get ball of dough 0.010 0.12 0.15 11

2. Flatten dough 0.030 0.25 0.25 23

3. Spin and toss dough 0.040 0.50 0.60 10

4. Place dough on counter 0.005 0.12 0.15 3

5. Pour sauce on formed dough 0.035 0.30 0.30 21

6. Place grated cheese on top 0.025 0.25 0.28 16

7. Place pepperoni on sauce 0.030 0.24 0.28 25

The analyst must calculate the observations for

each element to determine how many additional

observations must be taken. The maximum

number of 25 (in this case) for element #7

means that an additional 15 observations must

be made and then the observed times are

revised.

ns observatio 25

0.24

0.03

0.05

1.96

x

s

a

z

n

2 2

7 =

(

|

.

|

\

|

|

.

|

\

|

=

(

|

.

|

\

|

|

.

|

\

|

=

OTHER FACTORS USED IN CALCULATING

STANDARD TIME

The normal time (NT) is the mean observed time

multiplied by the performance rating factor

(PRF)

The PRF is a subjective estimate of a workers

pace relative to a normal work pace

The frequency of occurrence (F) is how often the

element must be done each cycle.

OTHER FACTORS USED IN CALCULATING

STANDARD TIME

The allowance factor (AF) is the amount of time

allowed for personal, fatigue, and unavoidable

delays

Standard Time=normal time x allowance factor,

where:

(NT)(AF) ST

117.6% 1.176

0.15 1

1

PFD 1

1

AF Worked Tme

=

= =

=

CALCULATING NORMAL TIME AND STANDARD

TIME AT PATS PIZZA

12

13

14

15

16

17

18

19

20

21

22

A B C D E F

Example 11.4 Calculating Standard Time for a Hand-Tossed Cheese and Pepperoni Pizza

Revised Observed Performance Rating Frequency Normal Time Standard Time

Work Element Time (minutes) Factor (minutes) (minutes)

1. Get ball of dough 0.15 0.90 1 0.135 0.159

2. Flatten dough 0.25 1.00 1 0.250 0.294

3. Spin and toss dough 0.60 0.85 1 0.510 0.600

4. Place dough on counter 0.15 1.10 1 0.165 0.194

5. Pour sauce on formed dough 0.30 1.20 1 0.360 0.423

6. Place grated cheese on top 0.28 1.00 1 0.280 0.329

7. Place pepperoni on sauce 0.28 0.95 1 0.266 0.313

Total Time 1.966 2.312

The standard time for preparing a large, hand-tossed

pepperoni pizza is 2.312 minutes. This means that a

worker can prepare 207 pizzas in an 8-hour shift (480

minutes divided by 2.312 minutes)

OTHER TIME STUDY METHODS

Elemental time data establishes standards

based on previously completed time studies,

stored in an organizations database.

Predetermined time data (e.g. MTM and MTS) is

a published database element time data used

for establishing standard times

Reach, grasp, move, engage, insert, turn, etc.

Work Sampling is a technique for estimating

the proportion of time a worker spends on an

activity

WORK SAMPLING PROCEDURE

1. Identify the worker or machine to be sampled

2. Define the activities to be observed

3. Estimate the sample size based on level of

accuracy and confidence level

4. Develop the random observation schedule. Make

observations over a time period that is

representative of normal work conditions

5. Make you observations and record the data. Check

to see whether the estimated sample size remains

valid

6. Estimate the proportion of the time spent on the

given activity

Work Sampling Example: We are interested in estimating the

proportion of time spent by secretaries arranging and

scheduling travel. We are considering the possibility of

bringing an on site travel agency to free up secretaries from

this time consuming task. We estimate that the proportion

might be as high as .50.

Step 1 We need to estimate the number of observations

needed to provide an estimate with 97% confidence (z=2.17),

and the resulting estimate will be within 5% of its true value.

We use

0.5 p =

( ) ns observatio 470.89 0.5 1 0.5

0.05

2.17

p 1 p

e

z

n

2 2

=

|

.

|

\

|

=

|

|

.

|

\

|

|

.

|

\

|

>

) )

Step 2 Based on the first 30 observations the secretary was

making travel reservations 6 times (6 out of 30

observations = 0.2). With this new estimate, recalculate the

sample size needed .

Final Step After making the 302 observations, the

secretary was making reservations 60 times or 19.9%.

