Professional Documents

Culture Documents

CH 11

Uploaded by

Priyanka CholletiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CH 11

Uploaded by

Priyanka CholletiCopyright:

Available Formats

11.

Prismatic Beam Design

CHAPTER OBJECTIVES

Design a beam to resist

both bending and

shear loads.

Develop methods used

for designing prismatic

beams.

Determine shape of fully

stressed beams.

Design of shafts based on

both bending and torsional moments.

11. Prismatic Beam Design

CHAPTER OUTLINE

1.

2.

3.

4.

Basis for Beam Design

Prismatic Beam Design

*Fully Stressed Beams

*Shaft Design

11. Prismatic Beam Design

11.1 BASIS FOR BEAM DESIGN

Beams are structural members designed to support

loadings perpendicular to their longitudinal axes.

Under load, internal shear force and bending

moment that vary from pt to pt along axis of beam.

Axial stress is ignored in design, as its much

smaller than the shear force and bending moment.

A beam designed to resist shear and bending

moment is designed on the basis of strength.

We use the shear and flexure formulae from

chapters 6 and 7 to design a beam, only if the beam

is homogeneous and displays linear-elastic

behavior.

3

11. Prismatic Beam Design

11.1 BASIS FOR BEAM DESIGN

As shown, external distributed and pt loads applied

to a beam is neglected when we do stress analysis.

Advanced analysis shows that the maximum value

of such stresses are of a small percentage

compared to bending stresses.

Also, engineers prefer

to design for bearing

loads rather than pt

loads to spread the

load more evenly.

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

The actual bending and shear stresses must not

exceed the allowable values specified in structural

and mechanical codes of practice.

We need to determine the beams section modulus.

Using flexure formula, = Mc/I, we have

Sreq'd

allow

11 - 1

M is determined from the beams moment diagram,

and allowable bending stress, allow is specified in a

design code.

5

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Once Sreqd is known, we can determine the

dimensions of the x-section of the beam.

However, for beams with x-section consisting of

various elements (e.g. wide-flange section), then

an infinite no. of web and flange dimensions can be

computed.

In practice, the engineer will choose a commonlymanufactured standard shape from a handbook

that satisfies S > Sreqd.

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Use symmetric x-section if allowable bending stress

is the same for tension and compression.

Otherwise, we use an unsymmetrical x-section to

resist both the largest positive and negative

moment in the span.

Once beam selected, use shear formula

allow = VQ/It to check that the allowable shear stress

has not been exceeded.

Exceptional cases are when the material used is

wood.

7

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Fabricated Beams

1. Steel sections

Most manufactured steel beams produced by rolling

a hot ingot of steel till the desired shape is

produced.

The rolled shapes have properties that are

tabulated in the American

Institute of Steel Construction

(AISC) manual. (Appendix B)

Wide flange shapes defined by

their depth and weight per unit

length.

8

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Fabricated Beams

1. Steel sections

Other properties are the dimensions, x-sectional

area, moment of inertia, section modulus, and the

radius of gyration r, which is related to the sections

buckling strength.

Other sections include channels and angles.

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Fabricated Beams

2. Wood sections

Most wooden beams are of rectangular x-section

due to ease of manufacture and handling.

The nominal and actual dimensions are reported in

the manuals.

Nominal dimensions are used to identify the

sections while the actual dimensions are smaller

due to sawing down the rough surfaces.

Actual dimensions are to be used when performing

stress calculations.

10

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Fabricated Beams

3. Built-up Sections

A built-up section is constructed from two or more

parts joined together to form a single unit.

Based on Eqn 11-1, the moment-resisting capacity

of such a section will be greatest for the greatest

moment of inertia.

Thus, most of the material should be built furthest

from the neutral axis.

11

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Fabricated Beams

3. Built-up Sections

For very large loads, we use a deep I-shaped

section to resist the moments.

The sections are usually

welded or bolted to

form the built-up section.

12

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Fabricated Beams

3. Built-up Sections

Wooden box beams are made from

plywood webs and larger boards for the

flanges.

For very large spans, glulam beams are

used. Such members are made from

several boards glue-laminated together.

