Professional Documents

Culture Documents

Chapter 06 Avi

Uploaded by

anton_deocampoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 06 Avi

Uploaded by

anton_deocampoCopyright:

Available Formats

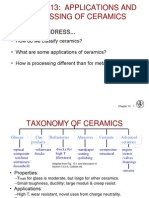

Chapter 6-

ISSUES TO ADDRESS...

Stress and strain: What are they and why are

they used instead of load and deformation?

Elastic behavior: When loads are small, how much

deformation occurs? What materials deform least?

Plastic behavior: At what point do dislocations

cause permanent deformation? What materials are

most resistant to permanent deformation?

1

Toughness and ductility: What are they and how

do we measure them?

CHAPTER 6:

MECHANICAL PROPERTIES

Chapter 6-

F

o

bonds

stretch

return to

initial

2

1. Initial 2. Small load 3. Unload

Elastic means reversible!

ELASTIC DEFORMATION

Chapter 6- 3

1. Initial 2. Small load 3. Unload

Plastic means permanent!

F

o

linear

elastic

linear

elastic

o

plastic

PLASTIC DEFORMATION (METALS)

Chapter 6- 4

Tensile stress, o: Shear stress, t:

o =

F

t

A

o

original area

before loading

Stress has units:

N/m

2

or lb/in

2

ENGINEERING STRESS

Chapter 6- 5

Simple tension: cable

o

o =

F

A

Simple shear: drive shaft

o

t =

F

s

A

Note: t = M/A

c

R here.

Ski lift (photo courtesy P.M. Anderson)

COMMON STATES OF STRESS

Chapter 6-

Canyon Bridge, Los Alamos, NM

6

Simple compression:

A

o

Balanced Rock, Arches

National Park

Note: compressive

structure member

(o < 0 here).

(photo courtesy P.M. Anderson)

(photo courtesy P.M. Anderson)

OTHER COMMON STRESS STATES (1)

Chapter 6- 7

Bi-axial tension: Hydrostatic compression:

Fish under water

Pressurized tank

o

z

> 0

o

u

> 0

o < 0

h

(photo courtesy

P.M. Anderson)

(photo courtesy

P.M. Anderson)

OTHER COMMON STRESS STATES (2)

Chapter 6- 8

Tensile strain: Lateral strain:

Shear strain:

u/2

t/2

t/2 - u

u/2

o/2

o/2

o

L

/2 o

L

/2

L

o

w

o

= tan u

Strain is always

dimensionless.

ENGINEERING STRAIN

Chapter 6-

Typical tensile specimen

9

Other types of tests:

--compression: brittle

materials (e.g., concrete)

--torsion: cylindrical tubes,

shafts.

Typical tensile

test machine

Adapted from Fig. 6.2,

Callister 6e.

Adapted from Fig. 6.3, Callister 6e.

(Fig. 6.3 is taken from H.W. Hayden,

W.G. Moffatt, and J. Wulff, The

Structure and Properties of Materials,

Vol. III, Mechanical Behavior, p. 2, John

Wiley and Sons, New York, 1965.)

STRESS-STRAIN TESTING

Chapter 6-

Modulus of Elasticity, E:

(also known as Young's modulus)

10

Hooke's Law:

o = E c

Poisson's ratio, v:

metals: v ~ 0.33

ceramics: ~0.25

polymers: ~0.40

Units:

E: [GPa] or [psi]

v: dimensionless

LINEAR ELASTIC PROPERTIES

Chapter 6-

Elastic Shear

modulus, G:

11

t

1

G

t = G

Elastic Bulk

modulus, K:

Special relations for isotropic materials:

P

P P

M

M

G=

E

2(1+ v)

K =

E

3(1 2v)

simple

torsion

test

pressure

test: Init.

vol =V

o

.

Vol chg.

