Professional Documents

Culture Documents

LPG Caverns Storage

Uploaded by

kamaldeshapriyaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LPG Caverns Storage

Uploaded by

kamaldeshapriyaCopyright:

Available Formats

Kamal Deshapriya

1

Going Underground

2

Up to second world war..

First solution mined cavern in the Canada

reportedly conceived in early 1940

3

4

60000T storage facility

for commercial

propane -1971

Storage facility for

butane 85000T - 1984

5

7.5 million m3 capacity

- 1969

6

7

8

First natural

underground storage

facility in Australia

135m under port

botany in Sydney

65000 MT of LPG

storage

Completed in 1999

9

Yeosu Terminal-1983

First Rock Cavern in Korea

Incheon LPG Cavern Korea

Sarajeh in Iran- 2009, 16 billion tons of LNG

Shurijeh in Iran- 2009, 20 billion cubic meters

of LNG

Qingdao facility China- 117000 T LPG capacity

10

11

Source: Report of Kim, Tae Moon, Advisor, The

Korean Institute of Gas, Republic of Korea

12

Visakhapatnam (Andra Pradesh)-2007

60000 MT LPG capacity for largest LPG terminal in

india

Owners are South Asia LPG company and Hindustan

Petroleum Corporation

Design and consultancy by GEOSTOCK France

Process

Geological

Hydro geological

Geo mechanical design

LARSEN & TOURBO Indian construction company

13

Suitable sub soil stratum for cavern

Hard gneissic rock

162 m below in sea level

Two main caverns 19m in height , 20 m in

width and 160 m in length connected with

small galleries

Receive large tankers

Re-exporting potential for south east Asia

14

Construction stages

Diaphragm wall excavated from surface to 20m in

sandy and unconsolidated rock

Shaft sinking in rock from -30m to -162m

Water curtain gallery at boreholes at -147 m

Storage cavern excavation

Installation of castings and tubing's in shafts

Construction of concrete plug above the cavern

15

Above ground facilities

To receive largest size LPG vessels ( 40000T)

LPG loading arms

Chilling and booster pumps

Seawater heat exchanger and pump house

Mixing skid and a vapor ejector

16

17

Gas Cavern

Storing

Technology

Example of Rock Cavern constructed using road headers for top heading & blasting for

benching followed by trimming by road headers. Cross section is 85 sq m

Source : Geostock

18

19

Mined Caverns

Lined Mined Caverns

Salt-leached Cavern

Porous Media

20

21

Access Ramp (AR)

Upper Connection (UC)

Intermediate connection

(IC)

Upper Shaft Connection (USC)

Access Shaft (AS)

Operation Shaft (OS)

Lower Shaft Connection

(LSC)

Water Gallery Operation

Shaft Connection (WOC)

Water Gallery Access Shaft

Connection (WAC)

Water Curtain Gallery

(WCG

Sump which houses the

submersible pumps

Lower connection (LC)

The finished rock cavern for LPG at Visakhapatnam

Example of an Underground Unlined Rock Cavern

22

Salt Dome

Salt Leached Caverns

Borehole

Water injection

Brine

Several

hundred

meters

Tens of

meters

23

Aquifers

Impermeable stratum

Porous & Permeable

Geological formation

Hydrocarbon Storage

24

Disused Mines

Water table

25

26

Access Ramp (AR)

Upper Connection (UC)

Intermediate connection

(IC)

Upper Shaft Connection (USC)

Access Shaft (AS)

Operation Shaft (OS)

Lower Shaft Connection

(LSC)

Water Gallery Operation

Shaft Connection (WOC)

Water Gallery Access Shaft

Connection (WAC)

Water Curtain Gallery

(WCG

Sump which houses the

submersible pumps

Lower connection (LC)

Source : Geostock

Example of cavern using a ramp for Access

Inclined Ramp

Water Curtain

Main Storage Galleries

Operation Shafts

27

Depth varies from 70m to 200m from

ground..