13

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

IMPORTANT

Beams support loadings that are applied

perpendicular to their axes.

If they are designed on the basis of strength, they

must resist allowable shear and bending stresses.

The maximum bending stress in the beam is

assumed to be much greater than the localized

stresses caused by the application of loadings on

the surface of the beam.

14

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Procedure for analysis

Shear and moment diagrams

Determine the maximum shear and moment in

the beam. This is often done by constructing the

beams shear and moment diagrams.

For built-up beams, shear and moment diagrams

are useful for identifying regions where the shear

and moment are excessively large and may

require additional structural reinforcement or

fasteners.

15

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Procedure for analysis

Average normal stress

If beam is relatively long, it is designed by finding its

section modulus using the flexure formula,

Sreqd = Mmax/allow.

Once Sreqd is determined, the x-sectional

dimensions for simple shapes can then be

computed, since Sreqd = I/c.

If rolled-steel sections are to be used, several

possible values of S may be selected from the

tables in Appendix B.

16

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Procedure for analysis

Average normal stress

Choose the one with the smallest x-sectional area,

since it has the least weight and is therefore the

most economical.

Shear stress

Normally, beams that are short and carry large

loads, especially those made of wood, are first

designed to resist shear and later checked against

the allowable-bending-stress requirements.

17

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Procedure for analysis

Shear stress

Use the shear formula to check to see that the

allowable shear stress is not exceeded;

allow VmaxQ/It.

If the beam has a solid rectangular x-section, the

shear formula becomes allow 1.5(Vmax/A),

Eqn 7-5, and if the x-section is a wide flange, it is

OK to assume that shear stress is constant over

the x-sectional area of the beams web so that allow

Vmax/Aweb, where Aweb is determined from the

product of the beams depth and the webs

thickness.

18

11. Prismatic Beam Design

11.2 PRISMATIC BEAM DESIGN

Procedure for analysis

Adequacy of fasteners

The adequacy of fasteners used on built-up

beams depends upon the shear stress the

fasteners can resist.

Specifically, the required spacing of nails or bolts

of a particular size is determined from the

allowable shear flow, qallow = VQ/I, calculated at pts

on the x-section where the fasteners are located.

19

11. Prismatic Beam Design

EXAMPLE 11.1

A steel beam has an allowable bending stress of

allow = 170 MPa and an allowable shear stress of

allow = 100 MPa. Select an appropriate W shape that

will carry the loading as shown.

20

11. Prismatic Beam Design

EXAMPLE 11.1 (SOLN)

Shear and moment diagrams

Support reactions calculated,

and shear and moment

diagrams are shown.

From diagrams,

Vmax = 90 kN and

Mmax = 120 kNm.

21

11. Prismatic Beam Design

EXAMPLE 11.1 (SOLN)

Bending stress

Required section modulus for the beam:

3

3

M max 120 kN m 10 mm/mm

3

3

Sreq 'd

706

10

mm

allow

170 103 kN/m 2

Using table in Appendix B, following beams are OK:

W 460 60

S 1120 103 mm3

W 410 67

S 1200 103 mm3

W 360 64

S 1030 103 mm3

W 310 74

S 1060 103 mm3

W 250 80

S 984 103 mm3

W 200 100

S 987 103 mm3

22

11. Prismatic Beam Design

EXAMPLE 11.1 (SOLN)

WE choose the beam having the least weight per

meter: W46060.

The actual maximum moment Mmax (incl. weight of

beam) can be computed and the adequacy of the

selected beam can be checked.

Comparing with the applied loads, the beams weight,

(60.35 kg/m)(9.81 N/kg)(6 m) = 3552.2 N = 3.55 kN,

will only slightly increase Sreqd. Thus,

Sreq 'd 706(10)3 mm3 1120 (10)3 mm3

23

11. Prismatic Beam Design

EXAMPLE 11.1 (SOLN)

Shear stress

Since beam is a wide-flange section, the average

shear stress within the web will be considered.

Here the web is assumed to extend from the very top

to the very bottom of the beam.

