Professional Documents

Culture Documents

KOM - Amal HRSG Final

Uploaded by

Nadim JilaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KOM - Amal HRSG Final

Uploaded by

Nadim JilaniCopyright:

Available Formats

AMAL HRSG 1

PROJECT

C311/333

Kick Off Meeting

( Wednesday 4th April 12, Muscat )

AMAL HRSG 1 PROJECT

KOM Agenda : TIME

TOPIC

13.30 to

Assembly

13.40

13.41

Welcome Address

13.50

13.51- 14.10 Introduction of PDO & AHEC

delegates

14.11

Project Introduction

14.20

14.21

15.00

15.01

15.20

15.21

15.30

Kick-off Presentation

SPEAKER

PROJECT

MANAGER

AHEC

AHEC & PDO

Discussions

Close Out

AHEC

AMAL HRSG 1 PROJECT

Project

AMAL HEAT RECOVERY STEAM GENERATOR -1

Owner

Petroleum Development Oman (PDO)

EPC Contractor

Location

:

South of Oman and approximately 1 KM to the

Existing Amal Sub station

Scope

Contract Value

Duration

660 Days

Start Date

21-Mar-12

Completion

10-Jan-14

Al Hassan Engineering Co. S.A.O.G.

EPC of Heat Recovery Steam Generator project.

6.93 Million RO

South west of

AMAL HRSG 1 PROJECT

PROJECT OBJECTIVES

To meet the future steam demand in AMAL West field, the Company

plans to install a Heat Recovery Steam Generator unit at AMAL Power

Plant. The HRSG shall be installed at the back end of an existing GE

Frame 9E Gas Turbine with a target net average calendar day per year

steam production of 6,000 tonnes per day at a delivery pressure of

100 barg and 80% quality.

AMAL HRSG 1 PROJECT

SCOPE OF WORK

Install and commissioning a new HRSG at the back of Amal

Power station gas turbine. The HRSG will have capability of

producing 6000 tons of steam per day. (The HRSG, Pumps and

DCS will be procured and free issued by PDO)

Install high pressure feed water pumps, instrument air

compressors and associated electrical switchgears systems.

Design and Construction of Utility building to house the

electrical switchgears and controls systems (DCS, IPS, etc.)

Design, supply and installation of Switchgears, UPS, Instrument

Air compressors & piping works.

Civil and mechanical work associated with the above.

AMAL HRSG 1 PROJECT

Supply and Installation of overflow interconnection piping from HRSG to

HRSG blow down Pit to Existing Amal steam blow down pit.

Design and construction of HRSG blow down pit.

HVAC System.

Design, supply and installation of balance of plant Piping works

Fire detection and alarm system.

Scope includes interfacing with HRSG OEM supplier/ Vendor.

Pre commissioning and Commissioning.

AMAL HRSG 1 PROJECT

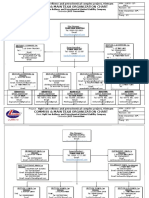

AMAL HRSG 1 PROJECT

Organisation Chart

AMAL HRSG 1 PROJECT

Staffing of Contract and Project Management

*

Project Manager : Shall be overall responsible for the complete project and

focal point for PDO for execution of the project. His responsibility includes

Engineering, Procurement, Project Management, Construction, Safety,

Contract

Management and Quality till successful completion of the

project. All other

personnel w.r.t. project execution will be under his guidance as per the project

organization chart.

*

Construction Manager: He shall be the site in charge for the construction

activity and full responsible for keeping the Project Manager updated of the

proceedings of the construction on regular basis as per reporting procedure,

including safety & Quality.

*

Engineering Manager: Shall be responsible for the proper interfacing and

co-ordination between the design consultant, PDO, PDOs PMC, AHEC Project

procurement & Construction team. He shall optimize the engineering activities in

such a manner that the project objectives w.r.t engineering shall meet the Companys

expectations with respect to schedule, quality of materials and service.

AMAL HRSG 1 PROJECT

Project Management:

The project management primarily be a Head Office based activity involving

project controls, Engineering coordination, Procurement, Cost control, Contracts

administration and construction activity monitoring include safety & quality

administration.

