Professional Documents

Culture Documents

Welding Robots

Uploaded by

Praveen BhadulaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Robots

Uploaded by

Praveen BhadulaCopyright:

Available Formats

WELDING ROBOTS

INTRODUCTION

Robot Welding is a process of joining different

materials.

The large bulk of materials that are welded are

metals and their alloys although welding is also

applied to the joining of other materials such as

thermoplastics.

Welding joins different metals or alloys with help of

a number of processes in which heat is supplied

either electrically or by means of a gas torch.

WHY ROBOT ARC WELDING?

Arc welding is performed by skilled workers who are assisted

by a person called fitter.

The purpose of the fitter is to organize the work and fixture

the parts of the welder.

The working condition of the welder is typically unpleasant

and hazardous.

The arc from the welding process emits ultra-violet radiations

which is injurious to human vision.

As a result welders are required to wear eye protection in the

form of a welding helmet with a dark window.

Sparks and smoke are generated during the process are a

potential threat to operators.

Because of the hazards for human workers in continuous arc

welding, it is logical to consider industrial robots for the

purpose.

BENEFITS OF ROBOT ARC WELDING

GREATER QUALITY OF PRODUCT

IMPROVED SAFTEY AND QUALITY-OF-WORK

LIFE

HIGHER PRODUCTIVITY

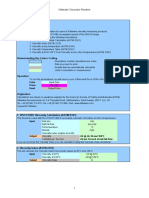

FEATURES OF ARC WELDING ROBOTS

WORK VOLUME AND DEGREES OF FREEDOM

MOTION CONTROL SYSTEM

PRECISION OF MOTION

PROGRAMMING

INTERFACE WITH OTHER SYSTEM

ARC WELDING ROBOT

PROBLEMS FOR ROBOTS IN ARC

WELDING

A related problem is that arc welding is often performed in confined

areas that are difficult to access, such as insides of tanks, pressure

vessels, and ship hulls. Humans can position in to these areas more

readily than robots.

One of the most difficult technical problems is the variation in the

dimensions of the parts in a batch production job. This type of

dimensional variations means that the arc-welding path to be

followed will change slightly from part to part.

Another technical difficulty is the variations in the edges and

surfaces to be welded together. Instead of being straight and

regular, the edges are typically irregular. This causes variations in

the gap between the parts and other problems in the way the pieces

mate together prior to the welding process.

Arc welding robots performing in a

workshop

WHY ROBOT SPOT WELDING?

For larger works on spot welding the welding guns with cables

attached is quite heavy and can easily exceed 100lb in weight.

To assist the operator in manipulating the gun, the apparatus

is suspended from an overhead hoist system.

Even with this assistance, the spot-welding gun represents a

heavy mass and is difficult to manipulate by a human worker

at high rates of production desired on a car body assembly

line.

There are often problems with the consistency of the welded

products made on such a manual line as a consequence of this

difficulty.

As a result of these difficulties robots have been employed

with great success on this type of production line to perform

some or all of the welding operations.

BENEFITS OF ROBOT SPOT WELDING

IMPROVED PRODUCT QUALITY

OPERATOR SAFETY

BETTER CONTROL OVER PRODUCTION

OPERATION

FEATURES OF SPOT-WELDING ROBOTS

Robots must be relatively large. It must have sufficient

payload capacity to readily manipulate the welding gun

for the application.

The work volume must be adequate for the size of the

product.

The robot must be able to position and orient the welding

gun in places on the product that might be difficult to

access. This might result in need for an increased

number of freedoms.

The controller memory must have enough capacity to

accomplish the many positioning steps required for the

spot-welding cycle.

A typical spot welding robot

Spot welding robot performing in a

welding cell

MANIPULATOR

The robot consists of a manipulator which is a series of

mechanical linkages and joints capable of producing all

sorts of designed movements.

The body, arm and wrist assembly of a robot is

sometimes called as a manipulator.

Each link of a manipulator is driven by activators which

may be operated either hydraulic or pneumatic power

cylinder or electrical motors.

The forearm of a robot can move in a nearly spherical

way, thus covering a large work volume and providing

greater application flexibility.

It is easily possible to reach down into or onto objects

placed over the conveyor.

SENSORS

The robotic arc welding sensor system considered here are all designed

to track the welding seam and provide the information to the robot

controller to help guide the welding path.

The approaches used for this purposes divide into two basic categories:

1. Contact sensors.

2. Non-Contact sensors

Contact arc welding sensors make use of a mechanical tactile probe to

touch the sides of the groove ahead of the welding torch and to feed back

position data so that course corrections can be made by the robot

controller.

Some systems use a separate control unit design to interpret the probe

sensor measurements and transmit the data to the robot controller.