From Appendix B, for a W1840, d = 455 mm,

tw = 8 mm, thus

Vmax

90 103 N

avg

24.7 MPa 100 MPa

455 mm 8 mm

Aw

Use a W46060.

24

11. Prismatic Beam Design

EXAMPLE 11.3

Laminated wooden beam supports a uniform

distributed loading of 12 kN/m. If the beam is to have

a height-to-width ratio of 1.5, determine its smallest

width. The allowable bending stress is allow = 9 MPa

and the allowable shear stress is allow = 0.6 MPa.

Neglect the weight of the beam.

25

11. Prismatic Beam Design

EXAMPLE 11.3 (SOLN)

Shear and moment diagrams

Support reactions at A and B

have been calculated and the

shear and moment diagrams

are shown.

Here, Vmax = 20 kN,

Mmax = 10.67 kNm.

26

11. Prismatic Beam Design

EXAMPLE 11.3 (SOLN)

Bending stress

Applying the flexure formula yields,

S req'd

M max 10.67 kN m

3

0.00119 m

3

2

allow 9 10 kN/m

Assume that width is a, then height is h = 1.5a. Thus,

1

a 1.5a 3

I

12

Sreq'd

0.00119 m3

0.75a

c

3

a 0.003160 m

a 0.147 m

27

11. Prismatic Beam Design

EXAMPLE 11.3 (SOLN)

Shear stress

Applying shear formula for rectangular sections

(special case of max = VQ/It), we have

max

Vmax

20 kN

1.5

1.5

0.147 m 1.5 0.147 m

A

0.929 MPa 0.6 MPa

28

11. Prismatic Beam Design

EXAMPLE 11.3 (SOLN)

Equation

Since shear criterion fails, beam must be redesigned

on the basis of shear.

3 Vmax

allow

2 A

2 3 20 kN

600 kN/m

2 a 1.5a

a 0.183 m 183 mm

This larger section will also adequately resist the

normal stress.

29

11. Prismatic Beam Design

*11.3 FULLY STRESSED BEAMS

To reduce a beams weight,

engineers sometimes choose

a beam having variable

x-sectional area, such that at

each x-section, bending stress

reaches its maximum

allowable value.

Such beams are called nonprismatic beams.

Examples shown here.

30

11. Prismatic Beam Design

*11.3 FULLY STRESSED BEAMS

In general, the size of the x-section of a

nonprismatic beam that supports a given loading

can be determined using the flexure formula as

M

S

allow

A beam designed in this manner is called a fully

stressed beam.

31

11. Prismatic Beam Design

EXAMPLE 11.4

Determine the shape of a fully stressed, simply

supported beam that supports a concentrated force at

its center. The beam has a rectangular x-section of

constant width b, and allowable stress is allow.

32

11. Prismatic Beam Design

EXAMPLE 11.4 (SOLN)

The internal moment in the beam, expressed as a

function of position, 0 x < L/2,

P

M x

2

Hence, required section modulus is

M

P

S

x

allow 2 allow

Since S = I/c, then for a x-sectional area h by b, we

3

1

have

bh

I

P

12

x

c

h/2

2 allow

2

3P

allowb

x

33

11. Prismatic Beam Design

EXAMPLE 11.4 (SOLN)

If h = h0 at x = L/2, then h 2

0

So that

3PL

2 allowb

2

h

h 2 0 x

L

By inspection, depth h must vary in a parabolic

manner with distance x. In practice, this shape is the

basis for design of leaf springs used to support the

rear-end axles of most heavy trucks.

Note that although this result indicates that h = 0 at

x = 0, its necessary that beam resist shear stress at

the supports, that is, h > 0 at the supports.

34

11. Prismatic Beam Design

*11.4 SHAFT DESIGN

Shafts with circular x-section are used in many

types of mechanical equipment and machinery.

Thus, they are subjected to cyclic or fatigue stress,

caused by the combined bending and torsional

loads they must transmit.

Stress concentrations will

also occur due to keys,

couplings, and sudden

transitions in its

x-sectional area.

35

11. Prismatic Beam Design

*11.4 SHAFT DESIGN

For example, we can resolve

and replace the loads with

their equivalent components.

