Professional Documents

Culture Documents

Workover Operations

Uploaded by

laaliauto100%(4)100% found this document useful (4 votes)

1K views19 pagesDescription of work over and procedures to follow

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDescription of work over and procedures to follow

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

100%(4)100% found this document useful (4 votes)

1K views19 pagesWorkover Operations

Uploaded by

laaliautoDescription of work over and procedures to follow

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 19

Final Evaluation Presentation By:

Chandra Shekhar AEE(P)

Pragyan Sharma AEE(P)

Rajnish Kumar AEE(P)

Suresh Kumar AEE(P)

Vikram Rai AEE(P)

9/9/2014 1 Workover Operations FE Presentation

WORKOVER OPERATIONS

Introduction

A production or injection well may be designed for

maximum efficiency but will always be subjected to

failure or declining performance.

These "failures" can be attributed to either:

Mechanical malfunction or the need for redesign of the

complete equipment to adapt to changing reservoir

conditions

Changes in reservoir performance or flow characteristics

as a result of reservoir dynamics and recovery

mechanism.

In general terms intervention may occur on a

producing or an injecting well and the operation is

normally referred to as a Workover.

9/9/2014 Workover Operations FE Presentation 2

General Approach To Workover

Problems on wells can largely be associated with one of

three areas, namely:-

The reservoir

The completion string

The wellbore

Normally a problem on a production or injection well

is evident by information gathered at surface, in

relation to

Flow rate,

Pressure

Composition & etc.

9/9/2014 Workover Operations FE Presentation 3

Logical Approach To Planning and

Conducting Workover Job

9/9/2014 Workover Operations FE Presentation 4

Types Of Intervention

The failures or the problems occurring in a well can be

either associated with the completion string or the

reservoir.

In general, problems associated with the completion string

can be classified as follows:

Problems which arise in the tubing bore and which can

be corrected by concentric through tubing operations

Problems which necessitate the retrieval of the

completion string from the well.

9/9/2014 Workover Operations FE Presentation 5

Completion String Problems

Internal Tubing Problems

Problems within the bore of the completion string can

be related to:

The failure and necessary retrieval/replacement of

wireline components and coiled tubing

The installation operation of, retrieval or equipment

within the tubing bore

The installation of equipment across the perforated

interval or in the sump of the well to exclude water, gas

or other production problems.

9/9/2014 Workover Operations FE Presentation 6

Tubing Retrieval Problem

There are a large number of problems which may occur on the well

which necessitate tubing retrieval.

These would include :

Mechanical failure of the tubing string, for example a leak or collapse of the tubing

Inability to conduct tubing wireline equipment replacement through the internal

bore of the string due to ID limitations - small tubing size.

The necessary replacement of the completion string by an alternative design, for

example to allow the installation of artificial lift.

The replacement of the tubing string to optimise reservoir performance, for

example to change the tubing string to a smaller size to better accommodate

declining reservoir productivity or increasing water, oil ratio.

9/9/2014 Workover Operations FE Presentation 7

Completion String Problems

Work Over Equipment And Techniques

Internal Through

Tubing Operations

Conventional slick

wireline operations

Through Flow Line

techniques for

application in subsea

wells

Concentric tubing

(CTU)

Tubing Retrieval

Operations

Work over Rig

9/9/2014 Workover Operations FE Presentation 8

Internal Through Tubing Operations

In general terms the

capabilities of

conventional/subsea

wireline and the

Through Flow Line

(TFL) techniques allow

the replacement and

installation of wireline

operated equipment

such as downhole valves,

chokes, regulators and

gauges.

Coiled tubing

operations involve the

insertion mechanically

of a small bore tube

which is unwound

continuously from a reel

and injected into the

well, optionally under

pressure.

Coiled tubing is

available in lengths up

to 22,000 ft of

continuous reel,

depending upon outside

diameter. It is available

in diameters ranging

from less than 1 to 7

9/9/2014 Workover Operations FE Presentation 9

Schematic Of CTU

Coiled tubing can

assist in conducting

the following range of

operations:

Circulation of fluid

placement within the

wellbore

Retrieval and

installation of wireline

or through tubing

equipment

Drilling or milling

operations

9/9/2014 Workover Operations FE Presentation 10

Work Over Jobs

Work over to

reduce water

production in oil

wells.