Size vary according to the geological

condition

There are two types

Mined caverns

Mined Lined caverns

For Poor geological condition

Plastic or metal lining with concrete plaster mine surface

28

Igneous

Granite, diorite

Metamorphic

Gneisis

Schists

hornfels

Sedimentary rocks

Sandstone

Limestone

Chalk

shale

29

30

Cavity created in rock using mining techniques

Consist one or more galleries excavated in rock

Unlined Caverns, prevent product escape by

hydraulic containment principle

Rock must be hard enough to cavern to be stable

31

GOOD GEOLOGY MEDIUM TO BAD GEOLOGY

32

Lined Rock Caverns

These types of storage facilities can be used for small or medium sized caverns. The

lining can be steel or plastics. In the depths are large the linings have to be designed to

counter the hydrostatic pressure or the can get

Steel or

plastic lining

33

Over breaks and rock falls

Over breaks as shown can slow down progress to a large

extent. Also a major safety issue.

Method of addressing poor rock conditions

To ensure there is good stability of the cavern, rock bolts need to be installed and

shortcrete applied. Poorer the rock strata, larger is the support requirement.

Rock bolts

Shotcrete

Example of Poor Rock Conditions

Large number of cracks and fissures in the rock could lead to

large over breaks .and excessive supports

Example of a water bearing zone

Water bearing zones could result in large water ingress if

pre-grouting is not resorted to. The time taken up by

grouting could delay excavation.

Pre-Grouting in excessive water bearing zones

Pre-Grouting involves

drilling a number of holes

on the face and pumping

cement paste under

pressure into them till

sealing is achieved.

High permeability and water bearing strata could

result in higher grouting and slow excavation

progress.

38

39

40

Gas Cavern

Construction

41

Access Ramp (AR)

Upper Connection (UC)

Intermediate connection

(IC)

Upper Shaft Connection (USC)

Access Shaft (AS)

Operation Shaft (OS)

Lower Shaft Connection

(LSC)

Water Gallery Operation

Shaft Connection (WOC)

Water Gallery Access Shaft

Connection (WAC)

Water Curtain Gallery

(WCG

Sump which houses the

submersible pumps

Lower connection (LC)

Pre- Feasibility

Feasibility study and site investigation

Project decision

Complimentary site investigation

Basic engineering Design

Permitting, Project financing

Contract award

Construction

First LPG import

42

CAN/CSA Z341 Series -98 Storage of

Hydrocarbons in Underground Formations

43

44

45

Excavation Using Drill & Blast (For Hard Rock)

Two Boom Jumbo (Used for drilling in hard rock)

Excavation using Road Headers (For Soft Rock)

Road Headers (Used in case of soft to medium hard rock Limestone, Chalk etc)

Equipment lowering through Shaft

Drilling & Blasting Method of Excavation

Holes are charged with

explosives after drilling

and controlled blasting

carried out

Jumbo used for

drilling holes in rock

49

Pull

Drilling & Blasting Method of Excavation

50

51

52

53

Example of Rock Cavern constructed using road headers for top heading & blasting for

benching followed by trimming by road headers. Cross section is 85 sq m

Source : Geostock

54

55

56

Product injection and withdrawal

Gas recirculation compressor

Seepage water degassing before disposal

(Water treatment plant)

Refrigeration system

Gas heating system

57

58

59

60

61

Storage capacity

C

o

s

t

/

m

3

o

f

s

t

o

r

a

g

e

Caverns in less favorable

geological conditions

Caverns in favorable

geological conditions

Lower Marginal Costs For larger

volumes

62

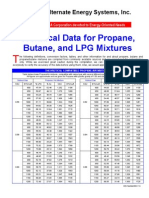

Volume Cost in USD/ Cu.m

Leached Salt Caverns 100-200

Rock Mined Caverns 10, 000 800-1200

50,000 340-580

100,000 300-500

500,000 180-280

Mounded Storage 2000-4000 800-1600

Pressurized Spheres 600-800

Refrigerated Tanks 600-800

63

Source: Report of Kim, Tae Moon, Advisor, The

Korean Institute of Gas, Republic of Korea

For All Volumes

For All Volumes

For All Volumes

Beyond certain capacities, the capital cost per ton of storage is

low.

Product is located at a depth and is fully isolated.

External Fires will not affect Storage

Maximum security. Safety hazards on account of sabotage,

storms, earthquakes and explosions are minimized.

Surface land requirement is low

Caverns by their very nature require very low maintenance.

Environment benefits. The rock debris generated can be used for

infrastructure development.

