Professional Documents

Culture Documents

Wellbore Hydraulics, Pressure Drop Calculations

Uploaded by

Dan MorrellOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wellbore Hydraulics, Pressure Drop Calculations

Uploaded by

Dan MorrellCopyright:

Available Formats

1

PETE 661

Drilling Engineering

Lesson 4

Wellbore Hydraulics,

Pressure Drop Calculations

2

Wellbore Hydraulics

Hydrostatics

Buoyancy

Pipe Tension vs. Depth

Effect of Mud Pressure

Laminar and Turbulent Flow

Pressure Drop Calculations

Bingham Plastic Model

API Power-Law Model

3

Assignments:

READ: ADE Ch. 4

HW #3: On the Web. - Axial Tension

Due 09-20-04

4

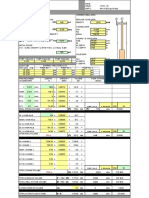

) D D ( 052 . 0 p p

1 i i

n

1 i

i 0

=

+ =

p

Fig. 4-3.

A Complex

Liquid

Column

D 052 . 0 p

p D 052 . 0 p

0

( p = (

+ p =

5

Fig. 4-4. Viewing the Well as a Manometer (U-Tube)

P

PUMP

= ?

6

Figure 4.4

} ) 000 , 10 ( 0 . 9 ) 000 , 1 ( 7 . 16

) 700 , 1 ( 7 . 12 ) 300 ( 5 . 8 ) 000 , 7 ( 5 . 10 { 052 . 0

0

+

+ + + = p p

a

psig 0

0

= p

psig 266 , 1 p

a

=

D 052 . 0 p ( p = (

7

Buoyancy Force = weight of fluid displaced

(Archimedes, 250 BC)

Figure 4-9. Hydraulic forces acting on a submerged body

8

Effective (buoyed) Weight

p

p

=

s

f

e

1 W W

Buoyancy Factor

Valid for a solid body or an open-ended pipe!

s

f

f

b e

W

- W

V - W

F W W

p

p =

p =

=

W

e

= buoyed weight

W = weight in air

F

b

= buoyancy force

V = volume of body

p

f

= fluid density

p

s

= body density

9

Example

For steel,

immersed in mud,

the buoyancy factor is:

gal / lbm .

s

5 65 = p

) gal / lbm . (

f

0 15 = p

771 . 0

5 . 65

0 . 15

1 1

s

f

=

p

p

A drillstring weighs 100,000 lbs in air.

Buoyed weight = 100,000 * 0.771 = 77,100 lbs

(= 490 lbm/ft

3

)

10

Axial Forces in Drillstring

F

b

= bit weight

F

1

& F

1

are pressure forces

11

Simple Example - Empty Wellbore

Drillpipe weight = 19.5 lbf/ft 10,000 ft

OD = 5.000 in

ID = 4.276 in

2 2

ID OD

4

A

x

=

A = 5.265 in

2

W = 19.5 lbf/ft * 10,000 ft = 195,000 lbf

AXIAL TENSION, lbf

D

E

P

T

H

,

f

t

0 lbf 195,000 lbf

12

Example - 15 lb/gal Mud in Wellbore

Drillpipe weight = 19.5 lbf/ft 10,000 ft

OD = 5.000 in

ID = 4.276 in

2 2

ID OD

4

A

x

=

A = 5.265 in

2

W = 195,000 - 41,100 = 153,900 lbf

AXIAL TENSION, lbf

D

E

P

T

H

,

f

t

0 195,000 lbf

Pressure at bottom = 0.052 * 15 * 10,000 = 7,800 psi

F = P * A

= 7,800 * 5.265

= 41,100 lbf

153,900 - 41,100

13

Axial Tension in Drill String

Example

A drill string consists of

10,000 ft of 19.5 #/ft drillpipe and

600 ft of 147 #/ft drill collars

suspended off bottom in 15#/gal mud

(F

b

= bit weight = 0).

What is the axial tension in the

drillstring as a function of depth?

14

Example

Pressure at top of collars

= 0.052 (15) 10,000 = 7,800 psi

Pressure at bottom of collars

= 0.052 (15) 10,600 = 8,268 psi

Cross-sectional area of pipe,

2

2

2

3

1

in 73 . 5

ft

in 144

*

ft / lb 490

ft / lb 5 . 19

A = =

A

1

10,000

10,600

15

Cross-sectional area of collars,

2

2

in 2 . 43 144 *

490

147

A = =

2

1

5 37 73 5 2 43 in . . .