Change control and monitoring shall fall under the purview of Project Manager

10

AMAL HRSG 1 PROJECT

Key personnel CVs

* Key personnel inline with Contract requirement are already identified for the

project

Project Manager/ Contracts Manager

Engineering Manager

Construction Manager

Interface Manager

Construction Engineers (CME&I)

Procurement Manager

Commissioning Manager

Planning Manager

Lead Site QA/QC Engineer

HSE Manager

QC Inspector (CME&I)

*

Krishnaraj G B

Murali Krishna

M N Tamodharan

Karthikeyan

Girish

Arun Roshan DSouza

Kopula Sudakhar

Binil Mohan

Their respective CVs shall be Submitted to PDO focal point.

11

AMAL HRSG 1 PROJECT

Design Verification

FEED Documentation Review & Verification to ensure

Completeness, Correctness and compliance to the design intent.

Suitability of the FEED Package for Detailed Engineering.

Verification Scope change management.

Document Numbering & Equipment numbering philosophy.

Drawing and Document format.

To achieve above objective, following Key FEED documents will be reviewed.

*

*

*

*

Plot Plan / Layouts

General Arrangement Drawings

PEFS

Equipment / Material Selection and Sizing

Individual Discipline deliverables as necessary

Design Review

HAZOP Review

SAFOP Review

IPF Review

12

AMAL HRSG 1 PROJECT

Mobilization Plan

Engineering

* Mott Macdonald / TR Engineering to be finalised as a Design consultant

* All Engineering will carried out at Design consultant office at Muscat for the entire

project

Procurement

*

Procurement shall be handled by a dedicated team consisting of discipline wise

procurement engineers already identified. The team will be headed by

Procurement manager

13

AMAL HRSG 1 PROJECT

Scheduling and Execution of the work

We have prepared Level 3 schedule in consultation with all proposed discipline

Engineers and the same shall be circulated to the respective personnel for the

timely, safe & efficient execution of the project

Project controls under the guidance of Project Manager shall closely be

monitored by all Discipline Heads / Planning Engineers and keep comparing the

actual deliverables to the baseline schedule and take corrective action as and

when required to enable proper aligning of the project schedule to client

requirement and contract.

Planning will be monitored since start of the project to the end of the project. The

monitoring of the project is the continuous process.

Reporting shall be done and submitted to PDO as per contract documents C8

Procedure for Contractors.

14

AMAL HRSG 1 PROJECT

Testing, Commissioning & Training

* All testing of equipment will be carried out by PDO approved testing

engineer.

*

Approved commissioning Engineer will be mobilized 120 days prior to start of

pre commissioning activities.

* The commissioning plan will be prepared as per PR 1159 detailing all

aspects of the pre commissioning and commissioning.

* Commissioning plan will be prepared 3 months in advance including

activity checklist and approval will obtained before start of commissioning

activities.

*

Acceptance test will be carried out in accordance with the requirement of C6- 21

and ISO 2314. During this acceptance test the plant will be operated by

company staff.

15

AMAL HRSG 1 PROJECT

Final Documentation

*

As Built Drawings.

Operating and Maintenance manual.

Vendor bulletins and operating instructions.

* Design reference manual as per SP 1132.

*

Plant data book.

Complete drawing register as per the requirement of SP1003.

Commissioning Reports.

* A Documentary video (DVD Format) on project history from award to

commissioning

16

AMAL HRSG 1 PROJECT

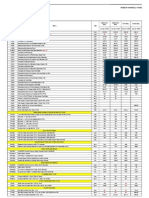

Histogram of resource levels.

17

AMAL HRSG 1 PROJECT

Site Establishment

Office & Camp Facilities: Existing Facilities of Amal power project shall be used

for Amal HRSG project. All office and camp facilities to the company personnel

will be provided as specified in C6-29.

On-site Fabrication Facilities: Existing fabrication workshop will be constructed

as part of Industrial Facilities. This facility shall be used for complete fabrication

of pipes, spools, structural, Painting works etc. In Addition to this AHEC is

planning to use Ghala work shop for fabrication of Structural / Piping.

Site office: Existing office facility will be used for this project.