This estimate can now be used to make the decision

on savings that might result by consolidating this

task with an in house travel agency

( ) ns observatio 302 0.2 1 0.2

0.05

2.17

n

2

=

|

.

|

\

|

>

COMPENSATION

Compensation is the third part of work system design

Time-based plans (pay based on the number of hours

worked) vs. output-based systems (pay based on the

number of units completed)

Group incentive plans: profit sharing & gain sharing

Plans put part of a workers salary at risk

Does the compensation system undermine teamwork?

Does plan prevent free-riders not doing their fair share?

Does the incentive plan encourage workers to support the

long-term health of the organization?

WORKER COMPENSATION SYSTEMS

Group incentive plans reward employees when

company achieves certain performance objectives

Profit sharing a employee bonus pool based on

sharing of companys profits

Gain sharing emphasizes cost reduction rather than

profits

Plans put part of a workers salary at risk

Compensation system may undermine teamwork

LEARNING CURVES

When the number of times the task is repeated

doubles, the time per task reduces as shown in

the graph

With an 85% learning curve rate, the 2nd time a

task is done will take 85% of the 1st time.

The 4

th

time will take 85% of the 2

nd

If an employee took 12 hours to complete an initial

task, how long will the 16

th

time take (4

th

doubling)?

T x L

n

= time required to perform a task the nth time

T = the time required to perform the task the first time

L = the rate of learning

n = the number of times the task has doubled

hours 6.26 (.85) x 12 task 16th for Hours

4

= =

You might also like

- Farparcor 2 Chapter 1 Exercises Problem AnswersDocument10 pagesFarparcor 2 Chapter 1 Exercises Problem AnswersWillnie Shane LabaroNo ratings yet

- Jamil - 1418 - 2494 - 1 - Cost and Management Accounting (Summer 2021)Document2 pagesJamil - 1418 - 2494 - 1 - Cost and Management Accounting (Summer 2021)kashif aliNo ratings yet

- Benha University Production Planning Forecasting TechniquesDocument2 pagesBenha University Production Planning Forecasting TechniquesMuhammad Naveed IkramNo ratings yet

- CS ASSESSMENT Map Coloring, Scheduling and Graph AnalysisDocument3 pagesCS ASSESSMENT Map Coloring, Scheduling and Graph AnalysisErica Bianca TorresNo ratings yet

- Final Term Assignment 2 on Partnership OperationsDocument2 pagesFinal Term Assignment 2 on Partnership OperationsAnne AlagNo ratings yet

- B-BBMD001 - Asynchronous Learning ActivityDocument2 pagesB-BBMD001 - Asynchronous Learning ActivityAnthony PrincipioNo ratings yet

- Quiz 22-26 AkeyDocument6 pagesQuiz 22-26 AkeyRheman RosasNo ratings yet

- Activity 3 Exercise 1: ST ND RD TH TH TH TH TH TH TH TH THDocument7 pagesActivity 3 Exercise 1: ST ND RD TH TH TH TH TH TH TH TH THKervin Rey Jackson100% (1)

- Operational ManagementDocument2 pagesOperational ManagementNur Amalienna SyaheraNo ratings yet

- Master in Managerial Advisory Services: Easy QuestionsDocument13 pagesMaster in Managerial Advisory Services: Easy QuestionsKervin Rey JacksonNo ratings yet

- Acc 311 - Exam 1 SolutionsDocument6 pagesAcc 311 - Exam 1 SolutionsSteve SmithNo ratings yet

- Quizzer Acctg2Document1 pageQuizzer Acctg2elminvaldez0% (1)

- Passignment1-Rena Gungon-6219 A-116Document6 pagesPassignment1-Rena Gungon-6219 A-116마리레나No ratings yet

- Valuation of ContributionDocument2 pagesValuation of ContributionsunshineNo ratings yet

- Reviewer Midterm Accounting Exercises in Financial and Accouting ReportingDocument20 pagesReviewer Midterm Accounting Exercises in Financial and Accouting ReportingFiel Marie SateraNo ratings yet

- Promoting Human Rights Through Online AdvocacyDocument6 pagesPromoting Human Rights Through Online AdvocacyDump GandaraNo ratings yet

- Saunders CH08 AccessibleDocument33 pagesSaunders CH08 AccessibleindriawardhaniNo ratings yet

- MEDINA - Homework 3 Nos. 6, 7, 8, & 14Document12 pagesMEDINA - Homework 3 Nos. 6, 7, 8, & 14Von Andrei MedinaNo ratings yet

- ACCTG 124 Chapter 7Document5 pagesACCTG 124 Chapter 7John Vincent A DioNo ratings yet

- Subject Code Subject Description Module Description Objective OF ThisDocument12 pagesSubject Code Subject Description Module Description Objective OF ThisRuby Amor DoligosaNo ratings yet

