Professional Documents

Culture Documents

Welding: Debasis Mitra Inspection Department

Uploaded by

Sanjoy Kr. DeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding: Debasis Mitra Inspection Department

Uploaded by

Sanjoy Kr. DeyCopyright:

Available Formats

WELDING

Debasis Mitra

Inspection Department

Contents

1. Welding

1.1 Definition

1.2 Type of welding processes.

2. Welding processes used in HPL.

2.1 Shielded Metal Arc Welding ( SMAW )

2.2 Gas Tungsten Arc Welding ( GTAW )

3. Welding process variables : - Welding Technique.

4. Fillers & Electrodes.

5. Welding Defects

1. Welding

Welding is a localized fusion of metals

produced by heating to suitable

temperatures. Pressure and/or filler may

or may not be used. The filler material has

a melting point approximately the same or

below that of the base metals.

1.1 Definition :-

1.2 Type of welding processes :-

Shielded Metal Arc Welding ( SMAW )

Gas Tungsten Arc Welding ( GTAW )

Gas Metal Arc Welding. ( GMAW )

Submerged Arc Welding ( SAW )

Flux Cored Arc Welding ( FCAW )

Electroslag welding

etc

2. Welding processes mainly used in HPL

Shielded Metal Arc Welding ( SMAW )

Gas Tungsten Arc Welding ( GTAW )

Welding Process Basics : SMAW and GTAW

Advantage and limitation of GTAW & SMAW

SMAW Process variable : Controlling issues

GTAW Process variable : Controlling Issues

Shielded Metal Arc Welding ( SMAW ) or Stick

welding as commonly known as is an arc

welding process where coalescence is produced

by heating the workpiece with an electric arc set

up between a flux coated electrode and the

workpiece.

2.1 Shielded Metal Arc Welding ( SMAW )

SMAW Process

SMAW Process : Advantages

Uses an electrode rod that is quickly consumed ( high

deposition rate)

Uses equipment that is simple, inexpensive, and highly

portable,

Uses an electrode that provides and regulates its own

flux,

Provides all position flexibility,

Is less sensitive to wind or drafts,

SMAW Process : Limitations

Yields a weld with a variable quality and appearance

based on operator skill,

Not applicable for very thin section ( < 1.6 mm )

Weld appearance not as good as GTAW

Root Penetration is not as excellent as GTAW

Gas Tungsten Arc Welding process is an arc welding

process wherein coalescence is produced by heating the

job with an electric arc struck between a tungsten

electrode and the job.

2.2 Gas Tungsten Arc Welding

GTAW Process

GTAW Process : Advantages

Produces very high-quality, superior welds,

Is excellent for thin section

Welds can be made with or without filler metal,

Provides precise control of welding variables (i.e. heat),

Heat Flux and deposition rate can be independently controlled

Excellent Root Penetration

Welding yields low distortion,

Leaves no slag or splatter.

GTAW Process : Limitations

Slow Process . Weld deposition rate is very low .

Needs more set up than SMAW . Complex than SMAW

Needs welder skill better than needed for SMAW

More expensive . Not economical for section thickness > 10

mm

Sensitive to Windy / Drafty environment

3. Welding Process Variables

Type of Current ( Power Source )

Terminal connection

Size of Electrodes

Amperage

Shielding Gas

Shielding Gas flow

Welding Process Variables : Welding technique

Arc length

Travel Speed

Travel Angle

Welding Bead / Welding Technique

Type of Power ( Current )

AC : advantage

Cheaper Power source

No ARC blow

Better Slag cleaning action

Limitations

Arc instability

Not preferred for Overhead / Vertical position

Type of Power ( Current )

DC : advantage

Mostly used

Smoother arc

Produces uniform weld bead size

Is good for short arc technique

Preferred for Vertical and Over Head welding

Produces good wetting action

Limitations

Arc Blow

Terminal connection

For GTAW

DCSP ( DC straight polarity ) /

DCEN ( DC Electrode negative )

For SMAW

DCRP ( DC Reverse polarity ) /

DCEP ( DC Electrode Positive )

Electrode Size : Selection factors

Deposition Rate requirement

Joint design ( Bevel angle / Root opening )

Position ( Flat / Horizontal / Vertical / Overhead)

Pass

Amperage setting

Higher the amperage : Higher the deposition rate

But Excess amperage produces defects

Also too low amperage produces defects

Welding Procedure Specification (WPS)

Prepared as per ASME Sec IX

Contains Essential and Non-Essential

variables.