A A area al Differenti

2

= =

=

A

2

A

1

Example contd

16

1. At 10,600 ft. (bottom of drill collars)

Compressive force = p A

= 357,200 lbf

[ axial tension = - 357,200 lbf ]

2

2

in 2 . 43 *

in

lbf

268 , 8 =

4

3

2

1

Example - contd

17

Example - contd

2. At 10,000 ft+ (top of collars)

F

T

= W

2

- F

2

- F

b

= 147 lbm/ft * 600 ft - 357,200

= 88,200 - 357,200

= -269,000 lbf

4

3

2

1

F

b

= F

BIT

= 0

18

3. At 10,000 ft - (bottom of drillpipe)

F

T

= W

1

+W

2

+F

1

-F

2

-F

b

= 88,200 + 7800 lbf/in

2

* 37.5in

2

- 357,200

= 88,200 + 292,500 - 357,200

= + 23,500 lbf

4

3

2

1

Example - contd

19

4. At Surface

F

T

= W

1

+ W

2

+ F

1

- F

2

- F

b

= 19.5 * 10,000 + 88,200

+ 292,500 - 357,200 - 0

= 218,500 lbf

Alternatively: F

T

= W

AIR

* BF

= 283,200 * 0.7710 = 218,345 lbf

4

3

2

1

Example - contd

20

Fig. 4-11. Axial tensions as a function of depth for Example 4.9

21

Example - Summary

1. At 10,600 ft F

T

= -357,200 lbf [compression]

2. At 10,000 + ft F

T

= -269,000 lbf [compression]

3. At 10,000 - ft F

T

= +23,500 lbf [tension]

4. At Surface F

T

= +218,500 lbf [tension]

22

Axial Load with F

BIT

= 68,000 lbf

23

24

For multiple nozzles in parallel

V

n

is the same for each nozzle

even if the d

n

varies!

This follows since (p is the same

across each nozzle.

t

n

A 117 . 3

q

v =

2

2

t

2

d

-5

bit

A C

q 10 * 8.311

p

p

=

10 * 074 . 8

p

c v

4

d n

p

(

=

&

C

d

= 0.95

25

Hydraulic Horsepower

of pump putting out 400 gpm at 3,000 psi = ?

Power, in field units:

1714

000 , 3 * 400

HHP =

1714

p q

HHP

(

=

Hydraulic Horsepower of Pump = 700 hp

26

What is Hydraulic Impact Force

developed by bit?

If:

psi 169 , 1 p

lb/gal 12

gal/min 400 q

95 . 0 C

n

D

=

= p

=

=

p q c 01823 . 0 F

d j

( p =

27

Impact = rate of change of momentum

lbf 820 169 , 1 * 12 400 * 95 . 0 * 01823 . 0 F

p q c 01823 . 0 F

60 * 17 . 32

v q

v

t

m

t

mv

F

j

d j

n

j

= =

( p =

p

= (

(

=

(

(

=

28

Laminar Flow

Rheological Models

Newtonian

Bingham Plastic

Power-Law (ADE & API)

Rotational Viscometer

Laminar Flow in Wellbore

Fluid Flow in Pipes

Fluid Flow in Annuli

29

Laminar Flow of Newtonian Fluids

A

F

L

V

Q =

Experimentally:

30

Newtonian Fluid Model

In a Newtonian fluid the shear stress is directly

proportional to the shear rate (in laminar flow):

i.e.,

The constant of proportionality, is the viscosity

of the fluid and is independent of shear rate.

=

sec

1

2

Q

cm

dyne

Q

y

K Q = t

31

Newtonian Fluid Model

Viscosity may be expressed in poise or centipoise.

poise 0.01 centipoise 1

s cm

g

1

cm

s - dyne

1 poise 1

2

=

= =

2

cm

sec dyne y

K

t

= Q

y

32

Shear Stress vs. Shear Rate for a

Newtonian Fluid

Slope of line = Q

.

K Q t =

33

Apparent Viscosity

Apparent viscosity =

is the slope at each shear rate,

. , ,

3 2 1

y y y

K K K

y

K t /

34

Typical Drilling Fluid Vs. Newtonian,

Bingham and Power Law Fluids

(Plotted on linear paper)

35

Rheological Models

1. Newtonian Fluid:

2. Bingham Plastic Fluid:

viscosity plastic

point yield

p

y

= Q

= t

What if t

y

= #

y

K Q = t

y

K Q + t = t

p y

rate shear

viscosity absolute

stress shear

= K

= Q

= t

y

36

Rotating

Sleeve

Viscometer

37

Figure 3.6

Rotating

Viscometer

Rheometer

We

determine

rheological

properties

of drilling

fluids in

this device

Infinite

parallel

plates

38

Rheometer (Rotational

Viscometer)

Shear Stress = f (Dial Reading)

Shear Rate = f (Sleeve RPM)

Shear Stress = f (Shear Rate)

) ( f K t =

BOB

sleeve

fluid

Rate Shear the (GAMMA), of value

the on depends Stress Shear the ), TAU (

K

t

39

Rheometer - base case

N (RPM) K sec

-1

)

3 5.11

6 10.22

100 170

200 340

300 511

600 1022

RPM * 1.703 = sec

-1

40

Example

A rotational viscometer containing a Bingham plastic

fluid gives a dial reading of 12 at a rotor speed of 300

RPM and a dial reading of 20 at a rotor speed of 600 RPM

Compute plastic viscosity and yield point

12 - 20

300 600 p

=

= Q

cp 8

p

= Q

o

= 20

1

= 12

See Appendix A

41

Example

8 - 12

p 300 y

=

= Q t

2

y

ft lbf/100 4 = t

o

= 20

1

= 12

(See Appendix A)

