Professional Documents

Culture Documents

Seal Oil System-Class

Uploaded by

Raja Ramachandran100%(1)100% found this document useful (1 vote)

461 views39 pagesseal oil

Original Title

Seal Oil System-class

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentseal oil

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

461 views39 pagesSeal Oil System-Class

Uploaded by

Raja Ramachandranseal oil

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 39

SEAL OIL SYSTEM

IN ORDER TO PREVENT ESCAPE OF HYDROGEN

FROM THE GENERATOR IT IS ESSENTIAL TO PROVIDE SHAFT

SEALS AT BOTH ENDS WHERE THE SHAFT EXTENDS

THROUGH THE CASING.

THIS IS ACHIEVED BY PROVIDING RADIAL OIL

FILMS IN THE SYSTEM, THIS OIL BEING KEPT AT A HIGHER

PRESSURE THAN THAT OF THE HYDROGEN INSIDE THE

GENERATOR.

THE LOCATION WHERE THE ROTOR SHAFT PASSES

THROUGH THE STATOR CASING ARE PROVIDED WITH

RADIAL OR RING TYPE SEAL RINGS.THE SEAL EING IS

FORMED BY JOINING TWO SEMICIRCULAR RINGS.

BABBIT METAL

BABBIT METAL IS A COMPOSITION OF TIN, ANTIMONY AND

COPPER .THE SEAL RING IS LINED WITH BABBIT METAL ON THE

SHAFT JOURNAL SIDE.

BABBIT METAL HAS A LOW MELTING TEMPERATURE TO

SAFEGUARD THE SHAFT IN CASE OF OIL STARVATION.

THE SEAL OIL IS SUPPLIED TO THE SEALING GAP FROM THE

SEAL BODY VIA RADIAL HOLES AND ANNULAR GROOVE IN

THE SEAL RING.

THE TWO HALF OF THE SEAL RING ARE GUIDED IN THE SEAL

BODY, WHICH IS BOLTED ON THE END SHIELD

SEALING PHENOMENON

TO ENSURE EFFECTIVE SEALING THE SEAL OIL PRESSURE IN

THE ANNULAR GAP IS MAINTAINED AT 1.5 KSC ABOVE THE GAS

PRESSURE WITHIN THE GENERATOR CASING.

THE OIL DRAINED ON THE HYDROGEN SIDE AND AIR SIDE OF

THE SEALRINGS IS THROUGH DRAINS IN THE SEAL BODY AND

SEALING COVER RESPECTIVELY.

ON THE AIR SIDE RING RELIEF OIL IS SUPPLIED AT 0.5KSC

ABOVE THE SEAL OIL PRESSURE LATERALLY TO THE SEAL

RING VIA AN ANNULAR GROOVE.

Seal oil system scheme

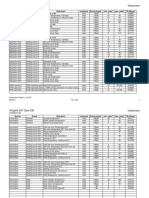

EQUIPMENTS IN SEAL OIL SYSTEM

SEAL OIL PUMP ( 3 X 100%) DUTY

VACUUM PUMP (1)

SEAL OIL COOLER ( 2 X 100%) DUTY

DIFFERENTIAL PRESSURE REGULATOR

SEAL OIL FILTERS (DUPLEX & SIMPLEX)

SEAL OIL PUMP

SEAL OIL PUMP IS A THREE SCREW DESIGN POSITIVE

DISPLACEMENT PUMP

ONE DOUBLE THREADED DRIVING ROTOR AND TWO DRIVEN IDLER

SCREWS ARE CLOSED MESHED AND RUN WITH A CLOSE

CLEARANCE IN THE CASING INSERT.

BY INTERMESHING, THE HELICAL PASSAGES IN THE ROTORS ARE

DIVIDED INTO COMPLETELY SEALED COMPARTMENTS, WHILE

ROTATING, TRAVEL UNIFORMLY AND WITH OUT UNDUE STRESSES

FROM SUCTION TO DISCHARGE END.

THIS ACTS LIKE A PISTON

DUE TO LOW COMPRESSIBILITY OF OIL VERY HIGH PRESSURE MAY

ARISE ON THE DELIVERY SIDE

HENCE RELIEF VALVE IS PROVIDED ON THE PUMP CASING TO

PROTECT THE SEAL OIL SYSTEM

VACUUM PUMP

THE VACUUM PUMP IS A SINGLE STAGE ROTARY VANE TYPE

ROTARY SLIDING VANE PUMP CONSISTS OF A CYLINDRICAL CASING

WHICH IS ECCENTRICALLY SUPPORTED

THE ROTOR HAS VANES WHICH ARE FORCED APART BY SPRINGS

THE VANES SLIDE ALONG THE CASING WALL.

IT PUSHING FORWARD THE AIR DRAWN IN AT THE SUCTION

CHANNEL AND FINALLY DISCHARGING IT AT THE PUMP THROUGH

THE OIL IMMERSED DISCHARGE VALVE

THE OIL ALSO SERVES AS THE PUMP LUBRICATION

OIL LEVEL IN THE PUMP HAS TO ENSURED AS OIL VAPOUR GETS

EXTRACTED WHEN EXPELLING THE GAS.

