Professional Documents

Culture Documents

Static

Uploaded by

Benin Patrick YawCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Static

Uploaded by

Benin Patrick YawCopyright:

Available Formats

Industrial Ventilation

Design Procedure

Design Procedure 2

Industrial Ventilation Design

Procedure

1. Find Q

2. Determine d

3. Calculate actual V

4. Calculate VP

5. Find VP loss coefficients

6. Calculate Fan SP

7. Calculate Fan TP

8. Choose Fan rpm from Fan Table

Design Procedure 3

Losses

Inches of water

Percent of velocity pressure

Friction losses

Elbow losses

Other losses

Hood entry losses

Orifice losses

Expansion and Contraction losses

Air cleaner losses

Stack losses

Design Procedure 4

Review Of Design Tables

Refer to FIGURE 5-15 to find hood entry loss

coefficients.

Refer to FIGURE 5-16 to find elbow losses.

Refer to TABLE 5-5 and TABLE 5-6 to find friction

loss for the given diameter and velocity.

Refer to TABLE 5-7A and TABLE 5-7B to find velocity

for a given VP.

Refer to TABLE 5-8 to find area for a given diameter.

Refer to TABLE 5-10 to find Air Density Correction

Factor for a given temperature and barometric

pressure.

Review rest of the tables given in chapter 5.

Design Procedure 5

Review Of Design Tables

For solving various problems given in chapter # 5 the

corresponding figures are given in chapter # 10.

For solving design problem 4, tables 10.70.1 to

10.70.4 will be useful.

Before solving the design problems go through the

figure and data given in chapter 10.

Design Procedure 6

Review Of Design Tables

Refer to TABLE 3-1 to find the various ranges of capture

velocities.

Refer to TABLE 3-2 to find the range of minimum duct

velocities for various contaminants.

Go through all the figures in chapter # 3 representing

various hoods.

Design Procedure 7

Design Procedure

GIVEN DATA:

Ventilation system:

Laboratory Hood

Volumetric Flow Rate, Q = 1500 CFM

Minimum Transport Velocity, V = 4000 FPM

Stamped elbow with R / D = 2

Design Procedure 8

Design Procedure

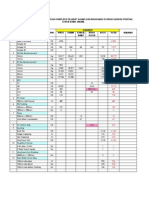

Download DESIGN PROBLEM-1

Line 1: Inlet Section

Line 2: Target Volume Flow Rate, Q = 1500 CFM (Given).

Line 3: Minimum Transport Velocity, V = 4000 FPM

(Given).

Line 4: Maximum Duct Diameter, D = 8.29

We know Q = V * A

Hence Duct Area = Q / A

= 1500 / 4000 = 0.375 Sq. Ft.

We know A = (Pi * D

2

) / 4

Hence, D = 8.29

Design Procedure 9

Design Procedure

Line 5: Selected duct diameter = 8

We got Maximum Duct Diameter D = 8.29

We have to choose a diameter that is less than maximum

selected diameter so that minimum transport velocity is

not maintained in the duct.

So, lets choose 8 diameter.

Note: Your choice is limited by the sizes given in the

table.

Line 6: Duct Area = 0.349 Sq. ft.

Duct Area (from TABLE 5-8 at D = 8) = 0.349 Sq. ft.

Line 7: Actual Duct Velocity = 4298 FPM

Velocity = Q / Area = 1500 / 0.349 = 4928 fpm

Design Procedure 10

Design Procedure

Line 8: Duct Velocity Pressure = 1.15 WG

Duct VP (from TABLE 5-7A at V = 4298 FPM) = 1.15

WG

Line 9-16 = N/A

(since there are no slots)

Line 17: Duct Entry Loss Coefficient = 0.49

Given, hood has a flanged duct end

From TABLE 5-15 for a hood that has a flanged duct

end, entry loss coefficient is 0.49

Design Procedure 11

Design Procedure

Line 18: Acceleration Factor ( 1 or 0) = 1

Since acceleration factor is 1 for hoods.

Line 19: Duct Entry Loss per VP (17 + 18) = 1.49 WG

Line 20: Duct Entry Loss (8 * 19) = 1.714

Line 21: Other Losses = 0

Line 22: Hood Static Pressure, SP

h

(16+20+21) = 1.714 WG

Line 23: Straight Duct Length = 35 ft (Given)

Line 24: Friction Factor (H

f

) = 0.0304

From TABLE 5-5 at D = 8 and V = 4000 FPM H

f

= 0.0304

Line 25: Friction Loss per VP (23 * 24) = 1.064

Line 26: No. of 90

0

degree Elbows = 1

Design Procedure 12

Design Procedure

Line 27: Elbow Loss Coefficient = 0.13

From TABLE 5-16 for a stamped elbow and R/D = 2

Line 28: Elbow Loss Factor (26 * Loss Factor(27)) = 0.13

Line 28-32 = N/A

Since there are no branch entries

Line 33: Duct Loss per VP (25 + 28 + 31+ 32) = 1.1940

Line 34: Duct Loss (8 * 33) = 1.3731

Line 35: Duct Segment SP Loss (22 + 34) = 3.087 WG

Line 36: Other Losses = N / A

Line 37: Cumulative Static Pressure = 3.087 WG

Line 38: Governing Static Pressure = -3.087 WG

Design Procedure 13

Design Procedure

Line 39-42 = N / A

Line 1: Outlet Section

Line 2-8 same as for inlet section

Line 9-22 = N / A as outlet is exhaust that is it will not have

suction part

Line 23: Straight Duct Length = 10 ft (Given)