Work over for

servicing artificial

lift wells

Work over to

reduce/control

gas production.

Work over for

zone transfer

Work over for

sand control

Profile

modification in

WI wells

Deepening of pre

existing well

bores

Fishing and

Milling

Operations

Secondary

cementing jobs,

plugging and

abandonment

9/9/2014 Workover Operations FE Presentation 11

Work Over To Reduce Water Production In

A Well

PLT can help in indicating flow behind casing from a water zone, this

communication can usually be stopped with a low-pressure fluid-loss

cement squeeze and the well can be re-perforated in the desired

interval.

a) Fingering of water: Remedial measures are:

For perforated casing completions , squeeze water producing zone

with a low pressure low fluid loss cement squeeze.

For open hole completion where the lowest zone is producing water, a

plug back is the solution.

If the remaining oil and gas zones are below than the water producing

zone, then it is necessary to put a liner and cement against the water

producing zone to shut off water and then re-complete in the desired

oil or gas producing zone.

9/9/2014 Workover Operations FE Presentation 12

Water Coning

b. Water Coning.

Plug back and re-complete as high above the oil-

water or gas-water contact.

Control of water in high permeability reservoirs

where all zones appear to be producing with a

high water cut and squeeze cementing is

ineffective then it may be practical to produce

the well by high volume pumping or gas lift

with all zone open to the well bore.

A second approach to shut off water by using

gels wherein polymers are pumped into the well

.The gel after coming in contact with water forms

a pancake type barrier to the flow of water owing

to cross linking of polymer molecules and thus

stops water production.

9/9/2014 Workover Operations FE Presentation 13

Work Over to Control Gas Production

A well can produce gas if-

Completed too close to an expanding gas cap , may produce gas

prematurely.

If well produced at too high rate and the gas cones down

The gas can usually be shut off by-

Squeezing off the existing perforation, and perforating lower interval.

Since the GOC will move with production, the well will eventually

starts making gas again.

Oil squeeze Squeeze oil with surfactant-Reduce permeability to gas.

Shut in well near the gas cap by cement squeeze and produce from

further Down.

9/9/2014 14 Workover Operations FE Presentation

Sand Control & Zone Transfer

Work Over For Sand Control

In Unconsolidated or sand prone reservoir sand is deposited near the well

bore, plugged perforation and flow ceased. The remedial measures are:

Produce at control rate.

Gravel packing.

Pre-pack slotted liner.

Sand consolidation with plastic.

Open hole gravel pack job.-Re-entry followed by open hole GP

Testing And ZoneTransfer

Zone testing can be done by :

- Cement plug

- Bridge plug .

A zone once decided to be abandoned is plugged and new zone above

thatzone is perforated and brought in to production.

9/9/2014 Workover Operations FE Presentation 15

Other Work Over Jobs

Servicing Of Wells

Servicing jobs are generally safety related and involve operations such as replacement

of:

Gas lift valves

Sub-surface safety valves

Tubing and packers etc. and

Removal of-Tubing blockage due to sand

Scales

Wax and Paraffin

Problems With Artificial Lift

Problems with Artificial equipments can be ascertained by two- pen recorder,

echo meter survey, dynamometer surveys, ammeter surveys etc. After diagnosis

of the problem the necessary rectification/modification and re-designing the

pump is done and then installation and completion takes place .

Re-Completion

Such operation involve change in completion type such as:

From Single to Dual Completion or vice versa.

Re completing a well with gas lift etc.

The single completions are re completed dually either to avoid cross flow from one

layer to other owing to unequal pressure depletions over the producing life or to

control injection rates in individual layers in an injection well.