SEAL OIL COOLER

THIS COOLER IS DESIGNED FOR SERVICE WITH RAW WATER.

COOLER CONSISTS OF

I. UPPER WATER BOX

II. SHELL

III. TUBE SYSTEM

IV. LOWER WATER BOX

THE LOWER TUBE PLATE IS FIXED AND THE UPPER TUBE

PLATE IS MADE FLOATING TO CATER FOR THE THERMAL

DIFFERENTIAL EXPANSION BY USING A RUBBER RING.

OIL INLET AND OUTLET ARE PROVIDED IN THE SHELL.

THE CIRCULATING WATER SIDE OF THE TUBE PLATE AND THE

INNER SURFACE OF THE WATER BOX ARE PAINTED WITH EPOXY

COAL TAR

SEAL OIL COOLER MAINTENANCE

THE EFFICIENCY OF THE COOLER DEPENDS VERY MUCH ON THE

CLEANLINESS OF THE COOLING SURFACE

CLEANING OF THE INSIDE OF THE TUBES CAN BE CARRIED OUT BY MEANS

OF SOFT BRASS WIRE BRUSH MECHANICALLY.

IF THERE ARE HARD SCALES CHEMICAL TREATMENT HAS TO BE RESORTED

LIKE WISE SHELL SIDE CAN BE CLEANED.

SHELL CAN BE CLEANED IN A HOT BATH OF 10% CAUSTIC SODA SOLUTION

IN CASE OF LEAKAGE OF COOLER TUBE IS SUSPECTED THE SHELL SIDE

SHOULD BE SUBJECTED TO A PRESSURE OF 16 KSC USING LUBE OIL.

KEEPING THE COOLER IN THE HORIZONTAL POSITION AND THE FAULTY

TUBE SHOULD BE PLUGGED WITH TAPER PLUGS. 5 % OF THE TUBES CAN

BE PLUGGED WITH OUT SACRIFICING THE DUTY.

DIFFERENTIAL PRESSURE REGULATING VALVE

DIFFERENTIAL PRESSURE REGULATING VALVE IS INTENDED TO

REGULATE THE SEAL OIL PRESSURE BEING SUPPLIED TO SHAFT SEALS

IN RELATION TO GAS PRESSURE IN THE GENERATOR CASING.

DIFFERENTIAL PRESSURE REGULATOR HAS

1. VALVE HEAD

2. MAIN BELLOWS

3. UPPER STUFFING BELLOWS

4. VALVE STEM

5. COMPRESSION SPRING

6. ADJUSTING NUT

7. CHECK NUT

8. YOKE

9. LOWER STUFFING BELLOWS

10. VALVE HOUSING

11. VALVE CONE

SEAL OIL TANK

GAS

IMPULSE

OIL

IMPULSE

O

I

L

S

E

A

L

S

SEAL OIL

PUMP

DIFFERENTIAL PRESSURE REGULATOR A

FUNCTION

DIFFERENTIAL PRESSURE REGULATOR

FUNCTION

THE DIFFERENCE BETWEEN OIL AND GAS IS SET BY COMPRESSION OF THE

SPRING WITH HELP OF THE ADJUSTING NUT.

COMPRESSION OF THE SPRING LEADS TO DOWN MOVEMENT OF THE

VALVE STEM AND VALVE CONE.

THIS MOVEMENT REDUCES THE PRESSURE THROUGH THE VALVE AS THE

VALVE CLOSES AND INCREASES THE PRESSURE THROUGH THE LINE.

INCREASE IN H

2

PRESSURE WILL LEAD TO COMPRESSION OF THE MAIN

OPERATING BELLOW WHICH IN TURN WILL MOVE THE VALVE HEAD IN TURN

VALVE AND VALVE CONE TO CLOSE THE VALVE

CLOSING OF THE VALVE WILL REDUCE THE PRESSURE OF THE OIL AT THE

OUT LET OF THE VALVE WHILE OIL PRESSURE GOING TO THE SEALS WILL

INCREASE.

DIFFERENTIAL PRESSURE REGULATOR B

FUNCTION

GAS

IMPULSE

OIL

IMPULSE

OIL SEALS

FROM

GOVERNING

OIL

SEAL OIL FILTER

THE DUPLEX AND SIMPLEX FILTERS ARE USED IN SINGLE FLOW RING TYPE

SEAL OIL SYSTEM

THE FILTER IS INSERTED INTO THE PIPE CIRCUIT BY MEANS OF FLANGES

A CHECK IS KEPT ON THE STRAINER SCREEN BY MEANS OF THE

RECOMMENDED DIFFERENTIAL PRESSURE INDICATOR .

WHEN PRESSURE REACHES 0.6 KSC THE STRAINER SHOULD BE CLEANED.

THE COMMON PROBLEM IS THE O RING FAILURE IN THE STOP COCK.

SEAL OIL FILTER -I

IF THERE IS LEAK FROM THE STOP COCK

REMOVE THE PINS

PULL OUT THE STOP COCK

REMOVE THE O RING

WASH OUT THE STOP COCK AND HOUSING

INTRODUCE THE STOP COCK AFTER GOOD OILING BUT WITHOUT O RINGS INTO

THE OPENING IN THE HOUSING

PUSH THE STOP COCK UNTIL THE GROOVE FOR THE O RING IS FREE

FIT THE O RING AND CAREFULLY PULL BACK THE STOP COCK UNTIL THE

GROOVE AT THE OPPOSITE END IS FREE.

