Professional Documents

Culture Documents

Types Profibus Communication

Uploaded by

Ahmed ElsayedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Types Profibus Communication

Uploaded by

Ahmed ElsayedCopyright:

Available Formats

Ref: P .

ppt (9/27/2014) 1

EUROTHERM

CONTROLS

Profibus

Ref: P .ppt (9/27/2014) 2

EUROTHERM

CONTROLS

This Talk

Brief overview of Profibus family

Profibus DP - Where it came from, how it works

Profibus GSD Files

Profibus Slave Operation

Eurotherm GSD File editor

Future

Ref: P .ppt (9/27/2014) 3

EUROTHERM

CONTROLS

Profibus Family

Profibus DP

Fast transfer of time critical I/O data

Machine building/Automation ~ 10mS scan time

DPV1 adds Acyclic messages and high level data type

definitions

Profibus PA

DPV1 Messaging + Device Profiles + Intrinsic Safety

Slower Physical Medium (31.25 kbit/s) with loop power

Process Applications

Profibus FMS

Full Messaging (I/O + non time critical)

Higher level Communications (PLC <-> PLC)

Ref: P .ppt (9/27/2014) 4

EUROTHERM

CONTROLS

Traditional PLC Control System

Internal Backplane

Transfers Input and Output data

between CPU and Modules prior

to PLC scan cycle

Data from modules appears

in I/O registers in the CPU.

Processed by application

Point to Point wiring to Plant - Essentially 1 wire per signal

Ref: P .ppt (9/27/2014) 5

EUROTHERM

CONTROLS

PLC Control With DP

Internal backplane replaced by

external High Speed RS485 cable

connected to Scanner Module.

I/O data from devices is transferred

cyclically - appears in PLC registers

to be processed by application.

Modules replaced by Devices -

I/O or special function

Ref: P .ppt (9/27/2014) 6

EUROTHERM

CONTROLS

Cyclic I/O Data Transfer

Slave Input Data (To PLC)

Slave Output Data (From PLC)

Temperature

Working Setpoint

Loop Output Power

Alarm Status word

PLC Registers

Target Setpoint

Manual Output

Scanner transfers I/O

Data from/to PLC once

each scan cycle for each

slave ~ 10mS cycle

Application uses

data from input

registers and

sets values in

output registers

Ref: P .ppt (9/27/2014) 7

EUROTHERM

CONTROLS

General Benefits of using Fieldbuses

Wiring Cost reduction (35 - 40% of total)

Easier maintenance, and flexibility to add new

devices when and where needed

Use best of breed, specialised, devices easily at all

points in the application - reduces load on PLC

Devices located close to point of application and

closely coupled to it

Feedback from smart devices reduces planned

maintenance and allows quality improvement via

SPC etc.

Not limited to modules produced by vendor of PLC

(or PC3000!)

Ref: P .ppt (9/27/2014) 8

EUROTHERM

CONTROLS

DP is popular with users...

Easily understandable - no need to read the spec!

Easily applicable - devices interwork without

problems

Transparent to PLC programmers

Very little ongoing network maintenance

Supported by a very wide range of device and PLC

vendors

DP systems are now being constructed on a very

routine basis without problems - not an R&D

exercise.

Ref: P .ppt (9/27/2014) 9

EUROTHERM

CONTROLS

DP is popular with vendors

Based on a range of Siemens ASICs - easy hardware

implementation for slave devices

Pre-Canned modules available (Siemens, Hilscher,

SST etc) to add DP to products without significant

hardware development

Easy to support - ASICs ensure third party devices

work in a consistent and predictable manner

Result is a healthy proliferation of different kinds of I/O

and specialised devices

Ref: P .ppt (9/27/2014) 10

EUROTHERM

CONTROLS

Why Eurotherm chose Profibus DP

DP is currently the best choice for networking PLCs

with I/O and other devices. Fast, simple, and

available.

DeviceNet is too limited in bandwidth for larger

applications, and third party support not as

comprehensive.

Foundation Fieldbus not widely adopted.

Profibus DP now adopted within Eurotherm as our

main Fieldbus platform.