= AV

OTHER ELASTIC PROPERTIES

Chapter 6- 12

0.2

8

0.6

1

Magnesium,

Aluminum

Platinum

Silver, Gold

Tantalum

Zinc, Ti

Steel, Ni

Molybdenum

Graphite

Si crystal

Glass -soda

Conc rete

Si nitride

Al oxide

PC

Wood( grain)

AFRE( fibers) *

CFRE *

GFRE*

Glass fibers only

Carbon fibers only

Aramid fibers only

Epoxy only

0.4

0.8

2

4

6

10

20

40

60

80

10 0

200

600

800

10 00

1200

400

Tin

Cu alloys

Tungsten

<100>

<111>

Si carbide

Diamond

PTFE

HDP E

LDPE

PP

Polyester

PS

PET

CFRE( fibers) *

GFRE( fibers)*

GFRE(|| fibers)*

AFRE(|| fibers)*

CFRE(|| fibers)*

Metals

Alloys

Graphite

Ceramics

Semicond

Polymers

Composites

/fibers

E(GPa)

10

9

Pa

Based on data in Table B2,

Callister 6e.

Composite data based on

reinforced epoxy with 60 vol%

of aligned

carbon (CFRE),

aramid (AFRE), or

glass (GFRE)

fibers.

YOUNGS MODULI: COMPARISON

Chapter 6-

Simple tension:

13

Simple torsion:

M=moment

o =angle of twist

2r

o

L

o

Material, geometric, and loading parameters all

contribute to deflection.

Larger elastic moduli minimize elastic deflection.

USEFUL LINEAR ELASTIC RELATIONS

Chapter 6- 14

Simple tension test:

(at lower temperatures, T < T

melt

/3)

PLASTIC (PERMANENT) DEFORMATION

Chapter 6- 15

Stress at which noticeable plastic deformation has

occurred.

when cp = 0.002

tensile stress, o

engineering strain, c

o

y

c

p

= 0.002

YIELD STRENGTH, o

y

Chapter 6- 16

Room T values

o

y(ceramics)

>>o

y(metals)

>> o

y(polymers)

Based on data in Table B4,

Callister 6e.

a = annealed

hr = hot rolled

ag = aged

cd = cold drawn

cw = cold worked

qt = quenched & tempered

YIELD STRENGTH: COMPARISON

Chapter 6- 17

Maximum possible engineering stress in tension.

Metals: occurs when noticeable necking starts.

Ceramics: occurs when crack propagation starts.

Polymers: occurs when polymer backbones are

aligned and about to break.

Adapted from Fig. 6.11,

Callister 6e.

TENSILE STRENGTH, TS

Chapter 6- 18

Room T values

TS

(ceram)

~TS

(met)

~ TS

(comp)

>> TS

(poly)

Based on data in Table B4,

Callister 6e.

a = annealed

hr = hot rolled

ag = aged

cd = cold drawn

cw = cold worked

qt = quenched & tempered

AFRE, GFRE, & CFRE =

aramid, glass, & carbon

fiber-reinforced epoxy

composites, with 60 vol%

fibers.

TENSILE STRENGTH: COMPARISON

Chapter 6-

Plastic tensile strain at failure:

19

Another ductility measure:

%AR =

A

o

A

f

A

o

x100

Note: %AR and %EL are often comparable.

--Reason: crystal slip does not change material volume.

--%AR > %EL possible if internal voids form in neck.

%EL =

L

f

L

o

L

o

x100

Adapted from Fig. 6.13,

Callister 6e.

DUCTILITY, %EL

Chapter 6-

Energy to break a unit volume of material

Approximate by the area under the stress-strain

curve.

20

smaller toughness-

unreinforced

polymers

Engineering tensile strain, c

Engineering

tensile

stress, o

smaller toughness (ceramics)

larg er toughness

(metals, PMCs)

TOUGHNESS

Chapter 6-

Resistance to permanently indenting the surface.

Large hardness means:

--resistance to plastic deformation or cracking in

compression.

--better wear properties.

21

Adapted from Fig. 6.18, Callister 6e. (Fig. 6.18 is adapted from G.F. Kinney, Engineering Properties

and Applications of Plastics, p. 202, John Wiley and Sons, 1957.)