CLEANING OF FILTER CHAMBER IS NECESSARY ONLY AFTER EVERY THIRD

FILTER ELEMENT CLEANING

STATOR WATER SYSTEM

ONE OF THE EFFICIENT WAYS OF TAKING AWAY THE LOSSES

FROM THE WINDINGS OF ANY ELECTRICAL MACHINE IS BY

DIRECT COOLING USING WATER.

EQUIPMENTS INVOLVED IN THE STATOR WATER SYSTEM

EXPANSION TANK

STATOR WATER PUMP

STATOR WATER COOLERS

STATOR WATER MECHANICAL FILTERS

STATOR WATER MAGNETIC FILTERS

POLISHING UNIT

GAS TRAP

STATOR WATER SYSTEM HEADERS

INLET

HEADER

OUTLET

HEADER

STATOR WATER TO BUSHING LEADS

QUALITY OF THE DISTILLATE

CONDUCTIVITY < 5 MICRO MHO, PREFERABLY

< 1 MICRO MHO

PH 6.5 TO 8.5

DISSOLVED OXYGEN MINIMUM, PREFERABLY LESS THAN 100 PPB

DISSOLVED CO

2

NIL

AMMONIA MINIMUM, PREFERABLY ZERO

CHLORIDE MINIMUM, PREFERABLY ZERO

DISSOLVED/UNDISSOLVED CU < 20 PPB

DISSOLVED/UNDISSOLVED FU < 20 PPB

DISSOLVED SOLIDS THE WATER SHOULD BE FREE OF

ANY CHEMICALS FROM TREATMENT

PROCESS,SUCH AS HYDRAZINE,

MORPHOLINE,LEVOXINE,PHOSPHATES

THE EXPANSION TANK

THE EXPANSION TANK IS A HERMETICALLY SEALED CONTAINER MADE

OF STAINLESS STEEL.

THE DM WATER FROM THE STATOR WINDING OUTLET HEADER

DISCHARGES IN TO A SECTION OF THE TANK THROUGH PERFORATED

PIPE.

THE TANK IS UNDER A VACUUM OF 250-300MM OF MERCURY.

THE TANK IS CLEANED DURING ANNUAL MAINTENANCE.

THE FLOAT VALVE OPERATION IS CHECKED BY HAND FOR SMOOTH

AND EASY OPERATION FROM ONE EXTREME LOWER POSITION TO

EXTREME TOP POSITION.

THE FLOAT IS CHECKED BY DIPPING IN WATER FOR 1 HOUR AT A

TEMPERATURE OF 60 DEGREE CENTIGRADE

THE HEALTHINESS OF THE TRANSDUCERS ARE CHECKED.

ALL THE JOINTS ARE CHECKED FOR ANY LEAK.

EXPANSION TANK

GAS OUT LET

WATER

INLET

FROM

WINDING

TANK

COVER

TRANSDUCER

RIB

LEVEL

GAUGE

D

R

A

I

N

WATER

OUTLET TO

PUMPS

LINE

REGULATOR

STATOR WATER PUMP

STATOR WATER PUMPS ARE SINGLE STAGE CENTRIFUGAL

TYPE SPIRAL CASING AND OVERHANG IMPELLER .

THE PUMP SUCTION IS ARRANGED IN THE AXIAL DIRECTION

WHILE THE DISCHARGE IS DIRECTLY RADIALLY UPWARD.

THE PUMP IMPELLER AND THE SPIRAL CASING IS OF

STAINLESS STEEL CONSTRUCTION.

NORMALLY THE PUMP IS OVERHAULED ONCE IN 5000 HOURS.

STATOR WATER COOLER

STATOR WATER COOLER

UPPER

WATER BOX

TUBE

PLATE

SEALING

CORD

VENT PLUG

PARTITION

TUBE

OUTER SHELL

SEALING RUBBER

DRAIN PLUG

THERMOMETER

STATOR WATER INLET

STATOR

WATER

OUTLET

VENT

DRAIN

PLUG

LOWER

WATER BOX

RUBBER

CORD

STATOR WATER COOLER-I

THE STATOR WATER COOLER IS SHELL AND TUBE TYPE HEAT

EXCHANGER SUITABLE FOR VERTICAL MOUNTING

THE SHELL IS MADE OF NONMAGNETIC STAINLESS STEEL AND THE DM

WATER FLOWS THROUGH THE SHELL.

TUBES ARE MADE OF STAINLESS STEEL AND THE COOLING WATER

FLOWS THROUGH THE TUBES.

TO HAVE EFFECTIVE HEAT TRANSFER BAFFLES ARE MADE OF BRASS

ARE PROVIDED ACROSS THE TUBE NEST.

THIS GUIDE THE WATER IN ZIG ZAG FASHION.

THE TUBES ARE CLEANED BY NYLON BRUSH.