Ref: P .ppt (9/27/2014) 11

EUROTHERM

CONTROLS

Profibus - Weaknesses.

Limited acyclic capacity. Not good for SCADA or

large scale file transfers.

Not really plug and play (like DeviceNet)

No pre-defined Function Block library (like FF)

Ref: P .ppt (9/27/2014) 12

EUROTHERM

CONTROLS

Eurotherms Profibus Range

T940

SCADA - PC Cards

Wonderware, Wizcon,

Interlution

subselect.me

OK OK OK OK OK

OK OK OK OK OK

2000F PID

Controllers

T630 Process

Controller

Thyristor

Power

Controllers

Chart

Recorders

AC/DC

Drives

2900

e

CPU

H

e a t

T e m

p

I n n e r T e m

p

M

a i n A

i r

M

a i n F a n

A

u x A

i r

A

u x F a n

R

u n

C

o o l

R

a i s e

L

o w

e r R

e s e t

H

o l d S e r v o

F r i d g e L

i g h t 1

L

o a d L

i g h t

2

Loop Loop Relay 4 DI/DO 8

2500

Multi-loop

PC3000/PC300

T800

Ref: P .ppt (9/27/2014) 13

EUROTHERM

CONTROLS

GSD

1

Files

Define third party devices to Profibus DP network

configuration tools.

Include timing information, supported baud rates,

links to bitmap images, etc.

Include details of I/O Mapping and Parameterisation

Contents downloaded to Slave devices on network

startup

In Eurotherm products, define the set of device

variables transferred over Profibus. Set up using our

GSD File Editor

1

Gertestammdaten

Ref: P .ppt (9/27/2014) 14

EUROTHERM

CONTROLS

DP Network Configuration

GSD

GSD

GSD

Ref: P .ppt (9/27/2014) 15

EUROTHERM

CONTROLS

DP Slave Operation

Units first parameterised by Master

Sends up to 244 bytes of Vendor Specific Data

Data comes from GSD file

In Eurotherm devices, defines content of I/O messages

Units then Configured by Master

Up to 244 bytes Type and Size data defining I/O

Data comes from GSD file

Slave enters Data Exchange

Exits back to parameterisation on timeout

Diagnostic requests made on status change or fatal error

Diagnostics

Not well understood (even by Siemens!)

Flagged during I/O exchange

Provide indication of Fatal Device Fault or

Provide indication of Status (e.g. sensor fail)

Ref: P .ppt (9/27/2014) 16

EUROTHERM

CONTROLS

Profibus DP Slave State Machine

Config Datafrom GSD File

User Parametisation Data

from GSD File

Ref: P .ppt (9/27/2014) 17

EUROTHERM

CONTROLS

Why Use a GSD Editor?

Profibus designed for simple bulk I/O devices (e.g.

16 words I + 0)

Our products are much more complex (500-3000

parameters).

Impossible to choose a universal subset for I/O, and

wasteful of bandwidth to transfer unnecessary

variables.

Best approach to allow I/O mapping selection by

users on a per application basis

Ref: P .ppt (9/27/2014) 18

EUROTHERM

CONTROLS

Problems

GSD file provides user data. Obvious place to define

I/O transfer, and values from file may be changed by

user using network configuration tool

However data type definitions are also in the GSD

file, and closely coupled to I/O definition.

Data type definitions are not usually changeable

using the network configuration tool

Solution Chosen - Create a GSD Editor tool to define

I/O transfer in userss terms, and manage type

definitions automatically...

Ref: P .ppt (9/27/2014) 19

EUROTHERM

CONTROLS

Eurotherm GSD File Editor

Creates Custom GSD file for use by network configurators

Ref: P .ppt (9/27/2014) 20

EUROTHERM

CONTROLS

Why Use the GSD File editor

Very easy to use - drag and drop interface

Allows optimum use of network bandwidth - only

transfer the variables you need

Permits very flexible use of devices - no need for a

lowest common denominator mapping

Avoids manual editing of GSD file employed by

other vendors - error prone and complicated

Build up a library of GSD files for different

applications

Use the PLC to wire between device variables for

complex control strategies

Web button for latest hints and tips on-line

Ref: P .ppt (9/27/2014) 21

EUROTHERM

CONTROLS

Demand Data

Cyclic Data interchange is great, but

Relentlessly overwrites values set via the front panel of the

instrument (though this can be overcome with sequence logic)

