Professional Documents

Culture Documents

Power

Uploaded by

Mohammed AL-MaaitahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power

Uploaded by

Mohammed AL-MaaitahCopyright:

Available Formats

Automatic Generation Control

(AGC)

by

Dr. Deependra Kumar Jha

ME (Power Systems), PhD (Electric Power System Engineering)

Professor, Department of Electrical Engineering

School of Engineering & Technology, Galgotias University

1

Outline

Purpose and Overview of AGC

Automatic Generation Control (AGC)

System modeling: control block

diagram

AGC for single generator

AGC for 2 generators

AGC for multi generators

Area Control Error (ACE)

2

Purpose of AGC

To maintain power balance in the

system.

Make sure that operating limits are not

exceeded:-

Generators limit

Tie-lines limit

Make sure that system frequency is

constant (not change by load).

3

Overview of AGC

Load is always changing.

To maintain power balance,

generators need to produce more or

less to keep up with the load.

When Gen < Load (Gen > Load),

generator speed and frequency will

drop (rise).

=> We use this generator speed and

frequency as control signals!

4

3 Components of AGC

Primary control

Immediate (automatic) action to sudden change of load.

For example, reaction to frequency change.

Secondary control

To bring tie-line flows to scheduled.

Corrective actions are done by operators.

Economic dispatch

Make sure that the units are scheduled in the most

economical way.

This presentation covers only primary and

secondary control of AGC.

5

AGC for Single Area

System Modeling

Single Generator

Multi Generators, special case: two

generators

6

System Modeling: Turbine-Governor

Model

Small signal analysis model, relating mechanical

power to the control power and the generator

speed.

Where = Small change in control setting power

= Small change in governor synchronous speed

= Small change in mechanical output power

= Regulation constant

= Transfer function relating mechanical power to control signals

7

e A

C

P A

M

P A

( )( )

T G

sT sT + + 1 1

1

( ) s G

M

R

1

+

-

e A

C

P A

M

P A

( ) s G

M

R

Speed-Power Relationship

( )

|

.

|

\

|

A A = A e

R

P s G P

C M M

1

8

From synchronous turbine-governor:

small signal analysis model,

At steady state (s 0, 1),

we have

e A A = A

R

P P

C M

1

( ) s G

M

Static Speed-Power

Curve

From,

Primary control: Immediate

change corresponding to

sudden change of load

(frequency)

Secondary control: Change in

setting control power to

maintain operating frequency.

The higher R (regulation), the

better.

9

e A A = A

R

P P

C M

1

e

Slope = -R

1 M

P

2 M

P

1 C

P

2 C

P

M

P

= =

1

2

0

e

Turbine and Generator Load

Model

Turbine Model

Generator load model

10

1

Kp

STp +

( ) F s A

( )

D

P s A

( )

g

P s A

-

+

1

Kt

STt +

( )

g

P s A

( )

E

Y s A

AGC for Single Generator

closed loop power control system as

below.

11

C

P A

( )( )

1 1

g T

Kg Kt

sT sT + +

R

1

+

-

1

Kp

STp +

( ) F s A

( )

D

P s A

( )

g

P s A

-

+

AGC for Multi Generators

Consider effect of

power flows in transmission lines, and

loads at each bus

to mechanical power of each

generator.

This analysis assumes that every bus

is a generator bus.

12

Power Balance Equation at Each

Bus

At each bus,

Where

= Generator i power

= Load power at bus I

= Power flow from bus i

Consider small

changes,

i Di Gi

P P P + =

13

2 G

P

1 G

P

Gi

P

Di

P

i

P

i Di Gi

P P P A + A = A

G1 G2

3 D

P

1 D

P

2

V

1

V

3

V

G3

2 D

P

3 G

P

2

P

1

P

Load Power Equation ( )

Assume that

Where

= Small change of load input

= Small change of load power

= Small change of voltage angle

Substitute in power balance equation,

We have

14

Li i Li Li i Li Di

P D P D P A + A = A + A = A o u

Di

P A

i

u

A

Li

P A

Di

P A

i Li i Li Gi

P P D P A + A + A = A o

i Di Gi

P P P A + A = A

Mechanical Power of Each Generator (

)

Linearized equation relating

mechanical power to generator power

and generator speed.

