Professional Documents

Culture Documents

Procedure For Analysis

Uploaded by

Omodibo Oghenekevwe KevinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure For Analysis

Uploaded by

Omodibo Oghenekevwe KevinCopyright:

Available Formats

Overview Electrical Transient Analyzer Program (ETAP)

Arc Flash Analysis

Motor Starting Analysis

Load Flow Analysis

ETAP

Transient Stability Analysis Star Device Coordination Analysis Short Circuit Analysis ANSI / IEEE

Single Line Diagram

Go to Edit Mode by Click the Edit button on the Mode toolbar.

select a Power Grid (Utility) element by clicking on the Power Grid button.. Click anywhere in the OLV to place a Utility on your one-line diagram

insert the elements

connect the elements in the one-line by clicking and dragging element to the connection pin of another element. Notice that a node is automatically inserted when connecting the cable to the transformer.

Enter the values for the elements shown in the figure above referring to the Editing Element Properties leaflet.

Purpose of Short Circuit Analysis

ETAP Short Circuit software program allows for short circuit calculations based on ANSI and IEEE standards.

voltage source at the fault location, which equals the prefault voltage at the location, replaces all external voltage sources and machine internal voltage sources.

Three different impedance networks are formed to calculate momentary, interrupting, and steady-state short circuit currents, and corresponding fault current duties for various protective devices. These networks are: cycle and 30 cycle network (steady-state network). ANSI/IEEE Standards recommend the use of separate R and X networks to calculate X/R values. An X/R ratio is obtained for each individual faulted bus and short circuit current. This X/R ratio is then used to determine the multiplying factor to account for the system DC offset.

In ANSI/IEEE short circuit software program, an equivalent

network (subtransient network), 1.5-4 cycle network (transient network),

Purpose for Transient Stability Analysis

Electrical power transient stability calculation program is used

to accurately model the power system dynamics and transient by simulating system disturbances and other events.

Typical transient stability studies include

identifying critical fault clearing time, checking generator rotor angle stability, assessing system stability margin, evaluating motor dynamic acceleration and reacceleration impact, preparing and testing load shedding schedule, computing fast bus transfer timing, calibrating and evaluating relay setting and simulating generator start-up. split a system or combine multiple subsystems, simulate automatic relay actions and associated circuit breaker operations, start or auto-start motors. enhanced plotting and graphical results

Purpose for Motor Starting Analysis

to investigate whether the starting motor can be successfully started under the operating conditions, and to see if starting the motor will seriously impede the normal operation of other loads in the system if a motor can be started and how much time is needed for the motor to reach its rated speed, as well as to determine the effect of voltage dips on the system using the dynamic motor starting

Purpose for Arc Flash Analysis

capabilities which allow for faster and easier assessment of arc flash hazards and arc flash incident. Identify and analyze high risk arc flash areas in your electrical power system with greater flexibility by simulating and evaluating various arc flash mitigation methods in your arc flash study. solves multiple scenarios to determine worst-case arc flash energy levels. produces professional reports and high quality arc flash safety also includes comprehensive single phase and three phase arc flash assessment calculations as well as an invaluable arc flash analyzer tool to summarize results from the arc flash study.

Purpose for Star Coordination Analysis

for performing steady-state and dynamic device coordination, protection, and testing. To provide informed and reliable recommendations regarding the feasibility of the protective devices under consideration. Help in resolving possible design issues and make informed decisions to improve system reliability, increase system stability, and boost financial savings. comprehensive over current protective device coordination analysis, using intelligent one-line diagrams, protective device libraries, and a three-dimensional database capable of plotting the starting, inrush, damage, etc. curves for equipment like motors, transformers, generators, and cables. Offering insight into troubleshooting false trips, relay and breaker mis-operation, and mis-coordination.