Allows access to a limited number of device variables

Demand Data provided to solve this problem

Uses 4 words in the input and output areas

Allows read or write access to all device variables on demand

Uses a simple mailbox system, easily programmable using a PLC

sequence program

Switched on or off by the GSD File Editor

Supported by specialised PC3000 Function Blocks

DPV1 provides proper acyclic messaging (currently 2500 E-

Suite only)

Ref: P .ppt (9/27/2014) 22

EUROTHERM

CONTROLS

Future

Profibus group pushing ProfiNet (Profibus on

Ethernet)

Various other developments (Plug and Play,

ProfiSafe, Expansion of Profibus PA).

May be better long term bets for higher level

Ethernet protocols (e.g. FF)

Ref: P .ppt (9/27/2014) 23

EUROTHERM

CONTROLS

Conclusion

Profibus DP allows easy interconnection of

Eurotherm and third party devices

Good for small scale Machine Building networks

Less good as a SCADA network

GSD file editor and Demand Data allow great

flexibility of operation with Eurotherm slaves.

You might also like

- Serial Port Complete: COM Ports, USB Virtual COM Ports, and Ports for Embedded SystemsFrom EverandSerial Port Complete: COM Ports, USB Virtual COM Ports, and Ports for Embedded SystemsRating: 3.5 out of 5 stars3.5/5 (9)

- Siemens Equipment Usage Guide Imdl: 1/28/2004 Last Updated: 9/13/04Document29 pagesSiemens Equipment Usage Guide Imdl: 1/28/2004 Last Updated: 9/13/04johnNo ratings yet

- Mark VieDocument4 pagesMark VieWalid Bahi100% (1)

- The Industrial Communication Systems PROFIBUS and PROFInet 01Document8 pagesThe Industrial Communication Systems PROFIBUS and PROFInet 01a_luisNo ratings yet

- Design of Innovative Ship Concepts UsingDocument22 pagesDesign of Innovative Ship Concepts UsingN KoteeswarNo ratings yet

- CENTUM VP System IntroductionDocument8 pagesCENTUM VP System IntroductionKevin NgoNo ratings yet

- Interfacecomponent SiemensDocument16 pagesInterfacecomponent Siemenssteam100deg1658No ratings yet

- BCI ICT ResilienceDocument57 pagesBCI ICT ResilienceOana DragusinNo ratings yet

- PCS7 With ProfibusDocument12 pagesPCS7 With ProfibusRaj ChavanNo ratings yet

- Profibus: Tim Linnell (Eurotherm LTD)Document23 pagesProfibus: Tim Linnell (Eurotherm LTD)sina20795100% (2)

- Strategic AssignmentDocument3 pagesStrategic Assignmentjukilili311550% (4)

- 03 RTU560 Introduction EDocument10 pages03 RTU560 Introduction EEdmund Stokes-WallerNo ratings yet

- OPC Unified ArchetictureDocument26 pagesOPC Unified ArchetictureAhmed ElsayedNo ratings yet

- GS SCL eDocument28 pagesGS SCL erigo_skNo ratings yet

- PLC MelsecDocument67 pagesPLC Melsecsafvanshaikh100% (1)

- Control Loop Hardware and TroubleshootingDocument51 pagesControl Loop Hardware and TroubleshootingAhmed ElsayedNo ratings yet

- Testing Aircraft AFDX SystemsDocument2 pagesTesting Aircraft AFDX SystemslokeshbnNo ratings yet

- Advance Embedded System Design: Shibu K VDocument73 pagesAdvance Embedded System Design: Shibu K VBhavya Reddy75% (4)

- Introduction To ScadaDocument97 pagesIntroduction To ScadaNicholas SheltonNo ratings yet

- Introduction To ScadaDocument97 pagesIntroduction To ScadaNicholas SheltonNo ratings yet