42

Gel Strength

43

Gel Strength

= shear stress at which fluid movement begins

The yield strength, extrapolated from the

300 and 600 RPM readings is not a good

representation of the gel strength of the fluid

Gel strength may be measured by turning the

rotor at a low speed and noting the dial

reading at which the gel structure is broken

(usually at 3 RPM)

44

Gel Strength

In field units,

In practice, this is often approximated to

t 06 . 1

g

=

2

ft 100 / lbf

2

ft 100 / lbf

The gel strength is the maximum dial reading

when the viscometer is started at 3 rpm.

t

g

=

max,3

45

Velocity Profiles

(laminar flow)

Fig. 4-26. Velocity profiles for laminar flow:

(a) pipe flow and (b) annular flow

46

It looks like concentric rings of fluid

telescoping down the pipe at different velocities

3D View of Laminar Flow in a pipe

- Newtonian Fluid

47

Table 4.3 - Summary of Equations for

Rotational Viscometer

Newtonian Model

N a

N

300

= Q

N

r

066 . 5

2

= K

300 a

= Q

or

48

Table 4.3 - Summary of Equations for

Rotational Viscometer

300

N

or

1

p N y

1

Q t =

rpm 3 at

max g

t =

Bingham Plastic Model

300 600 p

Q =

) (

N N

300

or

1 2

N N

1 2

p

Q

=

p 300 y

Q t =

or

or

49

Example 4.22

Compute the frictional pressure loss for a 7 x 5

annulus, 10,000 ft long, using the slot flow

representation in the annulus. The flow rate is 80

gal/min. The viscosity is 15 cp. Assume the flow

pattern is laminar.

7 5

1

6x

50

Example 4.22

The average velocity in the annulus,

) 5 2.448(7

80

) d 2.448(d

q

v

2 2 2

1

2

2

_

=

ft/s 1.362 v

_

=

2

1 2

_

f

d d 1000

v

dL

dp

=

51

Example 4.22

51.0750 psi 51

) 5 7 ( 1000

) 000 , 10 ( ) 362 . 1 ( ) 15 (

D

dL

dp

p

2

f

= = (

= =

f

p

2

1 2

_

f

d d 1000

v

dL

dp

=

52

Total Pump Pressure

Pressure loss in surf. equipment

Pressure loss in drill pipe

Pressure loss in drill collars

Pressure drop across the bit nozzles

Pressure loss in the annulus between the drill

collars and the hole wall

Pressure loss in the annulus between the drill

pipe and the hole wall

Hydrostatic pressure difference (p varies)

53

Types of flow

Laminar

Fig. 4-30. Laminar and turbulent flow patterns in a circular pipe: (a) laminar

flow, (b) transition between laminar and turbulent flow and (c) turbulent flow

Turbulent

54

Turbulent Flow -

Newtonian Fluid

We often assume that fluid flow is

turbulent if N

re

> 2100

cp. fluid, of viscosity

in I.D., pipe d

ft/s velocity, fluid avg. v

lbm/gal density, fluid where

_

=

=

=

=

d v 928

N

_

Re

=

55

Turbulent Flow -

Newtonian Fluid

25 . 1

25 . 0

75 . 1

_

75 . 0

f

d 1800

v

dL

dp Q p

=

Turbulent Flow -

Bingham Plastic Fluid

25 . 1

25 . 0

p

75 . 1

_

75 . 0

f

d 1800

v

dL

dp

Q p

=

25 . 1

1 2

25 . 0

p

75 . 1

_

75 . 0

f

d d 396 , 1

v

dL

dp

Q p

=

25 . 1

1 2

25 . 0

75 . 1

_

75 . 0

f

d d 396 , 1

v

dL

dp

Q p

=

In Annulus

In Pipe

56

API Power Law Model

K = consistency index

n = flow behaviour index

SHEAR

STRESS

t

psi

t = K K

n

SHEAR RATE, K , sec

-1

0

API RP 13D

57

Rotating Sleeve Viscometer

VISCOMETER

RPM

3

100

300

600

(RPM * 1.703)

SHEAR RATE

sec

-1

5.11

170.3

511

1022

BOB

SLEEVE

ANNULUS

DRILL

STRING

58

Pressure Drop Calculations

Example Calculate the pump pressure in

the wellbore shown on the next page, using the

API method.