Fillers / Electrodes as per ASME Sec II

Part C.

4. Electrodes and fillers

Functional difference between

Electrode

E-

Filler

ER-

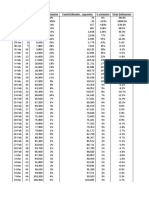

Electrode / Filler Specification designation

As per AWS ( American Welding Society ) .

E XXAB

E Electrode ER Filler

XX minimum tensile strength of weld metal in thousands of pounds per

sq.inch.

A indicates the welding position ( 1-> all , 2-> flat , 3-> horizontal , 4->

overhead )

B - Power supply, type of covering, type of arc, penetration characteristics,

etc.

Eg; E 6012 60000 psi 1 denotes all positions 2 High rutile sodium

silicate binder etc.

5. Welding Defects

Typical cracks in welding

Solidification crack

Thank You

You might also like

- Welding Process Notes BestDocument152 pagesWelding Process Notes Bestaravindan100% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Welding Processes: Nur Syahroni, ST., MT., PH.DDocument52 pagesWelding Processes: Nur Syahroni, ST., MT., PH.Dtrealdi suryoNo ratings yet

- Basic WeldingDocument40 pagesBasic WeldingVishnu Vardhan . C100% (8)

- Control Valve Training MaterialDocument36 pagesControl Valve Training MaterialSanjoy Kr. DeyNo ratings yet

- WHP - Equipment Layout DrawingDocument8 pagesWHP - Equipment Layout DrawingharrisNo ratings yet

- 3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingDocument96 pages3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingAditya KumarNo ratings yet

- Stationery Inventory List 03.2014Document2 pagesStationery Inventory List 03.2014Kunal SinghNo ratings yet

- Gmaw Thumb RuleDocument68 pagesGmaw Thumb Rule0502raviNo ratings yet

- Browning Machine Gun Cal .30 - Technical Air Intelligence Report 21 - Examination of Japanese Browning Machine Gun - 1944Document15 pagesBrowning Machine Gun Cal .30 - Technical Air Intelligence Report 21 - Examination of Japanese Browning Machine Gun - 1944ab212amisarNo ratings yet

- Mmaw & GmawDocument54 pagesMmaw & GmawSelvakumaran DhandapaniNo ratings yet

- Overview of Advanced Welding ProcessesDocument55 pagesOverview of Advanced Welding ProcessesSaravanan RajendranNo ratings yet

- Pump AlignmentDocument1 pagePump AlignmentSanjoy Kr. Dey100% (1)

- Paper - 5QA 002 SA1Document12 pagesPaper - 5QA 002 SA1kreksomukti5508100% (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- GMAW & FCAW Electrodes GuideDocument46 pagesGMAW & FCAW Electrodes GuidearavindanNo ratings yet

- Welding BasicsDocument37 pagesWelding BasicsSnehal DeshmukhNo ratings yet

- WeldingDocument52 pagesWeldingPhani Sridhar ChNo ratings yet

- WELDING PROCESSES GUIDEDocument52 pagesWELDING PROCESSES GUIDEAnil Kumar TNo ratings yet

- UCS 67 84 Flow ChartDocument1 pageUCS 67 84 Flow ChartPrashant RaneNo ratings yet

- WeldingDocument71 pagesWeldingg4gohar100% (2)

- MIG Welding Guide - Processes, Principles & Applications of GMAWDocument23 pagesMIG Welding Guide - Processes, Principles & Applications of GMAWAsad Bin Ala Qatari50% (2)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Welding EngineeringDocument338 pagesWelding EngineeringMuhammed Sulfeek100% (3)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Types of Electric WeldingDocument7 pagesTypes of Electric WeldingSUKhanNo ratings yet