- Accounting For LaborDocument1 pageAccounting For LaborkwekwkNo ratings yet

- Formation of DD and EE partnershipDocument3 pagesFormation of DD and EE partnershipmiss independent100% (1)

- If The Profits After Salaries and Bonuses Are To Be Divided Equally, and The Profits OnDocument2 pagesIf The Profits After Salaries and Bonuses Are To Be Divided Equally, and The Profits OnJoana TrinidadNo ratings yet

- Ict 2 Finals Quiz 1Document2 pagesIct 2 Finals Quiz 1Dmzjmb SaadNo ratings yet

- Art Title: Tobin Reese Fine Art Artist: FERNANDO AMORSOLO (1892-1972)Document1 pageArt Title: Tobin Reese Fine Art Artist: FERNANDO AMORSOLO (1892-1972)Ruby Baltar100% (1)

- Conversion ProblemsDocument6 pagesConversion ProblemsAce Maynard DiancoNo ratings yet

- Key Answers - Chap 6Document8 pagesKey Answers - Chap 6Mon Carla LagonNo ratings yet

- Japanese Quality InnovatorsDocument3 pagesJapanese Quality InnovatorsJennifer SamaniegoNo ratings yet

- Midterm MoiDocument2 pagesMidterm MoiSHENo ratings yet

- Problem 1: Rizal Review CenterDocument6 pagesProblem 1: Rizal Review CenterrenoNo ratings yet

- Self Test No. C3 Earnings Per Share and Book Value Per ShareDocument3 pagesSelf Test No. C3 Earnings Per Share and Book Value Per ShareAlthea CoronadoNo ratings yet

- 08 Activity 1.FMDocument3 pages08 Activity 1.FMAries Christian S PadillaNo ratings yet

- Partnership Formation ProblemsDocument2 pagesPartnership Formation ProblemsLizzeille Anne Amor MacalintalNo ratings yet

- Inventories ATs Garcia CristineJoy G BSA-1BDocument4 pagesInventories ATs Garcia CristineJoy G BSA-1BCj GarciaNo ratings yet

- Syllabi HRMA 40023 Project Management 2Document6 pagesSyllabi HRMA 40023 Project Management 2BSMA Third YearNo ratings yet

- Mas QuestionsDocument2 pagesMas QuestionsEll VNo ratings yet

- Introduction To Cost Management Systems: Cost Accounting: Foundations and Evolutions, 8eDocument34 pagesIntroduction To Cost Management Systems: Cost Accounting: Foundations and Evolutions, 8eMichelle RotairoNo ratings yet

- Labor Variance: By: Group 2Document24 pagesLabor Variance: By: Group 2Kris BayronNo ratings yet

- Audit Quiz 2Document1 pageAudit Quiz 2Von Andrei MedinaNo ratings yet

- AC17-602P-REGUNAYAN-End of Chapter 2 ExercisesDocument12 pagesAC17-602P-REGUNAYAN-End of Chapter 2 ExercisesMarco RegunayanNo ratings yet

- McDowell Industries Receivables AnalysisDocument8 pagesMcDowell Industries Receivables AnalysisTABUADA, Jenny Rose V.No ratings yet

- Chapter 1 Problem 3: Exercises: - Journal EntryDocument18 pagesChapter 1 Problem 3: Exercises: - Journal EntryAlarich CatayocNo ratings yet

- Choose Investment Projects Using NPV and Payback PeriodDocument5 pagesChoose Investment Projects Using NPV and Payback Periodbusinessdoctor23No ratings yet

- Job Order Costing Activity 2Document7 pagesJob Order Costing Activity 2RJ MonsaludNo ratings yet

- Question Text: Retained Earnings Retained Earnings Retained Earnings Retained EarningsDocument32 pagesQuestion Text: Retained Earnings Retained Earnings Retained Earnings Retained EarningsYou're WelcomeNo ratings yet

- ParCor Corpo EQ Set ADocument3 pagesParCor Corpo EQ Set AMara LacsamanaNo ratings yet

- Job Order CostingDocument8 pagesJob Order CostingAndrea Nicole MASANGKAYNo ratings yet

- SMA Chapter Four - Variance AnalysisDocument86 pagesSMA Chapter Four - Variance Analysisngandu100% (1)

- M1 C2 Case Study WorkbookDocument25 pagesM1 C2 Case Study WorkbookfenixaNo ratings yet

- CHAPTER Three NDocument17 pagesCHAPTER Three Ntemedebere100% (1)