The relevant rotational viscometer readings

are as follows:

R

3

= 3 (at 3 RPM)

R

100

= 20 (at 100 RPM)

R

300

= 39 (at 300 RPM)

R

600

= 65 (at 600 RPM)

59

P

PUMP

= (P

DP

+ (P

DC

+ (P

BIT NOZZLES

+ (P

DC/ANN

+ (P

DP/ANN

+ (P

HYD

Q = 280 gal/min

p = 12.5 lb/gal

Pressure Drop

Calculations

P

PUMP

60

Power-Law Constant (n):

Pressure Drop In Drill Pipe

Fluid Consistency Index (K):

Average Bulk Velocity in Pipe (V):

OD = 4.5 in

ID = 3.78 in

L = 11,400 ft

737 . 0

39

65

log 32 . 3

R

R

log 32 . 3 n

300

600

=

=

2 737 . 0

600

sec

017 . 2

022 , 1

65 * 11 . 5

022 , 1

11 . 5

cm

dyne R

K

n

n

= = =

sec

ft

00 . 8

78 . 3

280 * 408 . 0

D

Q 408 . 0

V

2 2

= = =

61

Effective Viscosity in Pipe (Q

e

):

Pressure Drop In Drill Pipe

Reynolds Number in Pipe (N

Re

):

OD = 4.5 in

ID = 3.78 in

L = 11,400 ft

n

1 n

e

n 4

1 n 3

D

V 96

K 100

= Q

cP 53

737 . 0 * 4

1 737 . 0 * 3

78 . 3

8 * 96

017 . 2 * 100

737 . 0 1 737 . 0

e

=

= Q

616 , 6

53

5 . 12 * 00 . 8 * 78 . 3 * 928 V D 928

N

e

Re

= =

Q

p

=

62

NOTE: N

Re

> 2,100, so

Friction Factor in Pipe (f):

Pressure Drop In Drill Pipe

OD = 4.5 in

ID = 3.78 in

L = 11,400 ft

So,

b

Re

N

a

f =

0759 . 0

50

93 . 3 737 . 0 log

50

93 . 3 n log

a =

+

=

+

=

2690 . 0

7

737 . 0 log 75 . 1

7

n log 75 . 1

b =

=

007126 . 0

616 , 6

0759 . 0

N

a

f

2690 . 0 b

Re

= = =

63

Friction Pressure Gradient (dP/dL) :

Pressure Drop In Drill Pipe

OD = 4.5 in

ID = 3.78 in

L = 11,400 ft

Friction Pressure Drop in Drill Pipe :

400 , 11 * 05837 . 0 L

dL

dP

P = (

= (

(P

dp

= 665 psi

ft

psi

05837 . 0

78 . 3 * 81 . 25

5 . 12 * 8 * 007126 . 0

D 81 . 25

V f

dL

dP

2

2

= =

p

=

64

Power-Law Constant (n):

Pressure Drop In Drill Collars

Fluid Consistency Index (K):

Average Bulk Velocity inside Drill Collars (V):

OD = 6.5 in

ID = 2.5 in

L = 600 ft

737 . 0

39

65

log 32 . 3

R

R

log 32 . 3 n

300

600

=

=

2

n

737 . 0 n

600

cm

sec dyne

017 . 2

022 , 1

65 * 11 . 5

022 , 1

R 11 . 5

K = = =

sec

ft

28 . 18

5 . 2

280 * 408 . 0

D

Q 408 . 0

V

2 2

= = =

65

Effective Viscosity in Collars(Q

e

):

Reynolds Number in Collars (N

Re

):

OD = 6.5 in

ID = 2.5 in

L = 600 ft

Pressure Drop In Drill Collars

n 1 n

e

n 4

1 n 3

D

V 96

K 100

= Q

cP 21 . 38

737 . 0 * 4

1 737 . 0 * 3

5 . 2

28 . 18 * 96

017 . 2 * 100

737 . 0 1 737 . 0

e

=

= Q

870 , 13

21 . 38

5 . 12 * 28 . 18 * 5 . 2 * 928 V D 928

N

e

Re

= =

Q

p

=

66

OD = 6.5 in

ID = 2.5 in

L = 600 ft

Pressure Drop In Drill Collars

NOTE: N

Re

> 2,100, so

Friction Factor in DC (f):

b

Re

N

a

f =

So,

0759 . 0

50

93 . 3 737 . 0 log

50

93 . 3 n log

a =

+

=

+

=

2690 . 0

7

737 . 0 log 75 . 1

7

n log 75 . 1

b =

=

005840 . 0

870 , 13

0759 . 0

N

a

f

2690 . 0 b

Re

= = =

67

Friction Pressure Gradient (dP/dL) :

Friction Pressure Drop in Drill Collars :

OD = 6.5 in

ID = 2.5 in

L = 600 ft

Pressure Drop In Drill Collars

ft

psi

3780 . 0

5 . 2 * 81 . 25

5 . 12 * 28 . 18 * 005840 . 0

D 81 . 25

V f

dL

dP

2

2

= =

p

=

600 * 3780 . 0 L

dL

dP

P = (

= (

(P

dc

= 227 psi

68

Pressure Drop across Nozzles

D

N1

= 11 32nds (in)

D

N2

= 11 32nds (in)

D

N3

= 12 32nds (in)