The sensors used in robotics include the following general categories.

1.Tactile sensors

2.Proximity and range sensors

3.Miscellaneous types

4.Machine vision

CONTROL SYSTEM

Typical block diagram configuration of a control system for a robot joint.

CONCLUSION

A substantial opportunity exists in the technology of robotics to

relieve people from boring, repetitive, hazardous and unpleasant

work in all forms of a human labor.

There is a social value as well as a commercial value in pursuing this

opportunity. The commercial value of robotics is obvious.

Properly applied, robots can accomplish routine, undesirable work

better than humans at a lower cost.

As the technology advances, and more people learn how to use

robots, the robotics market will grow at a rate that will approach the

growth of the computer market over the past thirty years.

There is every reason to believe that the automation of work

through robotics will lead to substantial increases in productivity,

and that these productivity increases year by year will permit

humans to engage in activities that are cultural and recreational.

Not only will robotics improve our standard of living, it will also

improve our standard of life.

THANK YOU!!!

www.playppt.com

You might also like

- Report Robot WeldingDocument23 pagesReport Robot WeldingKishan Singh100% (3)

- Robotic Arc WeldingDocument38 pagesRobotic Arc Weldingamirhazwan100% (2)

- Robotic Welding Guide Explains Processes, Benefits and ApplicationsDocument23 pagesRobotic Welding Guide Explains Processes, Benefits and ApplicationsPraveen Bhadula100% (1)

- Robot WeldingDocument10 pagesRobot WeldingSanatan ChoudhuryNo ratings yet

- Final ReportDocument40 pagesFinal ReportVaibhav Sharma0% (1)

- Robot WeldingDocument25 pagesRobot WeldingAmit Rajguru75% (8)

- Robot WeldingDocument6 pagesRobot WeldingsrrsekarNo ratings yet

- Introduction to Welding RobotsDocument22 pagesIntroduction to Welding RobotsBHUKYA GandhiNo ratings yet

- Spatter Reduction ReportDocument77 pagesSpatter Reduction ReportaabhimittalNo ratings yet

- Report Robot WeldingDocument23 pagesReport Robot Welding19AE8126 Ayaan MansuriNo ratings yet

- Case Studies:: Robotic Arc WeldingDocument13 pagesCase Studies:: Robotic Arc WeldingKoshy JohnNo ratings yet

- ME 6008 Welding Technology Question BankDocument9 pagesME 6008 Welding Technology Question BankkumareshNo ratings yet

- Robotic Arc WeldingDocument56 pagesRobotic Arc Weldingamirhazwan100% (1)

- Roller Hemming TrainingDocument18 pagesRoller Hemming TrainingBernardo Razo LNo ratings yet

- Robot Programming - PART1Document48 pagesRobot Programming - PART1Krushnasamy SuramaniyanNo ratings yet

- Robot Welding TipsDocument50 pagesRobot Welding Tipscentaury20130% (1)

- Design of Spot WeldDocument15 pagesDesign of Spot Weldkaustubh girgasNo ratings yet

- Selection &optimization of Spot Welding Process Parameters Using Taguchi MethodDocument40 pagesSelection &optimization of Spot Welding Process Parameters Using Taguchi MethodBabuli KumarNo ratings yet

- Robotics Lab Manual FinalDocument39 pagesRobotics Lab Manual FinalSanthosh100% (4)

- Spot Weld Parameters HLSDocument10 pagesSpot Weld Parameters HLSHemantNo ratings yet

- BIW - Points Discussed With The CustomerDocument9 pagesBIW - Points Discussed With The CustomerJyoti Kale100% (1)

- Mobile Robotic Welding System Final ReportDocument8 pagesMobile Robotic Welding System Final Reportveereshkoutal100% (1)

- Robot Cell DesignDocument18 pagesRobot Cell DesignShione T Mundawarara57% (7)

- Robotic WeldingDocument21 pagesRobotic WeldingLaurentiusDamasSulistya100% (1)

- Introducing Fast Robot Roller Hemming Process in Automotive IndustryDocument4 pagesIntroducing Fast Robot Roller Hemming Process in Automotive IndustryClaudiu LupuNo ratings yet

- Final PPT For Minor Project 2021-22Document19 pagesFinal PPT For Minor Project 2021-22Dashanand RavanNo ratings yet

- Simulation of Robort Roller Hemming ProcessDocument100 pagesSimulation of Robort Roller Hemming ProcessManju sattigeriNo ratings yet

- Design and Fabrication of Oil Skimmer RobotDocument46 pagesDesign and Fabrication of Oil Skimmer RobotSathiya Udumalpet100% (2)