Line 24: Friction Factor (H

f

) = 0.0304

From TABLE 5-5 at D = 8 and V = 4000 FPM H

f

= 0.0304

Line 25: Friction Loss per VP (23 * 24) = 0.3019

Line 26: No. of 90

0

degree Elbows = 1

Design Procedure 14

Design Procedure

Line 27: Elbow Loss Coefficient = 0.13

From TABLE 5-16 for a stamped elbow and R/D = 2

Line 28: Elbow Loss Factor (26 * Loss Factor(27)) = 0.13

Line 28-32 = N/A

Since there are no branch entries

Line 33: Duct Loss per VP (25 + 28 + 31+ 32) = 0.4319

Line 34: Duct Loss (8 * 33) = 0.4990

Line 35: Duct Segment SP Loss (22 + 34) = 0.499 WG

Line 36: Other Losses = N / A

Line 37: Cumulative Static Pressure = 0.499 WG

Line 38: Governing Static Pressure = -0.499 WG

Design Procedure 15

Design Procedure

Final Calculations:

The Fan SP = Sp

o

SP

in

- VP

in

= 0.499 (-3.087) 1.15

= 2.436 FPM

The Fan TP = VP

o

+ SP

o

SP

in

- VP

in

= 1.15 + 0.499 (-3.087) 1.15

= 3.586 FPM

BHP = (Fan TP * Q) / 6362 *

= (3.586 * 1500) / (6362 * 0.9)

= 0.94 hp

Where:

= Mechanical Efficiency (here taken as 0.9)

You have completed the design of laboratory hood.

Design Procedure 16

Design Problems

Download DESIGN PROBLEM 2, 3, 4 and start doing

the problems

All are of the same procedure with minor changes.

For fan pressure calculations refer 5.8 in the text

book.

Refer 5.9 to know the corrections for velocity

changes.

Refer 5.13 in the text book to get an idea of

corrections for non-standard density.

Go through various problems given in the text book.

Design Procedure 17

CALCULATION OF Vp

r

For design problems 3 and 4 you need to calculate

corrected volumetric flow rate and VP

r

.

For calculating corrected volumetric flow rate and VP

r

formulae are given in the design spread sheets.

Refer to the spread sheet solution and word solution

given carefully.

You might also like

- SQL Developer User Manual enDocument44 pagesSQL Developer User Manual ensyodudeNo ratings yet

- Communications Plan ExcelDocument12 pagesCommunications Plan ExcelPedro BentoNo ratings yet

- Excel Gantt v4Document14 pagesExcel Gantt v4PMPNo ratings yet

- Area CalculationsDocument11 pagesArea Calculationsash1968No ratings yet

- CALCULATION OF PUMP HEAD AND POWER REQUIREDDocument2 pagesCALCULATION OF PUMP HEAD AND POWER REQUIREDlutfi awn100% (1)

- Danzas IT Solutions EstimatorDocument457 pagesDanzas IT Solutions EstimatorAssem Elhajj100% (1)

- Anchor BoltDocument15 pagesAnchor BoltRyan Wiratama67% (3)

- Standard Org Chart & Role DescriptionsDocument15 pagesStandard Org Chart & Role DescriptionsAssem ElhajjNo ratings yet

- Chiller Maintenance ChecklistDocument2 pagesChiller Maintenance ChecklistAssem Elhajj100% (15)

- RET Org ChartDocument2 pagesRET Org ChartAssem ElhajjNo ratings yet

- 01 Build DeliverablesDocument7 pages01 Build DeliverablesAssem ElhajjNo ratings yet

- Electrical EstimateDocument55 pagesElectrical EstimateAssem ElhajjNo ratings yet

- Organization Charts UNDP AODocument2 pagesOrganization Charts UNDP AOAssem ElhajjNo ratings yet

- MFC Hierarchy Chart3of3Document1 pageMFC Hierarchy Chart3of3Assem ElhajjNo ratings yet

- Kaizen Structure Rev0Document86 pagesKaizen Structure Rev0hiattolaNo ratings yet

- Procurement PoliciesDocument18 pagesProcurement PoliciesAssem ElhajjNo ratings yet

- Project Charter TemplateDocument4 pagesProject Charter TemplateAssem ElhajjNo ratings yet

- Site Inspection Check List2Document38 pagesSite Inspection Check List2Assem Elhajj100% (2)

- Box PlotsDocument2 pagesBox PlotsAssem ElhajjNo ratings yet

- 0-Air Distribution System CHECKLISTDocument2 pages0-Air Distribution System CHECKLISTAssem ElhajjNo ratings yet

- 0 List of Checklists ItemsDocument3 pages0 List of Checklists ItemsAssem ElhajjNo ratings yet

- Activities: Gantt Chart - Priority Area - AgencyDocument2 pagesActivities: Gantt Chart - Priority Area - AgencyAssem ElhajjNo ratings yet

- Material Takeoff SheetDocument14 pagesMaterial Takeoff SheetAssem ElhajjNo ratings yet

- 0 Hvac ChecklistDocument13 pages0 Hvac ChecklistAssem Elhajj100% (1)

- Providing and fixing glazing in aluminium doors and windowsDocument1 pageProviding and fixing glazing in aluminium doors and windowsAssem Elhajj100% (1)

- 0030 Budget EstimateDocument56 pages0030 Budget EstimateAssem ElhajjNo ratings yet

- Project Establishment CostDocument6 pagesProject Establishment CostAssem ElhajjNo ratings yet

- Gantt Chart TemplateDocument2 pagesGantt Chart TemplateAssem ElhajjNo ratings yet

- Task Start Date Duration in Days End Date: Proposed Programme of WorksDocument2 pagesTask Start Date Duration in Days End Date: Proposed Programme of WorksAssem ElhajjNo ratings yet

- HistogramDocument2 pagesHistogramAssem ElhajjNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)