18

AMAL HRSG 1 PROJECT

Equipment Storage Yard

* The equipments supplied by vendor either through free issue or our own

procurement shall be safely stored as per the procedure furnished by vendor.

*

Material lay down area shall be used for storing of materials in identified areas

for different class of materials.

* Storage of rejected materials: A separate area shall be identified as quarantine

area for storage and subsequent disposal of rejected items.

19

AMAL HRSG 1 PROJECT

Living Accommodation:

Existing camp to be used for the accommodation of the construction personnel

and site workmen. The camp shall be in accordance with PDO norms.

All Facilities for company personnel will be provided as specified in C6 -29

Camp will be equipped with all facilities required.

Camp Boss will be the supervisor

Camp security will be provided.

20

AMAL HRSG 1 PROJECT

Camp Layout

21

AMAL HRSG 1 PROJECT

Site Office Facility

22

AMAL HRSG 1 PROJECT

Industrial/ Storage Facilities

23

AMAL HRSG 1 PROJECT

Communication To and From site:

1.

Existing Landline communication will be used for this project.

2.

E-mail and Fax Facilities shall be provided by AHEC at office Premises.

3.

All office automation to the company will be provided as specified in the C6

documents C6-29

24

AMAL HRSG 1 PROJECT

Construction services and utilities:

Local Community Contractor : We shall actively engage LCC services

wherever possible on various construction services, based on their

resources and potential ( Mainly Earth works)

Drinking Water : PDO RO plants will be used for drinking water.

Catering : Reputed catering contractor for this project has already been

identified.

Sewage Disposal :Sewage Disposal will be done at existing STP.

25

AMAL HRSG 1 PROJECT

Material Control Facilities:

* The following are the detailed material control procedure :

All equipment & materials including spare parts at the project site shall be

received by AHECs authorised personnel. Upon receipt, materials will be

inspected for specification, quantity, quality, shipping damage, certification of

approval and conformity to purchase order. Reporting on damages, if any, for

possible insurance claim / corrective action.

Material shall be handled with great care and protected from the impact of

throwing, dropping, dragging, bumping and hitting which may damage the

material or coating.

Materials shall be lifted by suitable equipment with non-abrasive wide nylon pipe

slings or special lifting hooks.

26

AMAL HRSG 1 PROJECT

Security:

Site security shall be arranged by AHEC. we shall appoint Security staff for the entire

duration of the project. The sources of Local Security will be done through Local

Wali / PDO authorities,

27

AMAL HRSG 1 PROJECT

HSE

Managing HSE Workshop.

Hazard Sheets & HEMP Register.

Toolbox Talks & Use of Prompt Card

STOP Implementation

Job Safety Plan & PTW application

Road Transport mentorship programme and drivers Forum.

Journey Management System/Journey Transit Point at Haima & AHEC IZZ Yard

with rest room facilities including for PDO.

HSE Audit and Review

28

AMAL HRSG 1 PROJECT

HSE

OPAL certified HSE Management System is in place

AHEC QHSE Management System & Sustainable development Management

System endorsed by PDO.

AHEC is ISO 14001 and OHSAS 18001 certified company.

Addresses all issues including Legal and other requirements in HSE Plan.

Provides frame work for Continual improvement

Visible demonstration of Companys Corporate Commitment.

Amal HRSG project addressed life saving rules for site implementation.

Sub Contactor Letter of Assurance Verification.

CEOs Letter of Assurance to P.D.O.

All incidents and RTA reporting through Project Manager responsibility.

29

AMAL HRSG 1 PROJECT

Subcontracting:

Identified subcontract areas are as follows:

NDT

Insulation.

Earth Works

HVAC Works

Design & Engineering

Catering Services

Road Works

30

AMAL HRSG 1 PROJECT

Detailed Design Activities and assurance

Engineering Contract Quality Plan will be prepared in compliance with ISO 9001-2000

Document & Drawing control register.

Preparation of Engineering documents & drawings.

Single Discipline Checks (SDC) and Inter discipline check

Incorporation comments of SDC/ IDC.

Internal Quality Audits.

External Quality Audits.

SAP Coding.