STATOR WATER COOLER -II

WHEN PUSHING THE BRUSH THROUGH THE TUBES IT SHOULD ALSO BE

TURNED AROUND SIMULTANEOUSLY

IF THE DIRT DEPOSITS DO NOT COME WITH MECHANICAL TREATMENT

CHEMICAL CLEANING IS NECESSARY.

THE MOST CAUSE OF LEAKAGE IS TUBE PERFORATION OR LEAKAGE.

THE ROLLED ENDS OF THE TUBE ARE LIKELY TO BECOME DEFECTIVE FIRST.

REROLL THE AFFECTED TUBE WITH TUBE EXPANDER.

IF NOT PLUG THE TUBE IF IT IS URGENT .

UPTO 5% OF THE COOLING TUBE CAN BE PLUGGED WITH OUT AFFECTING

THE DUTY

POLISHING UNIT-I

POLISHING UNIT SERVES TO MAINTAIN LOW ELECTRICAL CONDUCTIVITY

OF THE CONDUCTIVITY OF THE PRIMARY WATER.

POLISHING UNIT IS CONNECTED IN PARALLEL TO THE MAIN CIRCUIT

POLISHING UNIT CONTAINS

1. MIXED BED ION EXCHANGER

2. FILTER

3. FLOW METER

4. CONDUCTIVITY METER

THE BASE SUBSTANCES OF THE EXCHANGER ARE POLYMERS.

THE POLYMERS IN THE CATION EXCHANGER ARE HIGHLY ACIDIC GROUPS

THE POLYMERS IN THE ANION EXCHANGER ARE HIGHLYBASIC GROUP.

WHEN RESINS ARE EXHAUSTED THEY THEY MUST BE REPLACED.

POLISHING UNIT TECHNICAL DATA

CAPACITY 2 M

3

DESIGN CONDUCTIVITY AT THE IN LET 1 MICRO MHO/CM

CONDUCTIVITY OF THE WATER AT OUT LET 0.44 MICRO MHO/CM

PH VALUE OF THE WATER AT THE INLET 6 TO 7 MICRO MHO/CM

PH VALUE OF THE WATER AT THE OUTLET 70.2

OPERATING RESIN BED 6 MONTHS

FINAL FILTER SIZE 5 MICRONS

RESIN TULSION T 42

TULSION A-27 MP

REAGENT HCL 30% 20.3KG

NAOH 100% 11.5 KG

MAGNETIC FILTER-PRINCIPLE

THE MAGNETIC FILTER IS OF PERMANENT MAGNET TYPE

DESIGNED TO TRAP FERRO MAGNETIC PARTICLES

THE FILTER MAINLY CONSISTS OF AN UPPER AND A LOWER

BODY HOUSING THE PERMANENT MAGNET SYSTEM,

COMPRISING OF THE MAGNETS POLE SHOES AND POLE RINGS

THE DM WATER PASSES THROUGH TWO ANNULAR AIR GAPS IN

WHICH THE FERRO MAGNETIC PARTICLES ARE FILTERED OUT.

MAGNETIC FILTER MAINTENACE

THE UPPER BODY IS REMOVED

WITH HELP OF THE REMOVABLE BOLTS THE POLE RING IS

DISMANTLED .

THE POLE RING AND THE POLE SHOES ARE CLEANED AND THE

ENTRAPPED FERRO MAGNETIC PARTICLES ARE THOROUGHLY WIPED

THE FILTER IS ASSEMBLED AND INSTALLED BACK IN POSITION AND O

RING IS REPLACED , IF IT IS IN DAMAGED CONDITION

MAGNETIC FILTER

MAGNETIC FILTER TECHNICAL DATA

MAGNET TYPE PERMANENT MAGNET

THE CAPACITY OF THE MAGNETIC FILTER 36M

3

MAXIMUM INDUCTION DENSITY 4000GAUSS

PRESSURE RATING NOT MORE THAN 10 KSC

TYPE OF PARTICLES FILTERED HIGHLY AND

MEDIUM MAGNETIC

HYDRAULIC TEST PRESSURE 16KSC FOR 10 MINUTE

PRESSURE DROP NEGLIGIBLE

STATOR WATER MECHANICAL FILTER

THE FILTER BODY CONSISTS OF CYLINDRICAL BODY HAVING

SEPARATE INLET AND OUT LET CHAMBERS.

A PERFORATED CYLINDRICAL BODY HAVING HOLES ALL ALONG ITS

LENGTH AND PERIPHERY IS SURROUNDED BY THE ASSEMBLY OF 30 TO

34 FILTER ELEMENTS.

THE FILTER ELEMENTS ARE KEPT IN POSITION BY A HELICAL SPRING

WHICH IS KEPT PRESSED BY A COVER.

THE FILTER ELEMENTS CONSISTS OF CORRUGATED BRASS SHEET

WITH A CENTRE HOLE AND TWO SIZES OF WIRE MESH APERTURES

0.224 MM AND 0.5 MM HELD IN ONE ASSEMBLY BY INNER AND OUTER

BRASS RING.

THE WATER AFTER PASSING THROUGH THE FILTERING ELEMENTS

ENTERS THE PERFORATED CYLINDER FROM WHERE IT FLOWS TO THE

OUTLET CHAMBER.

IMPURITIES GET COLLECTED IN THE WIRE MESH.

