Professional Documents

Culture Documents

Diesel Power Plant

Uploaded by

Arudhra Nerella100%(2)100% found this document useful (2 votes)

625 views18 pagesA diesel power plant uses a diesel engine as the prime mover to generate electricity. Diesel is burned inside the engine to produce mechanical energy, which then drives an alternator to convert it to electrical energy. Diesel power plants are suitable for small-scale power generation where demand is low and other resources like coal, water, and transportation are limited. While they have higher costs than other options due to the price of diesel fuel, they have advantages such as being quick to start up and shut down, having minimal standby losses, and requiring less space, water, and staff to operate.

Original Description:

Diesel Power Plant

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA diesel power plant uses a diesel engine as the prime mover to generate electricity. Diesel is burned inside the engine to produce mechanical energy, which then drives an alternator to convert it to electrical energy. Diesel power plants are suitable for small-scale power generation where demand is low and other resources like coal, water, and transportation are limited. While they have higher costs than other options due to the price of diesel fuel, they have advantages such as being quick to start up and shut down, having minimal standby losses, and requiring less space, water, and staff to operate.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

625 views18 pagesDiesel Power Plant

Uploaded by

Arudhra NerellaA diesel power plant uses a diesel engine as the prime mover to generate electricity. Diesel is burned inside the engine to produce mechanical energy, which then drives an alternator to convert it to electrical energy. Diesel power plants are suitable for small-scale power generation where demand is low and other resources like coal, water, and transportation are limited. While they have higher costs than other options due to the price of diesel fuel, they have advantages such as being quick to start up and shut down, having minimal standby losses, and requiring less space, water, and staff to operate.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 18

G Satyanarayana

After studying this unit,

you should be able to understand about

diesel engine power plant,

explain subsystem and its functions, and

Understand advantages and disadvantages of

Diesel power plants

A generating station in which diesel engine is

used as the prime mover for the generation

of electrical energy is known as diesel power

station .

The diesel burns inside the engine and the

products of this combustion act as the

working fluid to produce mechanical energy.

The diesel engine drives alternator which

converts mechanical energy into electrical

energy.

As the generation cost is considerable due to

high price of diesel, therefore, such power

stations are only used to produce small power.

Although steam power stations and hydro-

electric plants are invariably used to generate

bulk power at cheaper costs, yet diesel power

stations are finding favour at places where

demand of power is less, sufficient quantity of

coal and water is not available and the

transportation facilities are inadequate. This

plants are also standby sets for continuity of

supply to important points such as hospitals,

radio stations, cinema houses and telephone

exchanges.

Diesel Power Plant - Distributed Energy

Generation

The design and layout of the plant are quite simple.

It occupies less space as the number and size of the

auxiliaries is small.

It can be located at any place.

It can be started quickly and it can pickup load in a

short time.

There are no standby losses.

It requires less quantity of water for cooling.

The overall cost is much less than that of steam

power station of same capacity.

The thermal efficiency of the plant is higher than that

of a steam power station.

It requires less operating staff.

It is an excellent prime mover for electric

generator capacities of from 75 kW to 1000

kW. The Diesel units used for electric

generation are more reliable and long - lived

piece of equipment compared with other

types of plants.

The plant has high running charges as the

fuel (diesel) used is costly.

The plant doesnt work satisfactorily under

overload conditions for a longer period.

The plant can only generate small power.

The cost of lubrication is generally high.

The maintenances charges are generally high

Noise is a serious problem in diesel power

plant.

1.They are quite suitable for mobile power

generation and are widely used in transportation

systems consisting of railroads, ships,

automobiles and aeroplanes.

2. They can be used for electrical power generation

in capacities from 75 kW t0 4000 kW.

3. They can be used as standby power plants.

4. They can be used as peak load plants for some

other types of power plants.

5. Industrial concerns where power requirement

are small say of the order of 500 kW, diesel

power plants become more economical due to

their higher overall efficiency.

Todays modern diesels are quiet and normally

require less maintenance than comparably sized

gas (natural gas or propane) units.

Fuel costs per kW produced with diesels is

normally thirty to fifty percent less than gas

units.

1800 rpm water-cooled diesel units operate on

average 1230,000 hours before major

maintenance is required.

1800 rpm water-cooled gas units normally

operate 610,000 hours because they are built

on a lighter duty gasoline engine block.

