Professional Documents

Culture Documents

By: Archit Gupta Aruncs Arun G Ashwaty Ravi B Rajni

Uploaded by

Asha ViswanathanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

By: Archit Gupta Aruncs Arun G Ashwaty Ravi B Rajni

Uploaded by

Asha ViswanathanCopyright:

Available Formats

BY: Archit Gupta Arun C S Arun G Ashwaty Ravi B Rajni

Introduction Properties Chemical structure Production methods Uses

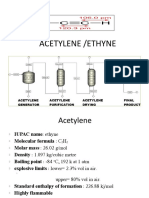

Gaseous organic compound with the formula C2H2 IUPAC name Acetylene. Systematic name Ethyne. Acetylene, either as gas or liquid is very explosive Easily decomposable into the elements(2C + H2) can be initiated by heat or mechanical shock Storage requires addition of a mutual solvent (acetone) and a porous inert material (asbestos) as safe release carrier.

Colourlesss gas 26.04g/mol-molar mass Triple point -86.6 C and 961.5 mm Hg pressure Ignition point 305 C MP: -80.8 C,BP:84 C

In terms of valence bond theory, in each carbon atom the 2s orbitals hybridizes with one 2p orbital thus forming an sp hybrid. The other two 2p orbitals remain unhybridized. The two ends of the two sp hybrid orbitals overlap to form a strong valence bond between the carbons, while on each of the other two ends hydrogen atoms attach also by bonds. The two unchanged 2p orbitals form a pair of weaker valence bond

From petroleum hydrocarbons

1. Partial or Stage-wise combustion 2. Pyrolysis 3. Arc process

From Calcium carbide

Raw Materials

1. Natural gas or higher mol.wt hydrocarbon 2. Low purity grade oxygen

Chemical reactions

1. Exothermic heat supply 2. Endothermic production reaction

CH4 + 2O2 CO2 + 2H2O 2CH4 C2H2 + 3H2 C2H2 2C + H2

3. Undesirable side reaction

Hydrocarbon feed and low purity oxygen are heated separately to 550 C Then fed to an acetylene production burner which can be designed for one-stage or twostage operation. The hydrocarbon is cracked to acetylene at the 1500 C operating temperature Then product gases are quenched immediately to avoid undue pyrolysis of acetylene .

The residence time is less than 100 milliseconds. Carbon black is removed in the water quench and on a moving bed. Separation of polymers from acetylene

Acetylene and its dimer are absorbed in cold dimethyl formamide and then stripped in a fractionating column.

Thermodynamic and kinetic consideration.

1. Rapid heat-up to induce the pyrolysis and then quench to low temperature again before the back reaction and side reaction to produce C + H2 becomes significant.

Burner design

1. One stage burner. 2. Two stage burner.

Separation of polymer and purification of acetylene Design of explosion proof plant operation

The polymerization of acetylene with Ziegler Natta catalysts produces polyacetylene films. Polyacetylene, a chain of CH centres with alternating single and double bonds, was the one of first discovered organic semiconductors. Its reaction with iodine produces a highly electrically conducting material. Although such materials are not useful, these discoveries led to the developments of organic semiconductors.

Welding

Acetylene is sometimes used for carburization (that is, hardening) of steel when the object is too large to fit into a furnace. Acetylene is used to volatilize carbon in radiocarbon dating.

Combustion of acetylene with oxygen produces a flame of over 3600 K , releasing 11.8 KJ/g. Oxyacetylene is the hottest burning common fuel gas. Acetylene is the third hottest natural chemical flame.

Reppe chemistry

In the presence of metal catalyst, acetylene can react to give a wide range of industrially significant chemicals. With alcohols, hydrogen cyanide, hydrogen chloride, or carboxylic acid to give vinyl compounds:

With aldehydes to give ethynyl diols.

1,4Butynediol is produced industrially in this way from formaldehyde and acetylene.

With carbon monoxide to give acrylic acid, or acrylic esters, which can be used to produce acrylic glass.

Cyclicization to give benzene and cyclooctatetraene

Highly flammable. Acetylene can explode with extreme violence if the pressure of the gas exceeds about 200 kPa It is therefore shipped and stored dissolved in acetone or dimmethylformamide (DMF), contained in a metal cylinder with a porous filling , which renders it safe to transport and use, given proper handling.