Process STATIC MOTOR STARTING

Switch to Motor Acceleration Analysis mode

open the Motor Starting Study Case editor

Event page change the Total Simulation Time to 10 seconds You can start or switch off individual loads You can add an event by selecting the Event page Open Syn1 s editor Acceleration Time (Static Starting) fields

Run Static Motor Starting button

Process DYNAMIC MOTOR STARTING

Switch to Motor Acceleration Analysis mode open the Motor Starting Study Case editor Event page change the Total Simulation Time to 10 seconds You can start or switch off individual loads You can add an event by selecting the Event page Open Syn1 s editor Acceleration Time (Static Starting) fields no load 1 full load 3

Open Syn1 s editor

Open Syn1 s editor

Go to Model page go to dynamic model and select any category other than none

Load Model and add model from lib

go to the Inertia page and enter 0.2

Run Dynamic Motor Starting button

Required Data for Motor Starting

Motor Starting Required Data Bus Data Required data for motor starting calculations for buses includes: Bus ID Nominal kV %V and Angle (when Initial Condition is set to use Bus Voltages) Load Diversity Factor (if the Loading option is set to use the Maximum or Minimum load) Branch Data Branch data is entered into the branch editors, including the 3-Winding Transformer Editor, 2-Winding Transformer Editor, Transmission Line Editor, Cable Editor, Reactor Editor, and Impedance Editor. Required data for motor starting calculations for branches includes the following: Branch ID Branch Z, R, X, or X/R values and units, tolerance, and temperatures, if applicable Cable and transmission line length and unit Transformer rated kV and kVA/MVA, tap and LTC settings Impedance base kV and base kVA/MVA Power Grid Data Required data for motor starting calculations for power grids includes: Utility ID Mode (Swing, Voltage Control or Mvar Control) Rated kV, and short-circuit MVA and impedance Generation category data (%V and Vangle) Synchronous Generator Data Required data for motor starting calculations for synchronous generators includes: Synchronous Generator ID Mode (Swing, Voltage Control or Mvar Control) Rated kW, kV, and power factor Xd and X/R ratio Generation category data, ( V%, MW and Mvar) Synchronous Motor Data Required data for motor starting calculations for synchronous motors includes: Synchronous Motor ID Rated kW/hp and kV Power factors and efficiencies at 100%, 75%, and 50% loading for operating motors Loading Category IDs and % Loading for operating motors Equipment cable data

Induction Motor Data Required data for motor starting calculations for induction motors includes: Induction Motor ID Rated kW/hp and kV Power factors and efficiencies at 100%, 75%, and 50% loading Loading Category ID and % Loading Equipment cable data Static Load Data Required data for motor starting calculation for static loads includes: Static Load ID Rated kVA/MVA and kV Power factors at 100%, 75%, and 50% loading Loading Category ID and % Loading Equipment cable data MOV Data Required data for motor starting calculation for MOV includes: MOV ID Rated kW/hp and kV Current, PF, and time for each operation stage Equipment cable data Capacitor Data Required data for motor starting calculation for capacitor includes: Capacitor ID Rated kV, kvar/bank and number of banks Loading category ID and % Loading Equipment cable data Lumped Load Data Required data for motor starting calculation for lumped load includes: Load ID Rated kV, MVA, power factor, and % for motor load Loading category ID and % Loading Additional Data for Starting Motors For Static Motor Starting studies, the additional data includes: Motor locked-rotor impedance and power factor Motor acceleration time at no load and full load Start and final percent loading and begin and end of load change time Starting device data when needed No load and full load accelerated time (for static motor starting)

Required Data for Motor Starting

Required Data for Motor Starting

For Dynamic Motor Acceleration studies, the additional data includes: Dynamic motor model for induction motors LR model for synchronous motors Load torque model Motor inertia Study Case Data There are some study case related data, which must also be provided. This data includes: Study Case ID Maximum number of iteration Precision of solution Total simulation time, simulation time step, and plot time step Prestart loading (loading category) Initial condition Transformer LTC data Equipment adjustment options Alert options Report (report format)

Process Harmonic Study

Purpose for Load Flow Study

To perform power flow analysis and voltage drop calculations with accurate and reliable results. By using the automatic equipment evaluation, alerts and warnings summary, load flow result analyzer, and To calculate the bus voltages, branch power factors, currents, and power flows throughout the electrical system.