Where

= Small change in mechanical power of

generator i

= Small change in electric power of generator i

= small change in internal voltage angle of

generator i

From,

We have

15

Gi i i i i Mi

P D M P A + A + A = A o o

Mi

P A

Gi

P A

i

o A

Gi

P A

i Li i Li Gi

P P D P A + A + A = A o

i Li i Li i i i i Mi

P P D D M P A + A + A + A + A = A o o o

Generator Block Diagram

From,

We can write

where

16

( )

( )

i Li Mi

i i

i

P P P

D s M

A A A

+

= A

~

1

o

i Li i Li i i i i Mi

P P D D M P A + A + A + A + A = A o o o

Li i i

D D D + =

~

i i

D s M +

1

s

1

+

-

-

Mi

P A

Li

P A

i

o A

i

o e

A = A

i

P A

AGC for Multi Generators: Block

Diagram

17

( ) s G

Mi

i

R

1

+

-

( ) s G

Pi

i

e A

Mi

P A

Li

P A

Ci

P A

i

P A

+

-

-

( )

( )

i i

Pi

D s M

s G

~

1

+

= ( )

( )( )

Ti Gi

Mi

sT sT

s G

+ +

=

1 1

1

Change in tie-line

power flow

Tie-line Model ( )

From power flow equation,

Approximate at normal operating

condition, we have

Then, for small change,

Where is called stiffness or synchronizing power coefficient

18

i

P A

( )

=

=

n

k

k i ik k i i

B V V P

1

sin u u

( )

=

~

n

k

k i ik i

B P

1

u u

( ) ( )

= =

A A = A A ~ A

n

k

k i ik

n

k

k i ik i

T B P

1 1

u u u u

ik

T

Tie-Line Block Diagram

From and

We have,

19

( )

=

A A = A

n

k

k i ik i

T P

1

u u

e u A = A

s

1

( )

=

A A = A

n

k

k i

ik

i

s

T

P

1

e e

s

1

+

+

+

ik

T

i

P A

i

u A i

e A

+

-

+

- +

-

k

u A

AGC for 2-Generator: Block

Diagram

20

( ) s G

M 2

2

1

R

+

-

( ) s G

P2

2

e A

2 M

P A

2 L

P A

2 C

P A

21 2

P P A = A

+

-

-

2

o A

s

-

( ) s G

M1

1

1

R

+

-

( ) s G

P1

1

e A

1 M

P A

1 L

P A

1 C

P A

12 1

P P A = A

+

-

-

1

o A

s

+

-1

12

T

AGC for 2-Generator:

Static Speed-Power Curve

Load increases.

Frequency drops.

Steady state is reached

when frequency of both

generators is the same.

e

21

1 M

P

2 M

P

+ Ae

M

P

1

2

0

e

+ = Change in

total load

1 M

P'

2 M

P'

Steady State Frequency Calculation:

2 generators

From

Consider the frequency at steady

state,

22

i Li i i i Li i i i i Mi

P P D P P D M P A + A + A = A + A + A + A = A e e e

~ ~

line tie L M

P P D P

A + A + A = A

1 1 1 1

~

e

line tie L M

P P D P

A A + A = A

2 2 2 2

~

e

2 1

e e e A = A = A

e A = A

1

1

1

R

P

M

e A = A

2

2

1

R

P

M

|

|

.

|

\

|

+ + +

A A

= A

2 1

2 1

2 1

1 1 ~ ~

R R

D D

P P

L L

e

AGC for Multi Areas

Simplified Control Model

Area Control Error (ACE)

23

Simplified Control Model

Generators are grouped into control areas.

Consider

An area as one generator in single area, and,

Tie-lines between areas as transmission lines

connecting buses in single area.

We can apply the same analysis to multi-

area!!

However, we have to come up with

frequency-power characteristics of each

area.

Actual application of this model is for power

pool operation.

24

Power Pool Operation

Power pool is an interconnection of the

power systems of individual utilities.

Each company operates independently,

BUT,

They have to maintain

contractual agreement about power

exchange of different utilities, and,

same system frequency.

Basic rules

Maintain scheduled tie-line capacities.

Each area absorbs its own load changes.

25

AGC for Multi Areas

During transient period, sudden change of load

causes each area generation to react according to

its frequency-power characteristics.

This is called primary control.

This change also effects steady state frequency and

tie-line flows between areas.

We need to

Restore system frequency,

Restore tie-line capacities to the scheduled value, and,

Make the areas absorb their own load.

This is called secondary control.

26

Area Control Error (ACE)

Control setting power of each area

needs to be adjusted corresponding to

the change of scheduled tie-line

capacity and change of system

frequency.

ACE measures this balance, and is

given by,

for two area case.

Where = Frequency bias setting of area i (>0) and 27

e A + A =

1 12 1

B P ACE

e A + A =

2 21 2

B P ACE

i

B

|

|

.

|

\

|

+ =

i

Li i

R

D B

1

ACE: Tie-Line Bias Control

Use ACE to adjust setting control power,

, of each area.