2

2 2 2

2

12 11 11

280 * 5 . 12 * 156

P

+ +

= (

(P

Nozzles

= 1,026 psi

2

2

3 N

2

2 N

2

1 N

2

D D D

Q 156

P

+ +

p

= (

69

Pressure Drop

in DC/HOLE

Annulus

D

HOLE

= 8.5 in

OD

DC

= 6.5 in

L = 600 ft

Q = gal/min

p = l lb/gal

8.5 in

70

Power-Law Constant (n):

Fluid Consistency Index (K):

Average Bulk Velocity in DC/HOLE Annulus (V):

D

HOLE

= 8.5 in

OD

DC

= 6.5 in

L = 600 ft

Pressure Drop

in DC/HOLE Annulus

5413 . 0

3

20

log 657 . 0

R

R

log 657 . 0 n

3

100

=

=

2

n

5413 . 0 n

100

cm

sec dyne

336 . 6

2 . 170

20 * 11 . 5

2 . 170

R 11 . 5

K = = =

sec

ft

808 . 3

5 . 6 5 . 8

280 * 408 . 0

D D

Q 408 . 0

V

2 2 2

1

2

2

=

=

71

Effective Viscosity in Annulus (Q

e

):

Reynolds Number in Annulus (N

Re

):

D

HOLE

= 8.5 in

OD

DC

= 6.5 in

L = 600 ft

cP 20 . 55

5413 . 0 * 3

1 5413 . 0 * 2

5 . 6 5 . 8

808 . 3 * 144

336 . 6 * 100

5413 . 0 1 5413 . 0

e

=

= Q

600 , 1

20 . 55

5 . 12 * 808 . 3 * 5 . 6 5 . 8 928

V D D 928

N

e

1 2

Re

=

=

Q

p

=

n

1 n

1 2

e

n 3

1 n 2

D D

V 144

K 100

= Q

Pressure Drop

in DC/HOLE Annulus

72

So,

D

HOLE

= 8.5 in

OD

DC

= 6.5 in

L = 600 ft

NOTE: N

Re

< 2,100

Friction Factor in Annulus (f):

01500 . 0

600 , 1

24

N

24

f

Re

= = =

ft

psi

05266 . 0

5 . 6 5 . 8 81 . 25

5 . 12 * 808 . 3 * 01500 . 0

D D 81 . 25

V f

dL

dP

2

1 2

2

=

p

=

600 * 05266 . 0 L

dL

dP

P = (

= (

(P

dc/hole

= 31.6 psi

Pressure Drop

in DC/HOLE Annulus

73

q = gal/min

p = l lb/gal

Pressure Drop

in DP/HOLE Annulus

D

HOLE

= 8.5 in

OD

DP

= 4.5 in

L = 11,400 ft

74

Power-Law Constant (n):

Fluid Consistency Index (K):

Average Bulk Velocity in Annulus (V

a

):

Pressure Drop

in DP/HOLE Annulus

D

HOLE

= 8.5 in

OD

DP

= 4.5 in

L = 11,400 ft

5413 . 0

3

20

log 657 . 0

R

R

log 657 . 0 n

3

100

=

=

2

n

5413 . 0 n

100

cm

sec dyne

336 . 6

2 . 170

20 * 11 . 5

2 . 170

R 11 . 5

K = = =

sec

ft

197 . 2

5 . 4 5 . 8

280 * 408 . 0

D D

Q 408 . 0

V

2 2 2

1

2

2

=

=

75

Effective Viscosity in Annulus (Q

e

):

Reynolds Number in Annulus (N

Re

):

Pressure Drop

in DP/HOLE Annulus

n 1 n

1 2

e

n 3

1 n 2

D D

V 144

K 100

= Q

cP 64 . 97

5413 . 0 * 3

1 5413 . 0 * 2

5 . 4 5 . 8

197 . 2 * 144

336 . 6 * 100

5413 . 0 1 5413 . 0

e

=

= Q

044 , 1

64 . 97

5 . 12 * 197 . 2 * 5 . 4 5 . 8 928

V D D 928

N

e

1 2

Re

=

=

Q

p

=

76

So, psi

Pressure Drop

in DP/HOLE Annulus

NOTE: N

Re

< 2,100

Friction Factor in Annulus (f):

02299 . 0

044 , 1

24

N

24

f

Re

= = =

ft

psi

01343 . 0

5 . 4 5 . 8 81 . 25

5 . 12 * 197 . 2 * 02299 . 0

D D 81 . 25

V f

dL

dP

2

1 2

2

=

p

=

400 , 11 * 01343 . 0 L

dL

dP

P = (

= (

(P

dp/hole

= 153.2 psi

77

Pressure Drop Calcs.