31

AMAL HRSG 1 PROJECT

Procurement Activities & Assurance

Material Tracking Sheet on regular basis.

All project material shall be procured from approved vendor list.

Floating enquiries to company approved suppliers with all relevant technical

specification.

Communication on changes, if any to an order during production by change control.

Expediting

Inspection by company approved third party/AHEC/Company.

Kick off/Inspection meeting between company, suppliers & contractors prior to start

of manufacturing activities.

32

AMAL HRSG 1 PROJECT

QA/QC activities and assurance

Contract Quality plan of SP 1171 will be prepared and approval from the client

shall be obtained.

ISO-9001:2008 Quality system shall be implemented.

AHEC is accredits certificate for U stamp (Pressure vessel), S Stamp

(Pressure boilers) and R Stamp (Repair works)

All the relevant QCPs (ITPs) shall be prepared initially with the project scope of

work and approval shall be obtained from client.

The approval for site key QA/QC Personnel shall be obtained from client and will

be mobilized to site on need basis.

The audit shall be conducted as per the audit plan. (In the CQP).

33

AMAL HRSG 1 PROJECT

34

AMAL HRSG 1 PROJECT

35

You might also like

- G050PZ001000F1Document20 pagesG050PZ001000F1ThirukkumaranBalasubramanianNo ratings yet

- How To Prepare Planning Deliverables For LNG Project?: Sapto Hari WibowoDocument17 pagesHow To Prepare Planning Deliverables For LNG Project?: Sapto Hari WibowoSalman Syafar RamzyNo ratings yet

- Routine Lift Plan for 5.5 Ton LoadDocument1 pageRoutine Lift Plan for 5.5 Ton LoadPanruti S SathiyavendhanNo ratings yet

- EPC Well Gathering System Chemical Injection PackagesDocument4 pagesEPC Well Gathering System Chemical Injection PackagesfarazhussainkhanNo ratings yet

- TechnipDocument36 pagesTechnipShashwat Nigam0% (1)

- C4 Specific PDFDocument44 pagesC4 Specific PDFNadim JilaniNo ratings yet

- Plant Inspection ReportDocument9 pagesPlant Inspection ReportKevin Keanu Ong100% (1)

- EIA Report for Petrochemical Plant in Sohar, OmanDocument672 pagesEIA Report for Petrochemical Plant in Sohar, OmanAhmed Ibrahim Ahmed EissaNo ratings yet

- Boiler Erection Project ManagementDocument1 pageBoiler Erection Project Managementspatil1472No ratings yet

- CP-117 - Project Engineering - CoPDocument93 pagesCP-117 - Project Engineering - CoPahmedengNo ratings yet

- EPC-5 PresentationDocument19 pagesEPC-5 PresentationPungky Tri WijayaNo ratings yet

- 43 Equipment Erection (Static and Rotary)Document5 pages43 Equipment Erection (Static and Rotary)Hamza DhariwalNo ratings yet

- Method Statement for HRSG ErectionDocument32 pagesMethod Statement for HRSG ErectionMIL RABNo ratings yet

- 1365 PDFDocument221 pages1365 PDFSaad SarfarazNo ratings yet

- Multidisciplinary Engineer CV For Project Engineering and Project Control (QS, Planning, Estimation, Cost Control, Contracts) ADocument4 pagesMultidisciplinary Engineer CV For Project Engineering and Project Control (QS, Planning, Estimation, Cost Control, Contracts) AHOSAM HUSSEINNo ratings yet

- Tulasi Rao - MECHANICAL ENGINEER 9 Yeras Experience CswipDocument3 pagesTulasi Rao - MECHANICAL ENGINEER 9 Yeras Experience Cswiptulasirao.nammiNo ratings yet

- Dung Quat Refinery Project WBS StructureDocument18 pagesDung Quat Refinery Project WBS Structurethanhvutn@yahoo.comNo ratings yet

- Complete Report Rla SWCC Ksa Phase 1 Unit5boilerDocument149 pagesComplete Report Rla SWCC Ksa Phase 1 Unit5boilerWaseem ArshadNo ratings yet

- Company Profile Rekind PDFDocument50 pagesCompany Profile Rekind PDFFirstiawanNo ratings yet