Longer life

64

Time consuming construction

Continuous monitoring required with

sufficient staff for operation

Moisture contamination

Critical, expensive temperature control

Inefficient heating and cooling

Gas Cushion and working volume

65

66

Sri Lanka is Part of a Shield area which

includes Peninsular India

Iland along with peninsular India is part of a

segment of the earth crust made up of an

ancient crystalline complex sufficiently rigid

to withstand crustal movements and thus has

remained in inflexible land mass.

67

Source: Science Education Series, No 17, by L.J.D.

Fernando. NERD, 1986

68

Special Credits for Geostock, France

You might also like

- Underground Storage in Rock CavernsDocument37 pagesUnderground Storage in Rock CavernsJinhan KimNo ratings yet

- Coal Mining Methods - EMFI SummaryDocument0 pagesCoal Mining Methods - EMFI SummaryCharles BinuNo ratings yet

- Permian Basin Development WellsDocument8 pagesPermian Basin Development WellsPesireron RoberthNo ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Underground Storage Design ComparisonDocument8 pagesUnderground Storage Design ComparisonPratik RaoNo ratings yet

- Benefits of Rock Cavern Development for Hong KongDocument23 pagesBenefits of Rock Cavern Development for Hong KongjausingchiNo ratings yet

- Formation and Stabilization of Rock Cavern Roof ArchesDocument6 pagesFormation and Stabilization of Rock Cavern Roof Archesdafo407No ratings yet

- Guide To Cavern EngineeringDocument149 pagesGuide To Cavern EngineeringTan Jee PohNo ratings yet

- Advances in Ccs Technology0409Document482 pagesAdvances in Ccs Technology0409JohanNo ratings yet

- 04 Basic Schematic Diagram of A Rotary Drilling Rig PDFDocument3 pages04 Basic Schematic Diagram of A Rotary Drilling Rig PDFSakthivel Swaminathan50% (2)

- Matthias SchulerDocument81 pagesMatthias SchulerSamuel UriarteNo ratings yet

- 31 Underground Hydrocarbon Storage in TexasDocument130 pages31 Underground Hydrocarbon Storage in Texasrachmad_irwanto100% (1)

- Mine Water DrainageDocument24 pagesMine Water DrainageDouglas YusufNo ratings yet

- Doctoral Thesis - D&B in TunnelsDocument73 pagesDoctoral Thesis - D&B in TunnelskiranismNo ratings yet

- Lec-04 & 05 Draiage & DewateringDocument33 pagesLec-04 & 05 Draiage & DewateringRahat fahimNo ratings yet

- When Rock Mechanics Met DrillingDocument13 pagesWhen Rock Mechanics Met Drillingxvacilo100% (2)

- Proposal On Horizontal Directional Drilling Research ThesisDocument3 pagesProposal On Horizontal Directional Drilling Research ThesisObumse Chukwuebuka Michael67% (3)

- CBM DrillingDocument6 pagesCBM DrillingAbhinav SharmaNo ratings yet

- Kumar 2019Document25 pagesKumar 2019RishiNo ratings yet

- Nanotechnology Applied To The Enhancement of Oil and Gas Productivity and Recovery of Colombian FieldsDocument68 pagesNanotechnology Applied To The Enhancement of Oil and Gas Productivity and Recovery of Colombian FieldsMontes? 021No ratings yet

- Overview of CO2 EORDocument34 pagesOverview of CO2 EORrecsco2No ratings yet

- Drilling Engineering IV - 2729853Document67 pagesDrilling Engineering IV - 2729853adeelsnNo ratings yet

- Applying Sand Management for Amal FieldDocument14 pagesApplying Sand Management for Amal Fieldabdulsalam alssafi94No ratings yet

- Shaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Document21 pagesShaft Sinking: Department of Mining Engineering Muet Jamshoro (11-04-2014)Carlos Arturo Casas HuamánNo ratings yet

- 2008 - 01spe 101491 MS P PDFDocument10 pages2008 - 01spe 101491 MS P PDFSusan Li HBNo ratings yet

- CementingDocument17 pagesCementingAvneesh PalNo ratings yet

- CO2 Storage Capacity Estimation Issues and DevelopmentDocument7 pagesCO2 Storage Capacity Estimation Issues and DevelopmentJulian De BedoutNo ratings yet

