Professional Documents

Culture Documents

Level Sensors

Uploaded by

владимир николенкоOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Level Sensors

Uploaded by

владимир николенкоCopyright:

Available Formats

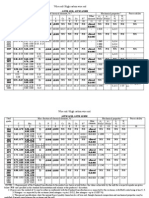

Capacitive Level Sensor

4/29/2012

L = level, Z = impedance, 1 = tank http://www.automation-talk.info/ 2 = liquid, 3 and 4 = electrodes.

Working Principle of Capacitive Sensor

http://www.automation-talk.info/

Conductivity and capacitive level sensors serve as a continuous and point-level sensors by measuring the impedance between two electrodes immersed in the liquid or between one electrode and the electro conductive tank's wall

4/29/2012 http://www.automation-talk.info/ 2

Float Type Level Sensor

L = level, 1 = tank, 2 = liquid, 3 = float, 4 = magnet, 5= 4/29/2012 magnetic armature, 6 = contacts, 7 = bellows, 8 = lever. 3 http://www.automation-talk.info/

Working Principle of Float type Level Sensor

In a float-type level sensor the buoyancy force holds the float on the surface of the liquid. The float carries a member having a magnetic coupling with a transduction element (coil, magnetic reed), that is mounted on the outside wall of the tank and can be actuated by the proximity of the float. In some designs, the float mechanically links the switching mechanism through the sealing in the wall (e.g., bellows). The switching system can respond to the restraining force developed by a spring element connected to the float

4/29/2012 http://www.automation-talk.info/ 4

Inductive Level Transducer

(a)Variable-inductance type (b) transformer-type level transducer L = level, Z = impedance, 1 = tank, 2 = liquid, 3 = coil, 4 =core

4/29/2012 http://www.automation-talk.info/ 5

Principle of Inductive level sensor

It is used in application of measurement of the level of liquid metals and other electro conductive liquids. In one of the designs, a coil is wound around a tube containing the liquid. The inductance of this coil changes rapidly as the liquid moves and approaches the coil. In another design, the transducer is introduced by a transformer with a primary coil wound on one limb of a twin-limbed iron core. The other limb is enclosed by a tube containing the liquid and forming one turn of the secondary winding. The effective resistance of this turn is inversely proportional to the height of the liquid column in the tube. The change in the height can be sensed by measuring the power consumption at the primary coil

4/29/2012 http://www.automation-talk.info/ 6

Photoelectric level sensor

(a) Transmittance-mode (b) reflectance-mode L = level, 1 = tank, 2 = liquid, 3 = light source, 4 = photo detector, 5 = prism

4/29/2012 http://www.automation-talk.info/ 7

Principle of Photoelectric level sensor

Operate in transmittance or reflection modes. In the transmittance mode, a sensing system, including a light beam source and a photo detector responds to the interruption of the light beam when the liquid breaks the beam path from the source to the detector. In the reflection mode, an optical prism mounted inside a tank changes the reflectance of the light when it is immersed in the liquid. The construction of the transducer is arranged so that a light source and photo detector for sensing the change in the light's intensity are mounted on the outside wall of the tank. The light beam passes through and is reflected from the faces 4/29/2012 http://www.automation-talk.info/ 8 of the prism

Pressure Type level sensor

L = level, 1 = tank, 2 = liquid, 3 = pressure transducer

4/29/2012 http://www.automation-talk.info/ 9

Working Principle of pressure type level sensor

A pressure-type level sensing system contains a pressure transducer mounted at the bottom of a liquid-filled tank. The transducer responds to the pressure developed by the weight of the liquid's column. This pressure is directly proportional to the measured height

4/29/2012 http://www.automation-talk.info/ 10

Weighing type level sensor

L= level, 1 = tank, 2 = liquid, 3 = load cell

4/29/2012 http://www.automation-talk.info/ 11

Working Principle of weighing type level sensor

A weighing sensing system for measuring level determines the level with load cells placed underneath the bottom of the tank or connected to the tank by a mechanical link. If the tank's weight and liquid's density are known, the level is readily calculated using data obtained with the cells.