Heat Balance Present and proposed Future Development

You might also like

- Power Generation: Schematic Diagram of Diesel Power StationDocument7 pagesPower Generation: Schematic Diagram of Diesel Power StationsoyabkhanNo ratings yet

- Diesel Electric Power Plant GuideDocument15 pagesDiesel Electric Power Plant GuideJennsonFernandezNo ratings yet

- Diesel Power PlantDocument22 pagesDiesel Power PlantJerry Andrews100% (1)

- Diesel Engine Power Plant ExplainedDocument15 pagesDiesel Engine Power Plant Explainedkasu s reddyNo ratings yet

- Diesel Power Plant Engineering GuideDocument50 pagesDiesel Power Plant Engineering Guidevigneysh tNo ratings yet

- Diesel Power PlantDocument17 pagesDiesel Power Plantkazi shahadatNo ratings yet

- Vdocument - in - Diesel Power Plant CatalogueDocument16 pagesVdocument - in - Diesel Power Plant CatalogueAhmed AteepNo ratings yet

- Diesel Power PlantDocument10 pagesDiesel Power Plantspj99696649148No ratings yet

- DieselPower PlantDocument12 pagesDieselPower PlantJC ElarmoNo ratings yet

- Lecture 1 - Diesel Engine Power PlantDocument60 pagesLecture 1 - Diesel Engine Power PlantbarryNo ratings yet

- Diesel Engine Power PlantsDocument58 pagesDiesel Engine Power PlantsVadiraj PatilNo ratings yet

- Nota Diesel Power PlantDocument16 pagesNota Diesel Power PlantFirdaus ZahariNo ratings yet

- K38 910kVA Prime PDFDocument4 pagesK38 910kVA Prime PDFapandey070273No ratings yet

- Calibu Diesel-Electric Power PlantDocument8 pagesCalibu Diesel-Electric Power PlantCharm100% (2)

- Newage Stamford Avk PowerportfolioDocument40 pagesNewage Stamford Avk Powerportfoliojorge luisNo ratings yet

- Diesel PPDocument58 pagesDiesel PPManvendra Pratap Singh Bisht100% (1)

- Genset Sizing GuideDocument27 pagesGenset Sizing GuidekhudoNo ratings yet

- 2-Pole Turbine Driven Generators - Brushless ExcitationDocument2 pages2-Pole Turbine Driven Generators - Brushless ExcitationChandrasekar Karuppasamy100% (1)

- Diesel Power Plant SystemsDocument17 pagesDiesel Power Plant SystemsDC ArkinNo ratings yet

- WKV Turbinen 2010 EN-rev1Document32 pagesWKV Turbinen 2010 EN-rev1mig22ismagoNo ratings yet

- Solar Diesel Grid HandbookDocument76 pagesSolar Diesel Grid HandbookR. Mega MahmudiaNo ratings yet

- Diesel power plant applications and layoutDocument3 pagesDiesel power plant applications and layoutAljebeth D. TuraNo ratings yet

- Diesel Power PlantDocument11 pagesDiesel Power PlantDr. B. Ramesh100% (2)

- Black Start Power Station RestorationDocument23 pagesBlack Start Power Station RestorationSyed Ijlal HaiderNo ratings yet

- Diesel Power Plant Technical Report SummaryDocument9 pagesDiesel Power Plant Technical Report SummaryVince Dominich MadroneroNo ratings yet

- NG112-06 Technical InformationDocument20 pagesNG112-06 Technical InformationyaasinNo ratings yet

- Lecture-Diesel Power PlantDocument32 pagesLecture-Diesel Power Plantvinmwale91430% (1)

- SolarPro 7.6Document88 pagesSolarPro 7.6HanyNo ratings yet

- Evolution and Components of Diesel Power PlantsDocument51 pagesEvolution and Components of Diesel Power PlantsJed Alcantara100% (2)

- Diesel Power PlantDocument3 pagesDiesel Power PlantdinnykumarNo ratings yet

- ACTED TENDER FOR GENERATOR MAINTENANCEDocument24 pagesACTED TENDER FOR GENERATOR MAINTENANCE213eknoNo ratings yet

- D.G MaintenanceDocument8 pagesD.G MaintenanceshaikamirulhasanNo ratings yet

- 21 Floating Power Plant Sarah BellewDocument17 pages21 Floating Power Plant Sarah BellewinderjitNo ratings yet

- Design Diesel-Photovoltaic Hybrid Power PlantDocument93 pagesDesign Diesel-Photovoltaic Hybrid Power PlantDaniel Okere100% (1)

- Gas Insulated SubstationDocument6 pagesGas Insulated SubstationSravani Daggubati100% (1)