- SIMATIC S7 GraphDocument11 pagesSIMATIC S7 GraphAhmed ElsayedNo ratings yet

- TheMaintGuide FieldcommDocument7 pagesTheMaintGuide Fieldcommaromero888No ratings yet

- Siemens Profibus 1Document34 pagesSiemens Profibus 1Miguel AngelNo ratings yet

- How Profibus Communication WorksDocument8 pagesHow Profibus Communication WorksRALPH JULES SARAUSNo ratings yet

- General Specifications: Models SSS7700, SSS7710, SSS7720 Plant Resource ManagerDocument26 pagesGeneral Specifications: Models SSS7700, SSS7710, SSS7720 Plant Resource ManagerapisituNo ratings yet

- MVI69 AFC DatasheetDocument3 pagesMVI69 AFC Datasheet김윤식No ratings yet

- Operator Control and Monitoring - Simple and Cost-Effective ... Perfect For The SIMATIC S7-200Document3 pagesOperator Control and Monitoring - Simple and Cost-Effective ... Perfect For The SIMATIC S7-200Robney FiuzaNo ratings yet

- Profibus DP & PaDocument5 pagesProfibus DP & PazaydFGNo ratings yet

- General Specifications: Models SSS7700, SSS7710, SSS7711, SSS7720, SSS7750 Plant Resource ManagerDocument20 pagesGeneral Specifications: Models SSS7700, SSS7710, SSS7711, SSS7720, SSS7750 Plant Resource ManagerapisituNo ratings yet

- Ai GETCPDocument9 pagesAi GETCPzrondjulNo ratings yet

- Advanced Power Technology and Services J.S.C. Advanced Power Technology and Services J.S.CDocument10 pagesAdvanced Power Technology and Services J.S.C. Advanced Power Technology and Services J.S.CQuang NgocNo ratings yet

- Profibus - Wikipedia, The Free EncyclopediaDocument5 pagesProfibus - Wikipedia, The Free EncyclopediakalyanupdownNo ratings yet

- Infoplc Net Curso Profibus 1Document18 pagesInfoplc Net Curso Profibus 1Jair malandrinNo ratings yet

- Instrumentation and Process ControlDocument1 pageInstrumentation and Process ControlYasmine ياسمينNo ratings yet

- Embeded Systems Unit 1Document73 pagesEmbeded Systems Unit 1Srinivasa RaoNo ratings yet

- COM 600 - OverviewDocument39 pagesCOM 600 - OverviewIsaac R-sNo ratings yet

- 4 7SR11 7SR12 Data CommunicationsDocument40 pages4 7SR11 7SR12 Data Communicationsmail2anoopmvNo ratings yet

- TESA DataDirect PDFDocument3 pagesTESA DataDirect PDFmarcolocomxNo ratings yet

- Nanodac AN 030817U001 1Document6 pagesNanodac AN 030817U001 1aca85No ratings yet

- ProfimDocument5 pagesProfimFernando ValenciaNo ratings yet

- Guia FieldmateDocument4 pagesGuia FieldmateAlexander RojasNo ratings yet

- Profibus: Actuator ControlDocument8 pagesProfibus: Actuator ControlMrSarvan100% (1)

- Abb PDP 22-fbpDocument38 pagesAbb PDP 22-fbpVenkatesh SubramanyaNo ratings yet

- SIMATIC S7-300: The Modular Controller For Factory Automation Sets Standards in Performance and New FeaturesDocument8 pagesSIMATIC S7-300: The Modular Controller For Factory Automation Sets Standards in Performance and New Featurescosmin75No ratings yet

- The Basics of Fieldbus: Technical Data SheetDocument4 pagesThe Basics of Fieldbus: Technical Data Sheetcharro1623No ratings yet

- ON Metso Automation PDFDocument29 pagesON Metso Automation PDFpradeep1987coolNo ratings yet

- An Open Electronic Marshalling SolutionDocument4 pagesAn Open Electronic Marshalling Solutionmanuelsantos2007No ratings yet

- Basics of Profibus Operation Chapter1Document20 pagesBasics of Profibus Operation Chapter1kerusacba_2011No ratings yet