HARDNESS

Chapter 6-

An increase in oy due to plastic deformation.

22

Curve fit to the stress-strain response:

HARDENING

Chapter 6-

Design uncertainties mean we do not push the limit.

Factor of safety, N

23

o

working

=

o

y

N

Often N is

between

1.2 and 4

Ex: Calculate a diameter, d, to ensure that yield does

not occur in the 1045 carbon steel rod below. Use a

factor of safety of 5.

o

working

=

o

y

N

220, 000N

t d

2

/ 4

|

\

|

.

|

5

DESIGN OR SAFETY FACTORS

Chapter 6-

Stress and strain: These are size-independent

measures of load and displacement, respectively.

Elastic behavior: This reversible behavior often

shows a linear relation between stress and strain.

To minimize deformation, select a material with a

large elastic modulus (E or G).

Plastic behavior: This permanent deformation

behavior occurs when the tensile (or compressive)

uniaxial stress reaches oy.

24

Toughness: The energy needed to break a unit

volume of material.

Ductility: The plastic strain at failure.

Note: For materials selection cases related to

mechanical behavior, see slides 22-4 to 22-10.

SUMMARY

Chapter 6-

Reading:

Core Problems:

Self-help Problems:

0

ANNOUNCEMENTS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- College of Engineering, Architecture, Fine Arts & Computing SciencesDocument2 pagesCollege of Engineering, Architecture, Fine Arts & Computing Sciencesanton_deocampoNo ratings yet

- Introduction To Data CommunicationDocument21 pagesIntroduction To Data Communicationanton_deocampoNo ratings yet

- Chapter 22: Materials Selection: Economic, Environ., & Design IssuesDocument17 pagesChapter 22: Materials Selection: Economic, Environ., & Design Issuesanton_deocampoNo ratings yet

- Heta Capacity of PolypropyleneDocument3 pagesHeta Capacity of PolypropyleneZaky IbenNo ratings yet

- Chapter 03 AviDocument24 pagesChapter 03 Avianton_deocampoNo ratings yet

- Chapter 18 AviDocument16 pagesChapter 18 Avianton_deocampoNo ratings yet

- Chapter 02 AviDocument19 pagesChapter 02 Avianton_deocampoNo ratings yet

- Lab Activity 2Document7 pagesLab Activity 2anton_deocampoNo ratings yet

- Chapter 21 AviDocument13 pagesChapter 21 Avianton_deocampoNo ratings yet

- Chapter 20 AviDocument11 pagesChapter 20 Avianton_deocampoNo ratings yet

- Chapter 16 AviDocument12 pagesChapter 16 Avianton_deocampoNo ratings yet

- Chapter 16 CorrosionDocument15 pagesChapter 16 CorrosionLuis Alejandro AvilaNo ratings yet

- Chapter 13 AviDocument18 pagesChapter 13 Avianton_deocampoNo ratings yet

- Chapter 14 15 AviDocument11 pagesChapter 14 15 Avianton_deocampoNo ratings yet

- Chapter 10 AviDocument20 pagesChapter 10 AviJohn PrincipioNo ratings yet

- Chapter 11 AviDocument21 pagesChapter 11 Avianton_deocampoNo ratings yet

- Chapter 12 AviDocument13 pagesChapter 12 Avianton_deocampoNo ratings yet

- Chapter 08 AviDocument25 pagesChapter 08 Avianton_deocampoNo ratings yet

- Chapter 09 AviDocument26 pagesChapter 09 Avianton_deocampoNo ratings yet

- Chapter 07 AviDocument30 pagesChapter 07 Avianton_deocampoNo ratings yet

- Chapter 04 AviDocument19 pagesChapter 04 AviSiva PraneethNo ratings yet

- Chapter 05 AviDocument21 pagesChapter 05 Avianton_deocampoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Soil LiquefactionDocument12 pagesSoil LiquefactionKikin Kikin PelukaNo ratings yet