Process Load Flow Study

Click the Load Flow Analysis button on the Mode toolbar to switch to Load Flow Analysis mode. select the name of an existing output report to overwrite, or Prompt. Go to Load Flow Study Case editor to specify the maximum number of iterations and precision; loading and generation categories can be individually selected; load diversity factors can be applied; and finally adjustments can be selected for different elements, e.g. transformer, reactor, overload heater, cable, transmission line, and more click on the Run Load Flow button located in the Load Flow toolbar

Go to Display Options in the Load Flow Toolbar to change the format of the results.

Go to Alert View button in the load flow toolbar to view any overload problems. This will open a window containing a list of undersized equipment. Click on Report Manager in the Load Flow toolbar, and go to the Result page and select Load Flow Report to output a more detailed and organized representation of the results in different formats

Check the results for marginal or critical flags in the Alert View window. The criteria for which a condition is flagged can be changed in the Load Flow Study Case editor.

Process Load Flow Study

ETAP allows Auto LTC settings to be applied to regulate buses that are directly or indirectly connected to a transformer. For example, we can use transformer T4 to regulate Bus1 at 100% of nominal voltage. Open the editor of T4 by double clicking on its graphic on the one-line. On the Tap page, enable (check) the Auto LTC box on the primary winding

Open the LTC settings window by clicking on the LTC box and change the Regulated Bus ID to Bus1. Click OK for both the LTC window and the Transformer Editor window.

After running the Load Flow study, you can analyze the output data for different elements in a very compact and summarized way by using the Load Flow Results Analyzer. To do so, click on the Load Flow Result Analyzer button in the Load Flow toolbar. Select the different reports that you want to consider from the Study Reports field. If you want to compare output reports from other projects along with the current project, you can select All Project in Active Directory from the Project Report field. The other projects must be in the same directory as your current project.

Select the report type from the Report Type field. The example above shows results for Loads. After selecting Loads, select the Load Types and Load Info to display. Select the units to display the results in, and the different fields that you want to display. In addition, you can create your own alerts and enable them from the Alert field.

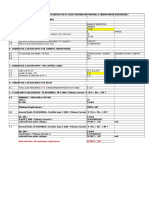

Process Short Circuit Study

Bus Data

Required data for load flow calculations for buses includes:

Nominal kV %V and Angle (when Initial Condition is set to use Use Bus Voltages) Load Diversity Factor (when the Loading option is set to use Diversity Factor)

Branch Data

Required Data for Load Flow Analysis

Branch data is entered into the Branch Editors, i.e., Transformer, Transmission Line, Cable, Reactor, and Impedance editors. Required data for load flow calculations for branches includes:

Branch Z, R, X, or X/R values and units, tolerance, and temperature, if applicable Cable and transmission line, length, and unit Transformer rated kV and kVA/MVA, tap, and LTC settings Impedance base kV and base kVA/MVA

Power Grid Data

Required data for load flow calculations for power grids includes:

Operating mode (Swing, Voltage Control, Mvar Control, or PF Control) Nominal kV %V and Angle for swing mode %V, MW loading, and Mvar limits (Qmax & Qmin) for Voltage Control mode MW and Mvar loading, and Mvar limits Mvar Control mode MW loading and PF, and Mvar limits for PF Control mode

Synchronous Generator Data

Required data for load flow calculations for synchronous generators includes:

Operating mode (Swing, Voltage Control, or Mvar Control) Rated kV %V and Angle for swing mode of operation %V, MW loading, and Mvar limits (Qmax and Qmin) for Voltage Control mode MW and Mvar loading, and Mvar limits Mvar Control mode MW loading and PF, and Mvar limits for PF Control mode