- 01 Introduction To Press ToolsDocument9 pages01 Introduction To Press ToolsAngelo De DominicisNo ratings yet

- NMOS FundamentalsDocument71 pagesNMOS FundamentalsManjit KaurNo ratings yet

- Hydrodynamic Bearing-Kingsbury PDFDocument27 pagesHydrodynamic Bearing-Kingsbury PDFMachineryengNo ratings yet

- Optimize Distillation ColumnsDocument16 pagesOptimize Distillation Columnscrnewsom100% (3)

- Welding ProcessDocument42 pagesWelding ProcessPankaj KumbhareNo ratings yet

- Multipass Tray DesignDocument12 pagesMultipass Tray DesignAyoun Ul HaqueNo ratings yet

- 1 - MMAW Process - PPT (Compatibility Mode)Document44 pages1 - MMAW Process - PPT (Compatibility Mode)Kumawat Prakash100% (1)

- 6 LubricationDocument20 pages6 LubricationSanjoy Kr. DeyNo ratings yet

- Essential Guide to Welding Processes, Inspection & StandardsDocument52 pagesEssential Guide to Welding Processes, Inspection & StandardsKaung Htet Cho100% (1)

- WTDocument299 pagesWTrsarunprasathNo ratings yet

- FCAW DocumentDocument19 pagesFCAW DocumentKentDemeterioNo ratings yet

- 4418 DatasheetDocument5 pages4418 DatasheetwholenumberNo ratings yet

- Fans & BlowersDocument7 pagesFans & BlowersSanjoy Kr. DeyNo ratings yet

- GMAWDocument42 pagesGMAWMuhammed SulfeekNo ratings yet

- Chapter9 GMAW FCAW WeldingDocument17 pagesChapter9 GMAW FCAW Weldingrusf123No ratings yet

- Gmaw & Fcaw-MsmeDocument73 pagesGmaw & Fcaw-MsmemilindNo ratings yet

- Welding Procedure & Welder Qualification: Pak-Arab Refinery LimitedDocument70 pagesWelding Procedure & Welder Qualification: Pak-Arab Refinery LimitedRizwan BangashNo ratings yet

- Shielded Metal Arc Welding: An IntroductionDocument10 pagesShielded Metal Arc Welding: An IntroductionAdhanom G.No ratings yet

- Welding Procedure & Welder QualificationDocument71 pagesWelding Procedure & Welder QualificationRizwan BangashNo ratings yet

- Indian Institute of Welding - ANB Refresher Course - Module 09Document43 pagesIndian Institute of Welding - ANB Refresher Course - Module 09dayalramNo ratings yet

- New Microsoft Office Word DocumentDocument16 pagesNew Microsoft Office Word DocumentsarathNo ratings yet

- Arc WeldingDocument42 pagesArc WeldingrkpnakNo ratings yet

- Q II Module 5 GR 12 Week5Document23 pagesQ II Module 5 GR 12 Week5WilmerNo ratings yet

- Common Welding ProcessDocument4 pagesCommon Welding ProcessLalit Bom MallaNo ratings yet

- Arc Welding GuideDocument29 pagesArc Welding GuideManojKumarNo ratings yet

- WeldingDocument93 pagesWeldingPradeepNo ratings yet

- Arc Welding Process: Michigan Occupational Safety & Health Administration Consultation Education & Training DivisionDocument10 pagesArc Welding Process: Michigan Occupational Safety & Health Administration Consultation Education & Training DivisionNamdeo YengadeNo ratings yet

- Sheilded Metal Arc Welding (Smaw)Document28 pagesSheilded Metal Arc Welding (Smaw)itsmeeeakkiNo ratings yet

- Joining MetalsDocument38 pagesJoining MetalsAmrik SinghNo ratings yet

- GTAW and Power SourcesDocument18 pagesGTAW and Power SourcesRavi Kumar SinghNo ratings yet

- 2) Welding Process, SMAWDocument128 pages2) Welding Process, SMAWDivyang MistryNo ratings yet

- Mig Mag Saw CswipDocument35 pagesMig Mag Saw CswipHamza DhariwalNo ratings yet

- Welding, Brazing & Cutting - 11-21-2007Document7 pagesWelding, Brazing & Cutting - 11-21-2007Jimmy ClavelNo ratings yet