THANK YOU

You might also like

- HHO Generation System For WeldingDocument17 pagesHHO Generation System For WeldingAbhilash Koka100% (2)

- Chemistry HSC Full Notes BEST NOTESDocument83 pagesChemistry HSC Full Notes BEST NOTESiloverabows100% (5)

- ASME Pressue Vessel ExampleDocument271 pagesASME Pressue Vessel ExamplesavanchandranNo ratings yet

- Theoretical CyclesDocument49 pagesTheoretical CyclesMariaEzzaSyUyNo ratings yet

- DJI F450 Construction Guide WebDocument21 pagesDJI F450 Construction Guide WebPutu IndrayanaNo ratings yet

- CulvertsDocument18 pagesCulvertsAmmar A. Ali100% (1)

- D06-002 - Fundamentals of Gas Cutting and Welding - USDocument73 pagesD06-002 - Fundamentals of Gas Cutting and Welding - USAjesh TGNo ratings yet

- Multi Organ Dysfunction SyndromeDocument40 pagesMulti Organ Dysfunction SyndromeDr. Jayesh PatidarNo ratings yet

- Water Gas Shift Reaction: Research Developments and ApplicationsFrom EverandWater Gas Shift Reaction: Research Developments and ApplicationsNo ratings yet

- The 10 Most Famousfilipino Artists and Their MasterworksDocument3 pagesThe 10 Most Famousfilipino Artists and Their MasterworksGina MagtibayNo ratings yet

- Brown GasDocument9 pagesBrown GasSagar Sachdeva100% (1)

- Kinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide CatalystsDocument9 pagesKinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide Catalysts李国俊No ratings yet

- Fuels & CombustionDocument44 pagesFuels & CombustionKaran Thakur100% (1)

- 2017CHE008 DetailedProcessDescription1Document17 pages2017CHE008 DetailedProcessDescription1Xi Liinett AqkoNo ratings yet

- Oxy Acetylene WeldingDocument27 pagesOxy Acetylene WeldingMudit DubeyNo ratings yet

- Autothermal Reforming ProcessDocument9 pagesAutothermal Reforming ProcessOliver Everett EspinoNo ratings yet

- FebvreDocument449 pagesFebvreIan Pereira AlvesNo ratings yet

- AcetyleneDocument13 pagesAcetyleneImtiaz AliNo ratings yet

- Compiled LecsDocument24 pagesCompiled LecsNur SetsuNo ratings yet

- Chapter 2-Gas WeldingDocument45 pagesChapter 2-Gas Weldingsipi maseleNo ratings yet

- Fundamentals of Gas Welding and CuttingDocument85 pagesFundamentals of Gas Welding and CuttingScott TrainorNo ratings yet

- Acetaldehyde Methods 2520of 2520 ProductionDocument6 pagesAcetaldehyde Methods 2520of 2520 Productionapi-3714811100% (3)

- Production of Acetylene and Acetylene-Based Chemicals From CoalDocument18 pagesProduction of Acetylene and Acetylene-Based Chemicals From CoalS.P.No ratings yet

- WeldingDocument193 pagesWeldingavutu_kunduruNo ratings yet

- Pyrolysis Furnace Rev 1 PDFDocument11 pagesPyrolysis Furnace Rev 1 PDFKmajdianNo ratings yet

- Flowchart For AcetaldehydeDocument2 pagesFlowchart For Acetaldehydeyigitilgaz0% (1)

- Pellicon 2 Validation Guide PDFDocument45 pagesPellicon 2 Validation Guide PDFtakwahs12135No ratings yet

- H2 ProductionDocument43 pagesH2 Productionnouman khanNo ratings yet

- Fuel AnalysisDocument34 pagesFuel AnalysisYedla Santosh kumar100% (2)

- Acetylene: Acetylene (Systematic Name: Ethyne) Is A HydrocarbonDocument6 pagesAcetylene: Acetylene (Systematic Name: Ethyne) Is A HydrocarbonS_VenkatNo ratings yet