Note: The Mvar limits (Qmax and Qmin) can also be calculated from the capability curve. The required additional data for this calculation includes: All data on the Capability page Synchronous reactance (Xd) Inverter Data Required data for load flow calculations for inverters includes: Inverter ID DC and AC rating data AC output voltage regulating data Synchronous Motor Data Required data for load flow calculations for synchronous motors includes: Rated kW/hp and kV Power factors and efficiencies at 100%, 75%, and 50% loadings % Loading for desired Loading Category Equipment cable data Induction Motor Data Required data for load flow calculations for induction motors includes: Rated kW/hp and kV Power factors and efficiencies at 100%, 75%, and 50% loadings % Loading for desired Loading Category Equipment cable data Static Load Data Required data for load flow calculations for static loads includes: Static Load ID Rated kVA/MVA and kV Power factor % Loading for desired Loading Category Equipment cable data Capacitor Data Required data for load flow calculations for capacitors includes:

Required Data for Load Flow Analysis

Conventional Load ID Rated kV, kVA/MVA, power factor, and % motor load % Loading for desired Loading Category Unbalanced Load ID Rated kV, kVA/MVA, power factor, % motor load, and % static load % Loading for desired Loading Category Exponential Load ID Rated kV, P0, Q0, a, and b % Loading for desired Loading Category Polynomial Load ID Rated kV, P0, Q0, p1, p2, q1, and q2 % Loading for desired Loading Category Comprehensive Load ID Rated kV, P0, Q0, a1, a2, b1, b2, p1, p2, p3, p4, q1, q2, q3, and q4 % Loading for desired Loading Category Charger and UPS Data Required data for load flow calculations for chargers and UPSincludes: Element ID Rated AC kV, MVA, and power factor, as well as DC rating data % Loading for desired Loading Category HV DC Link Data Required data for load flow calculations for HVDC links includes: Element ID All data on the Rating page is required for Load Flow calculations Inverter current margin (Im) SVC Data Required data for load flow calculations for SVCincludes: Element ID Rated kV Inductive Rating (Either QL, IL, or BL) Capacitive Rating (Either QC, IC, or BC) Max Inductive Rating (Either QL(Max), or IL(Max)) Max Capacitive Rating (Either Q , or I )

Required Data for Load Flow Analysis

Comprehensive Load ID Rated kV, P0, Q0, a1, a2, b1, b2, p1, p2, p3, p4, q1, q2, q3, and q4 % Loading for desired Loading Category Charger and UPS Data Required data for load flow calculations for chargers and UPSincludes: Element ID Rated AC kV, MVA, and power factor, as well as DC rating data % Loading for desired Loading Category HV DC Link Data Required data for load flow calculations for HVDC links includes: Element ID All data on the Rating page is required for Load Flow calculations Inverter current margin (Im) SVC Data Required data for load flow calculations for SVCincludes: Element ID Rated kV Inductive Rating (Either QL, IL, or BL) Capacitive Rating (Either QC, IC, or BC) Max Inductive Rating (Either QL(Max), or IL(Max)) Max Capacitive Rating (Either QC(Min), or IC(Min)) Note: QC, QC(Min), and BL must be entered as a negative value Panel Data Required data for load flow calculations for panels includes: Element ID Rated kV and Amps Number of Branch Circuits Loading and %Loading Phasing, Number of Poles, and State Connection Type, i.e. Internal, External, Spare, etc. Other Data There are some study case related data, which must also be provided. This includes: Method (Newton-Raphson, Fast-Decoupled, or Accelerated Gauss-Seidel) Max Iteration Precision Acceleration Factor (when Accelerated Gauss-Seidel method is selected)

Required Data for Load Flow Analysis

You might also like

- Short Circuit AnalysisDocument4 pagesShort Circuit AnalysisAprilian Sandi100% (1)

- PCPL-1409-4-300 R0 Short Circuit ReportDocument32 pagesPCPL-1409-4-300 R0 Short Circuit ReportMuthuvel GaneshNo ratings yet

- Short Circuit Calculation GuideDocument14 pagesShort Circuit Calculation GuideAnupam0103No ratings yet

- Elements of Radio Servicing-William MarcusDocument368 pagesElements of Radio Servicing-William MarcusJShearerNo ratings yet

- 06 - Short Circuit - ANSI PDFDocument50 pages06 - Short Circuit - ANSI PDFÁlvaro Alarcón MolinaNo ratings yet

