Professional Documents

Culture Documents

Freeze Drying Guide for Pharmaceuticals and Food

Uploaded by

Jabel PatesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Freeze Drying Guide for Pharmaceuticals and Food

Uploaded by

Jabel PatesCopyright:

Available Formats

AMPILOQUIO BAJALLA PATES

*REMOVE WATER TO

INCREASE SHELF LIFE

DRYING

*PREVENT CONTAMINATION

* ANTIBIOTICS AND

PHARMACEUTICALS

* VACCINES

* MICR0-ORGANISMS

* TISSUE CULTURES

* SPACE FOOD and other

FOODSTUFF

*How to dry these

important materials??

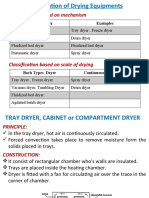

CONTACT / CONVECTIVE

DRYERS

HEATING

BAD IDEA!!!!!

HEAT SENSITIVE MATERIALS

MUST AVOID THERMAL

DEGREDATION!!

*WHY???

FREEZE

DRYER

FREEZE DRYING

Water is removed as

vapor by sublimation in

a vacuum chamber

Also known as

lyophilisation

Maintains the basic

structure and composition

of the material

Frozen substances provide

structural rigidity,

prevents collapse of the

porous structure

Highest Quality product

from a drying process

Aroma and flavor is

preserved in food

Expensive, long drying

times

DRYING PROCESS

PRETREATMENT

FREEZING

PRIMARY DRYING

SECONDARY DRYING

AFTER TREATMENT

PRE-TREATMENT

Product concentration

Stability Improvement

Decreasing High Vapor

Pressure solvent

Increase material

surface area

FREEZING

Removal of Heat to create a

state suitable for sublimation

drying

Material is cooled below triple

point

Usually, the freezing

temperatures are between 50

C and 80 C

FREEZING

Suitable freezing

technique must be

specified prior to drying

FREEZING

Freezing Methods for Solids

Blast Freezing

Individual Quick

Freezing

FREEZING

Freezing Methods for Liquids

Drum Freezing

Belt Freezing

Foaming

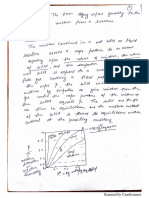

PRIMARY DRYING

Pressure is lowered to a few

millibars

Sufficient Heat is supplied to

allow sublimation

Heat of Sublimation of ice is

2838 kJ/kg

PRIMARY DRYING

Heat may be conducted:

Through the layer of

dried material

Through the frozen layer

PRIMARY DRYING

PRIMARY DRYING

PLANE OF

SUBLIMATION

PRIMARY DRYING

Combination of either:

Convection,

Conduction and

Radiation

Conduction and

Radiation

PRIMARY DRYING

CONVECTION

CONDUCTION

Heat is supplied by surrounding gases

SECONDARY DRYING

Remove unfrozen water

molecules

Strong physio-chemical

forces

Desorption Process

SECONDARY DRYING

Overcome capillary action

and other physio-chemcal

interactions of water and

the material

Higher Temperature, Low

Pressure

SECONDARY DRYING

Overcome capillary action

and other physio-chemical

interactions of water and

the material

Higher Temperature, Low

Pressure

AFTER TREATMENT

Storage mechanisms

PROCESS EXAMPLE

GEA Pharma Systems, supplier

for Pharmaceutical production

equipment

Pharmaceutical Freeze Drying

FREEZE DRYER:

CLASSIFICATIONS

MODE OF OPERATION

Batch Operation with low

capacities (Long Drying

Times)

Continuous Operations

exist

MODE OF THERMAL ENERGY

INPUT

Indirect Dryer. Heat is

transferred to the wet material

by conduction through a solid

retaining wall, usually metallic

Sorce: Perrys Chemical Engineers Handbook

BASIC PARTS

VACUUM CHAMBER

Vacuum pump, reduces

ambient presssure

Compressor, removes

the moisture through

condensation on a

surface

CATEGORIES OF FREEZE

DRIERS

Manifold Freeze-Dryer

Rotary Freeze-Dryer

Tray Style Freeze-Dryer

MANIFOLD FREEZE DRYER

MANIFOLD FREEZE DRYER

Laboratory scale

Special Products, only

used for a short period

of time

MANIFOLD FREEZE DRYER

a short circular tube is

used to connect multiple

containers with the dried

product to a condenser

ROTARY FREEZE DRYER

ROTARY FREEZE DRYER

Cylindrical reservoir that

is rotated during drying

for a more uniform

drying

ROTARY FREEZE DRYER

Used for drying

pellets, cubes and

other solid materials

that can flow

TRAY STYLE FREEZE DRYER

TRAY STYLE FREEZE DRYER

rectangular reservoir with

shelves on which products

can be placed in trays, vials

and other containers.