Bending-moment diagrams for

the loads in each plane can be

drawn and resultant internal

moment at any section along

shaft is determined by vector

addition, M = (Mx2 + Mz2).

36

11. Prismatic Beam Design

*11.4 SHAFT DESIGN

In addition, the torque diagram

can also be drawn.

Based on the diagrams, we

investigate certain critical

sections where the

combination of resultant moment M and

torque T creates the worst stress situation.

Then ,we apply flexure formula using the resultant

moment on the principal axis of inertia.

37

11. Prismatic Beam Design

*11.4 SHAFT DESIGN

In general, critical element D (or C)

on the shaft is subjected to plane

stress as shown, where

Mc

Tc

and

I

J

38

11. Prismatic Beam Design

*11.4 SHAFT DESIGN

Using the stress-transformation Eqn. 9-7, we have

2

allow 2

2

Mc

2I

Tc

Since I = c4/2 and J = c4/2,

allow

M T

39

11. Prismatic Beam Design

*11.4 SHAFT DESIGN

Solving for radius of the shaft, we get

2

allow

13

M T

11 - 2

40

11. Prismatic Beam Design

*EXAMPLE 11.6

Shaft is supported by smooth journal bearings at A

and B. Due to transmission of power to and from the

shaft, the belts on the pulleys are subjected to the

tensions shown. Determine the smallest diameter of

the shaft using the

maximum-shearstress theory,

with

allow = 50 MPa.

41

11. Prismatic Beam Design

EXAMPLE 11.6 (SOLN)

Support reactions are calculated and shown on the

free-body diagram of the shaft.

42

11. Prismatic Beam Design

EXAMPLE 11.6 (SOLN)

Bending-moment diagrams

for Mx and Mz are also

shown here.

43

11. Prismatic Beam Design

EXAMPLE 11.6 (SOLN)

Torque diagram is also shown.

44

11. Prismatic Beam Design

EXAMPLE 11.6 (SOLN)

By inspection, critical pts for bending moment occur

either at C or B. Also, just to the right of C and at B the

torsional moment is 7.5 Nm.

At C, resultant moment is

MC

118 .75 N m 2 37.5 N m 2 124.5 N m

Whereas at B it is smaller,

M B 75 N m

45

11. Prismatic Beam Design

EXAMPLE 11.6 (SOLN)

Since the design is based on the maximum-shearstress theory, Eqn 11-2 applies.

The radical (M2 + T2) will be the largest at section just

to the right of C. We have

M T

allow

13

50 10 N/m

c 0.0117 m

6

124.5 N m 7.5 N m

2

13

46

11. Prismatic Beam Design

EXAMPLE 11.6 (SOLN)

Thus the smallest allowable diameter is

d 2 0.0117 m 23.3 m

47

11. Prismatic Beam Design

CHAPTER REVIEW

Failure of a beam occurs when the internal shear

or moment in the beam is a maximum.

To resist these loadings, it is important that the

associated maximum shear and bending stress not

exceed allowable values as stated in codes.

Normally, the x-section of a beam is first designed

to resist the allowable bending stress, then the

allowable shear stress is checked.

For rectangular sections, allow 1.5 (Vmax/A).

For wide-flange sections, we use allow Vmax/Aweb.

48

11. Prismatic Beam Design

CHAPTER REVIEW

For built-up beams, the spacing of fasteners or

the strength of glue or weld is determined using

an allowable shear flow, qflow = VQ/I.

Fully stressed beams are nonprismatic and

designed such that each x-section along the

beam will resist the allowable bending stress.

This will define the shape of the beam.

A mechanical shaft generally is designed to

resist both torsion and bending stresses.

49

11. Prismatic Beam Design

CHAPTER REVIEW

Normally, bending can be resolved into two planes,

and so it is necessary to draw the moment

diagrams for each bending moment component

and then select the maximum moment based on

vector addition.

Once the maximum bending and shear stresses

are determined, then depending upon the type of

material, an appropriate theory of failure is used to

compare the allowable stress to what is required.