- Etap Tip 010Document9 pagesEtap Tip 010Michael Calizo PacisNo ratings yet

- CT, PT & NGT Calculation Sheet 09.03.2023 PDFDocument23 pagesCT, PT & NGT Calculation Sheet 09.03.2023 PDFAmit KumarNo ratings yet

- Power system simulation of Ferranti effect and power factor correctionDocument1 pagePower system simulation of Ferranti effect and power factor correctionSiddarthan AnnamalaiNo ratings yet

- Load Flow AnalysisDocument5 pagesLoad Flow AnalysisKelvin LiewNo ratings yet

- ETAP Relay CoordinationDocument6 pagesETAP Relay CoordinationJ Bagien100% (2)

- Nikola Tesla - Wikipedia, The Free EncyclopediaDocument11 pagesNikola Tesla - Wikipedia, The Free EncyclopediaEugene RebelloNo ratings yet

- Voltage Drop Calculation - 15 MVA TransformerDocument1 pageVoltage Drop Calculation - 15 MVA Transformerbalaeee123No ratings yet

- Load Flow Analysis of 66 KV Substation Using ETAP SoftwareDocument4 pagesLoad Flow Analysis of 66 KV Substation Using ETAP SoftwareAnonymous CUPykm6DZ100% (1)

- Short Circuit Current Calculation (Base KVA Method)Document16 pagesShort Circuit Current Calculation (Base KVA Method)PrateekNo ratings yet

- Sequential Motor Dynamic Acceleration and Re-Acceleration Simulations: Comparison of ETAP®Document6 pagesSequential Motor Dynamic Acceleration and Re-Acceleration Simulations: Comparison of ETAP®sundar12345No ratings yet

- Transformer SizingDocument5 pagesTransformer SizinggktahilianiNo ratings yet

- Sizing A MV Generator Circuit Breake1Document25 pagesSizing A MV Generator Circuit Breake1Afifah Zuhroh0% (1)

- Power FlowDocument19 pagesPower FlowЩахмиАзри50% (2)

- IEC Circuit Breaker Short-Time Withstand Duty PDFDocument1 pageIEC Circuit Breaker Short-Time Withstand Duty PDFgilbertomjcNo ratings yet

- Short-Circuit Analysis IEC StandardDocument46 pagesShort-Circuit Analysis IEC Standarddiogoufrn-1No ratings yet

- 2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONDocument5 pages2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONkkumar_717405No ratings yet

- MiP-PSCT LFA User Manual Load Flow Analysis GuideDocument119 pagesMiP-PSCT LFA User Manual Load Flow Analysis Guidedivya1587100% (1)

- Report08072020 PDFDocument124 pagesReport08072020 PDFramesh cuppu100% (1)

- Protective Device Coordination ETAP Star PDFDocument89 pagesProtective Device Coordination ETAP Star PDFTadala Maluwa0% (1)

- KM Setting CalculationDocument35 pagesKM Setting CalculationratheeshkumardNo ratings yet

- CT Sizing For MalawiDocument2 pagesCT Sizing For MalawiDharmenderSinghChoudharyNo ratings yet

- SC CalculationsDocument97 pagesSC CalculationsshrieersNo ratings yet

- N Fault Contribution PDFDocument15 pagesN Fault Contribution PDFhussainNo ratings yet

- Instrumentation ElementsDocument30 pagesInstrumentation ElementsManohar PotnuruNo ratings yet

- PHASE FAULT OVER CURRENT RELAY SETTING (WRKNG)Document35 pagesPHASE FAULT OVER CURRENT RELAY SETTING (WRKNG)Madhu DuraichamyNo ratings yet

- Motor para Estimation&Tuning - With Optimization PDFDocument13 pagesMotor para Estimation&Tuning - With Optimization PDFhussainNo ratings yet

- Etap Tip 008Document6 pagesEtap Tip 008yetignr0% (1)

- 08 - Device CoordinationDocument53 pages08 - Device Coordinationchanchai T60% (5)

- Design Analysis of 220132 KV Substation Using ETAP PDFDocument5 pagesDesign Analysis of 220132 KV Substation Using ETAP PDFRUBIONo ratings yet