THE FILTER IS PROVIDED WITH DRAIN AND VENT PLUGS.

STATOR WATER MECHANICAL FILTER

TECHNICAL DATA

TYPE WIRE MESH TYPE

RATED DISCHARGE 30 M

3

MAXIMUM PRESSURE RATING 12 KSC

MINIMUM SIZE OF THE PARTICLES 0.224

THAT CAN BE FILTERED

PRESSURE DROP 0.1 KSC TO 0.2 KSC

PRESSURE DROP WHEN CLEANING IS

RECOMMENDED 0.4 KSC

MATERIAL OF THE BODY AND

PERFORATED CYLINDER Stainless steel

MATERIAL OF THE FILTER ELEMENT BRASS

SIZE OF THE WIRE MESH 0.224 MM AND 0.5 MM

HYDRAULIC TEST PRESSURE 38 KSC FOR 15 MINUTES

GAS TRAP

GAS TRAP IS USED FOR DETECTING THE PRESENCE OF HYDROGEN

GAS IN THE STATOR WATER SYSTEM.

PRESENCE OF THE GAS IN THE WATER SYSTEM IS POSSIBLE DUE TO

LOOSE AND LEAK AS JOINTS AS THE WATER PRESSURE IS KEPT LOWER

THAN THE HYDROGEN PRESSURE IN THE GENERATOR CASING.

THE GAS ENTRAPPED IN THE WATER GOES TO THE UPPER CHAMBER

FROM WHERE THE GAS IS SAMPLED FOR ANY MIXING.

TOP POINTS OF THE SUPPLY AND DRAINAGE ARE CONNECTED TO ANY

INLET POINTS OF THE DEVICE.

THE THIRD POINT IS CONNECTED TO PIPE LINE AT THE OUTLET OF THE

GENERATOR.

GAS TRAP -I

DRAIN PIPE IS CONNECTED TO THE DRAINAGE SYSTEM.

THREE POINTS OF THE INLET ARE CRACK OPENED AND THE WATER IS

ALLOWED TO ENTER CONTINUOUSLY.

THE WATER SO ENTERED WILL BE CONFINED TO LOWER CHAMBER OF

THE DEVICE AND THE EXCESS WATER IS DRAINED TO THE DRAIN PIPE .

IN CASE OF WATER CARRYING HYDROGEN,THE SAME IS LIBERATED AT

THE TOP CHAMBER

THE GAS ENTERS THE SPACE THROUGH THE CENTRE HOLE IN THE

PLUG AND IS DIRECTED TO THE UPPER CHAMBER THROUGH THE

SLOT IN THE PLUG.

GAS SYSTEM-I

GAS REQUIREMENT 56M

3

AMOUNT OF HYDROGEN REQUIRED TO FILL THE GENERATOR 300M

3

CASING TO RATED PRESSURE AT NTP-M/C STATIONARY

AMOUNT OF HYDROGEN REQUIRED TO FILL THE GENERATOR

CASING TO RATED PRESSURE AT NTP-M/C STATIONARY 340M

3

MAKE UP OF HYDROGEN REQUIRED /DAY 15M

3

AMOUNT OF CO

2

REQUIRED TO REMOVE HYDROGEN AT NTP 120M

3

WHEN MACHINE IS RUNNING 168M

3

AMOUNT OF CO

2

REQUIRED TO REMOVE AIR AT NTP 90M

3

WHEN MACHINE IS RUNNING 112M

3

EACH H

2

CYLINDER IS OF CAPACITY 46.7 LITRES AND CONTAINING

APPROXIMATELY 7 M

3

AT 150 ATM

NO. OF H

2

CYLINDERS REQUIRED TO FILL THE MACHINE

WHEN STATIONARY 50

WHEN RUNNING 56

NO. OF CYLINDERS REQUIRED/DAY 2 TO 3

EACH CO

2

CYLINDER IS 30 KGS WEIGHT OF CO

2

WITH GAS

EQUIVALENT TO 15M

3

OF GAS VOLUME.

NO. OF CYLINDERS REQUIRED FOR PURGING HYDROGEN

WHEN STATIONARY 11

RUNNING 14

NO. OF CO

2

REQUIRED FOR PURGING AIR WHEN STATIONARY 8

NO. OF CO

2

REQUIRED FOR PURGING AIR WHEN RUNNING 10

GAS SYSTEM-II

GAS DRIER

THANK YOU

You might also like

- Seal Oil System (Presentation)Document16 pagesSeal Oil System (Presentation)ToniMelo100% (2)

- Steam Turbine Governing System 500 MW Unit: K. Dhinesh KumarDocument89 pagesSteam Turbine Governing System 500 MW Unit: K. Dhinesh KumarNandhalalNo ratings yet

- Prsentation: Ball and Tube MillDocument39 pagesPrsentation: Ball and Tube MillmkoelrealNo ratings yet

- Write Up On GeneratorDocument62 pagesWrite Up On GeneratorAbhishek RanjanNo ratings yet

- Handling of Turbine During EmergencyDocument17 pagesHandling of Turbine During EmergencyManohar TatwawadiNo ratings yet