50

You might also like

- Hibbeler, Mechanics of Materials-Prismatic Beam DesignDocument50 pagesHibbeler, Mechanics of Materials-Prismatic Beam Designpoom2007No ratings yet

- Prestressed Cantilever and Continuous Beam - Seminar - Group 5Document30 pagesPrestressed Cantilever and Continuous Beam - Seminar - Group 5Ganesh MistercoolNo ratings yet

- 107 ConcreteDocument44 pages107 Concretenoadspls2029No ratings yet

- Mobile Bridge Design for Military ApplicationsDocument7 pagesMobile Bridge Design for Military Applicationsravi vermaNo ratings yet

- 6.0 Beams & Shafts PDFDocument10 pages6.0 Beams & Shafts PDFLEONARD NYIRONGONo ratings yet

- Srividya College of Engineering and Technology Question BankDocument6 pagesSrividya College of Engineering and Technology Question BankAravindNo ratings yet

- Design of Horizontally Design of Horizontally Curved Girders Curved GirdersDocument43 pagesDesign of Horizontally Design of Horizontally Curved Girders Curved GirdersdsureshcivilNo ratings yet

- Curved BridgesDocument43 pagesCurved BridgesRam Nepali75% (4)

- Design and Analysis of Beams and ShaftsDocument8 pagesDesign and Analysis of Beams and ShaftsChristian Jay GamboaNo ratings yet

- WSD Beam DesignDocument11 pagesWSD Beam DesignThea Audrey SF DeritNo ratings yet

- Distribution of Strains and Stresses Across A Cross-Section and General Design EquationsDocument13 pagesDistribution of Strains and Stresses Across A Cross-Section and General Design EquationskingNo ratings yet

- Week 13 NotesDocument36 pagesWeek 13 NotesJalal Habib KhanNo ratings yet

- Design in Reinforced Concrete To BS 8110 1Document66 pagesDesign in Reinforced Concrete To BS 8110 1paul macharia100% (13)

- Chapter 9Document24 pagesChapter 9gilbert850507No ratings yet

- Chapter 5Document24 pagesChapter 5gilbert850507100% (1)

- LOAD Cell NotesDocument15 pagesLOAD Cell NotesLakshmanan VenkateswaranNo ratings yet

- Aula 7 - Vigas - Parte 1Document19 pagesAula 7 - Vigas - Parte 1Marcelo Zapata MuñozNo ratings yet

- Stress Based Topology Optimization of 30 Ton C Hook Using FEM.Document48 pagesStress Based Topology Optimization of 30 Ton C Hook Using FEM.Aravind J100% (1)

- Beam DesignDocument34 pagesBeam DesignM Refaat FathNo ratings yet

- Experimental Investigation of Composite Profiled Beams StrengthDocument50 pagesExperimental Investigation of Composite Profiled Beams StrengthManu C PeringelilNo ratings yet

- Chapter 2 Limit State Design For Flexure: Reinforced Concrete Structures I (Ceng-3111)Document50 pagesChapter 2 Limit State Design For Flexure: Reinforced Concrete Structures I (Ceng-3111)Muaz HararNo ratings yet

- Pile Foundation 18-10-10Document101 pagesPile Foundation 18-10-10patel jatin100% (1)

- REINFORCED COLUMN DESIGNDocument37 pagesREINFORCED COLUMN DESIGNMuhammad SadiqNo ratings yet

- Design of RC BeamsDocument42 pagesDesign of RC BeamsHarold Jackson MtyanaNo ratings yet

- Design Procedure For Crane Runway Girders - bk105 PDFDocument7 pagesDesign Procedure For Crane Runway Girders - bk105 PDFFWICIPNo ratings yet

- Lec#10, Economical SectionDocument19 pagesLec#10, Economical SectionKriselle DulayNo ratings yet

- TDS Lec 6Document94 pagesTDS Lec 6YAHAMPATH ARACHCHIGE PASAN MADURA YahampathNo ratings yet

- Composite DesignDocument21 pagesComposite DesignpanyabotNo ratings yet

- Design in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)Document66 pagesDesign in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)rashmiNo ratings yet

- Lecture 5 Year 2-1Document28 pagesLecture 5 Year 2-1Saurabh ChauhanNo ratings yet