- SUMMARY -

P

PUMP

= (P

DP

+ (P

DC

+ (P

BIT NOZZLES

+ (P

DC/ANN

+ (P

DP/ANN

+ (P

HYD

P

PUMP

= 665 + 227 + 1,026

+ 32 + 153 + 0

P

PUMP

= 1,918 + 185 = 2,103 psi

78

P

PUMP

= 1,918 + 185

= 2,103 psi

(P

HYD

= 0

P

PUMP

= (P

DS

+ (P

ANN

+ (P

HYD

(P

DS

= (P

DP

+ (P

DC

+ (P

BIT NOZZLES

= 665 + 227 + 1,026 = 1,918 psi

(P

ANN

= (P

DC/ANN

+ (P

DP/ANN

= 32 + 153 = 185

2,103 psi

P

=

0

79

"Friction" Pressures

0

500

1,000

1,500

2,000

2,500

0 5,000 10,000 15,000 20,000 25,000

Cumulative Distance from Standpipe, ft

"

F

r

i

c

t

i

o

n

"

P

r

e

s

s

u

r

e

,

p

s

i DRILLPIPE

DRILL COLLARS

BIT NOZZLES

ANNULUS

80

Hydrostatic Pressures in the Wellbore

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

0 5,000 10,000 15,000 20,000 25,000

Cumulative Distance from Standpipe, ft

H

y

d

r

o

s

t

a

t

i

c

P

r

e

s

s

u

r

e

,

p

s

i

BHP

DRILLSTRING ANNULUS

81

Pressures in the Wellbore

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

0 5,000 10,000 15,000 20,000 25,000

Cumulative Distance from Standpipe, ft

P

r

e

s

s

u

r

e

s

,

p

s

i

STATIC

CIRCULATING

82

Wellbore Pressure Profile

0

2,000

4,000

6,000

8,000

10,000

12,000

14,000

0 2,000 4,000 6,000 8,000 10,000

Pressure, psi

D

e

p

t

h

,

f

t

DRILLSTRING

ANNULUS

(Static)

BIT

83

Pipe Flow - Laminar

In the above example the flow down the

drillpipe was turbulent.

Under conditions of very high viscosity,

the flow may very well be laminar.

NOTE: if N

Re

< 2,100, then

Friction Factor in Pipe (f):

Re

N

16

f =

D 81 . 25

V f

dL

dP

2

p

=

Then and

84

85

d 8 . 25

v f

dL

dp

_

2

p

=

n = 1.0

You might also like

- 6.mud Hydraulics Fundamentals PDFDocument11 pages6.mud Hydraulics Fundamentals PDFمعلومات ممتعه mohammedNo ratings yet

- Drilling Engineering Ahmed-3Document83 pagesDrilling Engineering Ahmed-3Loh Chun Liang100% (2)

- Well Control Data Sheet: Vertical WellsDocument2 pagesWell Control Data Sheet: Vertical WellsscrbdgharaviNo ratings yet

- Ilker Drilling ProgrammeDocument71 pagesIlker Drilling Programmerıdvan duranNo ratings yet

- Casing Design CalculationDocument10 pagesCasing Design CalculationNurul Aishah100% (3)

- SPE-105068-MS-How Good Is The Torque-Drag ModelDocument9 pagesSPE-105068-MS-How Good Is The Torque-Drag ModelHassaanAhmedNo ratings yet

- Bit Hydraulics Optimization for Maximum Drilling PerformanceDocument23 pagesBit Hydraulics Optimization for Maximum Drilling PerformanceShakerMahmood100% (1)

- Mud NotesDocument56 pagesMud Notesrainaldy sebastianNo ratings yet

- Drilling HydraulicsDocument39 pagesDrilling HydraulicsAllbert Einstein100% (1)

- Well ControlDocument43 pagesWell ControlIsmail Mohammed100% (1)

- Basic Tubing ForcesDocument21 pagesBasic Tubing ForcesOzzie GonzalezNo ratings yet

- The Effect of Drilling Fluid Rheological Properties On Hole CleaningDocument5 pagesThe Effect of Drilling Fluid Rheological Properties On Hole CleaningJorge Gomez PortillaNo ratings yet

- Prevent Stuck Pipe with Proper Hole CleaningDocument23 pagesPrevent Stuck Pipe with Proper Hole CleaningddiazveNo ratings yet

- Functions of Drilling FluidsDocument7 pagesFunctions of Drilling FluidsAhmed AldabaNo ratings yet

- Effective Hole Cleaning at High - Angle and Horizontal WellsDocument14 pagesEffective Hole Cleaning at High - Angle and Horizontal WellsColin100% (3)

- Mud Engineer User ManualDocument48 pagesMud Engineer User ManualstevebeardsleyNo ratings yet

- How To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred GrowcockDocument16 pagesHow To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred Growcockrıdvan duranNo ratings yet

- Strengthen Wellbores During DrillingDocument32 pagesStrengthen Wellbores During Drillingrıdvan duranNo ratings yet

- 5B. High Pressure RiserDocument10 pages5B. High Pressure Riserdriller22No ratings yet

- Leak Off TestDocument2 pagesLeak Off TestLuisBlandónNo ratings yet

- Remedial Cementing TechniquesDocument4 pagesRemedial Cementing TechniquesColor RougeNo ratings yet