9/9/2014 Workover Operations FE Presentation 16

Other Work Over Jobs

Profile Modification In A Water Injection Well

Work over job for profile modification is carried out in water injection wells when

a) Some of the layers are taking either more or less amount of water than desirable.

b) b) A water flow log is used to record the injection profile of all the layers. The

Layers taking more than desired amount are squeezed off with cement. The layers

taking less water are re-perforated or some more layers are added.

Fishing Operation/Drilling and Milling Of Down Hole Tools

And Hole Clearing

Fishing refers to the application of tools, equipment and techniques for the removal

of junk, debris or fish from a well .

9/9/2014 Workover Operations FE Presentation 17

Other Work Over Jobs

Detection, Retrieving & Repair Of Casing.

The detection of damage and point can be ascertained by-

CCL and casing caliper log

Hermetical testing by Packer.

Isotope survey.

Once the casing leakage is detected it can be repaired by:

Cement squeeze job.

Re perforation and block cementation.

Casing patch.

Isolation of leakage by production packer.

In case the casing is totally damage or parted then damage casing above

cement rise can be retrieved and replaced.

Plugging & Abandonment

Plugging & Abandonment job involves abandonment of wells that

have outlived their economic producing lives for ensuring safety

and environmental protection in future.

9/9/2014 Workover Operations FE Presentation 18

Thank You!

9/9/2014 Workover Operations FE Presentation 19

You might also like

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!From EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Rating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Chapter 5 Well Services and WorkoverDocument55 pagesChapter 5 Well Services and Workoverstanlnleybuduka100% (3)

- Workover PlanningDocument21 pagesWorkover PlanningSandeep SuryavanshiNo ratings yet

- Ch02 Workover Oprnt and EquipmentsDocument94 pagesCh02 Workover Oprnt and EquipmentsNIRAJ DUBEYNo ratings yet

- Well Intervention and WorkoverDocument43 pagesWell Intervention and WorkoverSAI KIRAN KOOCHIMANCHI100% (2)

- Well CompletionDocument37 pagesWell Completionmusab doma100% (1)

- Well completion and intervention workover courseDocument73 pagesWell completion and intervention workover coursemissaoui100% (2)

- 8 WorkoverDocument124 pages8 WorkoverOmkar KurlekarNo ratings yet

- Well Intervention Presssure Control (IWCF)Document316 pagesWell Intervention Presssure Control (IWCF)rverret87% (23)

- Well Completion EquipmentDocument23 pagesWell Completion EquipmentSandeep SuryavanshiNo ratings yet

- Introduction to Well Intervention ServicesDocument36 pagesIntroduction to Well Intervention ServicesHaziq Yussof100% (1)

- P1R8789A Well Completion Workover Manual Volume1 PDFDocument416 pagesP1R8789A Well Completion Workover Manual Volume1 PDFe_syariefNo ratings yet

- Workover OperationsDocument46 pagesWorkover Operationspriyrnjn85% (13)

- Well ControlDocument40 pagesWell ControlNoumanIhsanNo ratings yet

- Workover PresentationDocument32 pagesWorkover PresentationNicky Adriaansz100% (3)

- Well Completion Functions and ApplicationsDocument112 pagesWell Completion Functions and Applicationsmissaoui100% (4)

- Well Intervention IntroductionDocument43 pagesWell Intervention Introductionmissaoui100% (3)

- Overview of Well Completion in 40 CharactersDocument92 pagesOverview of Well Completion in 40 CharactersTuesou MachereNo ratings yet

- Hydraulic Workover UnitDocument27 pagesHydraulic Workover UnitzenislerNo ratings yet

- 05 Well CompletionDocument57 pages05 Well CompletionKole Adeyemi100% (2)

- Well Completion Equipment OverviewDocument91 pagesWell Completion Equipment OverviewRanim Hisham100% (1)

- Completion & Workover.Document9 pagesCompletion & Workover.msu6383No ratings yet

- Tubing design stressesDocument12 pagesTubing design stressesakshitppe11No ratings yet

- Workover Planning: Ask For Skillup Drilling & Workover CoursesDocument44 pagesWorkover Planning: Ask For Skillup Drilling & Workover Coursessaer oklaNo ratings yet