- BIWDocument12 pagesBIWSatyawan KaleNo ratings yet

- Robot Cell Layouts and Interlocks PDFDocument48 pagesRobot Cell Layouts and Interlocks PDFPuru Gaur100% (1)

- Welding Machine WZM-400 Operating Manual-1Document34 pagesWelding Machine WZM-400 Operating Manual-1indo jasun0% (1)

- Robot Cell DesignDocument25 pagesRobot Cell Designnandkishor joshi100% (1)

- Laser Beam WeldingDocument2 pagesLaser Beam WeldingmonokoeNo ratings yet

- Accident Avoiding of Punching Machine - ReportDocument38 pagesAccident Avoiding of Punching Machine - ReportPrathmeshBhokari0% (1)

- Process Monitoring and Control During Spot Welding of Metallic CoDocument195 pagesProcess Monitoring and Control During Spot Welding of Metallic CoAhmad Azuwan100% (1)

- Project Report: On Summer Training inDocument45 pagesProject Report: On Summer Training inRNo ratings yet

- Machine Tool Guideway DesignDocument76 pagesMachine Tool Guideway DesignSrinivas MurthyNo ratings yet

- Mechanical Summer Training ReportDocument53 pagesMechanical Summer Training Reportishidewan40% (5)

- ABB Robotic Arc WeldingDocument12 pagesABB Robotic Arc Weldinganidarius301100% (1)

- SWW2014 PPT Costing GuideDocument33 pagesSWW2014 PPT Costing GuideAdithyan GowthamNo ratings yet

- Intelligent Active Suspensing System For Two WheelerDocument4 pagesIntelligent Active Suspensing System For Two WheelerMurali KrishnanNo ratings yet

- BIW-Body in WhiteDocument2 pagesBIW-Body in WhiteGokul PrabuNo ratings yet

- Welding AutomationDocument42 pagesWelding Automationharoub_nasNo ratings yet

- DESIGN - AND - FABRICATION - OF - AUTOMATIC - SPRAY - PAINTING - MACHINE - Ijariie7676 PDFDocument7 pagesDESIGN - AND - FABRICATION - OF - AUTOMATIC - SPRAY - PAINTING - MACHINE - Ijariie7676 PDFHussain MuslimNo ratings yet

- Self Healing Robots - Seminar ReportDocument33 pagesSelf Healing Robots - Seminar ReportVishnu Ravindran60% (10)

- A Report on Non-Destructive Testing MethodsDocument23 pagesA Report on Non-Destructive Testing MethodsManjunath g100% (2)

- Gmd1 IntroductionDocument1 pageGmd1 IntroductionOswaldo Neave100% (1)

- AE WeldFixtureDesignExecutionRequirementsForProduction 12012015 PDFDocument53 pagesAE WeldFixtureDesignExecutionRequirementsForProduction 12012015 PDFKetul ShahNo ratings yet

- Reverse EngineeringDocument19 pagesReverse EngineeringNithin RajanNo ratings yet

- Automotive Workshop On BiW-Structures PDFDocument41 pagesAutomotive Workshop On BiW-Structures PDFArvind KatyayanNo ratings yet

- TribologyDocument19 pagesTribologyMtech Design [Golden Batch]No ratings yet

- iNaCoMM 2019Document9 pagesiNaCoMM 2019anuNo ratings yet

- V6Document8 pagesV6oktayNo ratings yet

- ROBOTICS Part4Document94 pagesROBOTICS Part4Sandeep GogadiNo ratings yet

- Material Handling RobotsDocument42 pagesMaterial Handling RobotsMURTHY RAJNo ratings yet

- Feiya 27180068 Welding RobotDocument21 pagesFeiya 27180068 Welding RobotFarhan mahmud RashikNo ratings yet

- RobotDocument4 pagesRobotEfendi Wahyu100% (1)

- Selection and Applications of Automatic Spot Welding MethodsDocument5 pagesSelection and Applications of Automatic Spot Welding MethodsSam KashNo ratings yet

- Robot Notes 5-Robot Tasks PDFDocument6 pagesRobot Notes 5-Robot Tasks PDFWakaka foreverNo ratings yet

- Practical, Made Easy Guide To Robotics & Automation [Revised Edition]From EverandPractical, Made Easy Guide To Robotics & Automation [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Rigorous Steady-State Simulation of Acetone Production Using Aspen Hysys®Document9 pagesRigorous Steady-State Simulation of Acetone Production Using Aspen Hysys®eva apriliaNo ratings yet

- Fadum Chart SampleDocument3 pagesFadum Chart SampleSa'ad Abd Ar RafieNo ratings yet