- Submerged Arc Welding Metal Inert Gas Welding Tungsten Inert Gas Welding Oxy-Acetylene Gas WeldingDocument42 pagesSubmerged Arc Welding Metal Inert Gas Welding Tungsten Inert Gas Welding Oxy-Acetylene Gas WeldingRaj singhNo ratings yet

- GMAW Introduction: An Overview of Gas Metal Arc WeldingDocument13 pagesGMAW Introduction: An Overview of Gas Metal Arc Weldingsamyfr454No ratings yet

- By RPS Welding ConsultantsDocument41 pagesBy RPS Welding ConsultantsvairavnNo ratings yet

- L2-Arc - Welding - Process - PPTX Filename UTF-8''L2-Arc Welding ProcessDocument18 pagesL2-Arc - Welding - Process - PPTX Filename UTF-8''L2-Arc Welding Process222-020-651No ratings yet

- Arc Welding, Shielded Metal Arc Welding, Metal Inert Gas WeldingDocument44 pagesArc Welding, Shielded Metal Arc Welding, Metal Inert Gas WeldingDinesh InavoluNo ratings yet

- Pressure Vessel Code Asme Section IxDocument132 pagesPressure Vessel Code Asme Section IxImane KhammouriNo ratings yet

- 1a Arc Weld ProcessesDocument45 pages1a Arc Weld ProcessesskgcNo ratings yet

- JOINING of Metals: 1. WeldingDocument62 pagesJOINING of Metals: 1. WeldingMuhammad Ali BakhtNo ratings yet

- Arc WeldingDocument29 pagesArc WeldinguditNo ratings yet

- Quiz Test No DrieDocument17 pagesQuiz Test No Drieapurva karleNo ratings yet

- Mech - Seal Drawing 2H-107461 - 43-P-107Document1 pageMech - Seal Drawing 2H-107461 - 43-P-107Sanjoy Kr. DeyNo ratings yet

- Mech - Seal Drawing 2H-71465 - 41-P-001Document1 pageMech - Seal Drawing 2H-71465 - 41-P-001Sanjoy Kr. DeyNo ratings yet

- Ofd en WebDocument6 pagesOfd en WebSanjoy Kr. DeyNo ratings yet

- B-232 Model Premium Gearbox - DatasheetDocument1 pageB-232 Model Premium Gearbox - DatasheetSanjoy Kr. DeyNo ratings yet

- Mech - Seal Drawing 2H-84182 - 43-P-003D, EDocument1 pageMech - Seal Drawing 2H-84182 - 43-P-003D, ESanjoy Kr. DeyNo ratings yet

- 24#150-HB Valve-SWDocument1 page24#150-HB Valve-SWSanjoy Kr. DeyNo ratings yet

- 2H 73197Document1 page2H 73197Sanjoy Kr. DeyNo ratings yet

- Mech - Seal Drawing 2H-104559 - 42-P-004CDocument1 pageMech - Seal Drawing 2H-104559 - 42-P-004CSanjoy Kr. DeyNo ratings yet

- Mech - Seal Drawing 2H 72386 - 47 P 001Document1 pageMech - Seal Drawing 2H 72386 - 47 P 001Sanjoy Kr. DeyNo ratings yet

- Fundamentals of CompressorDocument16 pagesFundamentals of CompressorSanjoy Kr. DeyNo ratings yet

- Vertical and Horizontal Motor Alignment InstructionsDocument3 pagesVertical and Horizontal Motor Alignment InstructionsSanjoy Kr. DeyNo ratings yet

- 24#150 HB Valve-BodyDocument1 page24#150 HB Valve-BodySanjoy Kr. DeyNo ratings yet

- 24#150-HB Valve-HWDocument1 page24#150-HB Valve-HWSanjoy Kr. DeyNo ratings yet

- CouplingDocument19 pagesCouplingSujitkun NutalayaNo ratings yet

- Catalogo Lovejoy Serie JawDocument26 pagesCatalogo Lovejoy Serie JawJuan Pablo CirizaNo ratings yet