TRAY STYLE FREEZE DRYER

allows the product to be

frozen in place and performs

both primary and secondary

freeze-drying, thus producing

the driest possible end-

product

TRAY STYLE FREEZE DRYER

TRAY STYLE FREEZE DRYER

Tunnel Freeze Dryer

Continuous Radiation Freeze Drying Plant

You might also like

- Freeze DryingDocument10 pagesFreeze Dryingmamun_ru50% (2)

- Guide Freeze Drying: The Miracle of Food PreservationDocument6 pagesGuide Freeze Drying: The Miracle of Food PreservationBrunithNo ratings yet

- Freeze DryingDocument7 pagesFreeze Dryingbekku100% (1)

- Freeze DryingDocument1 pageFreeze DryingOnorio IervolinoNo ratings yet

- Essential Guide for Home Freeze Dryer OwnersDocument44 pagesEssential Guide for Home Freeze Dryer Ownerssgk102No ratings yet

- Freeze-Drying Proteins Emerging ConcernsDocument13 pagesFreeze-Drying Proteins Emerging Concernsamin138irNo ratings yet

- Freeze Drying ReportDocument23 pagesFreeze Drying ReportSanjana Bhattacharyya93% (14)

- DryingDocument37 pagesDryingPranjal AgarwalNo ratings yet

- Food Chilling and FreezingDocument12 pagesFood Chilling and FreezingNicholaus ShawNo ratings yet

- Thermal Processing - CanningDocument141 pagesThermal Processing - Canningthink_exergy75% (4)

- Freeze Drying With Ease!Document1 pageFreeze Drying With Ease!ravingrabbitsNo ratings yet

- Freeze Drying: Presented By: MR - Prem Patil M.Pharm+Mba (1 Year)Document33 pagesFreeze Drying: Presented By: MR - Prem Patil M.Pharm+Mba (1 Year)Hasif D. Müller100% (1)

- Coconut Milk YogurtDocument2 pagesCoconut Milk Yogurtsayakou78100% (1)

- Lyophilization DetailsDocument33 pagesLyophilization Detailsj.k.kumar100% (4)

- Freeze DryingDocument20 pagesFreeze DryingWanda Suryadinata100% (1)

- Dryers and Drying ProcessDocument33 pagesDryers and Drying ProcessddNo ratings yet

- DRYINGDocument31 pagesDRYINGNat TanNo ratings yet

- Lecture Notes On DryingdsgaaaaaaaaaaDocument15 pagesLecture Notes On DryingdsgaaaaaaaaaaSaumith DahagamNo ratings yet

- Unit 3 Dehydration and ConcentrationDocument62 pagesUnit 3 Dehydration and ConcentrationHayati SofiyahNo ratings yet

- Freeze drying: Principles, process, applications and problemsDocument15 pagesFreeze drying: Principles, process, applications and problemsLaxit PanaraNo ratings yet

- Cooling Presentation 3Document27 pagesCooling Presentation 3tadiwanashezinyuke4No ratings yet

- DRYINGDocument33 pagesDRYINGMISHIKA NARULANo ratings yet

- Freeze Drying: DR - Sangeetha SubramanianDocument21 pagesFreeze Drying: DR - Sangeetha SubramanianYoshita SinghNo ratings yet

- 1.5 DryingDocument23 pages1.5 DryingDerese BishawNo ratings yet

- Freeze DryingDocument10 pagesFreeze DryingAli ImranNo ratings yet

- FREEZE DRYING OF BIOPHARMACEUTICALSDocument20 pagesFREEZE DRYING OF BIOPHARMACEUTICALSDONA JOJONo ratings yet

- 5 PengeringanDocument14 pages5 PengeringanAl Zahra Khas KempekNo ratings yet

- Freeze Drying - An Introduction to the ProcessDocument39 pagesFreeze Drying - An Introduction to the ProcessrajagopalNo ratings yet

- DRYINGDocument71 pagesDRYINGARJYA ROY100% (1)

- Chapter 2Document22 pagesChapter 2amirul ashrafNo ratings yet

- Dehydration of Fruits and VegetablesDocument40 pagesDehydration of Fruits and VegetablesSwaminathan S. Raamanathan100% (2)

- Slide Freeze DryingDocument19 pagesSlide Freeze DryingFarah Mustapha100% (1)