- Depth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Document101 pagesDepth Issues in The Trajectory (Oil Patch) - Wellbore Position Uncertainty (Ekofisk)Roger GuevaraNo ratings yet

- 3.3 - Circulating System - Hole Volume, Hydrostatic and SlugsDocument26 pages3.3 - Circulating System - Hole Volume, Hydrostatic and Slugsrabiu nuhuNo ratings yet

- Casing Design PDFDocument41 pagesCasing Design PDFfabianandres23100% (2)

- Determine Surge and Swab PressureDocument5 pagesDetermine Surge and Swab PressureS MariusNo ratings yet

- Well Control Formulas Drillingformulas - Com 1Document101 pagesWell Control Formulas Drillingformulas - Com 1erickNo ratings yet

- Drilling Application: Name of Company: Well Name & Number: DateDocument1 pageDrilling Application: Name of Company: Well Name & Number: DatescrbdgharaviNo ratings yet

- CSG Design by AmrDocument19 pagesCSG Design by AmrSudish BhatNo ratings yet

- Casing & Cementing ConventionalDocument1 pageCasing & Cementing ConventionalDeepak TandonNo ratings yet

- PETE 355 Pore Pressure PDFDocument89 pagesPETE 355 Pore Pressure PDFNural MuradliNo ratings yet

- 2-Drilling Fluids AdidtivesDocument36 pages2-Drilling Fluids AdidtivesHayder AliNo ratings yet

- Kick Detection and ControlDocument63 pagesKick Detection and Controlcmrig74No ratings yet

- IRP 22 - Underbalanced Drilling & Managed Pressure Drilling Operations Using Jointed Pipe - Oct 17 - 2018 PDFDocument158 pagesIRP 22 - Underbalanced Drilling & Managed Pressure Drilling Operations Using Jointed Pipe - Oct 17 - 2018 PDFJohnny BreuerNo ratings yet

- A Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisDocument13 pagesA Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisMaulana Alan MuhammadNo ratings yet

- All About MudDocument91 pagesAll About MudDavide Boreaneze100% (1)

- Surge Pressure Prediction For Running LinersDocument13 pagesSurge Pressure Prediction For Running LinersPegasus Vertex, Inc.100% (1)

- Rahimov, MPDDocument102 pagesRahimov, MPDYassir HindiNo ratings yet

- ( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Document5 pages( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Nitin GandhareNo ratings yet

- How to Calculate Volume of CylindersDocument6 pagesHow to Calculate Volume of Cylinderschubby_hippoNo ratings yet

- TAMU - Pemex: Well ControlDocument54 pagesTAMU - Pemex: Well Controldriller22100% (2)

- Bit Hydraulics OptimizationDocument24 pagesBit Hydraulics OptimizationRebar Kaka100% (1)

- Introduction to Underbalanced Drilling Technologies (M2Document57 pagesIntroduction to Underbalanced Drilling Technologies (M2bon1ngNo ratings yet

- Drilling HydraulicsDocument78 pagesDrilling HydraulicsKarlos Rdgz100% (1)

- PETE 661: Drilling EngineeringDocument50 pagesPETE 661: Drilling Engineeringcmrig74No ratings yet

- Section 07 - Surge & SwabDocument17 pagesSection 07 - Surge & SwabrayvanadinurzeinNo ratings yet

- SPE-112544-Annular Pressure Loss Predictions For Various Stand-Off Devices CFDDocument8 pagesSPE-112544-Annular Pressure Loss Predictions For Various Stand-Off Devices CFDehsanNo ratings yet

- Technical Reference Self Study Material: Wellbore StabilityDocument11 pagesTechnical Reference Self Study Material: Wellbore StabilityArijit RayNo ratings yet

- Swab and Surge Pressures SHBDocument1 pageSwab and Surge Pressures SHBstevebeardsleyNo ratings yet

- HYD BaroidDocument2 pagesHYD BaroidHeris SitompulNo ratings yet

- Balanced Cement Plug CalculationDocument7 pagesBalanced Cement Plug CalculationAlejandro ViscarraNo ratings yet

- 12 Casing Running Speed - QuartzDocument1 page12 Casing Running Speed - QuartzRebarNo ratings yet

- Special ProblemsDocument42 pagesSpecial Problemsdriller22No ratings yet

- HydroLeaks v1.12 drilling hydraulics calculator guideDocument28 pagesHydroLeaks v1.12 drilling hydraulics calculator guideAntonio Hdez JmnzNo ratings yet

- Mud FactsDocument91 pagesMud FactsShamia EssamNo ratings yet

- Drilling String DesignDocument13 pagesDrilling String DesignMiguel Angel TiconaNo ratings yet

- Kicks and Gas MigrationDocument42 pagesKicks and Gas MigrationJohnny Sanchez100% (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Ammar Hafez Presentation SP2019Document66 pagesAmmar Hafez Presentation SP2019Sunita ChayalNo ratings yet