- Diesel Generator SpecificationDocument13 pagesDiesel Generator Specificationmtrj59No ratings yet

- Technology Gas EngineDocument10 pagesTechnology Gas Enginedtw26No ratings yet

- TMEIC Industrial Motors Overview Brochure Letter-HiResDocument12 pagesTMEIC Industrial Motors Overview Brochure Letter-HiResWallerson AbreuNo ratings yet

- Diesel Power PlantDocument47 pagesDiesel Power PlantRajput Divyapratap Singh Chauhan0% (1)

- PPS 1005Document6 pagesPPS 1005Boom08No ratings yet

- Generac SizingGuideDocument34 pagesGenerac SizingGuidekaushikray06No ratings yet

- Effective System GroundingDocument80 pagesEffective System GroundingHenry Gómez UrquizoNo ratings yet

- Diesel Engine Power PlantDocument13 pagesDiesel Engine Power PlantUtol JasonNo ratings yet

- Problems With Newer Generators 3Document72 pagesProblems With Newer Generators 3Engr Irfan AkhtarNo ratings yet

- Scania Jenerator DC1372A - 438-487kW PDFDocument2 pagesScania Jenerator DC1372A - 438-487kW PDFMehmet ErenNo ratings yet

- Grounding, Backfeed Breakers & PV Disconnect 2002Document3 pagesGrounding, Backfeed Breakers & PV Disconnect 2002ronniedakingpouNo ratings yet

- Motor and Starter TrainingDocument30 pagesMotor and Starter Trainingsrukeer100% (1)

- HYUNDAI PowerplantDocument16 pagesHYUNDAI PowerplantDavid Ortiz de Zevallos100% (3)

- Maintenance Schedule Checklist For GE PC Motors PDFDocument54 pagesMaintenance Schedule Checklist For GE PC Motors PDFrama jenaNo ratings yet

- DC-AC Ratio ArticleDocument7 pagesDC-AC Ratio ArticleYashpal VyasNo ratings yet

- Lecture Notes - Synchronous MachineDocument14 pagesLecture Notes - Synchronous MachineYuvraj GogoiNo ratings yet

- MCB or MCCBDocument4 pagesMCB or MCCBKurnia FajarNo ratings yet

- Generator Basics & Preventative Maintenance: Clifford K.F. Yuen, P.E. Engine Sales Manager Hawthorne Power SystemsDocument22 pagesGenerator Basics & Preventative Maintenance: Clifford K.F. Yuen, P.E. Engine Sales Manager Hawthorne Power SystemsTayran PrashadNo ratings yet

- GTG 1383om Piel Sul 48mchpDocument18 pagesGTG 1383om Piel Sul 48mchpjohn smithyNo ratings yet

- Maintenance Plan: Maintenenance Engineering (Me-403)Document22 pagesMaintenance Plan: Maintenenance Engineering (Me-403)moe100% (1)

- ME152P 2 - C3 - Final Plate - Diesel Power PlantDocument88 pagesME152P 2 - C3 - Final Plate - Diesel Power PlantkeaneNo ratings yet

- What Is Diesel Power PlantDocument6 pagesWhat Is Diesel Power PlantJomarie PanganibanNo ratings yet

- Advantages of Diesel Power PlantsDocument5 pagesAdvantages of Diesel Power PlantsRuss AñosaNo ratings yet

- Diesel Electric Power PlantsDocument16 pagesDiesel Electric Power PlantsCharlo AngelesNo ratings yet

- Mongis N - Diesel PowerplantDocument3 pagesMongis N - Diesel PowerplantNoemi JognoNo ratings yet

- 16 Types of Container Units and Designs For Shipping CargoDocument22 pages16 Types of Container Units and Designs For Shipping CargoArudhra NerellaNo ratings yet

- PWC Global Supply Chain Survey 2013Document19 pagesPWC Global Supply Chain Survey 2013mushtaque61No ratings yet

- SMDocument9 pagesSMArudhra NerellaNo ratings yet

- SafexpressDocument20 pagesSafexpressArudhra Nerella100% (1)

- SafexpressDocument20 pagesSafexpressArudhra Nerella100% (1)

- Ola cab presentation on business model, operations and pricingDocument15 pagesOla cab presentation on business model, operations and pricingArudhra NerellaNo ratings yet

- Aircargo PDFDocument64 pagesAircargo PDFArudhra NerellaNo ratings yet

- Principal of HPP PDFDocument33 pagesPrincipal of HPP PDFAshfaq AhmadNo ratings yet