Goal:

To drive ACE in all area to zero.

To send appropriate signal to setting control

power,

Use integrator controller so that ACE

goes to zero at steady state.

28

Ci

P A

Ci

P A

AGC for 2-Area with Tie-line Bias Control: Block

Diagram

29

( ) s G

M 2

2

1

R

+

-

( ) s G

P2

2

e A

2 M

P A

2 L

P A

2 C

P A

21 2

P P A = A

+

-

-

2

o A

s

-

( ) s G

M1

1

1

R

+

-

( ) s G

P1

1

e A

1 M

P A

1 L

P A

1 C

P A

12 1

P P A = A

+

-

-

1

o A

s

+

-1

12

T

-1

+

+

+

+

s

K

2

s

K

1

1

e A

2

e A

12

P A

21

P A

1

B

2

B

1

ACE

2

ACE

You might also like

- Extra Task 2 Task CardsDocument1 pageExtra Task 2 Task CardsAndrea PerezNo ratings yet

- ECE 3054: Signals, Systems, and TransformsDocument2 pagesECE 3054: Signals, Systems, and TransformsMohammed AL-MaaitahNo ratings yet

- ﻞﺒﻗ ، ﻰﻠﻋ ﻖﻓاو Agree toDocument20 pagesﻞﺒﻗ ، ﻰﻠﻋ ﻖﻓاو Agree tohmam_88No ratings yet

- Amplifier Circuits Analysis - GDLCDocument15 pagesAmplifier Circuits Analysis - GDLCMohammed AL-MaaitahNo ratings yet

- English Grammar in Use Extra Cd-Rom ReadmeDocument6 pagesEnglish Grammar in Use Extra Cd-Rom ReadmeLong Nguyễn HoàngNo ratings yet

- Medium-Voltage Matrix Converter Design Using Cascaded Single-Phase Power Cell ModulesDocument7 pagesMedium-Voltage Matrix Converter Design Using Cascaded Single-Phase Power Cell ModulesMohammed AL-MaaitahNo ratings yet

- Introduction To MATLABDocument8 pagesIntroduction To MATLABMohammed AL-MaaitahNo ratings yet

- Chap1 PlottingDocument1 pageChap1 PlottingRafiul Hossain ShihabNo ratings yet

- Amplifier Circuits Analysis - GDLCDocument15 pagesAmplifier Circuits Analysis - GDLCMohammed AL-MaaitahNo ratings yet

- 15es32 PDFDocument178 pages15es32 PDFMohammed AL-MaaitahNo ratings yet

- Morphological ProcessingDocument19 pagesMorphological ProcessingMohammed AL-MaaitahNo ratings yet

- Image Processing Using MATLABDocument22 pagesImage Processing Using MATLABMohammed AL-MaaitahNo ratings yet

- 10 Ec 44Document127 pages10 Ec 44GAURAVNo ratings yet

- DIGITAL IMAGE FUNDAMENTALSDocument11 pagesDIGITAL IMAGE FUNDAMENTALSGramoz CubreliNo ratings yet

- Chapter 2 - MATLAB Basics - Part 2Document7 pagesChapter 2 - MATLAB Basics - Part 2Mohammed AL-MaaitahNo ratings yet

- Materials Lab. (0944374) Lab. Report: TotalDocument10 pagesMaterials Lab. (0944374) Lab. Report: TotalMohammed AL-MaaitahNo ratings yet

- Towards The Guaranteed Control of Production Output: A Probabilistic ApproachDocument6 pagesTowards The Guaranteed Control of Production Output: A Probabilistic ApproachMohammed AL-MaaitahNo ratings yet

- Fuzzy Logic ControlDocument59 pagesFuzzy Logic ControlRayah SulimanNo ratings yet

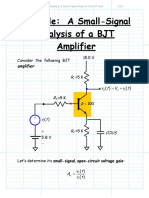

- 08 BJT ModelDocument10 pages08 BJT ModelMeenakshi VenkataramanNo ratings yet

- Small Signal Amplifier With Bipolar Junction TransistorDocument7 pagesSmall Signal Amplifier With Bipolar Junction TransistormohitNo ratings yet

- Module / Unit - 1: P - N DiodeDocument6 pagesModule / Unit - 1: P - N DiodeMohammed AL-MaaitahNo ratings yet

- Chapter 29Document42 pagesChapter 29Mohammed AL-MaaitahNo ratings yet

- ExamppleDocument2 pagesExamppleMohammed AL-MaaitahNo ratings yet

- TJB PDFDocument16 pagesTJB PDFJoão RaimundoNo ratings yet

- Introduction To MATLAB 7 For Engineers: An Overview of MATLABDocument67 pagesIntroduction To MATLAB 7 For Engineers: An Overview of MATLABMohammed AL-MaaitahNo ratings yet