- Me411 Group 2Document2 pagesMe411 Group 2John Phill YtangNo ratings yet

- DRYINGDocument37 pagesDRYINGAnusree AnilNo ratings yet

- Scanned Documents from CamScanner AppDocument128 pagesScanned Documents from CamScanner AppOğuzhan KocaoğluNo ratings yet

- Classification Based On Mechanism: Types of Dryer ExamplesDocument19 pagesClassification Based On Mechanism: Types of Dryer ExamplesTeenaNo ratings yet

- Ou PresentationDocument31 pagesOu PresentationYvince LohNo ratings yet

- Summer Training at Saurav Chemicals Limited: Prepared & Presented byDocument19 pagesSummer Training at Saurav Chemicals Limited: Prepared & Presented byRahul SarohaNo ratings yet

- Lyophilization of Parenterals FinalDocument25 pagesLyophilization of Parenterals FinalMostofa RubalNo ratings yet

- DryingDocument175 pagesDryingtalhawasimNo ratings yet

- Kehinde Taiwo Obafemi Awolowo University NigeriaDocument49 pagesKehinde Taiwo Obafemi Awolowo University NigeriaAnanthNo ratings yet

- Spray Drying 31.8.16Document22 pagesSpray Drying 31.8.16shutterbugsadiNo ratings yet

- Lyophilization/Freeze Drying: Dr. Nasir AbbasDocument12 pagesLyophilization/Freeze Drying: Dr. Nasir AbbasAdil AminNo ratings yet

- Nirav DryerDocument14 pagesNirav DryerRatikanta AcharyaNo ratings yet

- Types of EvaporatorsDocument50 pagesTypes of Evaporatorsjezreeleda.limNo ratings yet

- Spray Dryer & Freeze DryerDocument20 pagesSpray Dryer & Freeze DryerHaroon RahimNo ratings yet

- Design of Cold Storage For Food Products Construction AND Equipment SelectionDocument16 pagesDesign of Cold Storage For Food Products Construction AND Equipment SelectionervaishaliNo ratings yet

- Removal of Heat Energy: 1. Freeze Drying 2. Freeze ConcentrationDocument19 pagesRemoval of Heat Energy: 1. Freeze Drying 2. Freeze ConcentrationTasmia TasnimNo ratings yet

- 6877 DryingDocument53 pages6877 DryingSiri NalNo ratings yet

- FT 409 - (19 Arid 4816)Document32 pagesFT 409 - (19 Arid 4816)Hani TatlaNo ratings yet

- Use of Low TemperatureDocument49 pagesUse of Low TemperatureAiman Ghazanfar AliNo ratings yet

- Chemical Technology Subject Code: CH2001Document17 pagesChemical Technology Subject Code: CH2001U SANKAR TEJONo ratings yet

- Refrigeration SystemDocument21 pagesRefrigeration SystemshaieraNo ratings yet

- Drying: Muhammad Kashif M.Phil (Pharmaceutics)Document41 pagesDrying: Muhammad Kashif M.Phil (Pharmaceutics)Rana EhtishamNo ratings yet

- Principles of Lyophilization ExplainedDocument5 pagesPrinciples of Lyophilization Explainediqbalkhan62No ratings yet

- Dryers in Word FileDocument5 pagesDryers in Word FileHaroon RahimNo ratings yet

- Adiabatic Dryers PresentationDocument27 pagesAdiabatic Dryers PresentationJunaid IqbalNo ratings yet

- BCH 706 Lypholization 34587Document27 pagesBCH 706 Lypholization 34587zshanali6236No ratings yet

- Parenterals BPKDocument54 pagesParenterals BPKPragat KumarNo ratings yet

- 6877 DryingDocument21 pages6877 DryingDrx Namdev KachareNo ratings yet

- TrainingDocument8 pagesTrainingJabel PatesNo ratings yet

- J and E Valve Logic Modification PDFDocument1 pageJ and E Valve Logic Modification PDFJabel PatesNo ratings yet

- Bernoulli's EquationDocument11 pagesBernoulli's EquationJabel PatesNo ratings yet

- Chlorobenzene From Benzene and Chlorine: Design of A Chlorobenzene Distillation UnitDocument14 pagesChlorobenzene From Benzene and Chlorine: Design of A Chlorobenzene Distillation UnitJabel PatesNo ratings yet

- Plasmid DNA BioprocessingDocument7 pagesPlasmid DNA BioprocessingJabel PatesNo ratings yet

- Crystallizer DesignDocument20 pagesCrystallizer DesignJabel Pates100% (11)

- Responsibility in EngineeringDocument32 pagesResponsibility in EngineeringJabel PatesNo ratings yet