- Download-En - Data Sheet PLC-ANALYZER Pro 5Document4 pagesDownload-En - Data Sheet PLC-ANALYZER Pro 5Hhaabbde SybaritzNo ratings yet

- Substation Communications:: Technical InstituteDocument23 pagesSubstation Communications:: Technical InstitutenooralhudNo ratings yet

- Introduction To Profibus ProfinetDocument15 pagesIntroduction To Profibus ProfinetsoewinaungNo ratings yet

- Unit 3 System Interfacing and ControllersDocument48 pagesUnit 3 System Interfacing and ControllersSrinivasan V PNo ratings yet

- Openenterprise: New Capability of Integrating Dcs and Scada Client / Server ArchitectureDocument20 pagesOpenenterprise: New Capability of Integrating Dcs and Scada Client / Server Architectureilie_vlassaNo ratings yet

- Profibus: What A Fieldbus System Needs To OfferDocument48 pagesProfibus: What A Fieldbus System Needs To OfferSudipto MajumderNo ratings yet

- Absolute Rotary Encoder With Modbus/TCP InterfaceDocument26 pagesAbsolute Rotary Encoder With Modbus/TCP InterfaceLeonardoAcevedoNo ratings yet

- AbsoluteEncoders OCD IndustrialEthernet TCP IP Manual Modbus DataContentDocument26 pagesAbsoluteEncoders OCD IndustrialEthernet TCP IP Manual Modbus DataContentVoicu StaneseNo ratings yet

- K Profibus eDocument13 pagesK Profibus eRonald EscaleraNo ratings yet

- Communication ProtocolsDocument4 pagesCommunication Protocolsthiagarajan_adhirajNo ratings yet

- Any BusDocument4 pagesAny BusgreggherbigNo ratings yet

- E PLC400 Spec ProvisionalDocument8 pagesE PLC400 Spec ProvisionalNishant JhaNo ratings yet

- Plant Structuxure - Unity Pro and OPC Software - MKTED2140504EN (Web)Document47 pagesPlant Structuxure - Unity Pro and OPC Software - MKTED2140504EN (Web)Anonymous uXxyCieO3100% (1)

- Applicom GATEwayDocument4 pagesApplicom GATEwayjorgem_matiasNo ratings yet

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- Scad A 1Document76 pagesScad A 1ravindarsinghNo ratings yet

- SE WhitePaper Letter SCADAOverview V005Document13 pagesSE WhitePaper Letter SCADAOverview V005aromero888No ratings yet

- Control SystemDocument41 pagesControl SystemiekazalyNo ratings yet

- SE WhitePaper Letter SCADAOverview V005Document13 pagesSE WhitePaper Letter SCADAOverview V005aromero888No ratings yet

- Profibus TechnologyDocument31 pagesProfibus TechnologyAhmed ElsayedNo ratings yet

- Distributed Control Systems: Emad Ali Chemical Engineering Department King SAUD UniversityDocument24 pagesDistributed Control Systems: Emad Ali Chemical Engineering Department King SAUD Universityessakkirajm19902116No ratings yet

- FIELDBUS Engineering TechnologyDocument25 pagesFIELDBUS Engineering TechnologyAhmed ElsayedNo ratings yet

- Introduction To Realtime SystemsDocument11 pagesIntroduction To Realtime SystemsAhmed ElsayedNo ratings yet

- LabVIEW Introduction ThreeHourDocument50 pagesLabVIEW Introduction ThreeHourAhmed ElsayedNo ratings yet

- As InterfaceDocument19 pagesAs InterfaceAhmed ElsayedNo ratings yet

- LabVIEW IntroductionDocument29 pagesLabVIEW IntroductionAhmed ElsayedNo ratings yet

- Legal InformationDocument1 pageLegal InformationAhmed ElsayedNo ratings yet

- S7-300 Automation System Getting Started CPU 31x CommissioningDocument20 pagesS7-300 Automation System Getting Started CPU 31x CommissioningMancamiaicuruNo ratings yet