- Coal Bed MethaneDocument61 pagesCoal Bed MethaneBiswarup Akhuli100% (1)

- Cementing Thru CT 53244Document5 pagesCementing Thru CT 53244islam atifNo ratings yet

- Permian Basin Drilling Optimization: Scott Lowry Andrew N. Hunter January 2015 - DFW AADEDocument31 pagesPermian Basin Drilling Optimization: Scott Lowry Andrew N. Hunter January 2015 - DFW AADEE SchonNo ratings yet

- Extended Reach Drilling PDFDocument2 pagesExtended Reach Drilling PDFGina0% (1)

- INDOROCK 2017 Paper - Storage of Crude Oil in Solution Mined Salt CavernsDocument10 pagesINDOROCK 2017 Paper - Storage of Crude Oil in Solution Mined Salt Cavernschandan060812No ratings yet

- 1 - Introduction To Advanced Drilling EngineeringDocument40 pages1 - Introduction To Advanced Drilling EngineeringAli AbdullahNo ratings yet

- Fracking Powerpoint Presentation May 8 2014Document15 pagesFracking Powerpoint Presentation May 8 2014zendarazakNo ratings yet

- Wells Integrity Management Training Course PDFDocument4 pagesWells Integrity Management Training Course PDFCostas AggelidisNo ratings yet

- API L80 Versus N80Document1 pageAPI L80 Versus N80abrarkhan19706100% (1)

- Proposed Well Head Compression System For Production Optimization in Low Pressure CBM WellsDocument2 pagesProposed Well Head Compression System For Production Optimization in Low Pressure CBM WellsRishiNo ratings yet

- Geothermal Drilling Cost Optimization in IndonesiaDocument10 pagesGeothermal Drilling Cost Optimization in IndonesiaPhan Trong Huan100% (1)

- Increase Well Flow with a Velocity StringDocument2 pagesIncrease Well Flow with a Velocity StringDedy DayatNo ratings yet

- Case History Hydraulics Modeling Software Helps Optimize Drilling and ECD Control With High Degree of Accuracy On Deep, Hot Gulf of Mexico Shelf WellDocument9 pagesCase History Hydraulics Modeling Software Helps Optimize Drilling and ECD Control With High Degree of Accuracy On Deep, Hot Gulf of Mexico Shelf WellElias GonzalezNo ratings yet

- Cost Model For Geothermal Wells: Carolyn KipsangDocument12 pagesCost Model For Geothermal Wells: Carolyn Kipsangdimastaha100% (1)

- Well Integrity AssessmentDocument2 pagesWell Integrity AssessmentAnubhuti Purohit BhatnagarNo ratings yet

- Well Integrity ManagementDocument3 pagesWell Integrity ManagementStorm_RaiderNo ratings yet

- Interpret Magnetic & Gravity ToolfaceDocument17 pagesInterpret Magnetic & Gravity ToolfaceHeberth Desbloqueo100% (1)

- API Recommended Practice 1170: Design and Operation of Solution-Mined Salt Caverns Used For Natural Gas StorageDocument3 pagesAPI Recommended Practice 1170: Design and Operation of Solution-Mined Salt Caverns Used For Natural Gas Storageshahriar70No ratings yet

- Normet Microfine Cement Brochure Eng 0Document8 pagesNormet Microfine Cement Brochure Eng 0Sridhara GowdaNo ratings yet

- Advanced Well Stimulation TechnologiesDocument42 pagesAdvanced Well Stimulation TechnologiesPeter Mattews100% (1)

- Gravel Pack Process ExplainedDocument3 pagesGravel Pack Process ExplainedMusah HarunaNo ratings yet

- Shallow Gas Blowouts: Dangers and Mitigation StrategiesDocument6 pagesShallow Gas Blowouts: Dangers and Mitigation StrategiesYaqoob IbrahimNo ratings yet

- Pre-Recorded Information: X X X X XDocument3 pagesPre-Recorded Information: X X X X XOscar BustosNo ratings yet

- Hard Rock Tunnelling MethodsDocument20 pagesHard Rock Tunnelling Methodskiranism0% (1)

- Petroleum Geoscience and Geophysics Chapter 8Document23 pagesPetroleum Geoscience and Geophysics Chapter 8Shu En SeowNo ratings yet