- Lecture 7Document8 pagesLecture 7remi1988No ratings yet

- 3220 Daywan PeDocument7 pages3220 Daywan PeBenjamin Luke Jacildo IIINo ratings yet

- Acetylene How Products Are MadeDocument3 pagesAcetylene How Products Are MadeJoy MukherjeNo ratings yet

- Fundamentals of Gas Welding and CuttingDocument73 pagesFundamentals of Gas Welding and CuttingDilipNo ratings yet

- Cracking Term PaperDocument13 pagesCracking Term PaperKrittikaNo ratings yet

- Planta de AcetilenoDocument50 pagesPlanta de AcetilenoEduardo Vazquez NavarreteNo ratings yet

- Oxy Fuel WeldingDocument5 pagesOxy Fuel WeldingRao YasirNo ratings yet

- Alkanes: Draw Out and Name The Structural Isomers of C H and C HDocument7 pagesAlkanes: Draw Out and Name The Structural Isomers of C H and C Hsayma_akhter5074No ratings yet

- Alkanes: Alkanes Alkanes Alkenes Hydrocarbons As Fuels ArenesDocument23 pagesAlkanes: Alkanes Alkanes Alkenes Hydrocarbons As Fuels ArenesTeejay MakazhuNo ratings yet

- Alkanes: Draw Out and Name The Structural Isomers of C H and C HDocument7 pagesAlkanes: Draw Out and Name The Structural Isomers of C H and C H897291868No ratings yet

- CrackingDocument5 pagesCrackingnorlin facultadNo ratings yet

- EXPE8Document5 pagesEXPE8K-yanVehraaYomomaNo ratings yet

- Production of Pure Hydrogen by Ethanol DehydrogenationDocument9 pagesProduction of Pure Hydrogen by Ethanol DehydrogenationAbdulwahid SultanNo ratings yet

- DemonstrationsDocument42 pagesDemonstrationsJosé YalibatNo ratings yet

- Petrochemistry: Instructor: DAO THI KIM THOADocument25 pagesPetrochemistry: Instructor: DAO THI KIM THOASong Nguyên NguyễnNo ratings yet

- Act. 11 Answer To QuestionsDocument3 pagesAct. 11 Answer To QuestionsruruNo ratings yet

- Electrochemical Reduction of Co TO Methane in Methanol at Low TemperatureDocument2 pagesElectrochemical Reduction of Co TO Methane in Methanol at Low TemperatureHassaanNo ratings yet

- Mod 1 Revision Guide Organic2Document6 pagesMod 1 Revision Guide Organic2Saifulahmed49No ratings yet

- Gupta 1991Document6 pagesGupta 1991Andrian NugrohoNo ratings yet

- Oxy-Fuel Gas Welding ProcessDocument106 pagesOxy-Fuel Gas Welding ProcessAbere GetachewNo ratings yet

- 19.-Pyrolysis FurnaceDocument5 pages19.-Pyrolysis FurnaceWilfredo PastranaNo ratings yet

- Hydrogenation of Ethyl Acetate To Ethanol Over Bimetallic Cu-Zn/Sio Catalysts Prepared by Means of CoprecipitationDocument6 pagesHydrogenation of Ethyl Acetate To Ethanol Over Bimetallic Cu-Zn/Sio Catalysts Prepared by Means of CoprecipitationAtul TripathiNo ratings yet

- c1 Revision Poster - Set 1 OnlyDocument3 pagesc1 Revision Poster - Set 1 Onlyapi-320022467No ratings yet

- Aceytlene Paper AIPDocument14 pagesAceytlene Paper AIPlakshmanantNo ratings yet

- CombustionDocument5 pagesCombustionnabeelNo ratings yet

- 2H (G) + O (G) 2H O (G) : CombustionDocument6 pages2H (G) + O (G) 2H O (G) : CombustionWilliam Dave DomasinNo ratings yet

- Measuring The Dewpoint of Hydrogen Forming Gas With A Zirconia Oxygen Sensor White Paper v1.0Document11 pagesMeasuring The Dewpoint of Hydrogen Forming Gas With A Zirconia Oxygen Sensor White Paper v1.0phongNo ratings yet