- FMSDocument8 pagesFMSArudhra NerellaNo ratings yet

- 39 Design of V - Belt DrivesDocument10 pages39 Design of V - Belt DrivesPRASAD326100% (6)

- Mathematical InductionDocument8 pagesMathematical InductionArudhra NerellaNo ratings yet

- Recording As A Solution Over MRA (An Overview) : Technical Consulting Engineer Telepresence Solutions GroupDocument16 pagesRecording As A Solution Over MRA (An Overview) : Technical Consulting Engineer Telepresence Solutions GroupEnes ÇukurNo ratings yet

- Ventilation Calculation 1591013185963Document8 pagesVentilation Calculation 1591013185963mak ksaNo ratings yet

- BPMN With PrologDocument6 pagesBPMN With PrologCarlos Gomes de BarrosNo ratings yet

- KEIL For StellarisDocument18 pagesKEIL For StellarisdAnieLNo ratings yet

- GP PowerBank M520 DataDocument2 pagesGP PowerBank M520 DataElectronNo ratings yet

- Social Media Safety TipsDocument5 pagesSocial Media Safety TipsIthran IthranNo ratings yet

- Project Management Resume ExampleDocument2 pagesProject Management Resume ExampleGuino VargasNo ratings yet

- TH1n en Datasheet Mar 2018 AirbusDocument2 pagesTH1n en Datasheet Mar 2018 Airbuseng.ibrahim.abdo89No ratings yet

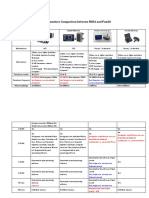

- Main Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayDocument3 pagesMain Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayAsep RifkyNo ratings yet

- BIM Execution Plan TemplateDocument1 pageBIM Execution Plan TemplateanuarNo ratings yet

- Case Study II - RoffDocument3 pagesCase Study II - RoffNikhil MaheshwariNo ratings yet

- Curriculum PDFDocument5 pagesCurriculum PDFstephen villaruzNo ratings yet

- Drive TechnologyDocument352 pagesDrive TechnologyBurak İLHANNo ratings yet

- LINSN LED Display Screen User's ManualDocument15 pagesLINSN LED Display Screen User's Manualcarlos auden villegas alcalaNo ratings yet

- ICT TERMS-WPS OfficeDocument3 pagesICT TERMS-WPS OfficeKate Hera RiegoNo ratings yet

- Mastering Apache Spark PDFDocument663 pagesMastering Apache Spark PDFchandra prakash VermaNo ratings yet

- WinPower ManualDocument94 pagesWinPower ManualDemetrius DanielNo ratings yet

- Guidelines on Occupational Safety and Health in Tunnel ConstructionDocument39 pagesGuidelines on Occupational Safety and Health in Tunnel ConstructionknabpshoNo ratings yet

- Wifi Controlled Light Using Esp32: Products Learning Center My AccountDocument6 pagesWifi Controlled Light Using Esp32: Products Learning Center My AccountbejaouiNo ratings yet

- ScadaDocument3 pagesScadaAkira SatoNo ratings yet

- Why Bridges CollapseDocument4 pagesWhy Bridges CollapseNataliaNo ratings yet

- 1991 Alfred Maul - A Pioneer of Camera RocketDocument13 pages1991 Alfred Maul - A Pioneer of Camera RocketAlysson DiógenesNo ratings yet

- Source of Business IdeasDocument30 pagesSource of Business IdeasHannie Salve Bodomo100% (2)

- A255 Robot Service ManualDocument272 pagesA255 Robot Service ManualGustavo Cahuana100% (1)

- USM Engineering CampusDocument28 pagesUSM Engineering Campusfai-fai-fai-8153No ratings yet

- Distant Traffic Light Recognition Using Semantic SegmentationDocument7 pagesDistant Traffic Light Recognition Using Semantic Segmentationz feieeeNo ratings yet

- Comparision Between Nokia and AppleDocument3 pagesComparision Between Nokia and AppleSushan SthaNo ratings yet

- Emerging Nokia Group Discusses Mobile Phone EvolutionDocument11 pagesEmerging Nokia Group Discusses Mobile Phone EvolutionArunachalamNo ratings yet

- Installation 2127 PDFDocument136 pagesInstallation 2127 PDFMichael SezeniasNo ratings yet

- Saes K 402Document18 pagesSaes K 402drbabithameringeorgemdsorthoNo ratings yet