4/29/2012

http://www.automation-talk.info/

12

Robotic Sensing

Stacking Height Control

4/29/2012

People Detection / Counting http://www.automation-talk.info/

13

Irregular Parts Detection For Hoppers and Feeder Bowls

Box Sorting Using Ultrasonic Monitoring System

4/29/2012

http://www.automation-talk.info/

14

Quality Control Inspection

http://www.automation-talk.info/

4/29/2012

Web Break Detection http://www.automation-talk.info/

15

www.automation-talk.info/

Thanks for Visiting. Do visit Again.

4/29/2012

http://www.automation-talk.info/

16

You might also like

- Point/Liquid Level Switch Measurement SystemsDocument6 pagesPoint/Liquid Level Switch Measurement SystemsJustin Paul CongeNo ratings yet

- Level ControlDocument7 pagesLevel ControlJoshua Peter Evangelista CadoyNo ratings yet

- Level Sensor NewDocument15 pagesLevel Sensor NewMaiud Abdalate OtmanNo ratings yet

- Level sensor guideDocument15 pagesLevel sensor guideMaiud Abdalate OtmanNo ratings yet

- 12level Sensor Mpklldfvfregreererwee rww343qr4 Sdfgrewretwerfserwetwrt43top4ipiprq Ewire0w0eowf0e JHOIIP90I90-9Document15 pages12level Sensor Mpklldfvfregreererwee rww343qr4 Sdfgrewretwerfserwetwrt43top4ipiprq Ewire0w0eowf0e JHOIIP90I90-9Maiud Abdalate OtmanNo ratings yet

- Moh AwadDocument17 pagesMoh AwadMohammedAwadAlwarfleNo ratings yet

- Level Senso SsDocument15 pagesLevel Senso SsMaiud Abdalate OtmanNo ratings yet

- Mlevel Sensor KKJ FGHDocument17 pagesMlevel Sensor KKJ FGHMohammedAwadAlwarfleNo ratings yet

- Measuring Spatial and Mechanical Variables GuideDocument42 pagesMeasuring Spatial and Mechanical Variables GuideAbeyu AssefaNo ratings yet

- LDT 16mp ManualDocument22 pagesLDT 16mp ManualMay M. TanNo ratings yet

- POINTDocument12 pagesPOINTMervin GautaneNo ratings yet

- S&i 1Document9 pagesS&i 1Adi KhardeNo ratings yet

- Automation in Water Distribution SystemDocument27 pagesAutomation in Water Distribution SystemKunal DeshmukhNo ratings yet

- Loat Transducer: Presented by Bilal Sarfraz Suffian Butt Hafiz AamirDocument18 pagesLoat Transducer: Presented by Bilal Sarfraz Suffian Butt Hafiz Aamirbilal sarfrazNo ratings yet

- Level Measurement DevicesDocument23 pagesLevel Measurement DevicesRahul JaiswalNo ratings yet

- Level Measurement - Course NotesDocument19 pagesLevel Measurement - Course Notespawan deepNo ratings yet

- AU-222-Automobile Instrumentation: Lecture No:16 DR - Saqib Jamshed RindDocument19 pagesAU-222-Automobile Instrumentation: Lecture No:16 DR - Saqib Jamshed RindAkber AnwarNo ratings yet

- Water Level IndicatorDocument11 pagesWater Level Indicatorpooja choudharyNo ratings yet

- Level Control (Our Report)Document31 pagesLevel Control (Our Report)Brishti Anwar100% (1)

- Level BasicsDocument22 pagesLevel Basicscool_rdNo ratings yet

- KUET Mechatronics Lab 01 on Sensors and SwitchesDocument22 pagesKUET Mechatronics Lab 01 on Sensors and SwitchesSourav RoyNo ratings yet

- Liquid Level MeasurementDocument11 pagesLiquid Level Measurementh.alipooriraniNo ratings yet

- MAINTOPIC Displacement MeasurementDocument43 pagesMAINTOPIC Displacement MeasurementLoreto CorderoNo ratings yet

- ICE Activity #3Document6 pagesICE Activity #3Groove GamingNo ratings yet

- Ic & S r16 - Unit-3Document28 pagesIc & S r16 - Unit-3nclary lazurNo ratings yet