- Montreal and Kyoto ProtocolDocument47 pagesMontreal and Kyoto ProtocolJabel Pates100% (1)

- As ISO 128.23-2005 Technical Drawings - General Principles of Presentation Lines On Construction DrawingsDocument9 pagesAs ISO 128.23-2005 Technical Drawings - General Principles of Presentation Lines On Construction DrawingsSAI Global - APAC0% (3)

- Partlist Smsport 110RDocument74 pagesPartlist Smsport 110RThai YunNo ratings yet

- Fajs FSXDocument8 pagesFajs FSXJunhy Bandeira CassandraNo ratings yet

- Internet Controlled Multifunctional UGV For SurvellianceDocument74 pagesInternet Controlled Multifunctional UGV For SurvellianceMd Khaled NoorNo ratings yet

- Service Menu - SamyGODocument5 pagesService Menu - SamyGOVenkatesh SubramanyaNo ratings yet

- EXPERIMENT 3a and 3b - Aluminum Content Via Redox and ColorimeterDocument13 pagesEXPERIMENT 3a and 3b - Aluminum Content Via Redox and ColorimeterTrupti soniNo ratings yet

- Micron Ezeprox Access Control KeypadDocument4 pagesMicron Ezeprox Access Control KeypadThuy VuNo ratings yet

- Saint Gobain - CertainTeed Roofing ShinglesDocument14 pagesSaint Gobain - CertainTeed Roofing ShinglesJagriti KashyapNo ratings yet

- Melter / Applicators: Modern Cracksealing TechnologyDocument16 pagesMelter / Applicators: Modern Cracksealing TechnologyEduardo RazerNo ratings yet

- Stokes' theorem simplifies integration of differential formsDocument6 pagesStokes' theorem simplifies integration of differential formssiriusgrNo ratings yet

- Struts by Kamalakar DanduDocument237 pagesStruts by Kamalakar DanduKamalakar DanduNo ratings yet

- CV Enric Durany enDocument2 pagesCV Enric Durany enenricduranyNo ratings yet

- Hydraulic Mining Shovel 6040AC: 08. Attachment Functions - FSDocument20 pagesHydraulic Mining Shovel 6040AC: 08. Attachment Functions - FShector50% (2)

- Establishing OPC UA Connectivity With Rockwell Automation® Integrated ArchitectureDocument3 pagesEstablishing OPC UA Connectivity With Rockwell Automation® Integrated ArchitecturehuiyitNo ratings yet

- List of Projects Related To Transportation Highway and BridgesDocument5 pagesList of Projects Related To Transportation Highway and BridgesOyedotun TundeNo ratings yet

- Timing Chain Tensioner ResetDocument4 pagesTiming Chain Tensioner ResetHybrid RacingNo ratings yet

- Operator Interface Hmi Touch Screen Cmore - 10Document54 pagesOperator Interface Hmi Touch Screen Cmore - 10QuantumAutomation100% (1)

- Support Orca3D HelpDocument281 pagesSupport Orca3D Helplavrik100% (1)

- WATCHDocument9 pagesWATCHGANTORONo ratings yet

- Experion Scada PinDocument7 pagesExperion Scada PinKhalid AliNo ratings yet

- Testing Machines For TextilesDocument35 pagesTesting Machines For TextilesAmarech YigezuNo ratings yet

- Cyber Security Research Proposal - SandboxingDocument23 pagesCyber Security Research Proposal - SandboxingAnonymous Sa6jc83D100% (4)

- Aso Airfield Standards Quick ReferenceDocument66 pagesAso Airfield Standards Quick ReferenceRahul RanaNo ratings yet

- DiodeDocument22 pagesDiodeSaurabh Mittal100% (1)

- Niveau S Longrine Type Pou05-S Section 20x25: A-A B-B C-C D-DDocument1 pageNiveau S Longrine Type Pou05-S Section 20x25: A-A B-B C-C D-DAWOUNANGNo ratings yet

- Unit-I: Introduction To J2EEDocument29 pagesUnit-I: Introduction To J2EEsurakshaNo ratings yet

- Racecar Engineering - September 2015Document100 pagesRacecar Engineering - September 2015MrRipleiNo ratings yet

- 3 Phase Induction Motors Objective Questions With AnswersDocument3 pages3 Phase Induction Motors Objective Questions With AnswersMohan Raj0% (2)

- Customize ADFS sign-in page brandingDocument4 pagesCustomize ADFS sign-in page brandingmicu0% (1)

- CompoundingDocument5 pagesCompoundingMajester RigsNo ratings yet