- Ayman Moussa EPC Const - Manager OffshoreDocument6 pagesAyman Moussa EPC Const - Manager OffshoreAyman MoussaNo ratings yet

- S-000-1654-0250v - A - 0010 Hs S e Ins TR U CT Ion S To Su B-C On Trac T OrsDocument59 pagesS-000-1654-0250v - A - 0010 Hs S e Ins TR U CT Ion S To Su B-C On Trac T OrsjenniferNo ratings yet

- Final Book - Lordegan ProjectDocument8 pagesFinal Book - Lordegan ProjectArash Sotoudeh100% (1)

- Isol Job References 2008-2017Document9 pagesIsol Job References 2008-2017Abu Zafeera Saqib SipahiNo ratings yet

- SATIP-ME-2002 HRSG Installation Rev 5Document6 pagesSATIP-ME-2002 HRSG Installation Rev 5zhang100% (1)

- CTRDocument2 pagesCTRMur LiveNo ratings yet

- 2012140409-MD-04-MT-RSELC-PD-018 Rev.01 Maintenance Procedure For Cathodic Protection SystemDocument28 pages2012140409-MD-04-MT-RSELC-PD-018 Rev.01 Maintenance Procedure For Cathodic Protection SystemHuy Thieu BuiNo ratings yet

- Thermal Power Plant ProjectsDocument21 pagesThermal Power Plant ProjectsKhristian Kier AlbertoNo ratings yet

- الخليجDocument10 pagesالخليجmohamedNo ratings yet

- Lifting Plan: (To Attach Crane Load Capacity Chart)Document1 pageLifting Plan: (To Attach Crane Load Capacity Chart)Douglas AlayónNo ratings yet

- 000 3BD Ee 01509 006Document93 pages000 3BD Ee 01509 006Samir Zaghlool100% (1)

- GPMC Profile SummaryDocument51 pagesGPMC Profile SummaryJayadevDamodaranNo ratings yet

- LLM18 MAIN & COMMISS Site Organization ChartDocument2 pagesLLM18 MAIN & COMMISS Site Organization Charttranvando1986No ratings yet

- Safety Training Essentials for Saudi ProjectsDocument27 pagesSafety Training Essentials for Saudi ProjectsRjeb mohamedNo ratings yet

- FlowchartDocument9 pagesFlowchartCatur PrihatmonoNo ratings yet

- Aramco and Affiliates - PoonamDocument2 pagesAramco and Affiliates - PoonamTarun BhandariNo ratings yet

- Punch List For Fire Water Pump & Foam Pump PackageDocument4 pagesPunch List For Fire Water Pump & Foam Pump PackageGomathyselviNo ratings yet

- METHOD STATEMENT FOR Pneumatic TestDocument11 pagesMETHOD STATEMENT FOR Pneumatic TestzahidNo ratings yet

- Saep 50Document33 pagesSaep 50Demac SaudNo ratings yet

- 076551C 000D Sow 9000 001 - R0Document37 pages076551C 000D Sow 9000 001 - R0ikenn100% (1)

- Eni - Iraq Zubair Oil Field Development Project TCF (Temporary Camp Facility)Document3 pagesEni - Iraq Zubair Oil Field Development Project TCF (Temporary Camp Facility)mohammad.a.d94No ratings yet

- PT Synergy Engineering Proposal for Detailed Engineering Support of Kerendan Field DevelopmentDocument7 pagesPT Synergy Engineering Proposal for Detailed Engineering Support of Kerendan Field DevelopmentmatsuruNo ratings yet

- Pramod Kumar Tripathi CVDocument3 pagesPramod Kumar Tripathi CVsamaksh bansalNo ratings yet

- HRSG Vertical PresentationDocument77 pagesHRSG Vertical PresentationAnonymous BzGb2fnfENo ratings yet

- Hydrotest Procedure For Unloading and Condensate Tanks: Shirvan Gas Turbine Power PlantDocument11 pagesHydrotest Procedure For Unloading and Condensate Tanks: Shirvan Gas Turbine Power PlantepbamdadNo ratings yet