- An Introduction To Well ServicesDocument70 pagesAn Introduction To Well ServicesAmit Jaiswal100% (4)

- Ch04 WELL HEAD EQUIPMENTS AND FLOW CONTROL DEVICESDocument16 pagesCh04 WELL HEAD EQUIPMENTS AND FLOW CONTROL DEVICESWhiskey /No ratings yet

- Well WorkoverDocument17 pagesWell WorkoverHasnain TariqNo ratings yet

- Senergy Completion Running Procedure 3 (EG50G7)Document27 pagesSenergy Completion Running Procedure 3 (EG50G7)uwuijaren_fridayNo ratings yet

- Completions and Workovers 1.9Document46 pagesCompletions and Workovers 1.9Maqbool Ahmad67% (3)

- P&Pof Intervention Pressure ControlDocument69 pagesP&Pof Intervention Pressure ControlRajat Khanna100% (4)

- Well Completion (2) Model AnswerDocument4 pagesWell Completion (2) Model Answermissaoui0% (1)

- Hydraulic Workover and Snubbing OperationsDocument46 pagesHydraulic Workover and Snubbing OperationsRoby Rido100% (5)

- Basic Surface Wellhead SchoolDocument47 pagesBasic Surface Wellhead SchoolIWCF IADC100% (2)

- Well Intervention Course: OrganizationsDocument31 pagesWell Intervention Course: OrganizationsAkol Majook100% (1)

- Introduction To Well Intervention Model AnswerDocument4 pagesIntroduction To Well Intervention Model Answermissaoui50% (2)

- Well Completion Equipment PDFDocument30 pagesWell Completion Equipment PDFAnonymous wHpCOKNo ratings yet

- ERTIKA Drilling Courses in Libya Power Failure and Snubbing OperationsDocument36 pagesERTIKA Drilling Courses in Libya Power Failure and Snubbing Operationssuifengniliu100% (3)

- WellheadDocument39 pagesWellheadTahir Haroon50% (2)

- Workover Class NotesDocument47 pagesWorkover Class NotesSorin100% (1)

- Snubbing Operations GuideDocument134 pagesSnubbing Operations Guidemjm_1365100% (1)

- Casing DesignDocument43 pagesCasing DesignBen Umobi Jnr50% (2)

- Well Head Chistmas TreeDocument9 pagesWell Head Chistmas TreeSatria 'igin' Girindra Nugraha100% (1)

- Workover PlanningDocument30 pagesWorkover PlanningGandhi Hetami50% (2)

- Chapter 6-Well CompletionDocument49 pagesChapter 6-Well Completionjorge_h_rivero100% (2)

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementFrom EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementRating: 4.5 out of 5 stars4.5/5 (2)

- 12.workover Operations PDFDocument23 pages12.workover Operations PDFMuhammad ShehryarNo ratings yet

- Workover - 10Document34 pagesWorkover - 10chemkumar16No ratings yet

- Well CompletionDocument26 pagesWell Completionnitesh kumarNo ratings yet

- Perforation GeometryDocument10 pagesPerforation GeometryJawaid HussainNo ratings yet

- 7 - Well Completion DesignDocument19 pages7 - Well Completion DesignAbdalla Magdy Darwish86% (7)

- SPE 88736 Expandable Tubular Completions For Carbonate ReservoirsDocument5 pagesSPE 88736 Expandable Tubular Completions For Carbonate ReservoirsmsmsoftNo ratings yet

- Well Completion Design and OperationsDocument43 pagesWell Completion Design and OperationsYusran Fahlevy Almajid100% (2)

- IATMI 09 - Innovative Chemical Water Shut Off Techniques Overcome Water Problems in Mature FieldsDocument7 pagesIATMI 09 - Innovative Chemical Water Shut Off Techniques Overcome Water Problems in Mature FieldswahyucrNo ratings yet

- Inflatable Plug Reduces Water in Slanted Ghawar WellsDocument4 pagesInflatable Plug Reduces Water in Slanted Ghawar WellsAneesh DohareyNo ratings yet