- Design and Analysis of RC BeamsDocument12 pagesDesign and Analysis of RC BeamsmyidmaranNo ratings yet

- RC design conceptsDocument32 pagesRC design conceptsSyed Yousuf AhmedNo ratings yet

- CIV 3164-Design of Reinforced Concrete Structures-I: Department of Civil, Environmental and Geomatics EngineeringDocument52 pagesCIV 3164-Design of Reinforced Concrete Structures-I: Department of Civil, Environmental and Geomatics EngineeringHakuna MatataNo ratings yet

- Reinforced Concrete Design BS 8110Document15 pagesReinforced Concrete Design BS 8110Kutty Mansoor75% (4)

- Chapter OneDocument28 pagesChapter OneAbyot yassabNo ratings yet

- STRUCTURAL DESIGN OF HAND RAIL TITLEDocument3 pagesSTRUCTURAL DESIGN OF HAND RAIL TITLEmsiddiq1100% (1)

- Floor, Beam, Column and Footing DesignDocument32 pagesFloor, Beam, Column and Footing DesignMaria Fe GonzalesNo ratings yet

- RC Beam DesignDocument52 pagesRC Beam DesignnaurahimanNo ratings yet

- 1 (Repaired)Document13 pages1 (Repaired)Benni AmirNo ratings yet

- Reinforced Concrete Columns: J. P. ForthDocument25 pagesReinforced Concrete Columns: J. P. ForthJeff Sun100% (1)

- CIV5304: Design of Structural Elements III: Engr DR Nuruddeen Muhammad MusaDocument20 pagesCIV5304: Design of Structural Elements III: Engr DR Nuruddeen Muhammad MusaNuruddeen MuhammadNo ratings yet

- Chapter 4 PDFDocument5 pagesChapter 4 PDFtrishia arcillaNo ratings yet

- 1.2 Beams and Columns: Chapter 1-Static Engineering SystemsDocument13 pages1.2 Beams and Columns: Chapter 1-Static Engineering SystemsGia BeNo ratings yet

- 7th Sem Prestressed Concrete StructuresDocument9 pages7th Sem Prestressed Concrete StructuresSubhikshaNo ratings yet

- Reinforced Concrete Torsion DesignDocument47 pagesReinforced Concrete Torsion DesignalaaNo ratings yet

- MyNotes Concrete ColDocument29 pagesMyNotes Concrete ColKarl Si AkoNo ratings yet

- Lateral Stability of Purlins and GirtsDocument7 pagesLateral Stability of Purlins and Girtsvpvipin93No ratings yet

- Design of tension members and splicesDocument7 pagesDesign of tension members and splicesSourabh SrivastavaNo ratings yet

- Design of RCC Structure (CE6G) - Design of Slab and BeamDocument32 pagesDesign of RCC Structure (CE6G) - Design of Slab and BeamSharath WankdothNo ratings yet

- Chapter 8Document12 pagesChapter 8gilbert850507No ratings yet

- Design in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)Document66 pagesDesign in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)Glistering DharNo ratings yet

- Steel Tutorial 2,3,4,5,6,7Document7 pagesSteel Tutorial 2,3,4,5,6,7Sankalp LamaNo ratings yet

- 2Document10 pages2chaojibai1213No ratings yet

- Shaft Design PDFDocument27 pagesShaft Design PDFRaverl XNo ratings yet

- Group 09 Presentation-1Document33 pagesGroup 09 Presentation-1rudolfNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Strength of Materials: Theory and ExamplesFrom EverandStrength of Materials: Theory and ExamplesRating: 4.5 out of 5 stars4.5/5 (13)

- LIU Jiemin @SJZU 2008 1 CH.2 Tension & COMPRESSIONDocument45 pagesLIU Jiemin @SJZU 2008 1 CH.2 Tension & COMPRESSIONPriyanka CholletiNo ratings yet

- CH 12Document118 pagesCH 12Priyanka CholletiNo ratings yet

- CH 14Document161 pagesCH 14Priyanka CholletiNo ratings yet

- Michigan Tech - Mechanical VibrationsDocument8 pagesMichigan Tech - Mechanical VibrationsPriyanka CholletiNo ratings yet