- Mixed PDFDocument8 pagesMixed PDFChris Tian FlorendoNo ratings yet

- Financial Planning and Forecasting Chapter 4 Learning ObjectivesDocument33 pagesFinancial Planning and Forecasting Chapter 4 Learning ObjectivesAL SeneedaNo ratings yet

- Actg328 Msa2Document1,344 pagesActg328 Msa2Carol PagalNo ratings yet

- T A T I: Investing Cycle Learning ObjectivesDocument15 pagesT A T I: Investing Cycle Learning ObjectivesAngelo PayawalNo ratings yet

- Activity 1.1 PDFDocument2 pagesActivity 1.1 PDFDe Nev OelNo ratings yet

- PRACTICAL ACCOUNTING 1 Part 2Document9 pagesPRACTICAL ACCOUNTING 1 Part 2Sophia Christina BalagNo ratings yet

- Work Measurement-Compressed VersionDocument48 pagesWork Measurement-Compressed VersionL.a. LadoresNo ratings yet

- Work Measurement: A Methodology Used For Establishing Time StandardsDocument24 pagesWork Measurement: A Methodology Used For Establishing Time StandardsLa GraciahNo ratings yet

- StopwatchDocument4 pagesStopwatchyasin husenNo ratings yet

- Time StudyDocument8 pagesTime Studyrub786No ratings yet

- Hollistic-Dominancy Test-Freedom Vs FreemanDocument5 pagesHollistic-Dominancy Test-Freedom Vs FreemanIm In TroubleNo ratings yet

- Part 2 - Annex F - SEC MC 13, S. 2009 PDFDocument19 pagesPart 2 - Annex F - SEC MC 13, S. 2009 PDFBeatriz VillafuerteNo ratings yet

- RFBT Finals EditedDocument2 pagesRFBT Finals EditedIm In TroubleNo ratings yet

- Secretarys Certificate NonExistence Corp DisputeDocument1 pageSecretarys Certificate NonExistence Corp DisputeIm In TroubleNo ratings yet

- I See Fire ChordsDocument4 pagesI See Fire ChordsIm In TroubleNo ratings yet

- ExerciseDocument1 pageExerciseIm In TroubleNo ratings yet

- Labor Law DigestDocument2 pagesLabor Law DigestIm In TroubleNo ratings yet

- 5 CorpoDocument46 pages5 CorpointerscNo ratings yet

- Depletion RevaluationDocument2 pagesDepletion RevaluationIm In TroubleNo ratings yet

- Paps 1003phDocument25 pagesPaps 1003phThessaloe B. FernandezNo ratings yet

- Let It Go ChordsDocument3 pagesLet It Go ChordsIm In TroubleNo ratings yet

- Let Her Go ChordsDocument4 pagesLet Her Go ChordsIm In TroubleNo ratings yet

- Employment ContractDocument3 pagesEmployment ContractIm In TroubleNo ratings yet

- Stairway To Heaven Tab GuideDocument17 pagesStairway To Heaven Tab GuideIm In Trouble100% (1)

- Case DigestDocument2 pagesCase DigestIm In TroubleNo ratings yet

- Dont Wait Too Long TabDocument3 pagesDont Wait Too Long TabIm In TroubleNo ratings yet

- Always A Use ChordsDocument2 pagesAlways A Use ChordsIm In TroubleNo ratings yet

- Dreamland ChordsDocument2 pagesDreamland ChordsIm In TroubleNo ratings yet

- Blue Alert ChordsDocument2 pagesBlue Alert ChordsIm In TroubleNo ratings yet

- COA Authority to Disallow Consultancy ContractsDocument2 pagesCOA Authority to Disallow Consultancy ContractsIm In Trouble100% (1)

- UP v. DizonDocument0 pagesUP v. DizonRonwell Lim100% (2)

- Case Digest Political 1Document31 pagesCase Digest Political 1Im In TroubleNo ratings yet

- Smokey Fashion Waste Bin (Yellow Paper)Document9 pagesSmokey Fashion Waste Bin (Yellow Paper)Im In TroubleNo ratings yet

- Archbishop Capalla v. COMELECDocument3 pagesArchbishop Capalla v. COMELECIm In Trouble100% (3)

- Implementing Rules RA 9184Document76 pagesImplementing Rules RA 9184marifer_fagelaNo ratings yet

- Remedial Law Memory AidDocument38 pagesRemedial Law Memory AidIm In TroubleNo ratings yet

- Philippines SGP Case StudyDocument101 pagesPhilippines SGP Case StudyIm In TroubleNo ratings yet