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonratNo ratings yet

- 210 MW Seal Oil SystemDocument6 pages210 MW Seal Oil Systemmag_ktps20021520No ratings yet

- Gov1 Sim 23.12.06Document25 pagesGov1 Sim 23.12.06SamNo ratings yet

- Turbine & Its Governing and Turbo Generator AlokDocument143 pagesTurbine & Its Governing and Turbo Generator AlokSHAMSIK2002100% (2)

- 600MW Final Scheme Tracing Book - by JIPT PDFDocument123 pages600MW Final Scheme Tracing Book - by JIPT PDFAnudeep ReddyNo ratings yet

- Operation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleDocument31 pagesOperation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleAshish Lanjewar100% (1)

- Salient Features of 500MWDocument63 pagesSalient Features of 500MWSamNo ratings yet

- Higher Capacity 500 MW Boiler: Key Features and Design FactorsDocument34 pagesHigher Capacity 500 MW Boiler: Key Features and Design Factorsdreamboy87No ratings yet

- TG Ele Hydro Oil PumpDocument8 pagesTG Ele Hydro Oil PumpsambhuNo ratings yet

- RollingDocument11 pagesRollingSam50% (2)

- TAKNIKI DARPAN - Issue 6Document40 pagesTAKNIKI DARPAN - Issue 6Rajarsi RayNo ratings yet

- Layout and Components of a Supercritical BoilerDocument41 pagesLayout and Components of a Supercritical BoilerLakshmi NarayanNo ratings yet

- Introduction to Auto Control Loops in Thermal Power PlantsDocument19 pagesIntroduction to Auto Control Loops in Thermal Power PlantsSai SwaroopNo ratings yet

- Knowledge Management Series-Low Vacuum in Steam Turbine PDFDocument4 pagesKnowledge Management Series-Low Vacuum in Steam Turbine PDFMadhusudhan Pasumarty100% (1)

- BFP Hyd CouplingDocument21 pagesBFP Hyd CouplingAditya Nandula100% (2)

- AGM & Sr. Faculty Member (PMI) NTPC LTD.: Dr. K. V. VidyanandanDocument46 pagesAGM & Sr. Faculty Member (PMI) NTPC LTD.: Dr. K. V. VidyanandanPraveen PeethambaranNo ratings yet

- Boiler OverviewDocument35 pagesBoiler Overviewshashank dasNo ratings yet

- L-02 Hp-Ip Modeules Features 500mw Anp 3Document10 pagesL-02 Hp-Ip Modeules Features 500mw Anp 3SamNo ratings yet

- Boiler Turbine Protection,,,EHC, Hydraullic-2Document21 pagesBoiler Turbine Protection,,,EHC, Hydraullic-2Balvir GangarNo ratings yet

- Gen-Seal&cool-New - 500 MWDocument98 pagesGen-Seal&cool-New - 500 MWharisankar100% (2)

- Boiler Overhauling Works Gyanendra Sharma NPTI DelhiDocument37 pagesBoiler Overhauling Works Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Control and Instrumentation Solutions for Safe Steam Turbine OperationDocument50 pagesControl and Instrumentation Solutions for Safe Steam Turbine Operationsen_subhasis_58No ratings yet

- 500mw Boiler Operating InstructionsDocument8 pages500mw Boiler Operating InstructionsRavindrababu Banothu100% (1)

- 500 MW Turbine Cycle DescriptionDocument8 pages500 MW Turbine Cycle DescriptionAhemadNo ratings yet

- Coal Combustion Optimisation Gyanendra Sharma NPTI DelhiDocument48 pagesCoal Combustion Optimisation Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Turbine Gland Sealing System ExplainedDocument12 pagesTurbine Gland Sealing System ExplainedPrudhvi Raj100% (1)

- New supercritical plants: constant vs sliding pressure optionsDocument28 pagesNew supercritical plants: constant vs sliding pressure optionsshambhoiNo ratings yet

- POWER PLANT GENERATOR OPERATION & AUXILIARIESDocument30 pagesPOWER PLANT GENERATOR OPERATION & AUXILIARIESrohit_0123100% (2)

- 660MW Turbo Generator & Its AuxiliariesDocument88 pages660MW Turbo Generator & Its AuxiliariesAshvani ShuklaNo ratings yet

- 500 MW Turbogenerator C&I Gyanendra Sharma NPTI DelhiDocument90 pages500 MW Turbogenerator C&I Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- HP - LP Bypass and Aprds SystemDocument47 pagesHP - LP Bypass and Aprds SystemSanjay Dadel100% (4)

- Monitoring Stator Water Systems for Large Turbine GeneratorsDocument12 pagesMonitoring Stator Water Systems for Large Turbine GeneratorsUmesh HadiyaNo ratings yet

- Automatic Turbine Runup System Gyanendra Sharma NPTI DelhiDocument32 pagesAutomatic Turbine Runup System Gyanendra Sharma NPTI DelhiNPTI100% (1)

- Bhel TG RollingDocument26 pagesBhel TG RollingAnand Swami100% (2)

- Write Up On FSSSDocument33 pagesWrite Up On FSSSdilbagh_scribdNo ratings yet

- Controlling Air Pollution with Electrostatic PrecipitatorsDocument30 pagesControlling Air Pollution with Electrostatic PrecipitatorsJerry FransiscusNo ratings yet