- Georgia Tech Sponsored ResearchDocument51 pagesGeorgia Tech Sponsored ResearchChristian SmallenNo ratings yet

- Lecture Notes Chem 51B S. King: ELECTRON DENSITY Around The Carbon Atom Rather Than A Complete Transfer ofDocument16 pagesLecture Notes Chem 51B S. King: ELECTRON DENSITY Around The Carbon Atom Rather Than A Complete Transfer ofHuấnĐìnhNguyễnNo ratings yet

- The Dehydrogenation of Isopropanol To Form Hydrogen GasDocument31 pagesThe Dehydrogenation of Isopropanol To Form Hydrogen GasEdidiong AsuquoNo ratings yet

- Webversion Production of EthyleneDocument7 pagesWebversion Production of EthyleneasyenvladiNo ratings yet

- Sustainable Energy: Linfeng ZhangDocument49 pagesSustainable Energy: Linfeng ZhangLuli NikiNo ratings yet

- IC Engine FuelDocument116 pagesIC Engine FueluchihaenomiNo ratings yet

- National Institute of Textile Engineering and Research (NITER)Document3 pagesNational Institute of Textile Engineering and Research (NITER)shahadat hossainNo ratings yet

- Acetylene Production-2023 4Document31 pagesAcetylene Production-2023 4Divyansh NagarNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- BITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball TesterDocument10 pagesBITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball Testerakash chNo ratings yet

- Reading Part 2Document14 pagesReading Part 2drama channelNo ratings yet

- Physics Unit 11 NotesDocument26 pagesPhysics Unit 11 Notesp.salise352No ratings yet

- Influence of Aesthetics Attributes of Brand Web Pages On Customer Brand EngagementDocument22 pagesInfluence of Aesthetics Attributes of Brand Web Pages On Customer Brand EngagementNOOR AKMA AIDANo ratings yet

- 1 Circuit TheoryDocument34 pages1 Circuit TheoryLove StrikeNo ratings yet

- Rectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Document4 pagesRectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Lintas LtiNo ratings yet

- PH & TemperatureDocument8 pagesPH & TemperatureNanaNo ratings yet

- English Class Vii PDFDocument101 pagesEnglish Class Vii PDFpannapurohitNo ratings yet

- Conceptual Artist in Nigeria UNILAGDocument13 pagesConceptual Artist in Nigeria UNILAGAdelekan FortuneNo ratings yet

- Dairy Products Theory XIIDocument152 pagesDairy Products Theory XIIDskNo ratings yet

- Coding DecodingDocument21 pagesCoding DecodingAditya VermaNo ratings yet

- RepaHeel Beeswax-Based Gel For Treating Heel Spurs Has Been Produced in EUDocument2 pagesRepaHeel Beeswax-Based Gel For Treating Heel Spurs Has Been Produced in EUPR.comNo ratings yet

- Chapter 7: Protein Function Part I: Myoglobin and HemoglobinDocument27 pagesChapter 7: Protein Function Part I: Myoglobin and HemoglobineliNo ratings yet

- Karl MarxDocument4 pagesKarl Marxeirvine noah isidroNo ratings yet

- Bardonna MenuDocument16 pagesBardonna MenuFarley ElliottNo ratings yet

- 1F-Korean-Nami Mun - Miles From NowhereDocument4 pages1F-Korean-Nami Mun - Miles From NowhereNeil PatelNo ratings yet

- Ecall Vs NG EcallDocument6 pagesEcall Vs NG EcallTrần Văn DũngNo ratings yet

- G-3 L-17 Internal QuestionsDocument4 pagesG-3 L-17 Internal QuestionsActivity MLZS BarhNo ratings yet

- Frye LGD As A Function of The Default Rate 091013 PDFDocument13 pagesFrye LGD As A Function of The Default Rate 091013 PDFSushant SinghNo ratings yet

- V. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsDocument17 pagesV. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsxiangyugeotechNo ratings yet

- A Study On Traditional Medicinal Herbs Used by The Ethnic People of Goalpara District of Assam, North East IndiaDocument6 pagesA Study On Traditional Medicinal Herbs Used by The Ethnic People of Goalpara District of Assam, North East IndiaDr. Krishna N. SharmaNo ratings yet