- Usjr Temfacil Balance of Work Schedule Aug 25, 2022Document5 pagesUsjr Temfacil Balance of Work Schedule Aug 25, 2022Maribeth PalumarNo ratings yet

- Compare Blocks - ResultsDocument19 pagesCompare Blocks - ResultsBramantika Aji PriambodoNo ratings yet

- Fraktur Dentoalevolar (Yayun)Document22 pagesFraktur Dentoalevolar (Yayun)Gea RahmatNo ratings yet

- 11 Baby Crochet Cocoon Patterns PDFDocument39 pages11 Baby Crochet Cocoon Patterns PDFIoanaNo ratings yet

- HVCCI UPI Form No. 3 Summary ReportDocument2 pagesHVCCI UPI Form No. 3 Summary ReportAzumi AyuzawaNo ratings yet

- Fundermax Exterior Technic 2011gb WebDocument88 pagesFundermax Exterior Technic 2011gb WebarchpavlovicNo ratings yet

- 24.postpartum Period-Physiological Changes in The MotherDocument16 pages24.postpartum Period-Physiological Changes in The MotherHem KumariNo ratings yet

- Chap 2 Debussy - LifejacketsDocument7 pagesChap 2 Debussy - LifejacketsMc LiviuNo ratings yet

- Flood FillDocument1 pageFlood FillshubhamNo ratings yet

- LTE EPC Technical OverviewDocument320 pagesLTE EPC Technical OverviewCristian GuleiNo ratings yet

- A Study On Customer Satisfaction Towards Honda Bikes in CoimbatoreDocument43 pagesA Study On Customer Satisfaction Towards Honda Bikes in Coimbatorenkputhoor62% (13)

- Gauss Contest: Grade 8Document4 pagesGauss Contest: Grade 8peter100% (1)

- Plate-Load TestDocument20 pagesPlate-Load TestSalman LakhoNo ratings yet

- Troubleshooting Hydraulic Circuits: Fluid PowerDocument32 pagesTroubleshooting Hydraulic Circuits: Fluid PowerMi LuanaNo ratings yet

- Conjoint Analysis Basic PrincipleDocument16 pagesConjoint Analysis Basic PrinciplePAglu JohnNo ratings yet

- KoyoDocument4 pagesKoyovichitNo ratings yet

- Chain Surveying InstrumentsDocument5 pagesChain Surveying InstrumentsSachin RanaNo ratings yet

- The Art of Now: Six Steps To Living in The MomentDocument5 pagesThe Art of Now: Six Steps To Living in The MomentGiovanni AlloccaNo ratings yet

- 7890 Parts-Guide APDocument4 pages7890 Parts-Guide APZia HaqNo ratings yet

- SB Z Audio2Document2 pagesSB Z Audio2api-151773256No ratings yet

- Lyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticDocument13 pagesLyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticJayr Mercado0% (1)

- 07.03.09 Chest Physiotherapy PDFDocument9 pages07.03.09 Chest Physiotherapy PDFRakesh KumarNo ratings yet

- Application of Fertility Capability Classification System in Rice Growing Soils of Damodar Command Area, West Bengal, IndiaDocument9 pagesApplication of Fertility Capability Classification System in Rice Growing Soils of Damodar Command Area, West Bengal, IndiaDr. Ranjan BeraNo ratings yet

- 40 26Document3 pages40 26Maxi452No ratings yet

- Math 202: Di Fferential Equations: Course DescriptionDocument2 pagesMath 202: Di Fferential Equations: Course DescriptionNyannue FlomoNo ratings yet

- SOR 8th Ed 2013Document467 pagesSOR 8th Ed 2013Durgesh Govil100% (3)

- Flexibility Personal ProjectDocument34 pagesFlexibility Personal Projectapi-267428952100% (1)

- Thermal BurnsDocument50 pagesThermal BurnsPooya WindyNo ratings yet

- Interpreting Piping and Instrumentation DiagramsDocument41 pagesInterpreting Piping and Instrumentation DiagramsFredric Tun100% (2)