- Oil and Gas Wellsite Production Operations ExplainedDocument37 pagesOil and Gas Wellsite Production Operations ExplainedMahmoud EidNo ratings yet

- Production Eng 2Document106 pagesProduction Eng 2himanshu_petroengg100% (1)

- CRM Assign 1 PDFDocument17 pagesCRM Assign 1 PDFlaaliauto50% (2)

- Subsea Oil TreeDocument2 pagesSubsea Oil TreelaaliautoNo ratings yet

- Sand Control PDFDocument13 pagesSand Control PDFzunuwanus100% (2)

- The Life of Steve JobsDocument31 pagesThe Life of Steve JobsDhaval AgrawalNo ratings yet

- Pit Cleaning Timeline - AA - 16 SEPT2017Document12 pagesPit Cleaning Timeline - AA - 16 SEPT2017laaliautoNo ratings yet

- Enerplus Resources Inc.: Proposed Drilling Wellbore SchematicDocument1 pageEnerplus Resources Inc.: Proposed Drilling Wellbore SchematiclaaliautoNo ratings yet

- Time Estimate For Gravel Pack JobDocument1 pageTime Estimate For Gravel Pack JoblaaliautoNo ratings yet

- Economics and Management DecionsDocument253 pagesEconomics and Management DecionsJaswinder Pal BehlNo ratings yet

- Sand Control PDFDocument13 pagesSand Control PDFzunuwanus100% (2)

- Sand Control PDFDocument13 pagesSand Control PDFzunuwanus100% (2)

- Basic Oilfield CalculationsDocument17 pagesBasic Oilfield CalculationslaaliautoNo ratings yet

- Phase Tester VXDocument2 pagesPhase Tester VXlaaliauto100% (1)

- Cleanwell System Technology: Completion SolutionsDocument8 pagesCleanwell System Technology: Completion SolutionslaaliautoNo ratings yet

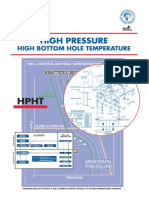

- Aberdeen Drilling School - HPHTDocument288 pagesAberdeen Drilling School - HPHTlaaliauto100% (4)

- (1961) The How and Why Wonder Book of The Human BodyDocument52 pages(1961) The How and Why Wonder Book of The Human BodyDoloma100% (2)

- Cleanout and Debris RemovalDocument49 pagesCleanout and Debris RemovallaaliautoNo ratings yet

- LM An INFO 0205 E Tutorial Rotational VibrometryDocument4 pagesLM An INFO 0205 E Tutorial Rotational VibrometrylaaliautoNo ratings yet

- Mechanical Debris MGMTDocument8 pagesMechanical Debris MGMTlaaliautoNo ratings yet

- Hand Out NVH Seminar IDIADA - SIAM - IndiaDocument82 pagesHand Out NVH Seminar IDIADA - SIAM - Indialaaliauto100% (1)

- UltrasonicDocument208 pagesUltrasoniclaaliautoNo ratings yet

- Garrett Turbo System OptimizationDocument11 pagesGarrett Turbo System OptimizationlaaliautoNo ratings yet

- Basic Mechanical EngineeringDocument859 pagesBasic Mechanical EngineeringVeera ReddyNo ratings yet

- 5 Steps To Success BY: Randy SlechtaDocument21 pages5 Steps To Success BY: Randy SlechtalaaliautoNo ratings yet

- Garrett Turbo System OptimizationDocument11 pagesGarrett Turbo System OptimizationlaaliautoNo ratings yet

- Wojciech Gryc - Neural Network Predictions of Stock Price FluctuationsDocument44 pagesWojciech Gryc - Neural Network Predictions of Stock Price FluctuationsjohnsmithxxNo ratings yet

- Dimensional Analysis AND Similarity: Chapter-5. (Frank White)Document46 pagesDimensional Analysis AND Similarity: Chapter-5. (Frank White)ShujaAmjadNo ratings yet

