Professional Documents

Culture Documents

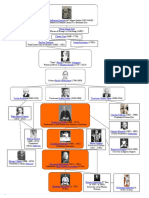

Arbore Genealogic Karate Shotokan

Uploaded by

ComanAdrianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arbore Genealogic Karate Shotokan

Uploaded by

ComanAdrianCopyright:

Available Formats

ASRV

YN 417000

Lesson Learnt – Foundation

and steel outfitting

1. Communication between departments needs to be improved (general remark)!

Moved equipment's has not been announced to the foundation department.

All these cases lead to an increased consumption of hours because the new/old location of equipment is unknown.

MEGA Ship Design Company member of the Damen Group Slide: 1

Detail Design by MEGA-examples

2. Routing of equipment involving stauff clamps need special attention!

2.1 According with pipe clamp stauff heavy series standard the weld plate could be 8/10 mm. In this case the

stauff clamps should be placed directly on plate (where is possible) at 8/10mm without any foundation for it.

MEGA Ship Design Company member of the Damen Group Slide: 2

2.2 Position of stauff clamps/nozzle must be done in such a way that they do not require extra foundations!

The location of clamps should be improved! Good location of clamps (near to the deck/bulkhead)!

MEGA Ship Design Company member of the Damen Group Slide: 3

3. Foundations for small equipment's placed on metal sheeting.

-The decision was excellent, but it came a little late because We spent many hours producing foundations for it-

MEGA Ship Design Company member of the Damen Group Slide: 4

4. Drip tray for flange above e-cabinets is not allowed!

MEGA Ship Design Company member of the Damen Group Slide: 5

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The28 DayGoutDietPlanThe SophiaKamverisDocument177 pagesThe28 DayGoutDietPlanThe SophiaKamverisFlo Rence100% (4)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 2011 Nissan JukeDocument345 pages2011 Nissan JukejoanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The 28 Day Gout Diet Plan The Optimal Nutrition Guide To Manage GoutDocument177 pagesThe 28 Day Gout Diet Plan The Optimal Nutrition Guide To Manage GoutComanAdrian100% (4)

- Website Academy ENG-1Document15 pagesWebsite Academy ENG-1Ismael Laaboudi100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Excersises Wim HofDocument12 pagesExcersises Wim Hofpetar2001100% (19)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Buteyko Breathing Guide PDFDocument1 pageButeyko Breathing Guide PDFFreddy Rafael Rosales HernandezNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Tabel Nominal Cu Examene de Grad - 6 - 1 - Kyu: Ministerul Tineretului Si SportuluiDocument3 pagesTabel Nominal Cu Examene de Grad - 6 - 1 - Kyu: Ministerul Tineretului Si SportuluiComanAdrianNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Innovative Medicine Diet Plan PDFDocument12 pagesInnovative Medicine Diet Plan PDFComanAdrianNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Arbore Genealogic Karate Shotokan PDFDocument1 pageArbore Genealogic Karate Shotokan PDFComanAdrianNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- CNAIR - Copie Client - Roviniete Emise: Scala Assistance S.R.L./ Sediu ClujDocument1 pageCNAIR - Copie Client - Roviniete Emise: Scala Assistance S.R.L./ Sediu ClujComanAdrianNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Arbore Genealogic Karate ShotokanDocument1 pageArbore Genealogic Karate ShotokanComanAdrianNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Basic Training CourseDocument350 pagesBasic Training Coursecoman_adrian0% (1)

- Invitation Letter European Fudokan Championship PDFDocument18 pagesInvitation Letter European Fudokan Championship PDFComanAdrianNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Cancer A Yogic PerspectiveDocument105 pagesCancer A Yogic PerspectiveComanAdrian100% (9)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Foundation CalculationDocument63 pagesFoundation CalculationComanAdrianNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)