- ECE312 Lec04 PDFDocument33 pagesECE312 Lec04 PDFMohammed AL-MaaitahNo ratings yet

- 08 BJT ModelDocument10 pages08 BJT ModelMeenakshi VenkataramanNo ratings yet

- 08 BJT ModelDocument10 pages08 BJT ModelMeenakshi VenkataramanNo ratings yet

- Chapter 29Document42 pagesChapter 29Mohammed AL-MaaitahNo ratings yet

- Image Processing Using MatlabDocument19 pagesImage Processing Using MatlabParamesh WaranNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Well Cementation: SynopsisDocument18 pagesWell Cementation: SynopsisHolger PinzonNo ratings yet

- Mini Esplit LGDocument76 pagesMini Esplit LGLEASUCNo ratings yet

- Train Backyard ToyDocument12 pagesTrain Backyard ToyJim100% (17)

- Blastmax 50 EngDocument96 pagesBlastmax 50 EngIslenaGarciaNo ratings yet

- Purchasing and Supply ManagementDocument78 pagesPurchasing and Supply Managementbilm100% (2)

- Ov2640 DS PDFDocument47 pagesOv2640 DS PDFpiramidon100% (1)

- Loading ArmDocument6 pagesLoading ArmSardar ShahnawazNo ratings yet

- LCA Training PackageDocument57 pagesLCA Training PackageSilvia PolliniNo ratings yet

- Study of Tig WeldingDocument11 pagesStudy of Tig WeldingChandan Srivastava100% (1)

- GeForce RTX 3090 GA102 GF PG136-A03 Rev BDocument67 pagesGeForce RTX 3090 GA102 GF PG136-A03 Rev BSe SavNo ratings yet

- Effect of Brick on Rubber Lining TemperatureDocument2 pagesEffect of Brick on Rubber Lining Temperaturetamago_fujiNo ratings yet

- Regal Raptor DAYTONA Euro IV Owner ManualDocument25 pagesRegal Raptor DAYTONA Euro IV Owner ManualKrzysztof Jakiś50% (2)

- As 1815.3-2007 Metallic Materials - Rockwell Hardness Test Calibration of Reference Blocks (Scales A B C D EDocument3 pagesAs 1815.3-2007 Metallic Materials - Rockwell Hardness Test Calibration of Reference Blocks (Scales A B C D ESAI Global - APACNo ratings yet

- UM4730 Integration GuideDocument0 pagesUM4730 Integration Guidenarse8488No ratings yet

- 2015 Dodge Grand Caravan SE 3.6L, V6, Gas, VIN GDocument6 pages2015 Dodge Grand Caravan SE 3.6L, V6, Gas, VIN GRafael Zuñiga TellezNo ratings yet

- Technical Assessment - Sample Questions: Correct Answer: 1Document5 pagesTechnical Assessment - Sample Questions: Correct Answer: 1Shruti PNo ratings yet

- EC6401-Electronic Circuits II 1Document20 pagesEC6401-Electronic Circuits II 1hod eceNo ratings yet

- Bernini PDFDocument13 pagesBernini PDFChris AntoniouNo ratings yet

- Pump KnowledgeDocument17 pagesPump Knowledgesmupy_122No ratings yet

- Leader in Innovative Packaging Solutions: Process Operating ManualDocument11 pagesLeader in Innovative Packaging Solutions: Process Operating ManualLyonelNo ratings yet

- 14.09.13 PPT On System TransientsDocument61 pages14.09.13 PPT On System TransientsRaja ShekarNo ratings yet

- Dbatu MisDocument1 pageDbatu Misgamingaao75No ratings yet

- jOOQ Manual 3.10Document303 pagesjOOQ Manual 3.10sifar786No ratings yet

- MTF - CSSDocument14 pagesMTF - CSSEdmar SamortinNo ratings yet

- Genie Operators Training Participants GuideDocument26 pagesGenie Operators Training Participants GuideAlex Killgore75% (4)

- Ds Ve 0014 enDocument6 pagesDs Ve 0014 enRudin Fahrudin RahmanNo ratings yet

- Altec Lmap CalibrationDocument17 pagesAltec Lmap Calibrationwilliam ortizNo ratings yet

- Vernacular HungarianDocument51 pagesVernacular HungariandeltagNo ratings yet

- M830ends AbDocument2 pagesM830ends Abjaved shaikh chaandNo ratings yet

- Trantech BrochureDocument4 pagesTrantech BrochureOmar Reinoso TigreNo ratings yet