- KYAMBOGO UNIVERSITY FACULTY OF SCIENCE DEPARTMENT OF CHEMISTRY BACHELOR OF SCIENCE IN CHEMICAL ENGINEERING YEAR 3, SEMESTER 1 INTRUMENTATION COURSE WORKDocument13 pagesKYAMBOGO UNIVERSITY FACULTY OF SCIENCE DEPARTMENT OF CHEMISTRY BACHELOR OF SCIENCE IN CHEMICAL ENGINEERING YEAR 3, SEMESTER 1 INTRUMENTATION COURSE WORKPaul RwomwijhuNo ratings yet

- Aparat Complex Pentru Analitica Apei. FinalDocument2 pagesAparat Complex Pentru Analitica Apei. FinalSidor AncaNo ratings yet

- Float Switch: Level Sensors Detect The Level of Liquids and Other Fluids and Fluidized Solids, IncludingDocument4 pagesFloat Switch: Level Sensors Detect The Level of Liquids and Other Fluids and Fluidized Solids, IncludingsweetsureshNo ratings yet

- Electric and Magnetic Sensors Actuators GuideDocument103 pagesElectric and Magnetic Sensors Actuators GuideGautam ChhabraNo ratings yet

- Liquid Level Measuring DevicesDocument4 pagesLiquid Level Measuring DevicesAnia SzyszkaNo ratings yet

- Instruments Training & Calibration PDFDocument95 pagesInstruments Training & Calibration PDFSreedhar PayyavulaNo ratings yet

- 08 - Chapter 1 PDFDocument39 pages08 - Chapter 1 PDFmannuu00100% (1)

- CFF M4Document12 pagesCFF M4saikrishnaps31No ratings yet

- 19d41a0307 Technical Seminar Document ModifiedDocument32 pages19d41a0307 Technical Seminar Document Modified20-119 KATRAVATH HARINo ratings yet

- PMC AssignmentDocument5 pagesPMC AssignmentKuda ChiroNo ratings yet

- Unit 4Document15 pagesUnit 4Hemanth Kumar VuribindiNo ratings yet

- Elements of Industrial Automation Week 03 NotesDocument7 pagesElements of Industrial Automation Week 03 NotesThanmay JSNo ratings yet

- Level GaugeDocument3 pagesLevel Gaugemerijan10No ratings yet

- LECTURE2Document25 pagesLECTURE2Kenani SaningaNo ratings yet

- Module 3Document10 pagesModule 3Michael godsonNo ratings yet

- Position, Displacement, and Proximity SensorsDocument27 pagesPosition, Displacement, and Proximity SensorsNyandaMadili MalashiNo ratings yet

- Transducers ExplainedDocument16 pagesTransducers ExplainedKenani SaningaNo ratings yet

- Watr LVL IndDocument21 pagesWatr LVL IndNaseem KhanNo ratings yet

- Sensor-Lect10Document24 pagesSensor-Lect10Jamal AbdullayevNo ratings yet

- Lecture Notes 14Document32 pagesLecture Notes 14Abdul Hakeem Semar KamaluddinNo ratings yet

- Engineering Knowledge (Border) FormatDocument8 pagesEngineering Knowledge (Border) FormatLegate LaniusNo ratings yet

- Sensors IA2Document7 pagesSensors IA2Pavan MNo ratings yet

- Control and MeasurementDocument16 pagesControl and MeasurementSandeep TanwarNo ratings yet

- Engineering Knowledge (Border) Format2Document38 pagesEngineering Knowledge (Border) Format2Vanessa RafaelNo ratings yet

- Een 11 Midterm Lec4Document31 pagesEen 11 Midterm Lec4Miggy VelasquezNo ratings yet

- Position Sensor: D KA CDocument8 pagesPosition Sensor: D KA CJamalkhanNo ratings yet

- 1-Level MeasurementDocument15 pages1-Level MeasurementAhmed KamelNo ratings yet

- Non Contact Sensor PDFDocument24 pagesNon Contact Sensor PDFGaurav R AgrawalNo ratings yet

- Level Switches 34Document25 pagesLevel Switches 34Hashem AliNo ratings yet

- A Pressure Sensor Measures PressureDocument12 pagesA Pressure Sensor Measures PressureSuvriti BishtNo ratings yet

- Ans: Electrical Pressure Sensor: Pressure Transducer Either Converts The Pressure IntoDocument6 pagesAns: Electrical Pressure Sensor: Pressure Transducer Either Converts The Pressure IntoSpryknterNo ratings yet

- ASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsDocument4 pagesASTM - D522 - 1993 Reapproved 2008 - Standard Test Methods For Mandrel Bend Test of Attached Organic CoatingsArmaghan ShiekhNo ratings yet

- Introduction To Aspen Plus 2013 Tutorial VDocument77 pagesIntroduction To Aspen Plus 2013 Tutorial VsyafieqNo ratings yet

- International Chemical Control Toolkit: Draft GuidelinesDocument15 pagesInternational Chemical Control Toolkit: Draft GuidelinesGuilherme BoscolliNo ratings yet

- RS 205 vacuum filler series for medium productionsDocument8 pagesRS 205 vacuum filler series for medium productionsSebastian RaduNo ratings yet

- Geology Geophysics in Oil ExplorationDocument70 pagesGeology Geophysics in Oil Explorationberbere68100% (1)

- 1 DNA Structure and ReplicationDocument96 pages1 DNA Structure and ReplicationmattMd100% (1)

- Bio Molecules 9Document3 pagesBio Molecules 9SilVI MARDELNo ratings yet

- Tissue Culture: Very Short Answer QuestionsDocument4 pagesTissue Culture: Very Short Answer QuestionskzrdurNo ratings yet

- Odour Filtration Range From BioactionDocument24 pagesOdour Filtration Range From BioactionLarry Botham100% (1)

- Decolorization and Organic Removal From Palm Oil Mill Effluent by Fenton's ProcessDocument5 pagesDecolorization and Organic Removal From Palm Oil Mill Effluent by Fenton's Processagungtiyo21No ratings yet

- Aerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionDocument16 pagesAerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionAlberto De La CruzNo ratings yet

- Fluid Flow Pressure Drop and Friction LossDocument148 pagesFluid Flow Pressure Drop and Friction Losslkjasdf8879100% (1)

- Dubai Municipality G+12 Concrete & Shoring QuestionsDocument7 pagesDubai Municipality G+12 Concrete & Shoring QuestionsMohammed Nasih Vettathur100% (2)

- A307 10Document6 pagesA307 10solrac4371No ratings yet

- 1400 10MDocument5 pages1400 10MAngelia WileyNo ratings yet

- Flexible PavementsDocument13 pagesFlexible PavementsAhmad NajiNo ratings yet

- High Carbon Wire RodDocument9 pagesHigh Carbon Wire Rodninganray6316100% (1)

- Ethanol Production by Fermentation and DistillationDocument3 pagesEthanol Production by Fermentation and DistillationChris WarnerNo ratings yet

- Use of Mössbauer Spectroscopy To Study Reaction Products of Polyphenols and Iron CompoundsDocument11 pagesUse of Mössbauer Spectroscopy To Study Reaction Products of Polyphenols and Iron CompoundsOmar MorteoNo ratings yet

- 6.3 RedoxDocument11 pages6.3 RedoxJosceline YeohNo ratings yet

- UTM Arau Prepares 4-BromobenzophenoneDocument7 pagesUTM Arau Prepares 4-BromobenzophenoneMay Lee100% (1)

- Vertical forces-WPS OfficeDocument2 pagesVertical forces-WPS OfficeJesusa EstradaNo ratings yet

- Water Flooding: Buckely-Leverett TheoryDocument23 pagesWater Flooding: Buckely-Leverett Theoryبشير الزامليNo ratings yet

- ADMIX CATALOG 2015 16 WEB Links PDFDocument248 pagesADMIX CATALOG 2015 16 WEB Links PDFdan0427No ratings yet

- Equal Percentage Control Valves and Applications - Control NotesDocument6 pagesEqual Percentage Control Valves and Applications - Control NotesShubham PisalNo ratings yet

- Drilling Formulas Calculation Sheet Verson 1.4Document190 pagesDrilling Formulas Calculation Sheet Verson 1.4Adedire FisayoNo ratings yet

- X-MET8000: X-MET8000 For The Analysis of PT, PD and RH in Catalytic ConvertersDocument4 pagesX-MET8000: X-MET8000 For The Analysis of PT, PD and RH in Catalytic ConvertersAnson AndrewsNo ratings yet

- Nutritive Evaluation of Ammoniated Benggala GrassDocument2 pagesNutritive Evaluation of Ammoniated Benggala GrassRolan TuturoongNo ratings yet