- The Importance of The Non-Newtonian Characteristics of BloodDocument25 pagesThe Importance of The Non-Newtonian Characteristics of BloodMohammed Al-AzawyNo ratings yet

- Hydraulics-I IntroductionDocument16 pagesHydraulics-I IntroductionJôssŷ Fkr100% (2)

- Problem of RehologyDocument4 pagesProblem of RehologyShagufta AfaqueNo ratings yet

- Food Rheology: Understanding Flow and DeformationDocument37 pagesFood Rheology: Understanding Flow and DeformationCindi Pratiwi100% (1)

- Fluid 01Document77 pagesFluid 01Edgar HuancaNo ratings yet

- Fluid Mechanics d203Document302 pagesFluid Mechanics d203Vignesh SundaramNo ratings yet

- Derivation and applications of the Navier-Stokes equationsDocument13 pagesDerivation and applications of the Navier-Stokes equationssumiNo ratings yet

- Analysis of Drilling Fluid Rheology and Tool Joint Effect To Reduce Errors in Hydraulics CalculationsDocument191 pagesAnalysis of Drilling Fluid Rheology and Tool Joint Effect To Reduce Errors in Hydraulics CalculationsPeri RosewellNo ratings yet

- Fluid Mechanics - Gupta & Gupta.Document673 pagesFluid Mechanics - Gupta & Gupta.Rajat RathoreNo ratings yet

- Mcmaster MECH ENG 3O04 - Fluid Mechanics Notes by Dr. Mohamed S. HamedDocument394 pagesMcmaster MECH ENG 3O04 - Fluid Mechanics Notes by Dr. Mohamed S. Hamedcttiger7135100% (15)

- Topic 1: Introduction To Fluid MechanicsDocument19 pagesTopic 1: Introduction To Fluid MechanicsAeroNo ratings yet

- NSCET E-Learning Presentation on Fluid Mechanics FundamentalsDocument45 pagesNSCET E-Learning Presentation on Fluid Mechanics Fundamentalsdurai muruganNo ratings yet

- Fluid Mechanics Unit1Document100 pagesFluid Mechanics Unit1anjuNo ratings yet

- Extrusion Die Design and Process Control for Dimensional StabilityDocument62 pagesExtrusion Die Design and Process Control for Dimensional StabilityMun JiwonNo ratings yet

- 11 Chapter 2Document47 pages11 Chapter 2solomonNo ratings yet

- Generalized Reynolds Number For Non-Newtonian Fluids: K. Madlener, B. Frey, and H. K. CiezkiDocument14 pagesGeneralized Reynolds Number For Non-Newtonian Fluids: K. Madlener, B. Frey, and H. K. Ciezkirwilliams9001No ratings yet

- Fluid Properties: 1.10 SolutionDocument15 pagesFluid Properties: 1.10 Solutionjason403No ratings yet

- Chap 2 RheologyDocument35 pagesChap 2 RheologyALISHANo ratings yet

- Fluid Mechanics White 7th SOL Part1 Part6Document5 pagesFluid Mechanics White 7th SOL Part1 Part6Jose EscobarNo ratings yet

- FMM Notes By Vineet Tutorials_16656911_2023_05_14_13_44Document39 pagesFMM Notes By Vineet Tutorials_16656911_2023_05_14_13_44Mayur LokhandeNo ratings yet

- Drill Bench Hydraulics User GuideDocument68 pagesDrill Bench Hydraulics User GuideMujahed Taharwh100% (2)

- CE 2711 - Fluid Mechanics: Upaka Rathnayake 3 Floor - Engineering BuildingDocument26 pagesCE 2711 - Fluid Mechanics: Upaka Rathnayake 3 Floor - Engineering BuildingFearless HeroNo ratings yet

- Notes 4 (2023) Concepts of Fluid Kinematics and Internal FlowDocument26 pagesNotes 4 (2023) Concepts of Fluid Kinematics and Internal FlowVinn GTNo ratings yet

- Fluid Mechanics & Fluid MachinesDocument355 pagesFluid Mechanics & Fluid MachinesSatish Kumar100% (6)

- phân tích dòng chảy trong khuôn nhựaDocument94 pagesphân tích dòng chảy trong khuôn nhựaAnh Tài VũNo ratings yet

- Fluid Properties: Elger Et Al. TextbookDocument18 pagesFluid Properties: Elger Et Al. TextbookAfwan IrfanNo ratings yet

- Differential Analysis of Fluid Flow: Fluid Mechanics: Fundamentals and ApplicationsDocument104 pagesDifferential Analysis of Fluid Flow: Fluid Mechanics: Fundamentals and ApplicationsqistinaNo ratings yet

- Chap. 1 Fluid PropertiesDocument45 pagesChap. 1 Fluid PropertiesctkhadeejaNo ratings yet

- Fluid Dynamics and Turbomachines: WEEK 1: AssignmentDocument16 pagesFluid Dynamics and Turbomachines: WEEK 1: AssignmentAsrar AhmedNo ratings yet