- Go Ong VsDocument3 pagesGo Ong VsIm In TroubleNo ratings yet

- Smewhre ChordsDocument11 pagesSmewhre ChordsIm In TroubleNo ratings yet

- AirwayBill 0NGKT15231058Document1 pageAirwayBill 0NGKT15231058halipzramlyzNo ratings yet

- 06 100 HR Management PlanDocument12 pages06 100 HR Management PlanBrian Shanny100% (1)

- 3rd Module Consumer BehaviorDocument9 pages3rd Module Consumer BehaviorAnantha NagNo ratings yet

- Harrison - The Peasant Mode of Production in The Work of AV ChayanovDocument14 pagesHarrison - The Peasant Mode of Production in The Work of AV ChayanovAndrea LeónNo ratings yet

- Transfer of Property Act - Ramesh Chand Vs Suresh Chand, Delhi High CourtDocument18 pagesTransfer of Property Act - Ramesh Chand Vs Suresh Chand, Delhi High CourtLatest Laws TeamNo ratings yet

- Audit Working Papers ReceivablesDocument3 pagesAudit Working Papers ReceivablesKeith Joshua GabiasonNo ratings yet

- Date (Value Date) Narration Ref/Cheque No. Debit Credit BalanceDocument5 pagesDate (Value Date) Narration Ref/Cheque No. Debit Credit BalanceanubhaNo ratings yet

- Administrative Secretary Job DescriptionDocument8 pagesAdministrative Secretary Job DescriptionadministrativemanageNo ratings yet

- ISO 9001 For Hammer Strength Fitness ClubDocument9 pagesISO 9001 For Hammer Strength Fitness Clubsayem.unicertNo ratings yet

- Process Design AssignmentDocument2 pagesProcess Design Assignmentcarlme012132100% (5)

- Pub 100427Document5 pagesPub 100427Engr Nabeel AhmadNo ratings yet

- Rate of Return Analysis (Online Version)Document35 pagesRate of Return Analysis (Online Version)samiyaNo ratings yet

- OD125549891478426000Document1 pageOD125549891478426000अमित कुमारNo ratings yet

- The Science of Ship ValuationDocument10 pagesThe Science of Ship ValuationWisnu KertaningnagoroNo ratings yet

- New Product Planning ProcessDocument18 pagesNew Product Planning ProcessAqeel MuradNo ratings yet

- Sales Tracker - SeptDocument33 pagesSales Tracker - SeptNikhilNo ratings yet

- SUCCESS STORIES OF FIVE ENTREPRENEURS IN PAKISTANDocument25 pagesSUCCESS STORIES OF FIVE ENTREPRENEURS IN PAKISTANharis khanNo ratings yet

- Agreements - HTML: Dassault Systemes Biovia Corp.Document5 pagesAgreements - HTML: Dassault Systemes Biovia Corp.Joakin BahamondesNo ratings yet

- ProjectDocument20 pagesProjectnandsirNo ratings yet

- Alacan (48 Bakal)Document107 pagesAlacan (48 Bakal)Marc Dared CagaoanNo ratings yet

- 0115 GearSolutionsDocument60 pages0115 GearSolutionsignaciomarin0% (1)

- Felipe, Fisher. Aggregation in Production Functions. What Applied Economists Should Know - Metroeconomica - 2003 PDFDocument55 pagesFelipe, Fisher. Aggregation in Production Functions. What Applied Economists Should Know - Metroeconomica - 2003 PDFjuancahermida3056No ratings yet

- OKR One PagerDocument1 pageOKR One Pagermyrudyku100% (1)

- Vouching ControlDocument42 pagesVouching ControlSundayNo ratings yet

- BIM Execution Plan ExampleDocument20 pagesBIM Execution Plan ExampleDarell IvanderNo ratings yet

- Thesis Main - Nishanth VadduriDocument56 pagesThesis Main - Nishanth VaddurinishanthnaiduNo ratings yet

- SAP ABAP FundamentalsDocument26 pagesSAP ABAP FundamentalsRachit Goyal100% (1)

- Kenya: IEBC Polling Stations Without 3GDocument161 pagesKenya: IEBC Polling Stations Without 3GWanjikũRevolution Kenya100% (1)

- SEC Registration Memo New Logo 11-22-11Document6 pagesSEC Registration Memo New Logo 11-22-11sfplayrNo ratings yet

- Rezza Prayogi - Master ThesisDocument193 pagesRezza Prayogi - Master ThesisRezza100% (13)