- CH 08Document46 pagesCH 08Priyanka CholletiNo ratings yet

- CH 13Document98 pagesCH 13Priyanka Cholleti100% (3)

- CH 10Document124 pagesCH 10Priyanka CholletiNo ratings yet

- Mech VibrationDocument14 pagesMech VibrationSquakx BescilNo ratings yet

- Lecture 20Document11 pagesLecture 20John Larry CorpuzNo ratings yet

- Problem Set 3Document6 pagesProblem Set 3Priyanka CholletiNo ratings yet

- XRNL So UWANZc B1 LA9 FR 8 DSZ Kofwqo 3 FBV 7 QHHK BXVV UDocument8 pagesXRNL So UWANZc B1 LA9 FR 8 DSZ Kofwqo 3 FBV 7 QHHK BXVV UPriyanka CholletiNo ratings yet

- Lecture 21Document11 pagesLecture 21Aniruddh FaujdarNo ratings yet

- Problem Set 2Document14 pagesProblem Set 2Priyanka Cholleti100% (1)

- MEEM 3700 Mechanical VibrationsDocument6 pagesMEEM 3700 Mechanical VibrationsJohn Larry CorpuzNo ratings yet

- Problem Set 1Document9 pagesProblem Set 1Priyanka CholletiNo ratings yet

- AzTpAcrG41CdDKGw8WF8tnKRoAkjrlyFixZm SPwCsEDocument9 pagesAzTpAcrG41CdDKGw8WF8tnKRoAkjrlyFixZm SPwCsEPriyanka CholletiNo ratings yet

- MEEM 3700 Mechanical VibrationsDocument8 pagesMEEM 3700 Mechanical VibrationsJohn Larry CorpuzNo ratings yet

- Mechanical Vibration RaoDocument13 pagesMechanical Vibration RaoVipin ShuklaNo ratings yet

- Fly by WireDocument2 pagesFly by WirePriyanka CholletiNo ratings yet

- JN 8 T 9 o 5 Ezcxxos 0/bh/9 S 0 Texaioq 71 Vbfrix 1 Z 4 JW 4Document9 pagesJN 8 T 9 o 5 Ezcxxos 0/bh/9 S 0 Texaioq 71 Vbfrix 1 Z 4 JW 4Priyanka CholletiNo ratings yet

- Lecture 11Document6 pagesLecture 11Nits WakNo ratings yet

- Design of Solar Powered Airplanes for Continuous FlightDocument18 pagesDesign of Solar Powered Airplanes for Continuous FlightSam FraserNo ratings yet

- Lecture 7-Log DecrementDocument3 pagesLecture 7-Log DecrementDevilboneNo ratings yet

- Matlab and SimulinkDocument15 pagesMatlab and SimulinkOnur KımıllıNo ratings yet

- Lecture 16Document6 pagesLecture 16John Larry CorpuzNo ratings yet

- Lecture 21Document11 pagesLecture 21Aniruddh FaujdarNo ratings yet

- CyCxTzuyG10vneoAREwgUTOjm 89TcSiR5tqEkxAwADocument5 pagesCyCxTzuyG10vneoAREwgUTOjm 89TcSiR5tqEkxAwAPriyanka CholletiNo ratings yet

- Aircraft Maint TechDocument2 pagesAircraft Maint TechPriyanka CholletiNo ratings yet

- Fluent Tutorial 2008Document5 pagesFluent Tutorial 2008SHASHI KUMARNo ratings yet

- Baby Bulbasaur PatternDocument15 pagesBaby Bulbasaur PatterncynticatNo ratings yet

- Mumbai's First Female DJ Lil'BDocument2 pagesMumbai's First Female DJ Lil'BMonica KshirsagarNo ratings yet

- Characteristics of Asian LitDocument3 pagesCharacteristics of Asian LitKent Vincent Alburan38% (8)

- Tips On Planetarium BuildingDocument32 pagesTips On Planetarium BuildingSriKallidai0% (1)