- Provision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) ProjectDocument15 pagesProvision of Engineering, Procurement, Construction, Installation & Commissioning (Epcic) For Yetagun Acid Gas Removal Unit (Agru) Projectmohsin moin100% (1)

- Project Execution Plan - Tank Foundation WorksDocument13 pagesProject Execution Plan - Tank Foundation WorksFresly Patria100% (1)

- Orifice Cal. Rev.2Document75 pagesOrifice Cal. Rev.2waheed2286No ratings yet

- MCCS Mechanical Completion and Commissioning ServicesDocument32 pagesMCCS Mechanical Completion and Commissioning ServicesNur FarahatanNo ratings yet

- Process Operator Gas ExperienceDocument3 pagesProcess Operator Gas Experiencejohn MNo ratings yet

- HSES RR - Closed Drain-Injection Quill - 3rd March 16Document29 pagesHSES RR - Closed Drain-Injection Quill - 3rd March 16Akhil AnanthakrishnanNo ratings yet

- TE-419843 - Rev.A - MR For Chemical Injection PackageDocument76 pagesTE-419843 - Rev.A - MR For Chemical Injection Packagerizwan.zamanNo ratings yet

- SAMPLE - P4A-Daily Progress Report 210427 KZP 988Document3 pagesSAMPLE - P4A-Daily Progress Report 210427 KZP 988MEMONo ratings yet

- 037-Procedure For Cleanliness PDFDocument21 pages037-Procedure For Cleanliness PDFKöksal PatanNo ratings yet

- Estimate Kickoff Meeting KBR Management System - Offshore PM-GL-OFF-PC-201 Manage Project Controls LegendDocument4 pagesEstimate Kickoff Meeting KBR Management System - Offshore PM-GL-OFF-PC-201 Manage Project Controls LegendgfgNo ratings yet

- Site HSE Plan (TOYO) (R)Document200 pagesSite HSE Plan (TOYO) (R)STG INSTRUMENT100% (1)

- Boiler Manual Umpp PDFDocument53 pagesBoiler Manual Umpp PDFRanjanaWajeNo ratings yet

- Current Projects 2010-N°172Document73 pagesCurrent Projects 2010-N°172Subramaniam RamasamyNo ratings yet

- HSE Training Program OverviewDocument15 pagesHSE Training Program OverviewDebby WijayantiNo ratings yet

- Method - Statement - For RCC in Beams and SlabsDocument15 pagesMethod - Statement - For RCC in Beams and Slabsirfan khan75% (4)

- Scope of WorkDocument5 pagesScope of WorkKausik DewanNo ratings yet

- Month Wise Work Target 20-07-15 To 20-09-15Document5 pagesMonth Wise Work Target 20-07-15 To 20-09-15Nadim JilaniNo ratings yet

- Updated B - 209 - MDF - DMS - 20-April-15 - Rev 01Document148 pagesUpdated B - 209 - MDF - DMS - 20-April-15 - Rev 01Nadim JilaniNo ratings yet

- Next 14 Day Concrete ProgramDocument4 pagesNext 14 Day Concrete ProgramNadim JilaniNo ratings yet

- Nov Dec Jan Feb March AprilDocument40 pagesNov Dec Jan Feb March AprilNadim JilaniNo ratings yet

- B O Q Summ 26-05-15Document275 pagesB O Q Summ 26-05-15Nadim JilaniNo ratings yet

- B O Q Summ 26-05-15Document275 pagesB O Q Summ 26-05-15Nadim JilaniNo ratings yet

- C311530 - On Plot Site Progress - Meeting - 010 - 21 05 2015 PDFDocument5 pagesC311530 - On Plot Site Progress - Meeting - 010 - 21 05 2015 PDFNadim JilaniNo ratings yet

- Nov Dec Jan Feb March AprilDocument40 pagesNov Dec Jan Feb March AprilNadim JilaniNo ratings yet

- Trade Supplied To LLCC SMTC Harweel Total AHEC Manpower Wokring For Ahec at On PlotDocument4 pagesTrade Supplied To LLCC SMTC Harweel Total AHEC Manpower Wokring For Ahec at On PlotNadim JilaniNo ratings yet