- Short Circuit Calculation For Triumph PDFDocument17 pagesShort Circuit Calculation For Triumph PDFEdijs DaukulsNo ratings yet

- NGR - Ohm Calc Trafo 5MVA-20kVDocument6 pagesNGR - Ohm Calc Trafo 5MVA-20kVbarukomkssNo ratings yet

- Fault Analysis On LVDocument15 pagesFault Analysis On LVVENKATESAN RNo ratings yet

- Fault Current Calculation Notes SummaryDocument25 pagesFault Current Calculation Notes SummaryMohamed SabeerNo ratings yet

- Short CircuitDocument29 pagesShort CircuitFrancisco AndradeNo ratings yet

- Applicable Electrical StandardsDocument4 pagesApplicable Electrical Standardsamirtha_s2238No ratings yet

- Arc FlashDocument6 pagesArc FlashvenkyeeeNo ratings yet

- 21 - DCLF and DCSCDocument24 pages21 - DCLF and DCSCchanchai T100% (2)

- Steady State IEC Current (Ik) Results PDFDocument2 pagesSteady State IEC Current (Ik) Results PDFgilbertomjcNo ratings yet

- The Use of Software for Electrical Fault Current CalculationsDocument11 pagesThe Use of Software for Electrical Fault Current CalculationsSankara Rao Bonala100% (2)

- Impact of Source Impedance On ANSI 2W Transformer Damage Curve PDFDocument4 pagesImpact of Source Impedance On ANSI 2W Transformer Damage Curve PDFgilbertomjcNo ratings yet

- MV Capacitor CalculationDocument2 pagesMV Capacitor CalculationPramod B.Wankhade100% (1)

- ETAP Workshop Notes Creating New Project File & One Line DiagramDocument7 pagesETAP Workshop Notes Creating New Project File & One Line DiagramHamza Ziane0% (1)

- Etap Tip 013Document2 pagesEtap Tip 013Miguel Blasco Martínez100% (1)

- II.2 Set-2 Differential Protection For 380KV Dhahiyah Line-1 P546Document4 pagesII.2 Set-2 Differential Protection For 380KV Dhahiyah Line-1 P546Jay WinNo ratings yet

- Protection Relay Coordination Study - Comments From Middle East ClientDocument4 pagesProtection Relay Coordination Study - Comments From Middle East ClientnknfiveNo ratings yet

- Etap FinalDocument27 pagesEtap FinalJaya Rajesh Raaj100% (1)

- ArcFlash Example14 PDFDocument3 pagesArcFlash Example14 PDFgilbertomjcNo ratings yet

- Design of Electrical System Based On Short Circuit PDFDocument6 pagesDesign of Electrical System Based On Short Circuit PDFDeri Rio HeryantoNo ratings yet

- Procedure For IEEE 1584 Based Arc Flash Calculations - Electric Arc PDFDocument3 pagesProcedure For IEEE 1584 Based Arc Flash Calculations - Electric Arc PDFanuragpugaliaNo ratings yet

- SIZING TRANSFORMERS FOR LARGE MOTOR LOADSDocument20 pagesSIZING TRANSFORMERS FOR LARGE MOTOR LOADSserban_el100% (1)

- Appendix C Fault Level Calculation Rev 0Document2 pagesAppendix C Fault Level Calculation Rev 0Vikram SinghNo ratings yet

- Neta World Warren Industry TopicsDocument4 pagesNeta World Warren Industry TopicsDhruvam PandyaNo ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- ShortCircuit - Table of ContentDocument8 pagesShortCircuit - Table of ContentFasil Paruvanath0% (1)

- Calculation For Short Circuit Current Calculation Using IEC IEEE Standard PDFDocument11 pagesCalculation For Short Circuit Current Calculation Using IEC IEEE Standard PDFMaktoob M Knif100% (1)

- Load Flow Analysis PDFDocument5 pagesLoad Flow Analysis PDFDhiren PrajapatiNo ratings yet