- Electro-Hydraulic Controller Functional DescriptionDocument8 pagesElectro-Hydraulic Controller Functional DescriptionvesridharNo ratings yet

- HPLP Bypass SystemDocument16 pagesHPLP Bypass SystemRakesh Kiran100% (1)

- CMCDocument32 pagesCMCAnubhav Amu PanditNo ratings yet

- Line TraceDocument84 pagesLine TraceSam100% (1)

- Emergency Procedure For Total Station Power FailureDocument4 pagesEmergency Procedure For Total Station Power FailureSelva Manian100% (1)

- Boiler Ash Handeling System Gyanendra Sharma NPTI DelhiDocument46 pagesBoiler Ash Handeling System Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- A Presentation On Turbine Rolling Atrs Final 2Document59 pagesA Presentation On Turbine Rolling Atrs Final 2Ramakrishna75% (4)

- Turbine Emergency - Thermal Power Plant A-ZDocument5 pagesTurbine Emergency - Thermal Power Plant A-ZSiva Kulanji100% (1)

- EHTCDocument22 pagesEHTCVicky Singh100% (1)

- 07 - Combustion - Optimisation PDFDocument90 pages07 - Combustion - Optimisation PDFLakshmi NarayanNo ratings yet

- LMW Turbine Governing SystemDocument80 pagesLMW Turbine Governing SystemAravazhi Ramasami Thangaraj100% (1)

- Turbine Trip LogicDocument2 pagesTurbine Trip Logicdilbagh_scribd50% (2)

- Aux PRDS SystemDocument22 pagesAux PRDS SystemKhan Ahmed MuradNo ratings yet

- Gen Seal Oil SysDocument21 pagesGen Seal Oil SyslrpatraNo ratings yet

- HeatersDocument9 pagesHeatersDevidutta PandaNo ratings yet

- Seal Oil System of Generator in Thermal Power PlantDocument39 pagesSeal Oil System of Generator in Thermal Power PlantHari Prasad100% (5)

- Stator Water Sys.Document29 pagesStator Water Sys.cyyguy3kNo ratings yet

- Well Head EquipmentDocument37 pagesWell Head Equipmentmohit narayanNo ratings yet

- Stern TubesDocument46 pagesStern Tubesvivek100% (2)

- Vehicle DynamicsDocument4 pagesVehicle DynamicsRaja RamachandranNo ratings yet

- Vehicle Body EnggDocument6 pagesVehicle Body EnggRaja RamachandranNo ratings yet

- Thermodynamics - Sunil PDFDocument5 pagesThermodynamics - Sunil PDFRaja RamachandranNo ratings yet

- Faculty of Engineering Course Plan for Theory of Automotive EnginesDocument7 pagesFaculty of Engineering Course Plan for Theory of Automotive EnginesRaja RamachandranNo ratings yet

- CE1136 Lesson Plan88Document3 pagesCE1136 Lesson Plan88Raja RamachandranNo ratings yet

- Manufacturing TechnologyDocument7 pagesManufacturing TechnologyRaja RamachandranNo ratings yet

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course PlanRaja RamachandranNo ratings yet

- Automotive Transmission Systems: Course Plan and SyllabusDocument5 pagesAutomotive Transmission Systems: Course Plan and SyllabusRaja RamachandranNo ratings yet

- Thermodynamics - SunilDocument5 pagesThermodynamics - SunilRaja RamachandranNo ratings yet

- Non Traditional Machining TechniquesDocument4 pagesNon Traditional Machining TechniquesRaja RamachandranNo ratings yet

- Lesson Plan on Global Warming and Climate ChangeDocument2 pagesLesson Plan on Global Warming and Climate ChangeRaja RamachandranNo ratings yet

- Sources and Types of Municipal Solid WastesDocument2 pagesSources and Types of Municipal Solid WastesRaja RamachandranNo ratings yet

- Mechanics of SolidsDocument2 pagesMechanics of SolidsRaja RamachandranNo ratings yet

- CE1206 Lesson PlanDocument2 pagesCE1206 Lesson PlanRaja RamachandranNo ratings yet

- Machines and MechanismDocument3 pagesMachines and MechanismRaja RamachandranNo ratings yet

- CE1020 Lesson Plan333Document2 pagesCE1020 Lesson Plan333zaidNo ratings yet

- CE1017 Lesson PlanDocument5 pagesCE1017 Lesson PlanRaja RamachandranNo ratings yet

- Sources and Types of Municipal Solid WastesDocument2 pagesSources and Types of Municipal Solid WastesRaja RamachandranNo ratings yet

- CE1017 Lesson Plan18Document3 pagesCE1017 Lesson Plan18Raja RamachandranNo ratings yet

- CE1008 Lesson PlanDocument3 pagesCE1008 Lesson PlanRaja RamachandranNo ratings yet

- CE1008 Lesson PlanDocument3 pagesCE1008 Lesson PlanRaja RamachandranNo ratings yet

- CE1017 Lesson PlanDocument5 pagesCE1017 Lesson PlanRaja RamachandranNo ratings yet