- Maersk Oil - Under The SurfaceDocument100 pagesMaersk Oil - Under The SurfaceUhrinImreNo ratings yet

- The China Continental Scientific Drilling Project CCSD-1 Well Drilling Engineering and Construction PDFDocument375 pagesThe China Continental Scientific Drilling Project CCSD-1 Well Drilling Engineering and Construction PDF杨建政No ratings yet

- High Speed Sinking by Mechanized Sinking MethodDocument18 pagesHigh Speed Sinking by Mechanized Sinking MethodHaresh Kumar100% (1)

- 1 Laigle - Large and Deep Caverns FV2Document56 pages1 Laigle - Large and Deep Caverns FV2pawan paudelNo ratings yet

- Type of WellsDocument10 pagesType of WellsAddrien Daniel100% (1)

- Development of Volcanic Gas Reservoirs: The Theory, Key Technologies and Practice of Hydrocarbon DevelopmentFrom EverandDevelopment of Volcanic Gas Reservoirs: The Theory, Key Technologies and Practice of Hydrocarbon DevelopmentNo ratings yet

- Tank CalculationDocument5 pagesTank CalculationkamaldeshapriyaNo ratings yet

- Medical Waste ManagementDocument38 pagesMedical Waste ManagementkamaldeshapriyaNo ratings yet

- Assignment 1-CH5401 PDFDocument14 pagesAssignment 1-CH5401 PDFkamaldeshapriyaNo ratings yet

- ApagscanDocument14 pagesApagscankamaldeshapriyaNo ratings yet

- Approval From Colombo Municipal CouncilDocument4 pagesApproval From Colombo Municipal CouncilkamaldeshapriyaNo ratings yet

- Pressure Vessel Design DetailsDocument1 pagePressure Vessel Design DetailskamaldeshapriyaNo ratings yet

- Prices Kero GasDocument2 pagesPrices Kero GaskamaldeshapriyaNo ratings yet

- Assignment 1-CH5401 PDFDocument14 pagesAssignment 1-CH5401 PDFkamaldeshapriyaNo ratings yet

- Physical PropertiesDocument27 pagesPhysical Propertieskamaldeshapriya100% (1)

- Fuels and Lubricants PDFDocument20 pagesFuels and Lubricants PDFkamaldeshapriyaNo ratings yet

- Drawing of LPG 235kg TankDocument1 pageDrawing of LPG 235kg TankkamaldeshapriyaNo ratings yet

- Technical Data For LPGDocument4 pagesTechnical Data For LPGsizwehNo ratings yet

- Nfpa Vs SlsiDocument1 pageNfpa Vs SlsikamaldeshapriyaNo ratings yet

- LPG World Market (CP)Document17 pagesLPG World Market (CP)kamaldeshapriyaNo ratings yet

- LPG World Market (CP)Document17 pagesLPG World Market (CP)kamaldeshapriyaNo ratings yet

- 0100 4741Document115 pages0100 4741kamaldeshapriyaNo ratings yet

- Intro to Process Control Lecture 1Document21 pagesIntro to Process Control Lecture 1kamaldeshapriyaNo ratings yet

- Chemistry BookDocument0 pagesChemistry BookkamaldeshapriyaNo ratings yet

- National Environmental ActDocument15 pagesNational Environmental ActSanjaya RupasingheNo ratings yet

- Bioconversion of Water Hyacinth into EthanolDocument0 pagesBioconversion of Water Hyacinth into EthanolkamaldeshapriyaNo ratings yet

- Econ 2Document7 pagesEcon 2tadeyfenNo ratings yet

- Lecture 6 - Induction MotorsDocument34 pagesLecture 6 - Induction Motorsswamy_satya20004521No ratings yet

- Cylinder Re-Qualification ProcedureDocument1 pageCylinder Re-Qualification ProcedurekamaldeshapriyaNo ratings yet

- Guidance For Hazard Determination For Compliance With The OSHA Hazard Communication StandardDocument29 pagesGuidance For Hazard Determination For Compliance With The OSHA Hazard Communication Standardbatorn@mac.comNo ratings yet

- Motorola Talkabout T5100Document25 pagesMotorola Talkabout T5100Aleksandar TomićNo ratings yet

- Prevent, control and fight fires on board shipsDocument22 pagesPrevent, control and fight fires on board shipsEfon 3689No ratings yet