- Chapter 3 Iec 60909Document6 pagesChapter 3 Iec 60909Fran R JayNo ratings yet

- Selective Coordination Breaker Application ChartDocument5 pagesSelective Coordination Breaker Application Charthanner90No ratings yet

- Wave Practice 2Document24 pagesWave Practice 2Soyoko U.No ratings yet

- ViscosityDocument17 pagesViscosityZzPumpkingNo ratings yet

- Assignment - Electrostatic Charge FieldDocument7 pagesAssignment - Electrostatic Charge FieldMohammad Sabihul HaqueNo ratings yet

- UCTE TerminologieDocument320 pagesUCTE TerminologieBogdan Vicol100% (1)

- Vdocuments - MX - The Physics of Archery 1Document29 pagesVdocuments - MX - The Physics of Archery 1Music PranaNo ratings yet

- Plekhanov-The Task of The Social-Democrats (1891)Document4 pagesPlekhanov-The Task of The Social-Democrats (1891)MattGildnerNo ratings yet

- d10sc4m DiodeDocument11 pagesd10sc4m DiodeHD QuanNo ratings yet

- Braking of Electric Motors: Need..... ?Document8 pagesBraking of Electric Motors: Need..... ?Ramesh VeerNo ratings yet

- S Ramp CalculationsDocument4 pagesS Ramp CalculationsRonald PeetersNo ratings yet

- Eastern Visayas CE Board Exam ReviewDocument6 pagesEastern Visayas CE Board Exam ReviewJoshuaNo ratings yet

- Contactors: Introduction - Contactors Power ContactorsDocument8 pagesContactors: Introduction - Contactors Power ContactorsBilal AhmadNo ratings yet

- Basic Electronics GuideDocument39 pagesBasic Electronics GuideHanhoaiNguyenNo ratings yet

- JEE Main Question Papers Answer Keys PDFDocument421 pagesJEE Main Question Papers Answer Keys PDFsaksham mishraNo ratings yet

- Chapter 4: Movement: The Keystone of Physical Education and SportDocument18 pagesChapter 4: Movement: The Keystone of Physical Education and SportAnonymous GzRz4H50FNo ratings yet

- Chapter 2Document23 pagesChapter 2jesunathan44@yahoo.comNo ratings yet

- Basic Electronic Components (Post 1st Year Training ECE)Document23 pagesBasic Electronic Components (Post 1st Year Training ECE)Cutie100% (4)

- Varispeed V7 MANUALDocument256 pagesVarispeed V7 MANUALMateus CorrêaNo ratings yet

- Earthing Principles and Practices in LV and MV Power SystemsDocument39 pagesEarthing Principles and Practices in LV and MV Power Systemssudershan rawatNo ratings yet

- Kech102 PDFDocument45 pagesKech102 PDFAlex RiderNo ratings yet

- InTech-Ultra Wideband Antennas For High Pulsed Power ApplicationsDocument31 pagesInTech-Ultra Wideband Antennas For High Pulsed Power ApplicationsprasenjitmailNo ratings yet

- SCIENCE 6 PPT Q3 W2 - Gravitation and Frictional ForcesDocument16 pagesSCIENCE 6 PPT Q3 W2 - Gravitation and Frictional Forcesmar galiaNo ratings yet

- The Linear Variable Differential Transformer (LVDT) Position Sensor For Gravitational Wave Interferometer Low-Frequency ControlsDocument19 pagesThe Linear Variable Differential Transformer (LVDT) Position Sensor For Gravitational Wave Interferometer Low-Frequency Controlsnikhilrane91_7522800No ratings yet

- MEG1000 ManualDocument17 pagesMEG1000 ManualKostas TressosNo ratings yet

- N ' L M I: Ewton S Aws of OtionDocument8 pagesN ' L M I: Ewton S Aws of OtionSamyak JainNo ratings yet

- Springs 3 231118 200148Document25 pagesSprings 3 231118 2001486153No ratings yet

- Design & Development of Helmholtz Coil For Hyperpolarized MRIDocument6 pagesDesign & Development of Helmholtz Coil For Hyperpolarized MRIJosué Daniel Meneses DíazNo ratings yet