- CE1006 Lesson Plan7Document2 pagesCE1006 Lesson Plan7Raja RamachandranNo ratings yet

- Lesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Document3 pagesLesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Raja RamachandranNo ratings yet

- Lesson 1493762094Document1 pageLesson 1493762094Raja RamachandranNo ratings yet

- Faculty Name: Sucheta Panda: Total Number of Hours 48Document1 pageFaculty Name: Sucheta Panda: Total Number of Hours 48Raja RamachandranNo ratings yet

- CE1006 Lesson PlanDocument2 pagesCE1006 Lesson PlanRaja RamachandranNo ratings yet

- CE1006 Lesson PlanDocument2 pagesCE1006 Lesson PlanRaja RamachandranNo ratings yet

- Lesson Plan Branch-Mca 3 Semester Operating SystemDocument1 pageLesson Plan Branch-Mca 3 Semester Operating Systemsanthi saranyaNo ratings yet

- Lesson 1493761977Document1 pageLesson 1493761977santhi saranyaNo ratings yet

- ශ්රව්ය වර්දකDocument6 pagesශ්රව්ය වර්දකChathuranga ManukulaNo ratings yet

- LXC31X0 LXC31X0 LXC31X0 LXC31X0 Series Series Series Series Genset Genset Genset Genset Controller Controller Controller ControllerDocument28 pagesLXC31X0 LXC31X0 LXC31X0 LXC31X0 Series Series Series Series Genset Genset Genset Genset Controller Controller Controller ControllerlucasNo ratings yet

- CMOS Technology: An IntroductionDocument7 pagesCMOS Technology: An IntroductionMaria Ana DanganNo ratings yet

- Inductive Shrink Devices and Accessories Inductive Shrink DevicesDocument3 pagesInductive Shrink Devices and Accessories Inductive Shrink DevicesVlad LeucutaNo ratings yet

- ECOS System Error Code GuideDocument23 pagesECOS System Error Code Guidemohamed100% (1)

- Benchmarking EV and HEV Technologies: Tim Burress Oak Ridge National LaboratoryDocument22 pagesBenchmarking EV and HEV Technologies: Tim Burress Oak Ridge National LaboratoryTanawat ThanthongNo ratings yet

- Vt200wo1ab Wpr300enDocument9 pagesVt200wo1ab Wpr300enThomas GressNo ratings yet

- Artic Cat 1990 - 1998Document500 pagesArtic Cat 1990 - 1998Garrett Ross83% (6)

- Automatic Roofing Sheet Making MachineDocument12 pagesAutomatic Roofing Sheet Making MachinesylvesterNo ratings yet

- Tomar - Industrial Signalling CatalogDocument82 pagesTomar - Industrial Signalling CatalogPrejit RadhakrishnaNo ratings yet

- Computer Organization and ArchitectureDocument2 pagesComputer Organization and ArchitectureNitin JaiswalNo ratings yet

- ABC Siemens IECMotorsDocument168 pagesABC Siemens IECMotorsFernando MuneraNo ratings yet

- SM 8Document127 pagesSM 8Jan Svein HammerNo ratings yet

- NetCol5000-C030 In-Row Chilled Water Smart Cooling Product User Manual (Simple Configuration) PDFDocument198 pagesNetCol5000-C030 In-Row Chilled Water Smart Cooling Product User Manual (Simple Configuration) PDFRissel MorettiNo ratings yet

- MotherboardDocument6 pagesMotherboardRadu GavriliuNo ratings yet

- Fuel Optimized: Specification SheetDocument3 pagesFuel Optimized: Specification SheetTesla GeneradoresNo ratings yet

- Catálogo Interruptor SiemensDocument12 pagesCatálogo Interruptor SiemensJoel FigueroaNo ratings yet

- BC-2000 - K2 User ManualDocument1 pageBC-2000 - K2 User Manualamad4youNo ratings yet

- MCDO of Diesel Shed, AndalDocument12 pagesMCDO of Diesel Shed, AndalUpendra ChoudharyNo ratings yet

- SC750-1 60HZ Cummins Generator STAMFORDDocument4 pagesSC750-1 60HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Iq Plus 710 ManualDocument84 pagesIq Plus 710 Manualluiscgh55No ratings yet

- Communications & Signal Systems OverviewDocument27 pagesCommunications & Signal Systems OverviewChristian MuliNo ratings yet

- FPH-HP Install Manual V2.8Document38 pagesFPH-HP Install Manual V2.8steve67% (3)

- Power Pavers SF-1700 Parts ManualDocument77 pagesPower Pavers SF-1700 Parts ManualJulian Fraile100% (3)

- GHOST Mansory 2Document1 pageGHOST Mansory 2jhrvtnwghnNo ratings yet

- APC120 Platform Customer Error Codes V1 - 3Document30 pagesAPC120 Platform Customer Error Codes V1 - 3Daniel Aguirre67% (3)

- UnistrutDocument4 pagesUnistrutben0% (1)

- Inert Gas Smith Pressure Controller KS 90 PDFDocument84 pagesInert Gas Smith Pressure Controller KS 90 PDFraden_aditiya39No ratings yet

- IR Proximity Sensor GuideDocument10 pagesIR Proximity Sensor GuideTony Stark100% (1)