- Report On The Quantitative Techniques in BusinessDocument10 pagesReport On The Quantitative Techniques in BusinessBaron FrancisNo ratings yet

- Chemistry Sectionwise Analysis of PYQs (2024) - Ec3e53a7 c902 4e85 A5dd 12c4bf1f4ae7 1Document5 pagesChemistry Sectionwise Analysis of PYQs (2024) - Ec3e53a7 c902 4e85 A5dd 12c4bf1f4ae7 1lakhbhat2020No ratings yet

- Jm-10 Operation Manual Rev02 UnlockedDocument121 pagesJm-10 Operation Manual Rev02 UnlockedAlan Jimenez GonzalezNo ratings yet

- Forrester Roi StudyDocument30 pagesForrester Roi StudymcgettsNo ratings yet

- MCB and ELCB PDFDocument35 pagesMCB and ELCB PDFChris AntoniouNo ratings yet

- Balmer PDFDocument3 pagesBalmer PDFVictor De Paula VilaNo ratings yet

- Grade 8 Diagnostic Test 2022-2023Document2 pagesGrade 8 Diagnostic Test 2022-2023JennyNo ratings yet

- Fix Disk & Partition ErrorsDocument2 pagesFix Disk & Partition Errorsdownload181No ratings yet

- Sybsc Physics Practical Usphp3Document3 pagesSybsc Physics Practical Usphp3Ujjwala GokheNo ratings yet

- Essay For Villa Savoye AbstractDocument1 pageEssay For Villa Savoye AbstractFrancis PohNo ratings yet

- D Lucky Labeling of Graphs PDFDocument6 pagesD Lucky Labeling of Graphs PDFtony augustineNo ratings yet

- Cost Estimation TechniquesDocument41 pagesCost Estimation TechniquessubashNo ratings yet

- Connective TissueDocument6 pagesConnective TissuecrtgyhujikNo ratings yet

- JefimenkoDocument10 pagesJefimenkoBilly M. SpragueNo ratings yet

- TM View Software User - S ManualDocument190 pagesTM View Software User - S ManualLuis SánchezNo ratings yet

- 9 CE AmplifierDocument5 pages9 CE AmplifierAnsh PratapNo ratings yet

- Acids and Bases NotesDocument17 pagesAcids and Bases NotesNap DoNo ratings yet

- Treatment of Electroplating Wastewater Containing Cu2+, ZN 2+ and CR (VI) by ElectrocoagulationDocument8 pagesTreatment of Electroplating Wastewater Containing Cu2+, ZN 2+ and CR (VI) by ElectrocoagulationAnonymous ZAr1RKNo ratings yet

- Probability DPP (1 To 7) 13th WADocument16 pagesProbability DPP (1 To 7) 13th WARaju SinghNo ratings yet

- Welding Machine CatalogueDocument12 pagesWelding Machine CatalogueRodney LanagNo ratings yet

- Chapter 1: Introduction: 1.1 Background TheoryDocument36 pagesChapter 1: Introduction: 1.1 Background TheoryBe-fit Be-strongNo ratings yet

- Thinsat®300 Installation and User'S Manual: Thinkom Solutions, IncDocument39 pagesThinsat®300 Installation and User'S Manual: Thinkom Solutions, IncHiep Mai Van100% (1)

- Applications of Redox ReactionsDocument50 pagesApplications of Redox ReactionsMlamuli MlarhNo ratings yet

- SQL SlidesDocument65 pagesSQL SlidescopsamostoNo ratings yet

- Renormalization Group: Applications in Statistical PhysicsDocument37 pagesRenormalization Group: Applications in Statistical PhysicsJaime Feliciano HernándezNo ratings yet

- 3-Lecture 03 Translational Mechanical System3-SDocument23 pages3-Lecture 03 Translational Mechanical System3-SHamza KhanNo ratings yet

- OM5510 05 (Positioner)Document16 pagesOM5510 05 (Positioner)JayeshJayarajanNo ratings yet

- PID CONTROL SIMULATIONDocument6 pagesPID CONTROL SIMULATIONadrianordsNo ratings yet