- Actual Plan ManpowerDocument5 pagesActual Plan ManpowerNadim JilaniNo ratings yet

- Nov Dec Jan Feb March AprilDocument85 pagesNov Dec Jan Feb March AprilNadim JilaniNo ratings yet

- Updated B - 209 - MDF - DMS - 20-April-15 - Rev 01Document148 pagesUpdated B - 209 - MDF - DMS - 20-April-15 - Rev 01Nadim JilaniNo ratings yet

- C311530 - On Plot Site Progress - Meeting - 010 - 21 05 2015 PDFDocument5 pagesC311530 - On Plot Site Progress - Meeting - 010 - 21 05 2015 PDFNadim JilaniNo ratings yet

- Trade Supplied To LLCC SMTC Harweel Total AHEC Manpower Wokring For Ahec at On PlotDocument4 pagesTrade Supplied To LLCC SMTC Harweel Total AHEC Manpower Wokring For Ahec at On PlotNadim JilaniNo ratings yet

- B - 209 - MDF - DMS - 028-02-15Document64 pagesB - 209 - MDF - DMS - 028-02-15Nadim JilaniNo ratings yet

- Actual Plan ManpowerDocument5 pagesActual Plan ManpowerNadim JilaniNo ratings yet

- T3 PDFDocument28 pagesT3 PDFNadim JilaniNo ratings yet

- Building Progress Details As Per Baseline and Revision ScheduleDocument83 pagesBuilding Progress Details As Per Baseline and Revision ScheduleNadim JilaniNo ratings yet

- Petroleum Development Oman LLC Contract Number C311333 Amal Heat Recovery Steam Generator (HRSG) - 1 Project T2, Instructions To TenderersDocument9 pagesPetroleum Development Oman LLC Contract Number C311333 Amal Heat Recovery Steam Generator (HRSG) - 1 Project T2, Instructions To TenderersNadim JilaniNo ratings yet

- C311333 - Amal HRSG-1 ProjectDocument2 pagesC311333 - Amal HRSG-1 ProjectNadim JilaniNo ratings yet

- C8 PDFDocument12 pagesC8 PDFNadim JilaniNo ratings yet

- T1 - Al Hassan PDFDocument7 pagesT1 - Al Hassan PDFNadim JilaniNo ratings yet

- C5 SCH E - FinalDocument5 pagesC5 SCH E - FinalNadim JilaniNo ratings yet

- C10 PDFDocument3 pagesC10 PDFNadim JilaniNo ratings yet

- C7 PDFDocument5 pagesC7 PDFNadim JilaniNo ratings yet

- C5 SCH A - FinalDocument13 pagesC5 SCH A - FinalNadim JilaniNo ratings yet

- Petroleum Development Oman LLC Contract Number C311333 Amal Heat Recovery System Generator (HRSG) - 1 Project C9, HSE SpecificationsDocument11 pagesPetroleum Development Oman LLC Contract Number C311333 Amal Heat Recovery System Generator (HRSG) - 1 Project C9, HSE SpecificationsNadim JilaniNo ratings yet

- C5 SCH F PDFDocument4 pagesC5 SCH F PDFNadim JilaniNo ratings yet

- Petroleum Development Oman L.L.C. Schedule D' - Unit Rates For Alterations & Day Works C-5Document10 pagesPetroleum Development Oman L.L.C. Schedule D' - Unit Rates For Alterations & Day Works C-5Nadim JilaniNo ratings yet

- C5 SCH B and C - FinalDocument16 pagesC5 SCH B and C - FinalNadim JilaniNo ratings yet

- Apollo Saturn V Facility Description Vol. 3Document124 pagesApollo Saturn V Facility Description Vol. 3Bob Andrepont86% (7)

- Arnold S. Berger - Embedded Systems Design - An Introduction To Processes, Tools, and Techniques-CMP Books (2001)Document1 pageArnold S. Berger - Embedded Systems Design - An Introduction To Processes, Tools, and Techniques-CMP Books (2001)Anonymous 6WoK61sYpyNo ratings yet