- DMSO MsdsDocument6 pagesDMSO MsdsDavid FooNo ratings yet

- Warframe Abilities in ConclaveDocument40 pagesWarframe Abilities in ConclaveAustin HoNo ratings yet

- Battery Room RequirementDocument4 pagesBattery Room RequirementKrishna KumarNo ratings yet

- Msds 56.21 PDFDocument4 pagesMsds 56.21 PDFHendra Cipto SaputroNo ratings yet

- Warnings and Instructions For Consumers in Transporting, Storing, Handling and Using Explosive MaterialsDocument35 pagesWarnings and Instructions For Consumers in Transporting, Storing, Handling and Using Explosive Materials123098qwepoiNo ratings yet

- Building The Formula For Calculating The Vapor of The LPG Liquid Generating in The Explosion Risk of LPG TankDocument3 pagesBuilding The Formula For Calculating The Vapor of The LPG Liquid Generating in The Explosion Risk of LPG TankLy Ngoc MinhNo ratings yet

- Methyl Alcohol Absolute MsdsDocument6 pagesMethyl Alcohol Absolute Msdsshella168No ratings yet

- Ow Arc 400 ManualDocument78 pagesOw Arc 400 ManualMynor Mèndez CruzNo ratings yet

- Dust ExplosionsDocument40 pagesDust ExplosionsAbhishek VaidyaNo ratings yet

- Definition of Intermediate Ballistics: The Distribution of Energy at Muzzle Exit Can Be Simplified Down ToDocument28 pagesDefinition of Intermediate Ballistics: The Distribution of Energy at Muzzle Exit Can Be Simplified Down ToWoldehawryatNo ratings yet

- Explosives, Ground Vibration and Air BlastDocument31 pagesExplosives, Ground Vibration and Air Blastpartha das sharma100% (4)

- Deltaweld 453 MilDocument40 pagesDeltaweld 453 MilHugo RodriguezNo ratings yet

- Atomic Suicide - Walter and Lao RussellDocument300 pagesAtomic Suicide - Walter and Lao RussellJason Verbelli100% (16)

- Shadowrun Sourcebook - Adept Handybook (Unofficial)Document30 pagesShadowrun Sourcebook - Adept Handybook (Unofficial)eric scott100% (4)

- Iatg 05.20 Types of Buildings For Explosives Storage V2 Amd 1 Ver2Document56 pagesIatg 05.20 Types of Buildings For Explosives Storage V2 Amd 1 Ver2DOC LABNo ratings yet

- Msds NaohDocument6 pagesMsds NaohNurul Imaama ShabraniNo ratings yet

- 003Document17 pages003Eliseo Rios IngenieroNo ratings yet

- A Case Study in Furnace Explosion of CFBC BoilerDocument14 pagesA Case Study in Furnace Explosion of CFBC Boilerparthi2006576883% (12)

- SV97Document2 pagesSV97nclogesh_1981No ratings yet

- JOB SAFETY ANALYSIS (JSADocument3 pagesJOB SAFETY ANALYSIS (JSAba ratnaparkhe100% (1)

- Flame Arresters: The Last Line of DefenseDocument6 pagesFlame Arresters: The Last Line of DefenseArunkumarNo ratings yet

- Nonel GuideDocument55 pagesNonel GuideIrvan Aryo Prakoso100% (5)

- Protego 2020 - 21Document429 pagesProtego 2020 - 21jleonclau1No ratings yet

- Mutants & Masterminds Power Profile 1 Fire PowersDocument6 pagesMutants & Masterminds Power Profile 1 Fire PowersJackEzdudehereNo ratings yet

- EN 14994 2007 Gas Explosion Venting Protective Systems PDFDocument30 pagesEN 14994 2007 Gas Explosion Venting Protective Systems PDFMohamed AdelNo ratings yet

- Msds - PHP Nikel KloridaDocument6 pagesMsds - PHP Nikel KloridaRanii Selaluww TersenyumNo ratings yet

- Department of The Army - Pamphlet 358-64 - Ammunition and Explosives Safety StandardsDocument194 pagesDepartment of The Army - Pamphlet 358-64 - Ammunition and Explosives Safety StandardsRussell Lawrence Benford100% (2)