- Understanding The Colour Coding: Kittiwake Viscotube ReadmeDocument15 pagesUnderstanding The Colour Coding: Kittiwake Viscotube ReadmemusaveerNo ratings yet

- Spe 151395 MSDocument14 pagesSpe 151395 MSOmidNo ratings yet

- Sdof 1211798306003307 8Document131 pagesSdof 1211798306003307 8AzTaurRivaiNo ratings yet

- Physical Chem HWDocument11 pagesPhysical Chem HWAkash ModyNo ratings yet

- Setalux D A 760 Ba X - Emea - enDocument2 pagesSetalux D A 760 Ba X - Emea - enMy SukkaNo ratings yet

- Mitsubishi CA 310 Brochure PDFDocument4 pagesMitsubishi CA 310 Brochure PDFw1naldoNo ratings yet

- Synthesis of p-NitroacetanilideDocument5 pagesSynthesis of p-NitroacetanilideNuratiqah SalamNo ratings yet

- Detection of Adulteration of Ghee (Clarified Milk Fat) With Palmolein and Sheep Body Fat Using Reichert-Meissl (RM) Value Coupled With Solvent Fractionation TechniqueDocument7 pagesDetection of Adulteration of Ghee (Clarified Milk Fat) With Palmolein and Sheep Body Fat Using Reichert-Meissl (RM) Value Coupled With Solvent Fractionation Techniquekamal gandhiNo ratings yet

- THEORIES OF IMPRESSION TECHNIQUESDocument16 pagesTHEORIES OF IMPRESSION TECHNIQUESAmar BhochhibhoyaNo ratings yet

- Factors Affecting Rates of Reaction Lab ReportDocument3 pagesFactors Affecting Rates of Reaction Lab Reportjohnson_tranvo100% (1)

- 1-5 Practice - ADocument2 pages1-5 Practice - AStanleyNo ratings yet

- Diametral Compression TestDocument11 pagesDiametral Compression TestCesar Rodolfo Angulo DelgadoNo ratings yet

- Measures of Central Tendency: No. Biostat - 5 Date: 18.01.2009Document40 pagesMeasures of Central Tendency: No. Biostat - 5 Date: 18.01.2009pradeepNo ratings yet

- Republic of The Philippines Department of Education Deped Complex, Pasig City Science Iii K To 12 Curriculum Guide Planner / Budget of WorkDocument3 pagesRepublic of The Philippines Department of Education Deped Complex, Pasig City Science Iii K To 12 Curriculum Guide Planner / Budget of WorkLedie Lou Cetoy SuperalesNo ratings yet

- Moore-Penrose Pseudo Inverse ExplainedDocument3 pagesMoore-Penrose Pseudo Inverse ExplainedcmtinvNo ratings yet

- 13 - Representations of The Angular Momentum Operators and Rotations PDFDocument17 pages13 - Representations of The Angular Momentum Operators and Rotations PDFUltrazordNo ratings yet

- Leaf Spring AnalysisDocument9 pagesLeaf Spring AnalysisThilli KaniNo ratings yet

- Transformation - 2DDocument93 pagesTransformation - 2DKashika MehtaNo ratings yet

- Design of spiral resistance heating elementsDocument6 pagesDesign of spiral resistance heating elementsarg0nautNo ratings yet

- University of Craiova Faculty of Electrotechnics: Eng. George Marian PISCDocument10 pagesUniversity of Craiova Faculty of Electrotechnics: Eng. George Marian PISCcfcshakerNo ratings yet

- Mechanics of Structures (CE130N) Lab 14 1 ObjectiveDocument10 pagesMechanics of Structures (CE130N) Lab 14 1 Objectiveram_108No ratings yet

- UFM interpretation synopsisDocument1 pageUFM interpretation synopsistazjuan1100% (1)

- Einstein's Relativity Stupidity On U TubeDocument26 pagesEinstein's Relativity Stupidity On U TubeJoe NahhasNo ratings yet

- HW 5 HTDocument26 pagesHW 5 HTMelkysedec Sierra SandovalNo ratings yet

- Lesson Plan Science Level 7Document58 pagesLesson Plan Science Level 7aries triwidajati100% (4)

- Bioenergetics of Aquatic AnimalsDocument182 pagesBioenergetics of Aquatic AnimalsDaniel FernándezNo ratings yet

- Chapter 3. Professor Roy E. Olson On Con PDFDocument17 pagesChapter 3. Professor Roy E. Olson On Con PDFVitor AlbuquerqueNo ratings yet

- Science 7 Exam 3rdDocument8 pagesScience 7 Exam 3rdEJ Atsilab100% (1)

![Practical, Made Easy Guide To Robotics & Automation [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/253466853/149x198/4281882d40/1709916831?v=1)