- 08 - Installation and Maintenance of Health IT Systems - Unit 9 - Creating Fault-Tolerant Systems, Backups, and Decommissioning - Lecture CDocument15 pages08 - Installation and Maintenance of Health IT Systems - Unit 9 - Creating Fault-Tolerant Systems, Backups, and Decommissioning - Lecture CHealth IT Workforce Curriculum - 2012No ratings yet

- Digital Circuits and Logic Design Lecture OverviewDocument42 pagesDigital Circuits and Logic Design Lecture Overviewramanaidu1No ratings yet

- World-wide Input Output Power Boost XL120DDocument2 pagesWorld-wide Input Output Power Boost XL120DJavier CastilloNo ratings yet

- C GraphicsDocument31 pagesC GraphicsArnav DasNo ratings yet

- Bugs Fixed in Each 19.0.0.0.0 Grid Infrastructure Release UpdateDocument56 pagesBugs Fixed in Each 19.0.0.0.0 Grid Infrastructure Release UpdateAuttapol TunwilaiNo ratings yet

- AI Sentiment Analysis of YouTube CommentsDocument18 pagesAI Sentiment Analysis of YouTube CommentsRey NeshNo ratings yet

- Resume Test AutomationDocument4 pagesResume Test AutomationAbhinav DesaiNo ratings yet

- Curriculum Vitae: Executive Summary & Covering LetterDocument9 pagesCurriculum Vitae: Executive Summary & Covering LetterKhalid MahmoodNo ratings yet

- Hadoop Installation CommandsDocument3 pagesHadoop Installation CommandssiddheshNo ratings yet

- Errer Code List Konica 7145Document16 pagesErrer Code List Konica 7145Pamela MitchellNo ratings yet

- Metastat Command Shows Soft Partition in Errored StateDocument3 pagesMetastat Command Shows Soft Partition in Errored StatecresmakNo ratings yet

- External Plugin en 1.11.3Document21 pagesExternal Plugin en 1.11.3Arief Trimanda MuhammadNo ratings yet

- Inspection Test Plan LPSDocument3 pagesInspection Test Plan LPSsafetyofficer752No ratings yet

- Build a better internet together with Cloudflare partnersDocument19 pagesBuild a better internet together with Cloudflare partnersVicky MahiNo ratings yet

- BGChain WhitepaperDocument31 pagesBGChain WhitepaperJohn DamonNo ratings yet

- Chziri zvf330 Ac Drive User Manual E375Document59 pagesChziri zvf330 Ac Drive User Manual E375Diego Armando Carrera palmaNo ratings yet

- Unit 2 - Practice 1Document11 pagesUnit 2 - Practice 1Mauricio MartinezNo ratings yet

- B, 40,41, Case 2 Goodyear, Jea, Osumc and MonsantoDocument10 pagesB, 40,41, Case 2 Goodyear, Jea, Osumc and MonsantoSuhel PathanNo ratings yet

- TIA and ET 200SP - Efficient Interaction Between All ComponentsDocument8 pagesTIA and ET 200SP - Efficient Interaction Between All Componentsaling alingNo ratings yet

- Ample Sarv3Document4 pagesAmple Sarv3ferea_sail100% (1)

- RCCBsDocument14 pagesRCCBsE.ANANDANNo ratings yet

- Objective: TH STDocument3 pagesObjective: TH STAmzal AhamedNo ratings yet

- The Unified Kill ChainDocument19 pagesThe Unified Kill ChainManuNo ratings yet

- Dolby Pulse BrochureDocument2 pagesDolby Pulse BrochureHà Huy HoàngNo ratings yet

- Fine Pitch LED Display Series TV-PH125-YM SpecsDocument1 pageFine Pitch LED Display Series TV-PH125-YM SpecsJUANSOLUSINDONo ratings yet

- Yealink W52P V73 - 27 User GuideDocument98 pagesYealink W52P V73 - 27 User GuideAleksey MarmiloNo ratings yet

- Case StudyDocument10 pagesCase StudyAL-Zheinie TupazNo ratings yet

- Professional Resume Form For Key Project Personnel: Job HistoryDocument4 pagesProfessional Resume Form For Key Project Personnel: Job HistoryUbaid ZiaNo ratings yet