- DSC (Dataloggin and Supervisory Control Module)Document16 pagesDSC (Dataloggin and Supervisory Control Module)cereales8100% (1)

- SAC Training 01Document11 pagesSAC Training 01Harshal RathodNo ratings yet

- Cyber ArkDocument2 pagesCyber ArkHendra SoenderskovNo ratings yet

- Unit 5 Cloud Computing Overview RKSDocument22 pagesUnit 5 Cloud Computing Overview RKSmr yashNo ratings yet

- Appendix B: Technical InformationDocument11 pagesAppendix B: Technical InformationOnTa OnTa60% (5)

- Flitedeck Pro X: Release NotesDocument28 pagesFlitedeck Pro X: Release NotesŁukasz BarzykNo ratings yet

- Temario Spring MicroserviciosDocument5 pagesTemario Spring MicroserviciosgcarreongNo ratings yet

- Cgaxis Models Volume 118Document26 pagesCgaxis Models Volume 118AntezanaFernandoNo ratings yet

- Problem 5 Limocon, MelendezDocument24 pagesProblem 5 Limocon, MelendezMaria Angela MelendezNo ratings yet

- CSEC Information Technology June 2015 P02Document18 pagesCSEC Information Technology June 2015 P02SiennaNo ratings yet

- Enterprise Resourse Planning - Assessment-3Document8 pagesEnterprise Resourse Planning - Assessment-3Sha iyyaahNo ratings yet

- Pharmaceutical Distribution Management System - ERDiagramDocument1 pagePharmaceutical Distribution Management System - ERDiagram1000 ProjectsNo ratings yet

- HP Pavilion 14 - x360 Touchscreen 2-In-1 Laptop - 12th Gen Intel Core I5-1235u - 1080p - Windows 11 - CostcoDocument4 pagesHP Pavilion 14 - x360 Touchscreen 2-In-1 Laptop - 12th Gen Intel Core I5-1235u - 1080p - Windows 11 - CostcoTanish JainNo ratings yet

- Release Notes - READDocument3 pagesRelease Notes - READHari KurniadiNo ratings yet

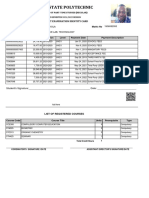

- Lagos State Polytechnic: Student Examination Identity CardDocument1 pageLagos State Polytechnic: Student Examination Identity CardSunday PeterNo ratings yet

- Statistical Analysis With R - A Quick StartDocument47 pagesStatistical Analysis With R - A Quick StartPonlapat Yonglitthipagon100% (1)

- College Brochure ProjectDocument2 pagesCollege Brochure Projectapi-275943721No ratings yet

- Table of Contents For Computer Architecture: A Minimalist PerspectiveDocument6 pagesTable of Contents For Computer Architecture: A Minimalist PerspectiveWilliam GilreathNo ratings yet

- JNTUH Syllabus 2013 M.Tech CSEDocument33 pagesJNTUH Syllabus 2013 M.Tech CSESRINIVASA RAO GANTANo ratings yet

- LOGO-Simply Ingenious For Small AutomationDocument8 pagesLOGO-Simply Ingenious For Small Automationcc_bauNo ratings yet

- Upload 1 Document To Download: Kill Team 2021 - Core BookDocument4 pagesUpload 1 Document To Download: Kill Team 2021 - Core BookgoneoNo ratings yet

- International Molecular Pathology Catalog 2020Document222 pagesInternational Molecular Pathology Catalog 2020nam7124119No ratings yet

- Report On Mango Cultivation ProjectDocument40 pagesReport On Mango Cultivation Projectkmilind007100% (1)

- HCD RG221Document64 pagesHCD RG221Berenice LopezNo ratings yet

- UNLV PHD InformaticsDocument3 pagesUNLV PHD InformaticsAnonymous gzESmV9No ratings yet

- Web Technologies SyllabusDocument2 pagesWeb Technologies SyllabusMythri PhaniNo ratings yet

- DSLC™ Digital Synchronizer and Load Control: Installation and Operation ManualDocument114 pagesDSLC™ Digital Synchronizer and Load Control: Installation and Operation ManualEdy TonelNo ratings yet