- Distillation Tray DegassingDocument2 pagesDistillation Tray DegassingSanjoy Kr. DeyNo ratings yet

- 4 Mounted BearingsDocument23 pages4 Mounted BearingsSanjoy Kr. DeyNo ratings yet

- Distill TraysDocument2 pagesDistill TraysSanjoy Kr. DeyNo ratings yet

- Steps To Check SKF BearingsDocument1 pageSteps To Check SKF BearingsSanjoy Kr. DeyNo ratings yet

- Cathodic ProtectionDocument36 pagesCathodic ProtectionSanjoy Kr. DeyNo ratings yet

- Protech Bearing Isolator Seal TheoryDocument8 pagesProtech Bearing Isolator Seal TheorySanjoy Kr. DeyNo ratings yet

- Coupling AlignmentDocument1 pageCoupling AlignmentMahmoud AhmedNo ratings yet

- Surface Hardening of SteelDocument17 pagesSurface Hardening of SteelElapse Dreammaker KibriaNo ratings yet

- Boeuf-Iedm SC 2013-Nov15 Full VersionDocument95 pagesBoeuf-Iedm SC 2013-Nov15 Full VersionDuckie CucuNo ratings yet

- Advantages and uses of rotational molding, blow molding, and other plastic forming processesDocument2 pagesAdvantages and uses of rotational molding, blow molding, and other plastic forming processesapril_ian02No ratings yet

- List of Inventionts and The InventorsDocument9 pagesList of Inventionts and The InventorsDaengda DindaNo ratings yet

- Design of A Low Power 10T SRAM Cell: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument3 pagesDesign of A Low Power 10T SRAM Cell: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologySuyash KumarNo ratings yet

- Electro Chemical MachiningDocument10 pagesElectro Chemical Machiningdev2945No ratings yet

- BlueprintDocument3 pagesBlueprintEhij ZheyNo ratings yet

- BRTC Bus routes and numbers for 8 depots in DhakaDocument2 pagesBRTC Bus routes and numbers for 8 depots in DhakaZayaan ShohailNo ratings yet

- Autodesk® Inventor™ and Sheet Metal Manufacturing From Drawing To FabricationDocument15 pagesAutodesk® Inventor™ and Sheet Metal Manufacturing From Drawing To FabricationGraham MooreNo ratings yet

- CT 727 (EDocument26 pagesCT 727 (EjucatorNo ratings yet

- Steel GradesDocument2 pagesSteel GradesAmit Rajmane100% (1)

- Design Rules: Digital Integrated Circuits © Prentice Hall 1995Document9 pagesDesign Rules: Digital Integrated Circuits © Prentice Hall 1995大 橋 カルロスNo ratings yet

- Summer Training PresentationDocument18 pagesSummer Training Presentationnufaza97No ratings yet

- Nuevo Hoja de Cálculo de Microsoft ExcelDocument14 pagesNuevo Hoja de Cálculo de Microsoft ExcelMarcelo SalasNo ratings yet

- Solid State WeldingDocument14 pagesSolid State WeldingRaju_pancal100% (1)

- 3rd Quarter Quiz in Arts - Lines PrintmakingDocument1 page3rd Quarter Quiz in Arts - Lines PrintmakingPeter BelenNo ratings yet

- Returned Receipt For Equipment: Land Transportation OfficeDocument68 pagesReturned Receipt For Equipment: Land Transportation Officemaricris punayNo ratings yet

- Assignment 6Document12 pagesAssignment 6Harshita AnandNo ratings yet

- Company Profile Berca SchindlerDocument22 pagesCompany Profile Berca SchindlerbayuargadNo ratings yet

- Tarea. de Ingles.Document10 pagesTarea. de Ingles.ManÜel PerenNo ratings yet

- Guide To CompositesDocument1 pageGuide To CompositesmiraclelovesgamesNo ratings yet

- DatasheetDocument87 pagesDatasheetmdelcos100% (1)

- First Internal Question & Answer For Plastic ProcessingDocument17 pagesFirst Internal Question & Answer For Plastic ProcessingSupreeth PremkumarNo ratings yet