- Fruits and Vegetable Carving Development of Carving Patterns For BanquetsDocument10 pagesFruits and Vegetable Carving Development of Carving Patterns For Banquetskarthika4aNo ratings yet

- Percubaan PMR 09 Sabah Marking Scheme MTK Paper 2Document5 pagesPercubaan PMR 09 Sabah Marking Scheme MTK Paper 2732456100% (3)

- Elapsed Time Word Problems TV Show WorksheetDocument2 pagesElapsed Time Word Problems TV Show WorksheetmarialisaNo ratings yet

- Britacel Silicones LTD.: Sebacel 540 Micro Amino SiliconesDocument2 pagesBritacel Silicones LTD.: Sebacel 540 Micro Amino Siliconesraju_hosssenNo ratings yet

- Introduction To Woman Studies "Image of Woman": Merlin Maya Maukar, M.PDDocument3 pagesIntroduction To Woman Studies "Image of Woman": Merlin Maya Maukar, M.PDBenedict MarcelNo ratings yet

- Sync Your Ipad With Linux PDFDocument0 pagesSync Your Ipad With Linux PDFricardox28No ratings yet

- LiliumDocument2 pagesLiliumHenry ChuangNo ratings yet

- ABRSM TheoryDocument24 pagesABRSM TheoryJane Haddad83% (6)

- (Sooky) Feng Yu Jiu Tian Volume 2 PDFDocument367 pages(Sooky) Feng Yu Jiu Tian Volume 2 PDFJussa Leilady Alberba75% (4)

- Talking About Likes and DislikesDocument33 pagesTalking About Likes and DislikesAna Cifuentes OrozcoNo ratings yet

- List of Radio StationsDocument13 pagesList of Radio StationsNishi Kant ThakurNo ratings yet

- Footprints of Giants - Discover & Develop Habits of Greatness T. Ayodele Ajayi EDITOR NOTEDocument135 pagesFootprints of Giants - Discover & Develop Habits of Greatness T. Ayodele Ajayi EDITOR NOTEPedro KissiçaNo ratings yet

- Hydraulic Pile Driving Rig Spec-Dh558-110m-5Document21 pagesHydraulic Pile Driving Rig Spec-Dh558-110m-5dennisNo ratings yet

- NNH4 65B R6Document1 pageNNH4 65B R6billfreelyNo ratings yet

- SMITE: A Guide to the Third-Person MOBADocument2 pagesSMITE: A Guide to the Third-Person MOBAEduNo ratings yet

- Language and Literature DP 2 - 2019-2020Document29 pagesLanguage and Literature DP 2 - 2019-2020Shuaib MohamedNo ratings yet

- Fellowship - Playbook 3Document44 pagesFellowship - Playbook 3Bubba McBimbam100% (1)

- Phillips, Projected Fears, 1-10Document8 pagesPhillips, Projected Fears, 1-10Maria José BarrosNo ratings yet

- 37 Best SmsDocument12 pages37 Best SmsSandeep KumarNo ratings yet

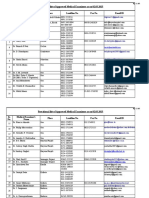

- List Provisional Medicalexaminer 020315Document10 pagesList Provisional Medicalexaminer 020315Arnav JoshiNo ratings yet

- EIKON EngDocument204 pagesEIKON EngDan PopescuNo ratings yet

- Form and Meaning - Studies in Literary Techniques in The Book of JonahDocument204 pagesForm and Meaning - Studies in Literary Techniques in The Book of JonahXavier Casamada100% (3)

- Power Plus Air 2009Document12 pagesPower Plus Air 2009Thim SnelsNo ratings yet

- Prayer To Break Off Generational CursesDocument5 pagesPrayer To Break Off Generational CursesRonald ManyamaNo ratings yet

- Tonebase Piano Scales and ArpeggiosDocument13 pagesTonebase Piano Scales and Arpeggiosneia_moda71% (7)

- Succeed in Cambridge Pet 10 Practice tests-KEYS PDFDocument2 pagesSucceed in Cambridge Pet 10 Practice tests-KEYS PDFTienNguyen50% (6)